Solidification orientation device under magnetic field

An orientation and magnetic field technology, applied in the field of solidification orientation devices, can solve the problems of difficult temperature gradient control, reduced experimental efficiency, waste of raw materials and energy, etc., and achieves the effect of reducing the number of experiments, improving experimental efficiency, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

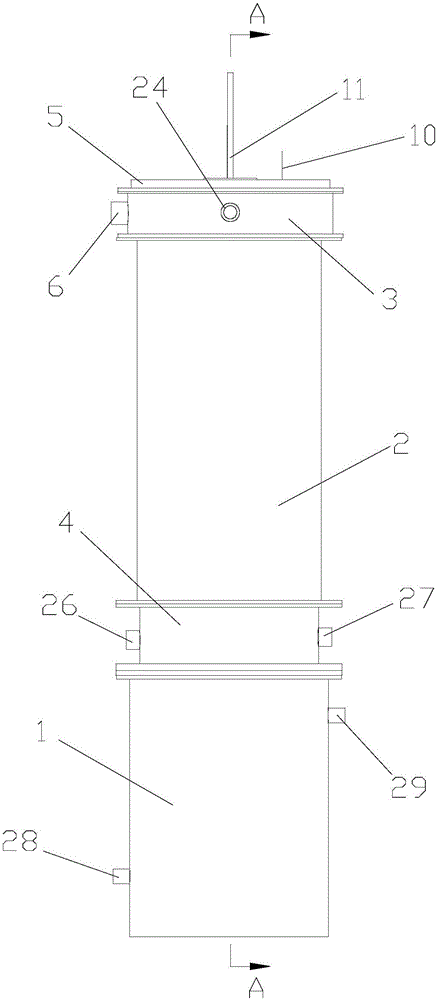

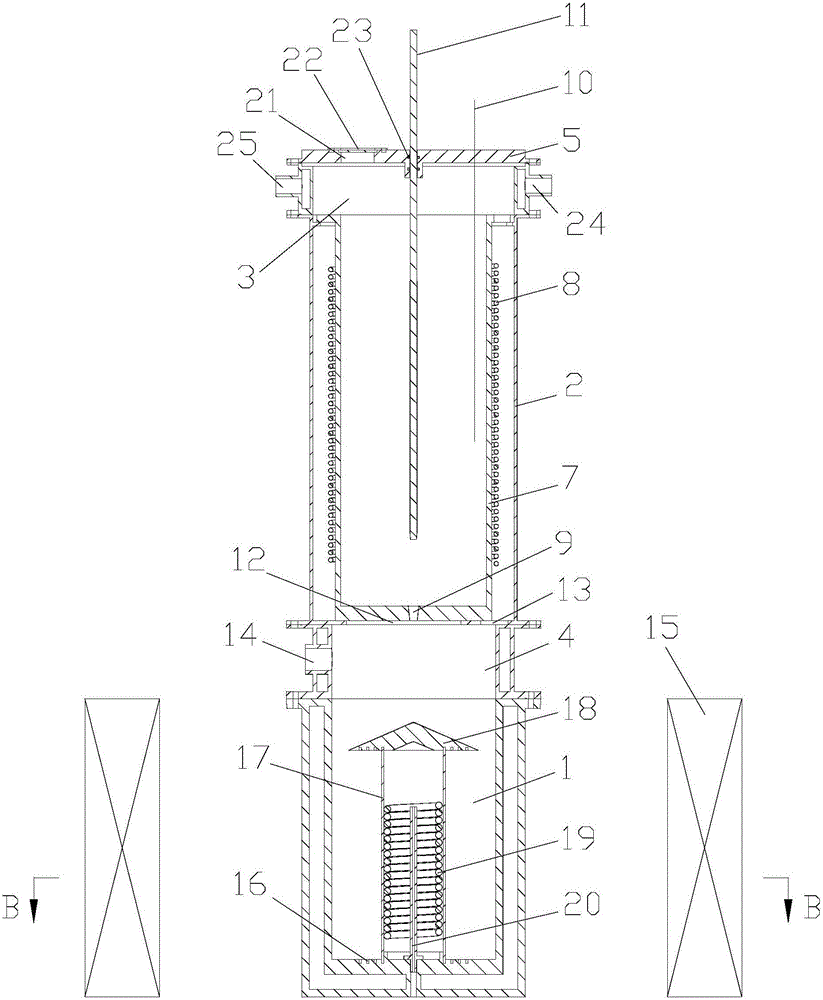

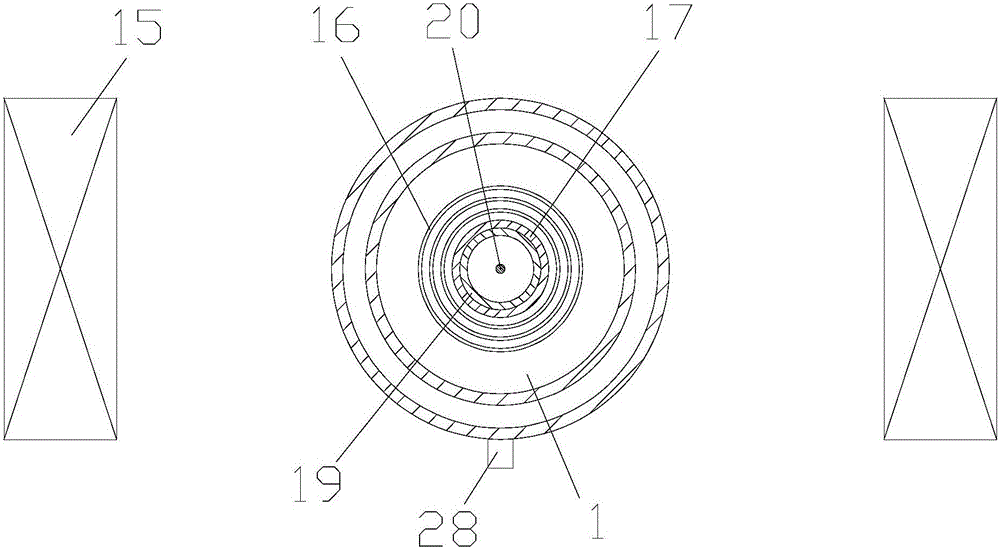

[0022] like Figure 1 to Figure 3 As shown, a solidification orientation device under a magnetic field belongs to the field of electromagnetic casting technology, and is used to study the relationship between the growth direction of multiple different solidification structures and the angle between the magnetic field direction.

[0023] The solidification orientation device under the magnetic field of the present invention comprises a cylindrical cooling copper mold 1, a housing 2, a first flange 3, a second flange 4 and a sealing cover 5, and the top of the cooling copper mold 1 and the bottom of the housing 2 pass through the first The two flanges 4 are connected, and the top of the housing 2 is connected to the sealing cover 5 through the first flange 3 . The first flange 3 is provided with an air filling hole 6, which is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com