Frame baffle for fixing electromagnetic casting magnetic field-aided generator

A technology of magnetic field generator and fixed bottom plate, which is applied to the electromagnetic-assisted casting process of slab horizontal continuous casting and the field of frame baffles, can solve the problems of increasing the cost of labor and auxiliary materials, reducing the service life, and difficulty in repairing and calibrating, and achieves offsetting unevenness. Thermal stress deformation and warpage, improve working life, eliminate the effect of thermal stress warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The device is formed by excavating process holes in the crystallizer filler frame baffle body. Theoretical analysis and practical application verification show that by setting symmetrical or asymmetric process holes on the upper and lower sides of the frame baffle, not only the fixed electromagnetic auxiliary The purpose of the cast magnetic field generator is also to effectively counteract the distortion and deformation caused by thermal stress. The consumption of industrial auxiliary materials is reduced, and the service life of the fixed frame baffle and the crystallizer packing frame is improved.

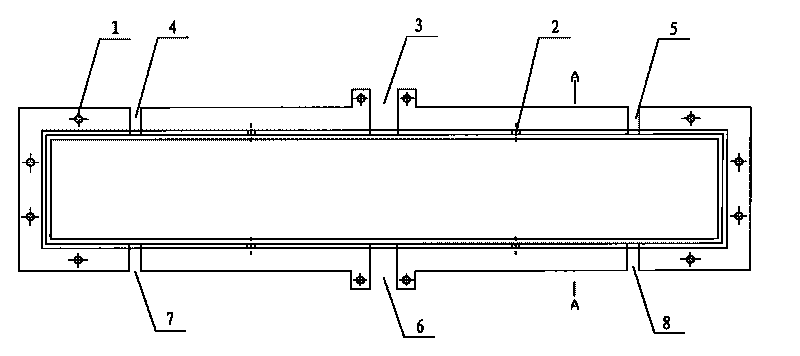

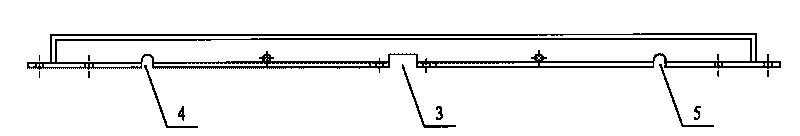

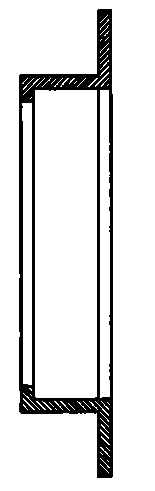

[0021] Frame baffles for securing electromagnetically assisted casting field generators such as Figure 1a~1c As shown, the frame baffle includes a fixed bottom plate and upper, lower, left, and right four side walls; on the four sides of the fixed bottom plate, lower, left, and right, there are fixing bolt holes 1 for the frame baffle, and on the upper side wall Bolt ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com