Beryllium-aluminum alloy sheet and manufacturing method thereof

A beryllium aluminum alloy and plate technology, which is applied in the field of beryllium aluminum alloy plate and its preparation, can solve the problems that beryllium and aluminum are difficult to mix uniformly, difficult to scale production, and the prospect of industrialization is not optimistic, and the as-cast structure of the alloy can be refined. , the effect of improving the plastic deformation ability of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

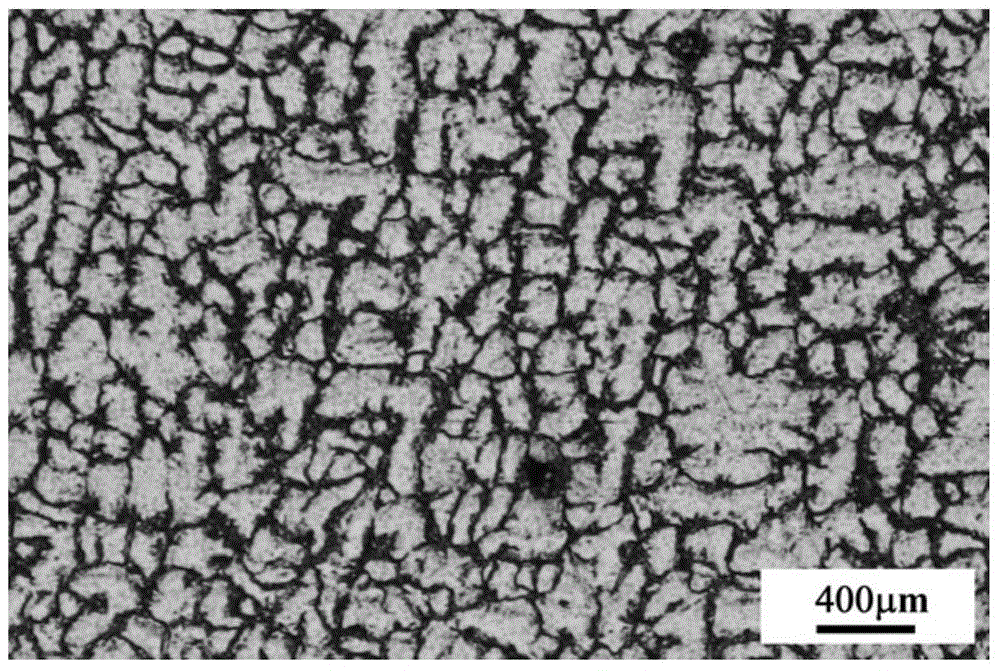

example 1

[0059] The preparation method is as follows:

[0060] (1) Ingredients, weigh 1.24kg of metal beryllium block and 0.76kg of metal aluminum ingot; put the prepared raw materials into an alumina crucible and place them in a resistance furnace for melting, control the melting temperature to 1300°C and melt for 15 minutes to obtain alloy melt.

[0061] (2) Cool down the alloy melt to 1145°C and keep it warm for 10min.

[0062] (3) Quickly and smoothly pour the heat-preserved alloy melt into a graphite mold with an alumina coating that has been preheated to 600°C, and at the same time turn on the alternating rotating magnetic field, control the input current to 100A and the stirring frequency to 10Hz , to obtain a beryllium aluminum alloy ingot.

[0063] (4) The surface scale of the beryllium-aluminum alloy ingot is removed by turning to obtain a beryllium-aluminum alloy billet.

[0064] (5) Heating the beryllium aluminum alloy billet to 600°C in a box-type resistance furnace.

...

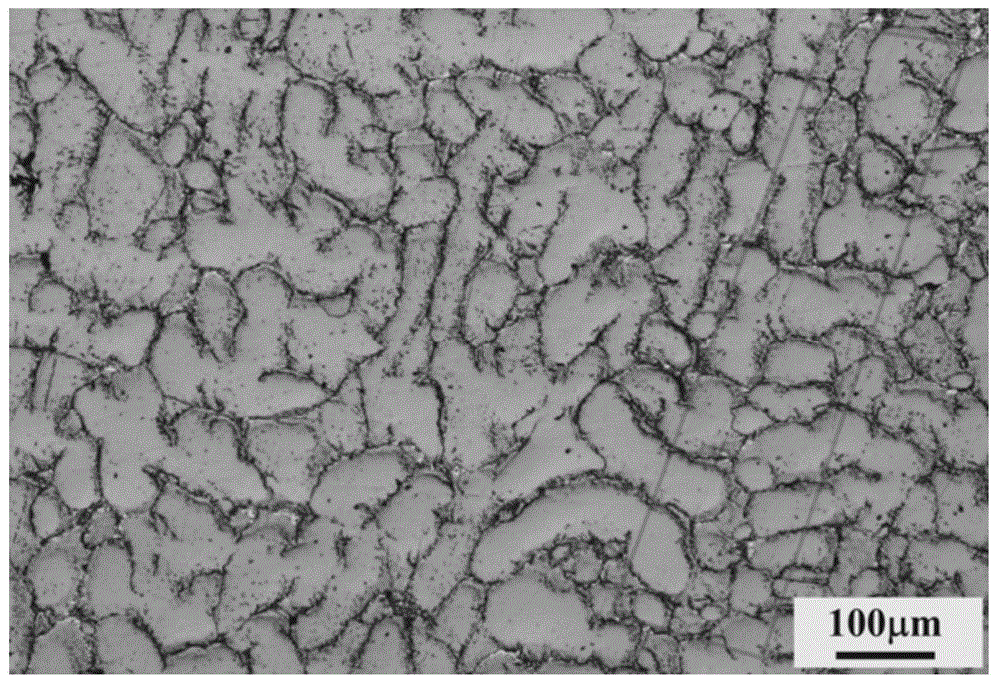

example 2

[0071] The preparation method is as follows:

[0072] (1) Ingredients, weighing 1.24kg of metal beryllium block and 0.76kg of metal aluminum ingot; putting the prepared raw materials into an alumina crucible and melting in a resistance furnace, controlling the melting temperature to be 1280°C and melting for 10 minutes to obtain alloy melt.

[0073] (2) Cool down the alloy melt to 1148°C and keep it warm for 15min.

[0074] (3) Quickly and smoothly pour the heat-preserved alloy melt into a graphite mold with an alumina coating that has been preheated to 500°C, and at the same time turn on the alternating rotating electromagnetic field, control the input current to 80A and the stirring frequency to 15Hz , to obtain a beryllium aluminum alloy ingot.

[0075] (4) The surface scale of the beryllium-aluminum alloy ingot is removed by turning to obtain a beryllium-aluminum alloy billet.

[0076] (5) Heating the beryllium-aluminum alloy billet to 380° C. in a box-type resistance f...

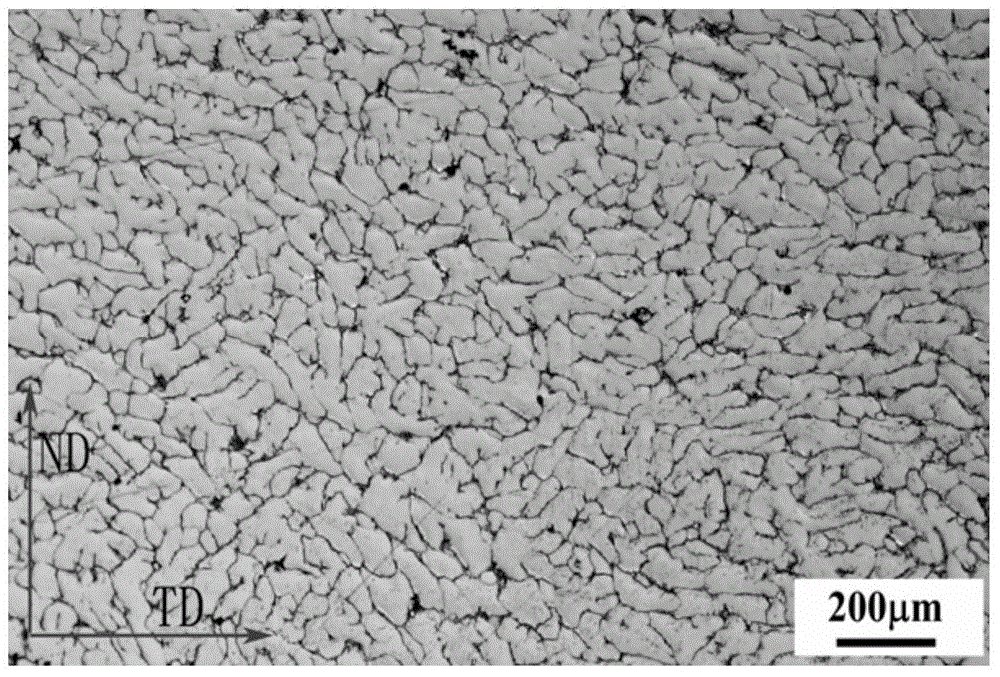

example 3

[0086] The preparation method is as follows:

[0087](1) Ingredients, weigh 1.55 kg of metal beryllium block and 0.95 kg of metal aluminum ingot; put the prepared raw materials into a beryllium oxide crucible and place them in a resistance furnace for melting, control the melting temperature to be 1300° C. and melt for 18 minutes to obtain alloy melt.

[0088] (2) Cool down the alloy melt to 1150°C and keep it warm for 18min.

[0089] (3) Quickly and smoothly pour the heat-preserved alloy melt into a graphite mold with an alumina coating that has been preheated to 550°C, and at the same time turn on the traveling wave magnetic field, control the input current to 100A and the stirring frequency to 30Hz, Obtain beryllium aluminum alloy ingot.

[0090] (4) The surface scale of the beryllium-aluminum alloy ingot is removed by turning to obtain a beryllium-aluminum alloy billet.

[0091] (5) Heating the beryllium aluminum alloy billet to 500°C in a box-type resistance furnace. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com