Electromagnetic casting method of difference phase traveling wave magnetic field

A traveling wave magnetic field and electromagnetic casting technology, applied in the field of differential phase traveling wave magnetic field electromagnetic casting, can solve the problems of limited electromagnetic action range, unadjustable electromagnetic conditions, low electromagnetic utilization rate, etc. The effect of improving the yield, mechanical properties and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

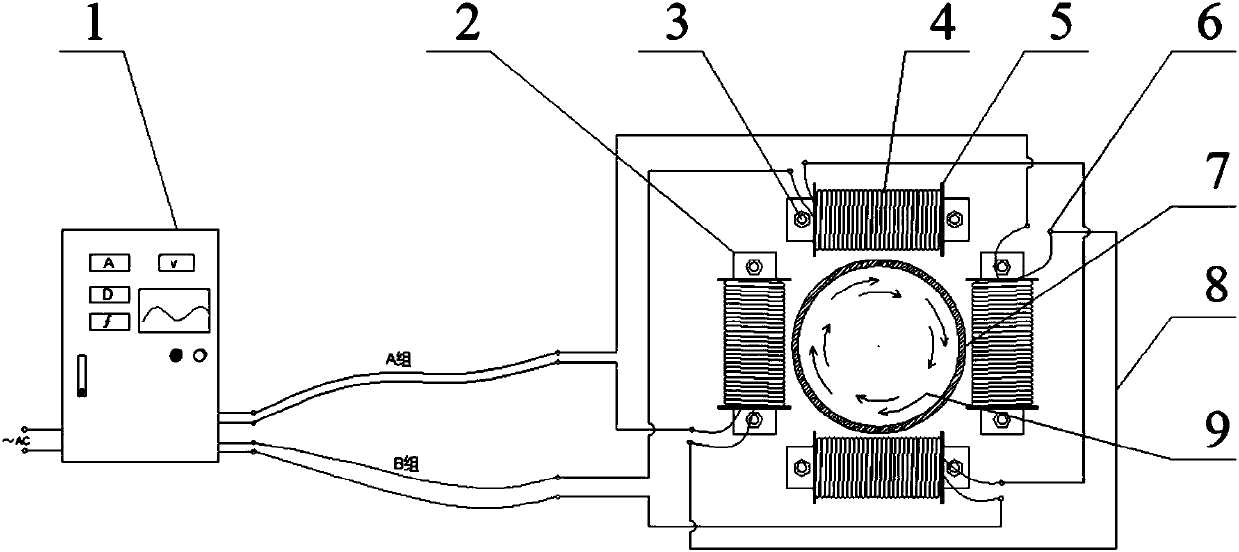

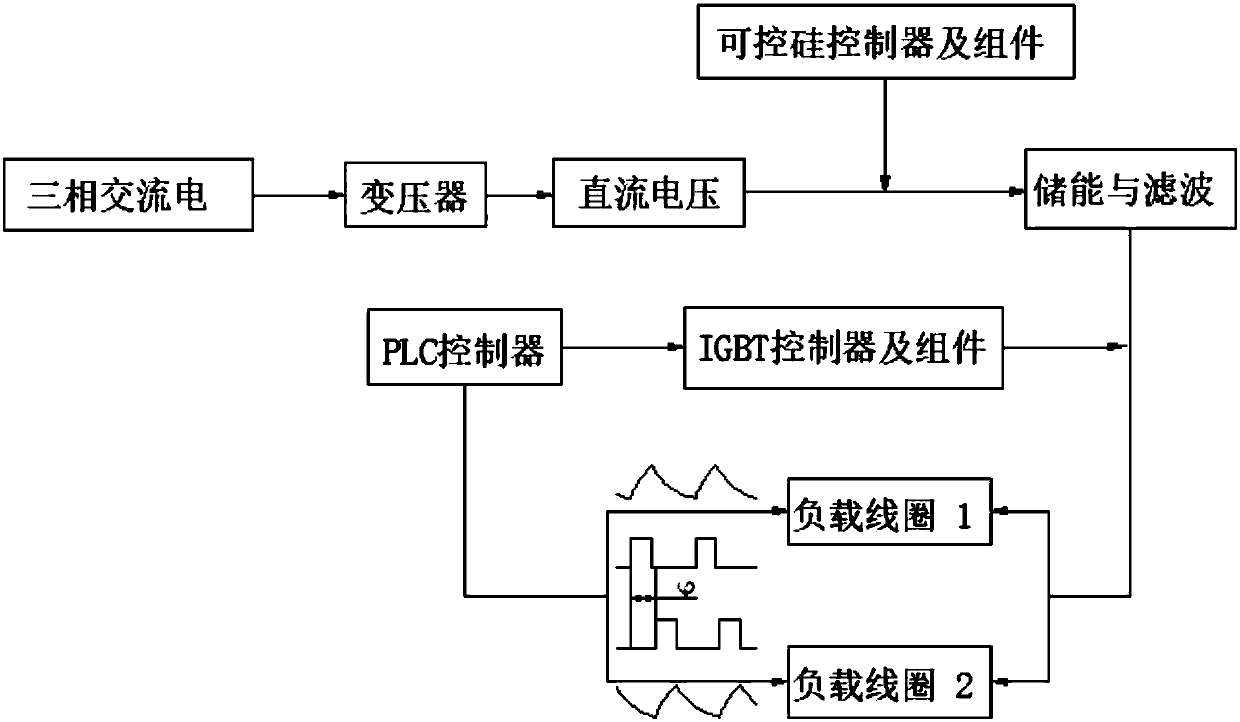

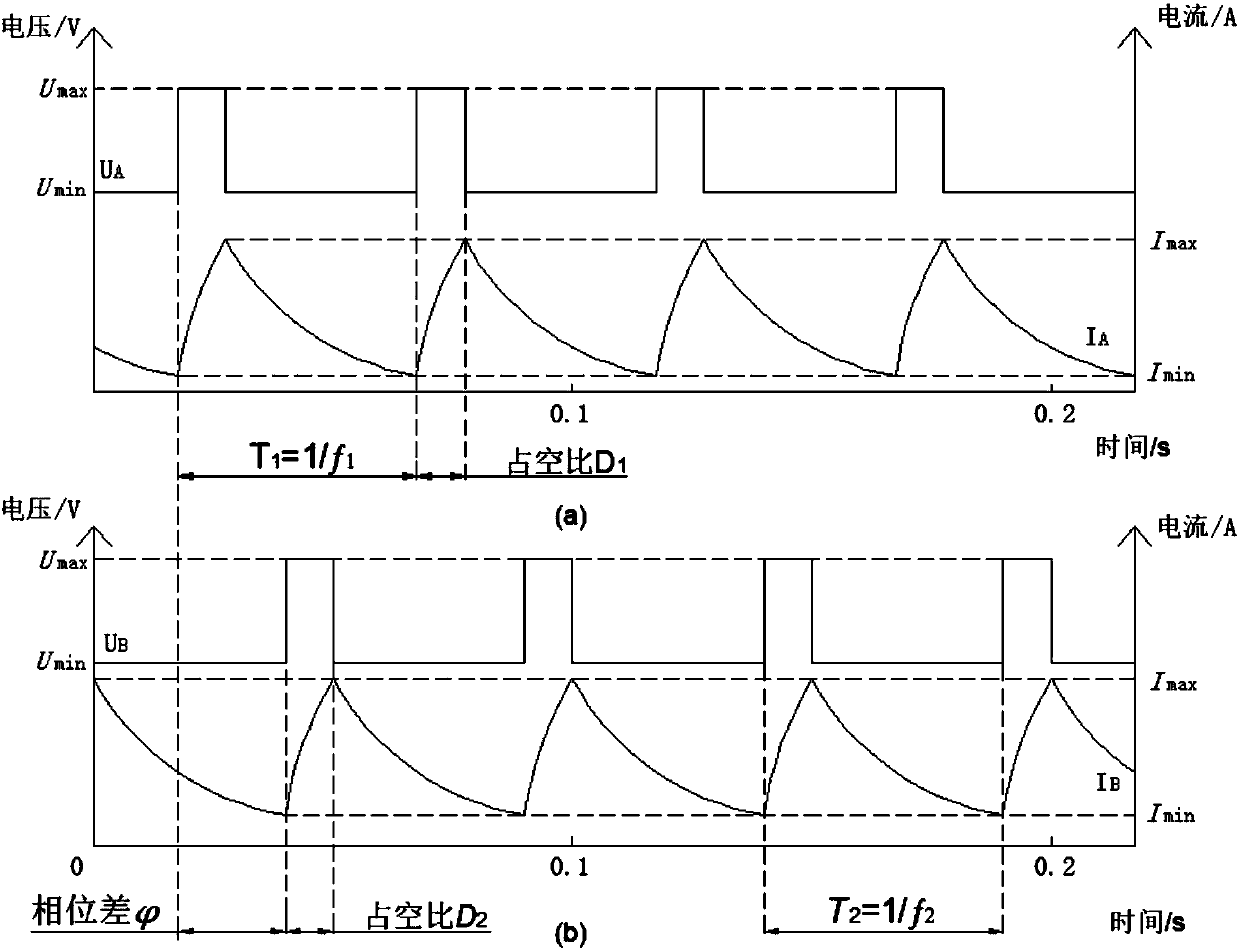

[0043] In the electromagnetic casting process, two sets of magnetic field application devices are arranged around the metal melt, the structure is as follows figure 1 Shown; Each magnetic field applying device comprises silicon steel sheet iron core 2, electromagnetic coil 4 and fixing device 3 (bolt nut), and the two ends of silicon steel sheet iron core 2 are fixed in the silicon steel sheet iron core cooling device 7 by fixing device 3, The silicon steel sheet core cooling device is provided with a cooling water inlet and a cooling water outlet; the electromagnetic coil 4 is wound on the silicon steel sheet iron core 2, and the two ends of the electromagnetic coil 4 are provided with an electromagnetic coil baffle 5, and the electromagnetic coil baffle 5 is fixed on the silicon steel On the sheet iron core 2, and the electromagnetic coil 4 is connected with the phase difference traveling wave magnetic field power supply system 1 through the connecting wire 8, and the connect...

Embodiment 2

[0054] Method is with embodiment 1, and difference is:

[0055] (1) Set up two sets of magnetic field application devices around the metal melt. The two magnetic field application devices are divided into A and B two sets of magnetic field application devices, which are called A1, A2, A3 and B1, B2, B3 respectively. Each set of magnetic field The application device is connected in series; the arrangement is as follows Figure 5 As shown in (b); every arbitrary 3 magnetic field applying devices constitute a group of magnetic field applying devices;

[0056] (2) The number of coil turns of each magnetic field applying device is 66 turns, which are arranged in two layers;

[0057] (3) The electromagnetic wire used by the electromagnetic coil is the winding wire of the submersible motor;

[0058] (4) Continuous casting is adopted, and the target product cast is an aluminum alloy billet;

[0059] Use the same method to carry out a comparative test without applying a magnetic fie...

Embodiment 3

[0061] Method is with embodiment 1, and difference is:

[0062] (1) The two magnetic field applying devices are divided into two groups of magnetic field applying devices, A and B, which are called A1~A4 and B1~B4 respectively, and each group of magnetic field applying devices is connected in series; the arrangement is as follows Figure 5 Shown in (a); every arbitrary 4 magnetic field application devices constitute a group of magnetic field application devices; the local structure is as Image 6 As shown, the location dimensions are as Figure 7 As shown, the silicon steel sheet iron core is fixed on the silicon steel sheet iron core cooling device by the silicon steel sheet iron core fixing bolt 10, 11, the outer cover of the silicon steel sheet iron core cooling device, 12, the inner sleeve of the silicon steel sheet iron core cooling device; The radius of r1 is between 25 and 300mm, the thickness of the inner sleeve of the silicon steel sheet iron core cooling device is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com