High-precision complicated white copper alloy ternary alloy production technology

A ternary alloy and production process technology, which is applied in the direction of metal material coating process, etc., can solve the problems of complex process procedures and difficult control of product quality, and achieve low energy consumption, excellent tensile properties and elongation, and corrosion resistance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

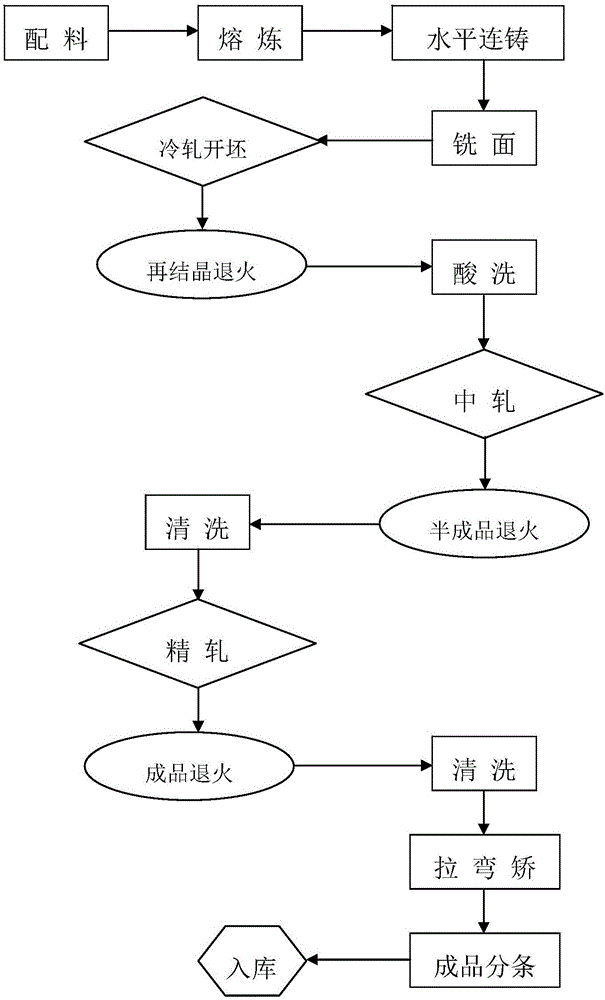

[0019] The steps and characteristics of a high-precision complex nickel-nickel ternary alloy production process of the present invention are described in detail as follows in conjunction with the accompanying drawings.

[0020] Step 1: Cupronickel casting billet.

[0021] In this step, the nickel-copper horizontal continuous casting is carried out after the ingredients are smelted. Electromagnetic casting technology is used in the horizontal continuous casting of cupronickel to improve the inner quality of the billet. The so-called electromagnetic casting technology is in the stage of solidification of liquid metal into a solid state. When it is in solid-liquid fusion, the electromagnetic force is generated by the electromagnetic coil, and the electromagnetic field is applied to the metal to improve the flow of the metal and the distribution of the solute, and effectively eliminate the surface and interior of the ingot. Defects such as segregation can be eliminated to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com