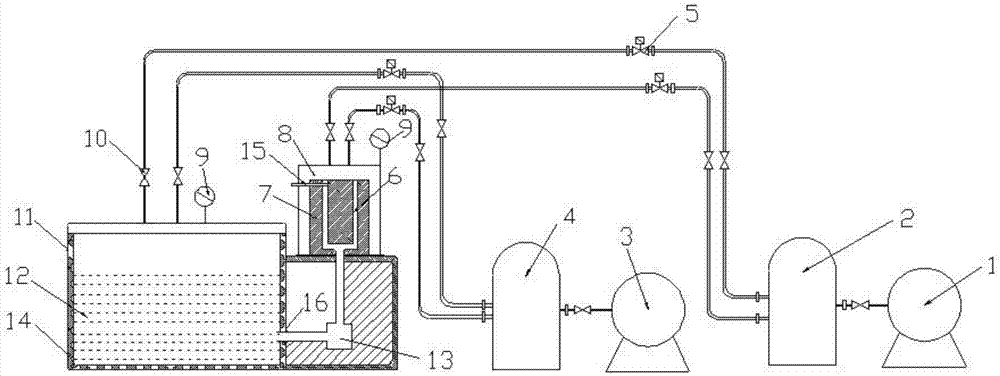

Electromagnetic casting system

A pouring system and electromagnetic technology, which is applied in the field of metal forming equipment, can solve the problems of refining and degassing in holding furnaces, porosity in castings, and affecting mechanical properties of castings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

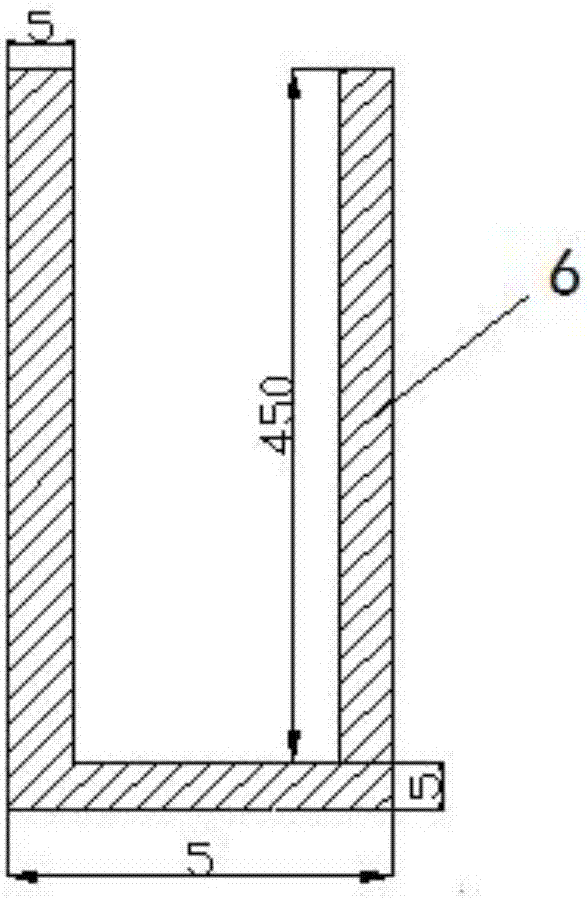

Method used

Image

Examples

example 1

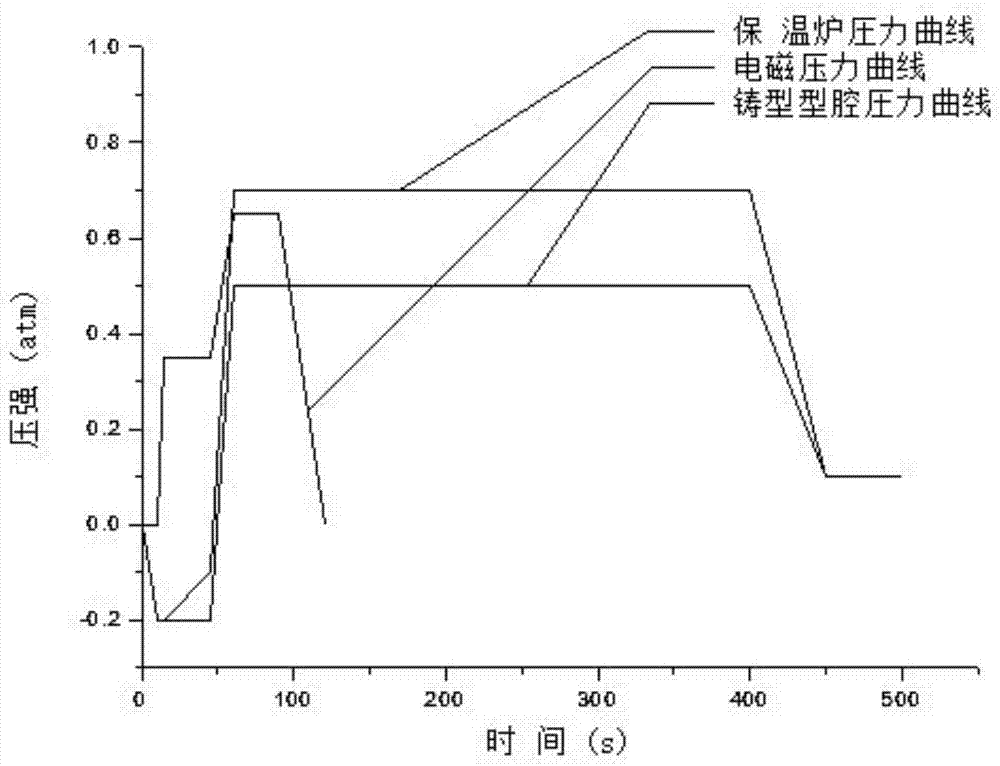

[0041] a. The molten metal enters the holding furnace from the sealed hatch on the left side of the holding furnace d, and the holding furnace starts to work; when the holding furnace maintains a constant temperature, turn on the vacuum pump to evacuate the holding furnace and the mold cavity at the same time.

[0042] b. When the vacuum degree reaches 0.01MPa, keep it for a certain period of time, so that the gas in the molten metal is completely extracted. At this time, both the holding furnace and the mold cavity are kept vacuum, and the vacuum degree on both sides is equal, which is conducive to smooth electromagnetic casting. filling.

[0043] c. Then start electromagnetic pouring, the current flowing in the metal flow will generate an induced magnetic field, which will be superimposed on the external magnetic field, so that the synthetic magnetic field will be unevenly distributed from the inlet to the outlet of the electromagnetic pump, and will flow with the liquid meta...

example 2

[0048] a. The molten metal enters the holding furnace from the sealed hatch on the left side of the holding furnace, and the holding furnace starts to work; when the holding furnace maintains a constant temperature, the vacuum pump is turned on to evacuate the holding furnace and the mold cavity at the same time.

[0049] b. When the vacuum degree reaches 0.01MPa, keep it for a certain period of time so that the gas in the molten metal is completely extracted. At this time, both the holding furnace and the mold cavity are kept vacuum, and the vacuum degree on both sides is equal, which is beneficial to electromagnetic pouring Smooth filling.

[0050] c. Then start electromagnetic pouring, the current flowing in the liquid metal will generate an induced magnetic field, which will be superimposed on the external magnetic field, so that the synthetic magnetic field will be unevenly distributed from the inlet to the outlet of the electromagnetic pump, and will flow with the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com