Preparation of copper-chromium alloy contact material by aluminothermal reduction-electromagnetic casting process

A copper-chromium alloy, electromagnetic casting technology, applied in contact materials, circuits, electrical switches, etc., can solve the problems of restricting the promotion and application of CuCr alloy contact materials, unqualified products, and low product performance. Gold slag separation effect, avoid macro segregation, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

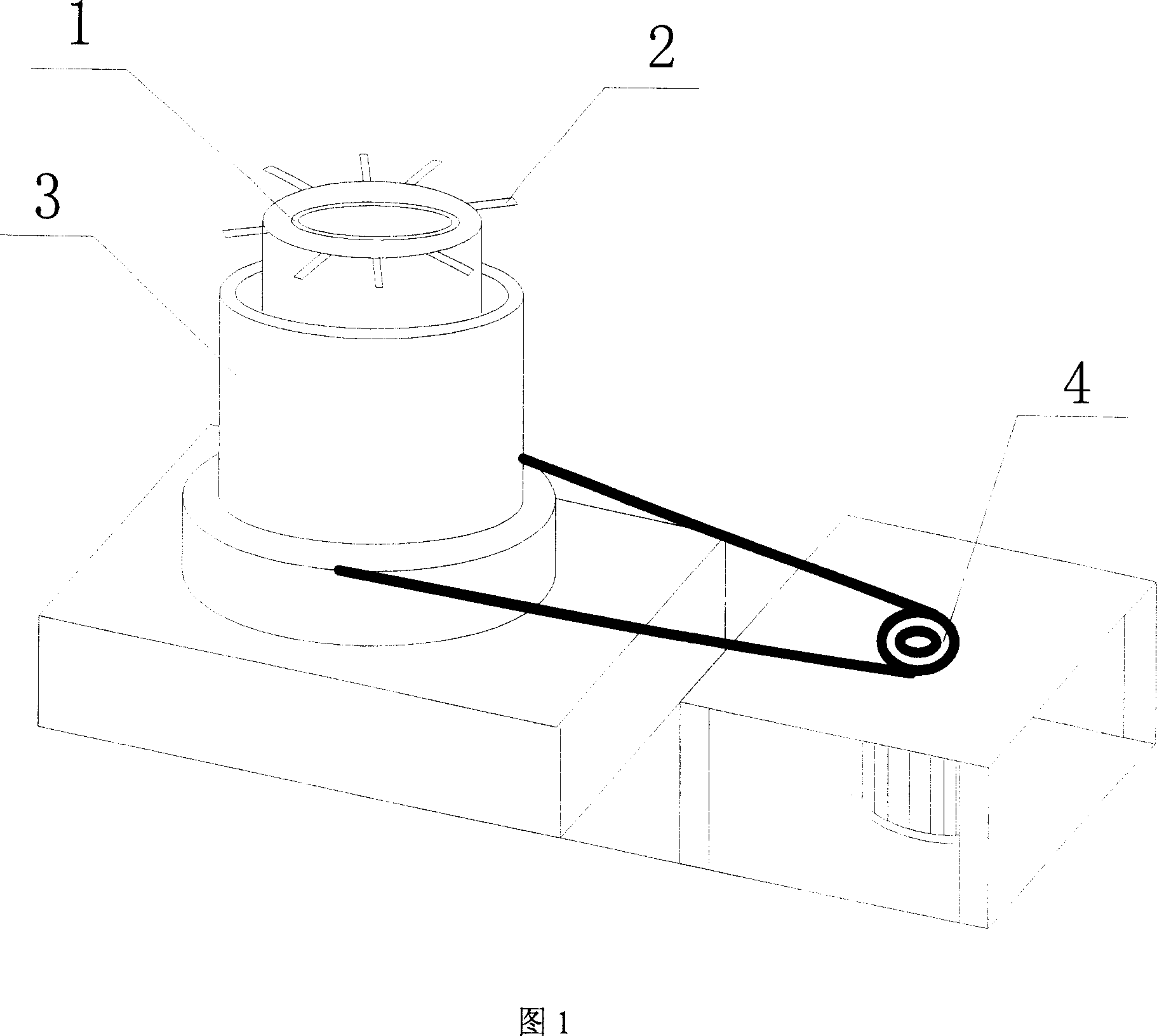

Method used

Image

Examples

Embodiment 1

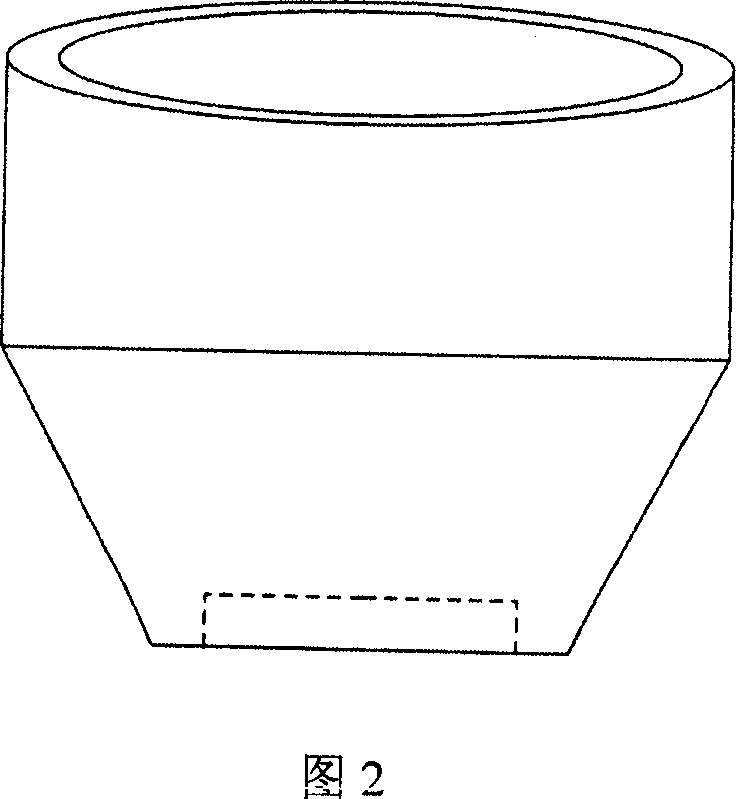

[0030] Take CuO, Cr 2 o 3 And Al powder by mass ratio CuO: Cr 2 o 3 : Al powder is a ratio of 100: 114: 160, that is, to ensure that the excess of Al powder is 50%. 2 o 3 and Al powder) the percentage of total mass adds 5% CaF in the raw material 2 , Mix the reactants evenly, then put the reaction mixture into the aluminothermic reduction reaction furnace, add an appropriate amount of Mg powder on the surface of the reactants as an ignition agent, heat the open flame in the air atmosphere to ignite the Mg powder, and initiate the aluminothermic reduction reaction. At the same time, the electromagnetic stirring device is turned on, under the action of electromagnetic field stirring, the gold slag separation process is carried out to obtain a high-temperature copper-chromium alloy melt, and the circulating water is started for circulating water cooling, and the separated high-temperature alloy melt will be continuously cast into graphite In the casting mold, the preheating ...

Embodiment 2

[0032] Take CuO, Cr 2 o 3 And Al powder, by mass ratio CuO: Cr 2 o 3 : The ratio of Al powder is 100: 110: 150, that is, to ensure that the excess of Al powder is about 40%. 2 o 3 and Al powder) the percentage of total mass to add 0.6% Ni as an alloying element, and add 3% of exothermic agent KClO by the percentage relative to the total mass of reactant 3 At the same time, add 2% NaF to the raw material, mix the reactant evenly, then put the reaction mixture into the aluminothermic reduction reaction furnace, add an appropriate amount of Mg powder on the surface of the reactant as an ignition agent, and heat it with an open flame in an air atmosphere to ignite Mg powder, triggering the thermite reduction reaction. At the same time, the electromagnetic stirring device is turned on, under the action of electromagnetic field stirring, the gold slag separation process is carried out to obtain a high-temperature copper-chromium alloy melt, and the circulating water is started ...

Embodiment 3

[0034] Take CuO, Cr 2 o 3 And Al powder, by mass ratio CuO: Cr 2 o 3 : The ratio of Al powder is 100:60:120, that is, to ensure that the Al powder is in excess of 20%, and add 2% of the exothermic agent KClO 3 At the same time, add 3% CaO to the raw material, mix the reactant evenly, then put the reaction mixture into the self-propagating reactor, add an appropriate amount of Mg powder on the surface of the reactant as the igniter, heat the open flame in the air atmosphere to ignite the Mg powder, triggering the aluminothermic reduction reaction. At the same time, the electromagnetic stirring device is turned on, under the action of electromagnetic field stirring, the gold slag separation process is carried out to obtain a high-temperature copper-chromium alloy melt, and the circulating water is started for circulating water cooling, and the separated high-temperature alloy melt will be continuously cast into graphite In the casting mold, the preheating temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com