Progressively increased tooth pitch traveling wave magnetic field casting equipment and casting method

A technology of traveling wave magnetic field and casting equipment, which is applied in the field of wide pitch traveling wave magnetic field casting equipment and casting, which can solve the problems of prone to dents on the surface and poor melt flow stability, and achieve the elimination of surface dents, stable mold filling, Effect of improving productivity and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

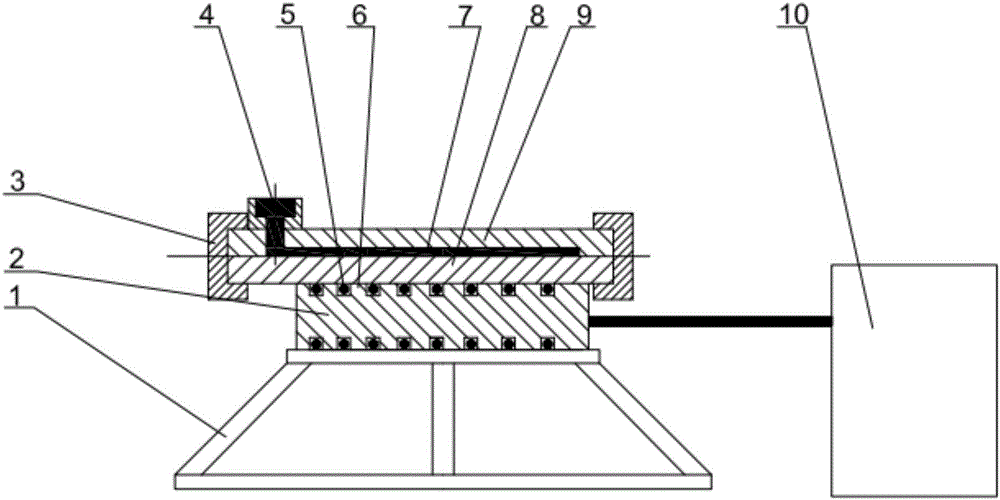

[0024] Such as figure 1 As shown, the present embodiment 1 provides a casting equipment, including: a horizontally placed metal melt filling device, a traveling wave magnetic field electromagnetic sensor located at the bottom of the metal melt filling device; wherein the traveling wave magnetic field electromagnetic The magnetic inductor generates a traveling wave magnetic field by loading current, so that the molten metal in the molten metal filling device moves at a constant speed to fill the mold.

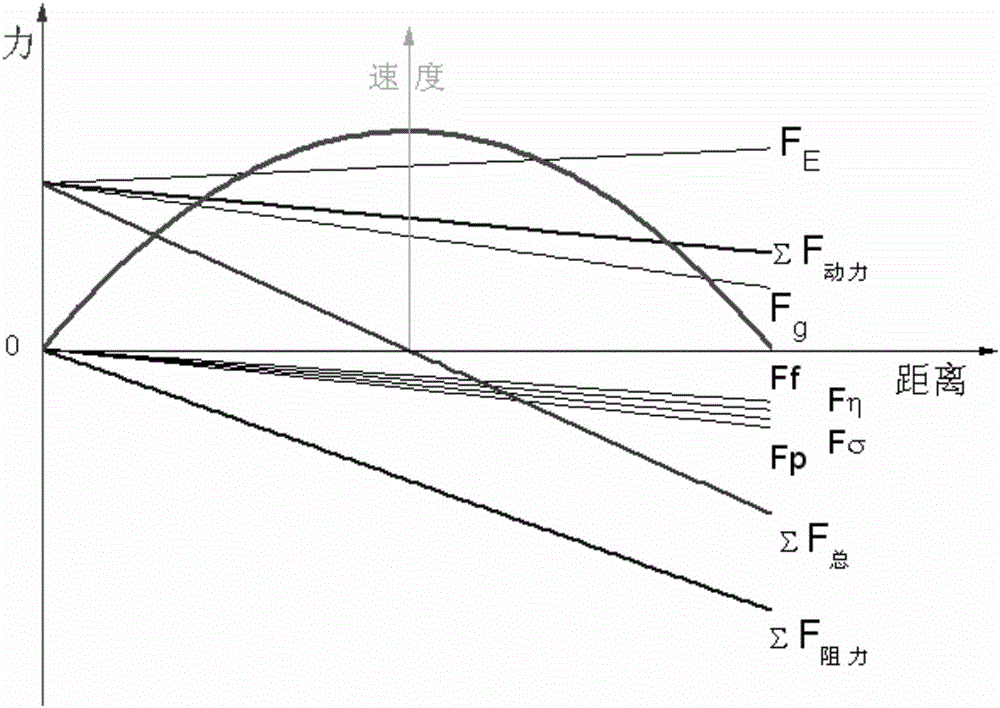

[0025] Working principle of the present invention: as figure 2 As shown, the forces received by the alloy melt during the filling process include the static pressure head pressure Fg, the electromagnetic propulsion force FE, the friction force Ff of the cavity, the internal friction force Fη of the melt, and the gas counterpressure Fp in the cavity and surface tension Fσ six forces, of which the static pressure head pressure Fg, electromagnetic propulsion FE is the driving for...

Embodiment 2

[0033] On the basis of embodiment 1, this embodiment 2 provides a casting method.

[0034] The casting method comprises: making the molten metal in the molten metal filling device move at a uniform speed to fill the mold through a traveling wave magnetic field.

[0035] Further, the traveling wave magnetic field is a decreasing traveling wave magnetic field, and is generated by a traveling wave magnetic field electromagnetic inductor, that is, the traveling wave magnetic field electromagnetic inductor decreases the electromagnetic propulsion obtained by the metal melt after being energized.

[0036] As a preferred implementation of the traveling wave magnetic field electromagnetic inductor, the traveling wave magnetic field electromagnetic inductor includes: an iron core 2, a plurality of teeth for coil winding are distributed on the outer circumference of the iron core, that is, the coil is embedded Between each tooth; and according to the moving direction of the molten metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com