Electromagnetic casting process applied to high-precision complex cupronickel ternary alloy production

A ternary alloy and electromagnetic casting technology, which is applied in the field of electromagnetic casting technology for the production of high-precision and complex cupronickel ternary alloys, can solve the problems of inclusions, lattice fractures, peeling, etc., so as to reduce production economic costs, improve solute distribution, The effect of uniform crystalline structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

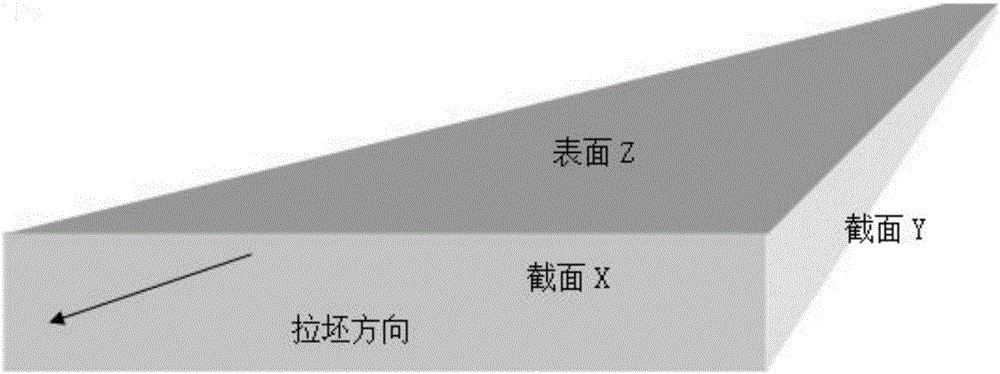

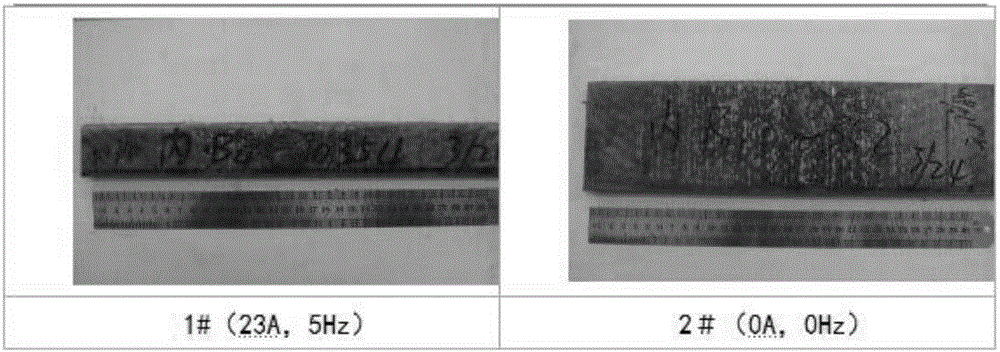

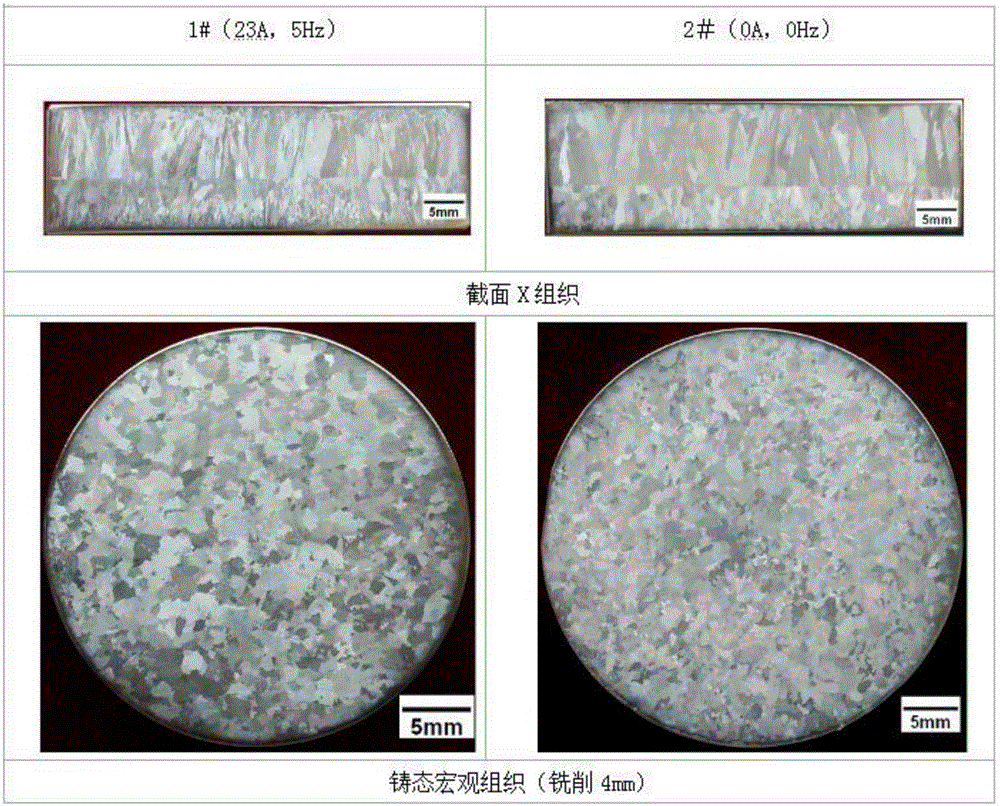

[0023] The following is the test and analysis of (23A, 5Hz) tin-phosphorus bronze alloy electromagnetic horizontal continuous casting slab samples (test and analysis report of white copper sample),

[0024] 1. Test purpose and test plan

[0025] 1) Purpose of the test

[0026] Study the microstructure and composition changes and surface quality of white copper under the action of a magnetic field, and explore reasonable process parameters.

[0027] 2) Test plan

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com