Silicon electromagnetic casting device

A technology of electromagnetic casting and structure, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve problems such as infiltration, and achieve the effect of preventing deformation and protecting crucibles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

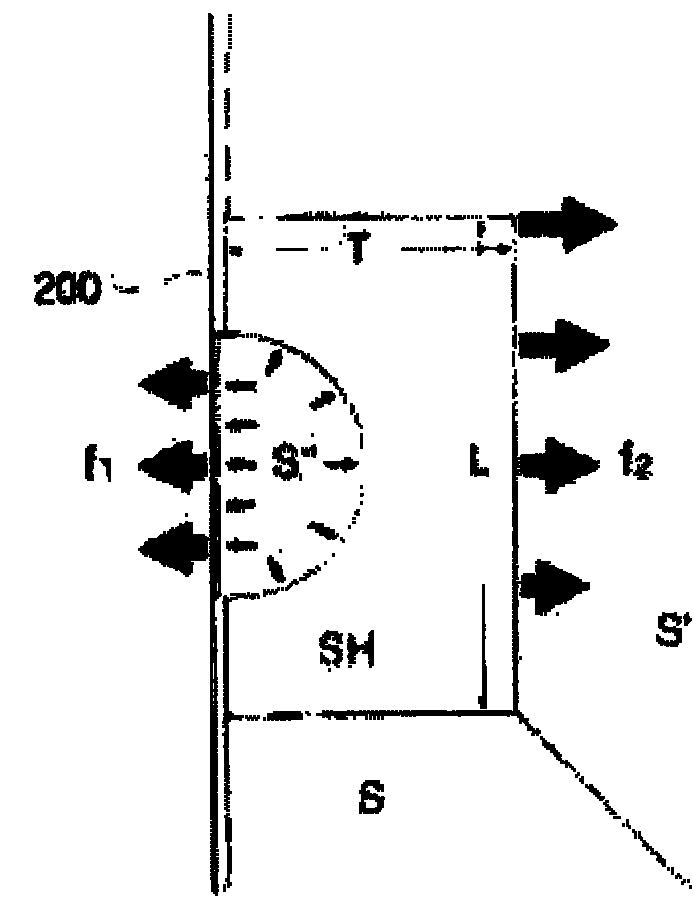

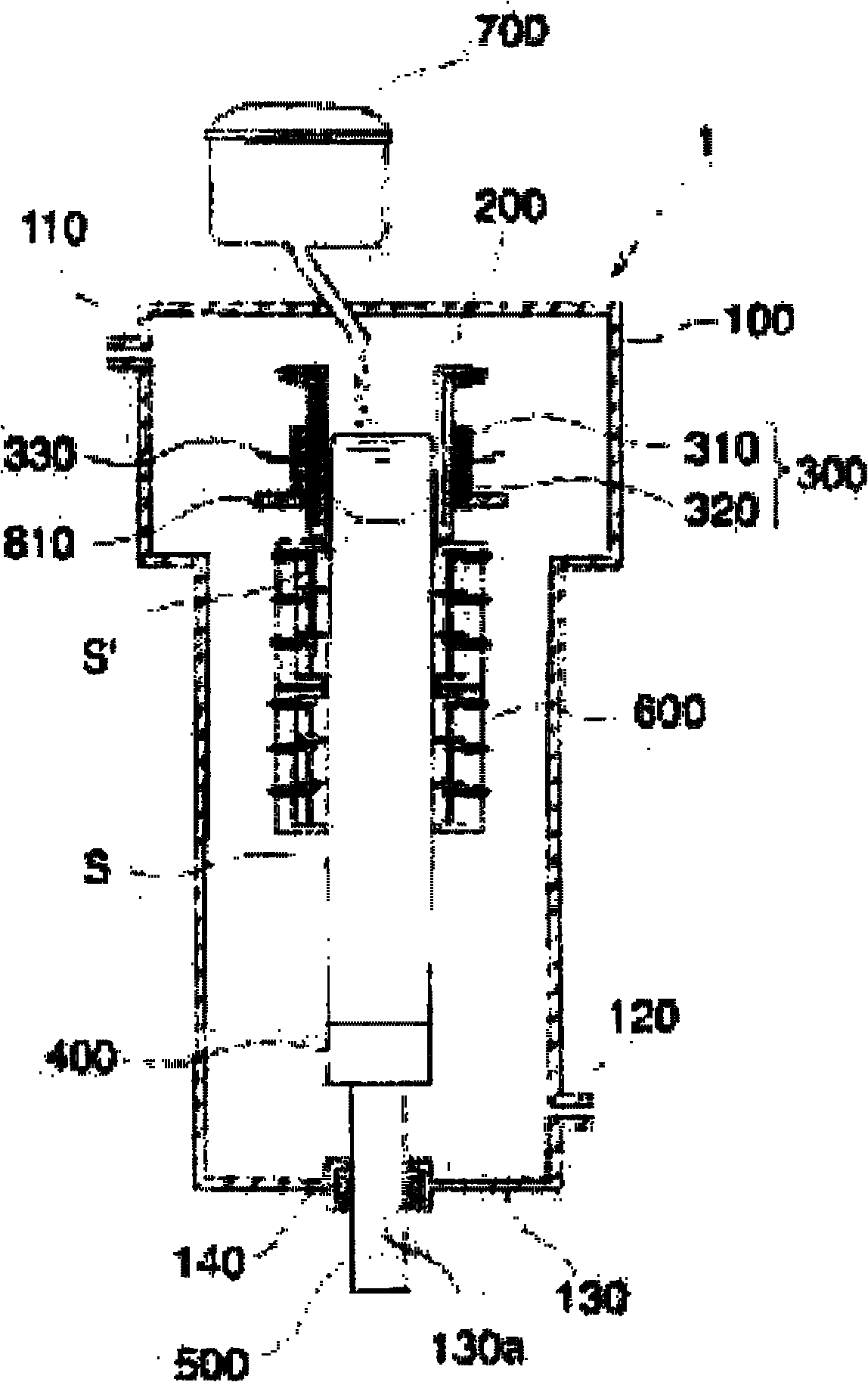

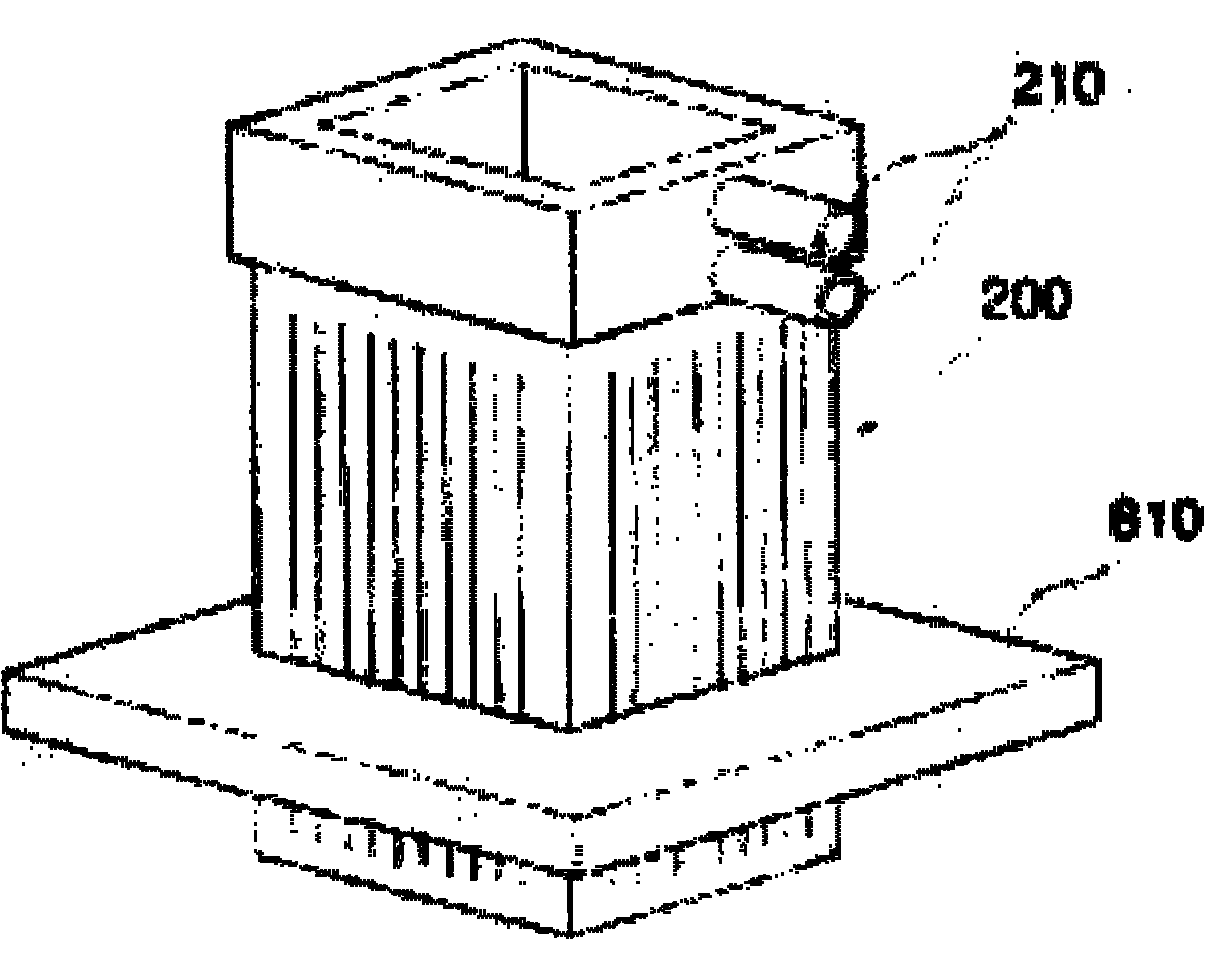

[0064] like figure 2 and image 3 As shown, a rigid structure 810 made of insulating material is embedded on the outer peripheral surface of the crucible 200, and when this silicon electromagnetic casting device is used to manufacture a silicon ingot S in the shape of a square column, the steps are as follows:

[0065] In this example, the cross section of the silicon ingot S in the casting direction is a square with a side length of 35 cm. Therefore, assuming that the cross-section in the horizontal direction is a square crucible 200 with an inner side length of 35 cm and an outer side length of 41.6 cm, the number of longitudinal insulation division regions of the crucible 200 is determined as 60, and each of the crucible 200 divided into 60 parts The length of the part is 70cm. During processing, there is cooling circulating water inside, and mica, an electrical insulating material, is inserted between each part. The flow of cooling water inside the crucible 200 is 500 l...

Embodiment 2

[0073] Figure 4 and Figure 5 In the operation example of the silicon electromagnetic casting device shown, a rigid structure 820 made of insulating material is embedded in the outer peripheral surface of the crucible 200. When using this device to manufacture a cylindrical silicon ingot S, the steps are as follows:

[0074] In this example, the silicon ingot has a circular cross-section in the casting direction with a diameter of 600 mm. Therefore, assuming that the inner diameter of the crucible 200 is 600 mm and the outer diameter is 660 mm, the number of insulating divisional regions in the longitudinal direction of the crucible 200 is set to 60. During processing, each part of the crucible 200 divided into 60 parts has cooling water circulating inside, and mica, an electrical insulating material, is inserted between each part. The flow of cooling water in the crucible 200 is 500 liters per minute in total.

[0075] In addition, an induction power supply with a maximum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com