Welding wire filling laser welding method utilizing non-oriented silicon steel

A technology of oriented silicon steel and laser wire filling, which is applied to laser welding equipment, welding media, welding equipment, etc., can solve the problems of increasing equipment investment and maintenance costs, having a greater impact on the production capacity of continuous units, and prolonging welding time, etc., to achieve improved Rollability, pass stability, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Choose a low-grade non-oriented silicon steel with a silicon content of 0.8% as the leader for laser welding; select a non-oriented silicon steel with a silicon content of 1.9% as the base material for laser welding; The lead is centered and spliced after cutting;

[0020] 2) The laser welding process specification is welded according to the parameters in Table 1; the welding wire composition requirements are shown in Table 2. Helium with a purity ≥99.999% is selected as the shielding gas to protect and cool the weld seam during the tailoring laser welding process.

[0021] 3) After the welding is completed, select a low-grade non-oriented silicon steel with a silicon content of 0.8% as a follow-up leader and repeat the above requirements to achieve continuous production.

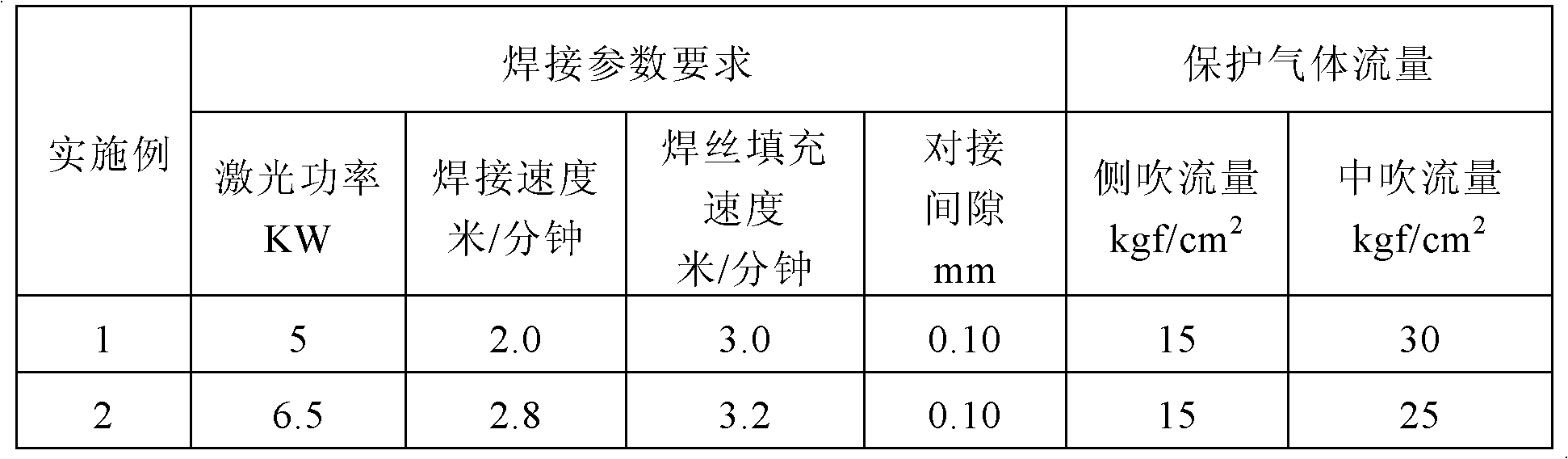

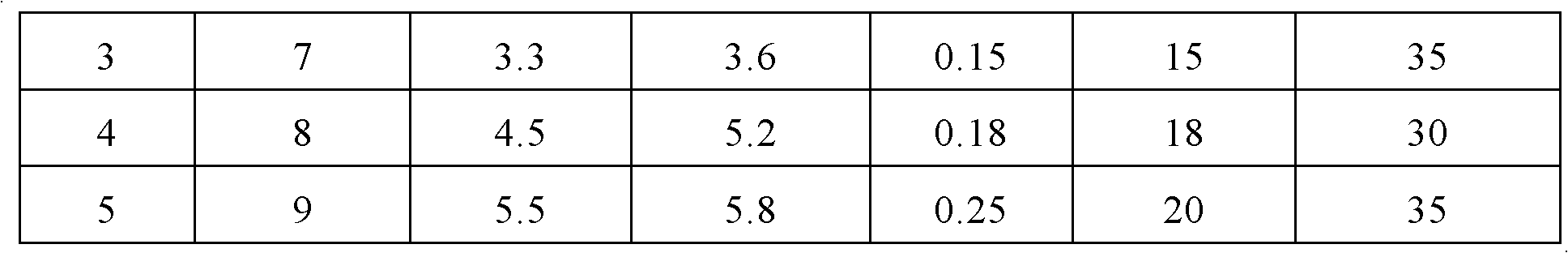

[0022] Table 1 Laser welding and shielding gas flow parameter control requirements

[0023]

[0024]

[0025] Table 2 Requirements for welding wire composition for laser filler wire weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com