5182 aluminum alloy and technology method for preparing tank cover material strip through aluminum alloy

A process method, aluminum alloy technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of uneven grain size and performance, unfavorable mass production control, large performance fluctuation range, etc., to achieve optimization Stretch bending straightening process, grain size control, effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

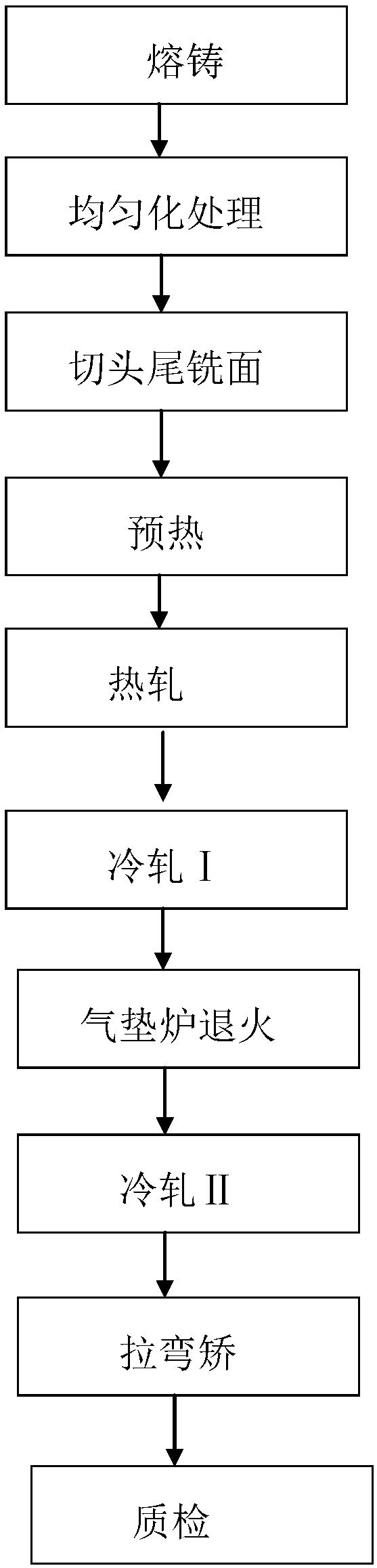

[0030] A kind of process method that 5182 aluminum alloy is prepared into can lid material strip, operation steps are as follows:

[0031] (1) Take 5182 aluminum alloy, which is composed of the following components according to weight percentage: Si: 0.045%, Fe: 0.16%, Cu: 0.049%, Mn: 0.5%, Mg: 4.62%, Cr: 0.015%; Zn : ≤0.027%, Ti: 0.023%, others are Al and some unavoidable impurity elements;

[0032] (2) Hot rolling: the 5182 aluminum alloy obtained in step (1) is kept at a temperature of 720-730°C for 8 hours for melting, 700-710°C for 5 hours, and then made into a flat ingot with a specification of 420mm×1420mm×6500mm, and the obtained The slab is maintained at a temperature of 550±10°C for 10 hours of thermal treatment, cooled, and the resulting slab is cut and milled at the head and tail, the upper and lower surfaces are milled at 15mm, and the side milling is 10mm. The preheating temperature of the material obtained after milling is 510 ℃, the time is 6h, hot rolling is ...

Embodiment 2

[0041] A kind of process method that 5182 aluminum alloy is prepared into can lid material strip, operation steps are as follows:

[0042] (1) Take 5182 aluminum alloy, which is composed of the following components according to weight percentage: Si: 0.0511%, Fe: 0.18%, Cu: 0.0505%, Mn: 0.34%, Mg: 4.5421%, Cr: 0.0308%; Zn : 0.0310%, Ti: 0.0180%, others are Al and some unavoidable impurity elements;

[0043](2) Hot rolling: the 5182 aluminum alloy obtained in step (1) is kept at a temperature of 730-740°C for smelting for 6 hours, kept at 700-710°C for 5 hours, and then made into a flat ingot with a specification of 420mm×1420mm×6500mm. The flat ingot is kept at a temperature of 550±10°C for 10 hours of soaking heat treatment, and cooled. After cooling, the obtained flat ingot is cut and face milled. The upper and lower surfaces are each milled with 15mm, and the side milled with 10mm. The preheating temperature of the material obtained after milling is 490 ℃, the time is 15h,...

Embodiment 3

[0049] A kind of process method that 5182 aluminum alloy is prepared into can lid material strip, operation steps are as follows:

[0050] (1) Take 5182 aluminum alloy, which is composed of the following components according to weight percentage: Si: 0.0369%, Fe: 0.1903%, Cu: 0.0501%, Mn: 0.3444%, Mg: 4.7460%, Cr: 0.0422%; Zn : 0.0258%, Ti: 0.0142%, others are Al and some unavoidable impurity elements;

[0051] (2) Hot rolling: the 5182 aluminum alloy obtained in step (1) is kept at a temperature of 750-760°C for 7 hours for melting, 700-710°C for 5 hours, and then made into a flat ingot with a specification of 420mm×1420mm×6500mm. The slab is maintained at a temperature of 550±10°C for 10 hours of soaking heat treatment, and cooled. After cooling, the slab is cut from head to tail and face milled. The upper and lower surfaces are each milled at 15mm, and the side milling is 10mm. The preheating temperature of the material obtained after milling is 520 ℃, the time is 5h, hot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com