Oxygen-free copper strip horizontal electromagnetic casting device

An electromagnetic casting and oxygen-free copper technology, which is applied in the field of oxygen-free copper strip horizontal electromagnetic casting equipment, can solve the problems of difficulty in meeting the needs of supporting industries, complex equipment structure, and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

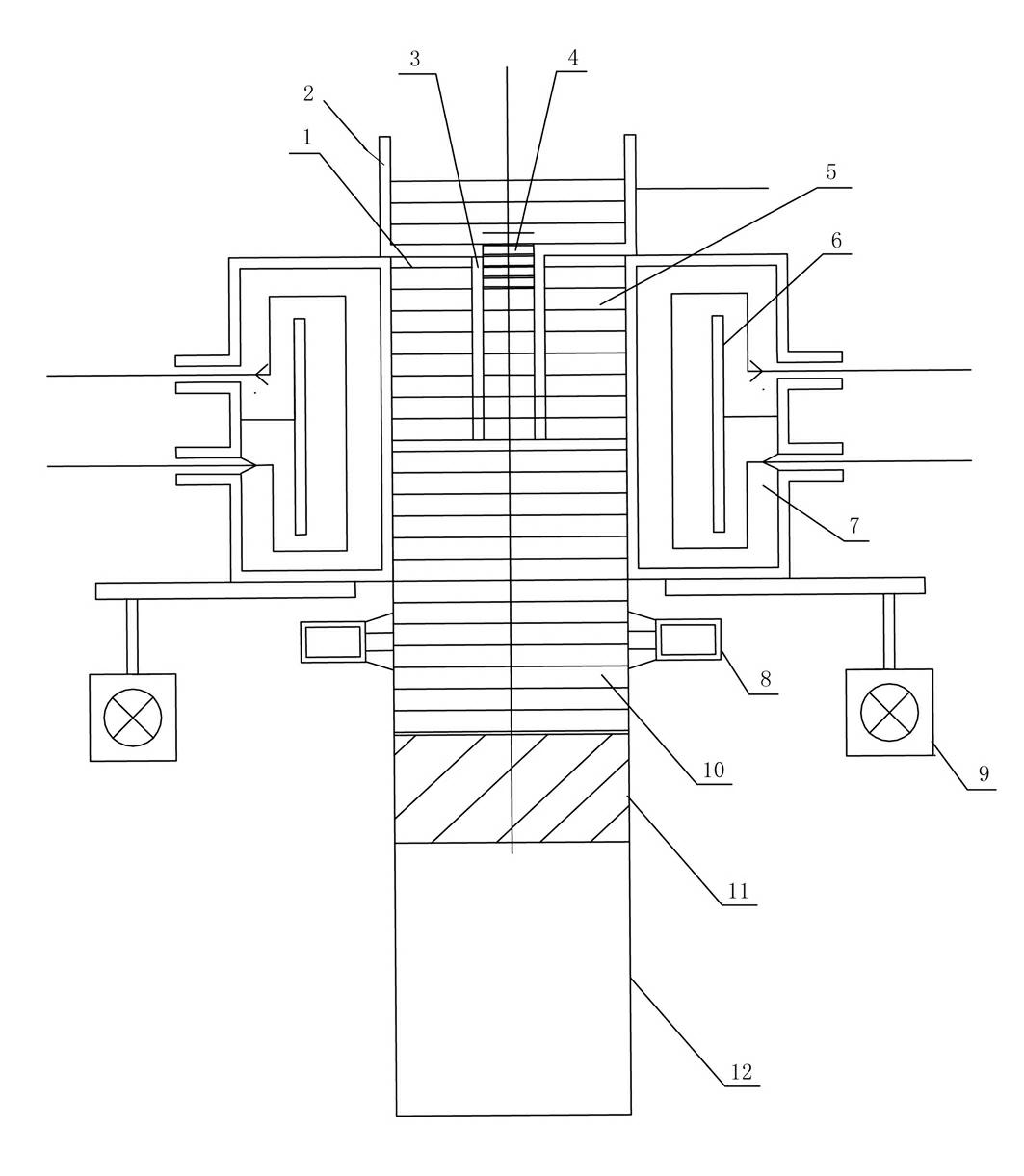

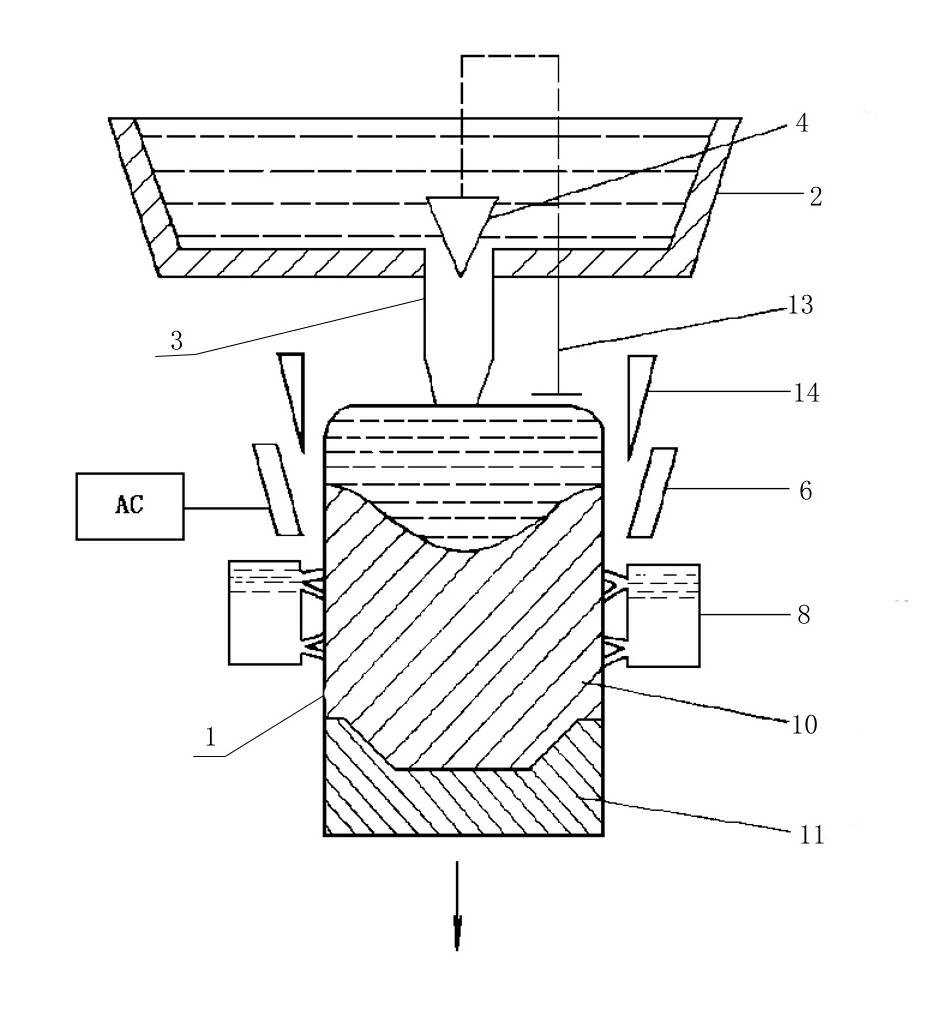

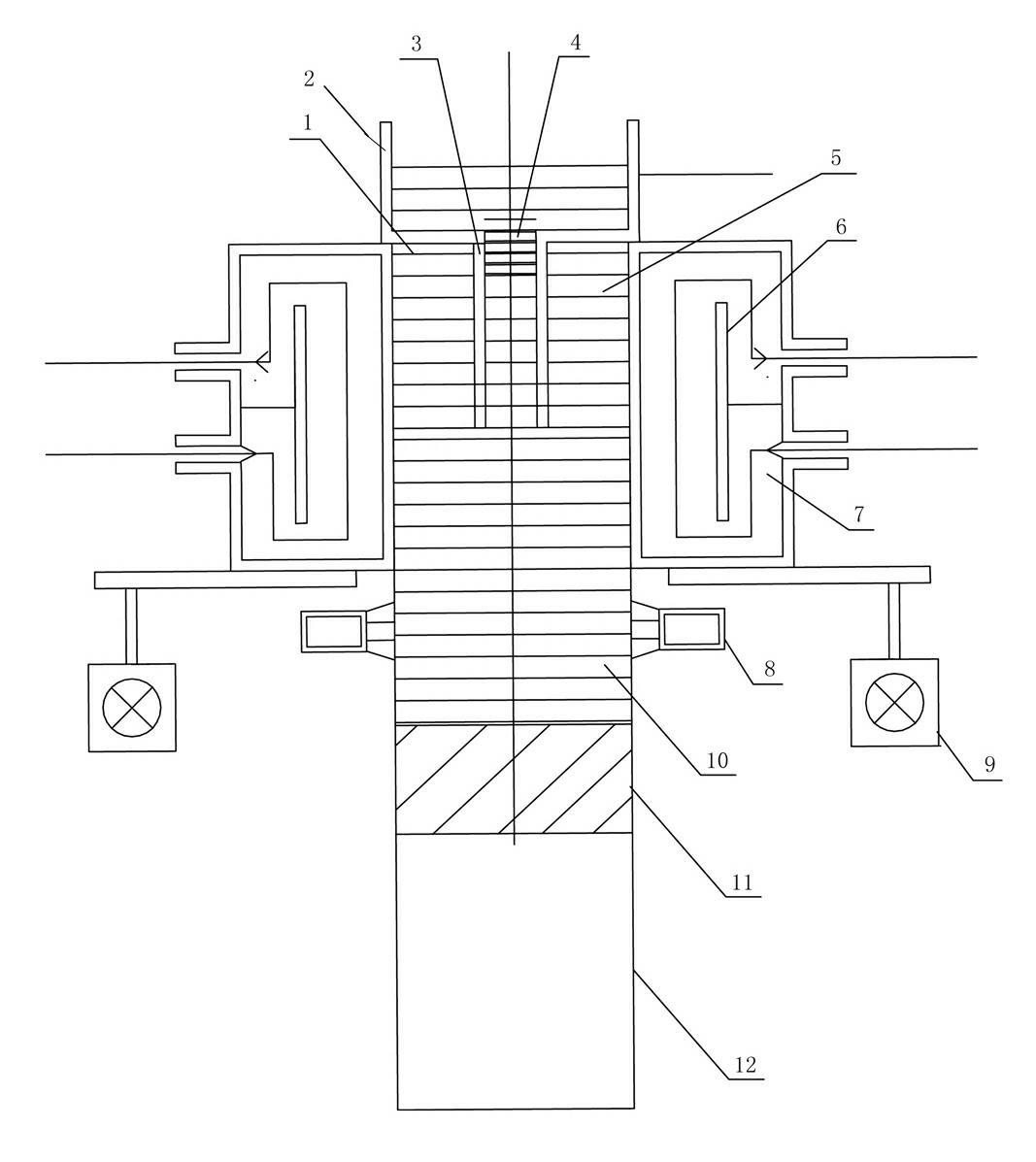

[0030] Refer to attached figure 1 , 2, The oxygen-free copper strip horizontal electromagnetic casting device of the present invention includes a crystallizer shell 1, an intermediate frequency power supply, an induction coil 6 (inductor), an electromagnetic oscillator 9, a shielding cover 13, a cooling water tank 8, a bottom mold 11 and a pouring mechanism. The pouring mechanism consists of a tundish 2 and a gate plug 4 . The tundish 2 is installed on the upper part of the crystallizer shell 1, the bottom of the crystallizer shell 1 is provided with a gate 3, and the gate 3 is equipped with a gate plug 4, and the tundish 2 communicates with the upper part of the crystallizer shell 1 through the gate 3 , the upper part of the crystallizer shell 1 is equipped with a liquid level sensor 13, the liquid level sensor 13 is connected with the supporting PLC controller, and the supporting PLC controller obtains the liquid level height signal in the crystallizer shell according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com