Silicon electromagnetic casting device

An electromagnetic casting and voltage technology, applied in the field of silicon electromagnetic casting devices, can solve problems such as increased input power, solidification, and electromagnetic interference, and achieve high-quality, large-volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

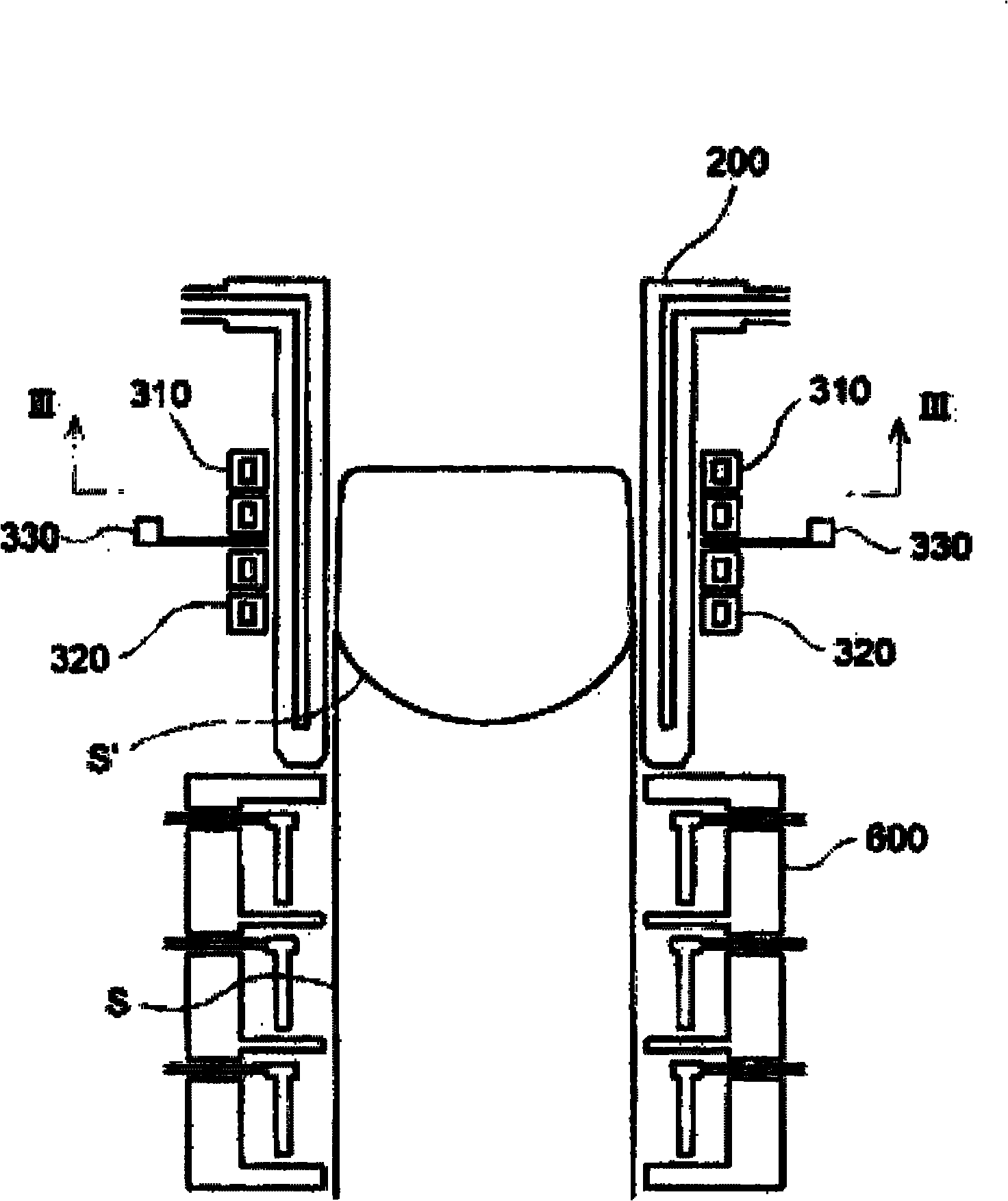

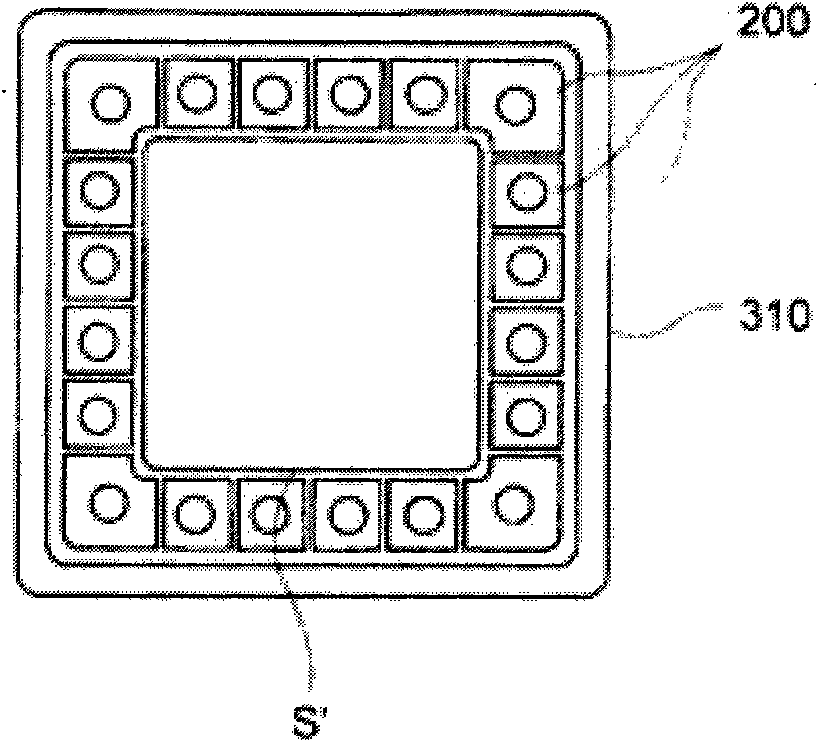

[0074] In this device 1, two induction coils 310, 320 with different induction frequencies are used, and the conductive crucible 200 which is insulated in the vertical direction and has a cooling water circulation inside interacts with the induction coil 300 arranged on the periphery of the crucible 200 to make silicon The block S melts and solidifies while falling. When using this device 1 to carry out silicon electromagnetic casting, the steps are as follows:

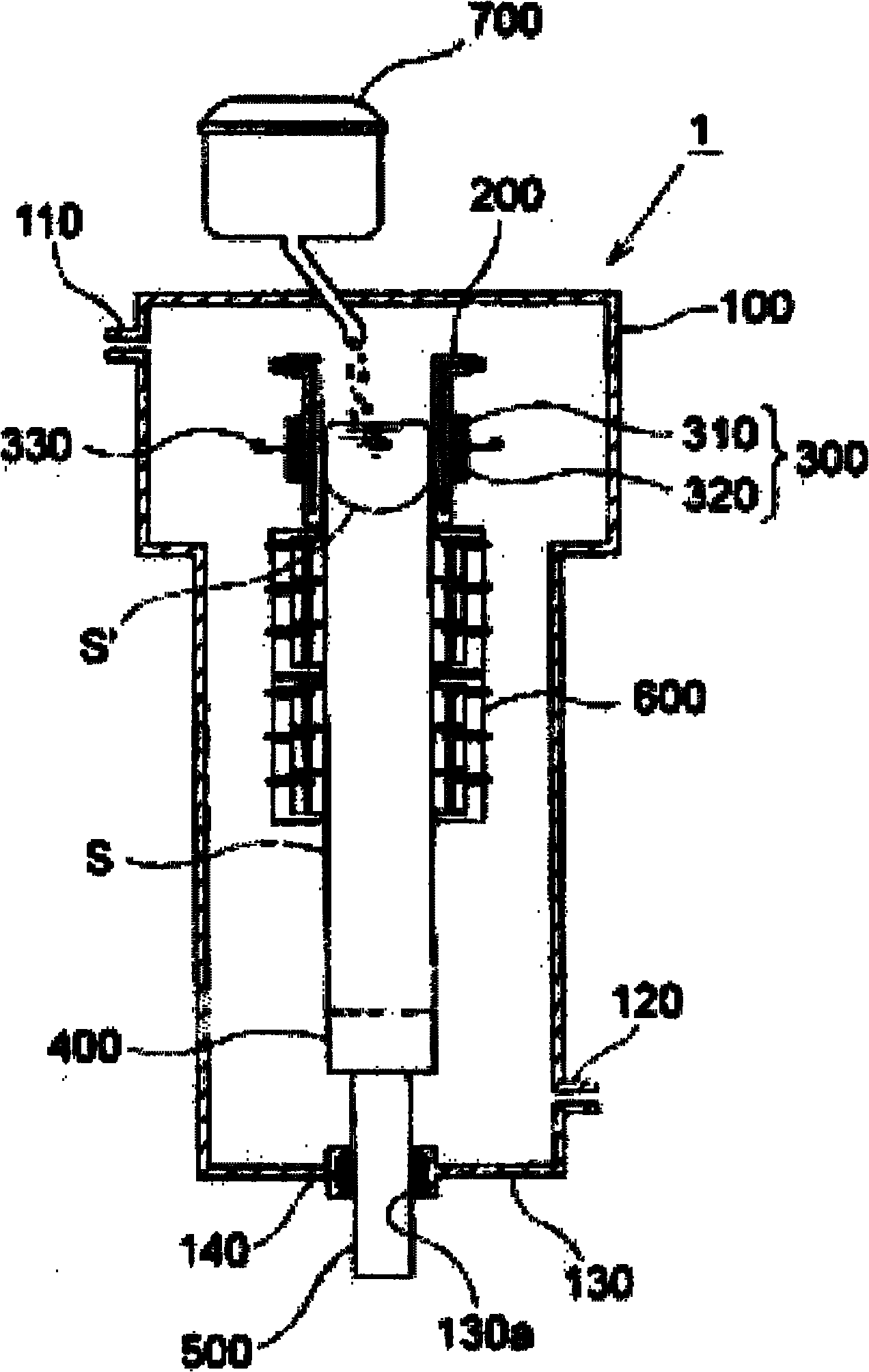

[0075] In this example, as figure 1 As shown, a crucible 200 and induction coils 310 , 320 installed up and down on the periphery of the crucible 200 are provided in the furnace container 100 with controllable internal pressure. Right below the crucible, a temperature-controlled furnace 600 for controlling the temperature of the solidification of the silicon block S and a vertical moving device 500 for moving the graphite table 400 up and down are installed so that the silicon block S can continue to descend.

[00...

Embodiment 2

[0089] In this device 1, not only two induction coils 310, 320 with different induction frequencies are used, but also a plasma torch 800 is provided, and a conductive crucible 200 with a cooling water circulation inside is insulated in the vertical direction and is arranged on the periphery of the crucible 200. The induction coil 300 on the top interacts to melt and solidify the silicon block S while falling. When using this device 1 to carry out silicon electromagnetic casting, the steps are as follows:

[0090] In this example, as Figure 4 As shown, a crucible 200 and induction coils 310 , 320 installed up and down on the periphery of the crucible 200 are provided in the furnace container 100 with controllable internal pressure. Right below the crucible, a temperature-controlled furnace 600 for controlling the temperature of the solidification of the silicon block S and a vertical moving device 500 for moving the graphite table 400 up and down are installed so that the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com