Using method of geopolymer based self-levelling ground material

A ground material and geopolymer technology, applied in cement production and other directions, can solve the problems of poor geopolymerization toughness, easy shrinkage and cracking, etc., and achieve the effects of less energy consumption, improved toughness and surface flatness, and less environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

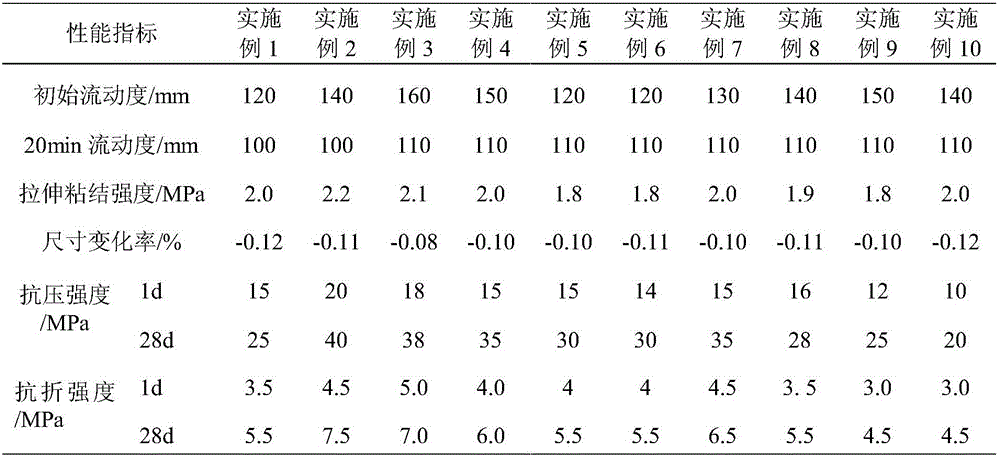

Embodiment 1

[0020] Weigh Na 2 O SiO 2 Dissolve in 20 parts of water, after standing for 24 hours, add metakaolin (particle size ≤ 200 mesh, metakaolin and Na 2 O SiO 2 The weight ratio is 100:10, a total of 100 parts), quartz river sand (100 parts, fineness modulus 0.8-1.2, mud content ≤ 0.5%), calcium sulfoaluminate concrete expansion agent (5 parts, limit expansion rate ≥ 0.025% (7 days in water)), ethylene / vinyl acetate copolymer latex powder (2 parts), PVA fiber (0.1 part), silicone defoamer (0.4 part), polycarboxylate superplasticizer ( 1 part), use a mortar mixer to stir for 2 minutes, pour the ground, self-leveling molding, and solidify to form a ground material. The properties are shown in Table 1.

Embodiment 2

[0022] Weigh Na 2 O 1.2SiO 2 Dissolve in 30 parts of water, after standing for 24 hours, add slag (particle size ≤ 200 mesh, slag and Na 2 O SiO 2 The weight ratio is 100:15, a total of 100 parts), quartz river sand (150 parts, fineness modulus 0.8-1.2, mud content ≤ 0.5%), calcium sulfoaluminate concrete expansion agent (10 parts, limit expansion rate≥0.025% (7 days in water)), ethylene / vinyl acetate copolymer latex powder (1 part), PP fiber (0.2 part), silicone defoamer (0.6 part), polycarboxylate superplasticizer ( 0.8 parts), use a mortar mixer to stir for 5 minutes, pour the ground, self-leveling molding, and solidify to form a ground material. The properties are shown in Table 1.

Embodiment 3

[0024] Weigh Na 2 O 1.2SiO 2 Dissolve in 35 parts of water, after standing for 24 hours, add slag, fly ash (particle size ≤ 200 mesh, slag, fly ash and Na 2 O SiO 2 The weight ratio is 100:16, a total of 100 parts, of which the weight ratio of slag and fly ash is 7:3), quartz river sand (200 parts, fineness modulus 0.8-1.2, mud content ≤0.5%), sulfur Calcium aluminate-calcium oxide concrete expansion agent (8 parts, limit expansion rate ≥ 0.025% (7 days in water)), vinyl acetate / tertiary carbonic acid ethylene copolymer latex powder (2 parts), PVA fiber (0.1 part), Polyacrylic acid defoamer (0.4 parts), polycarboxylate superplasticizer (0.5 parts), after stirring for 10 minutes with a mortar mixer, pour the ground, self-leveling molding, and solidify to form a ground material. The properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com