High-grade non-oriented silicon steel and production method thereof

A technology of oriented silicon steel and production methods, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems affecting cold rolling efficiency and yield, achieve excellent magnetic induction performance, improve rolling efficiency and production yield, The effect of raising the temperature

Active Publication Date: 2022-02-15

ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +1

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide a production method of high-grade non-oriented silicon steel, to solve the problem of high-grade non-oriented silicon steel in the prior art, which is prone to strip breakage accidents in the cold rolling process and affects the rolling efficiency and yield of cold rolling. problem; and the purpose of the present invention is also to provide a kind of high grade non-oriented silicon steel prepared by adopting said production method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

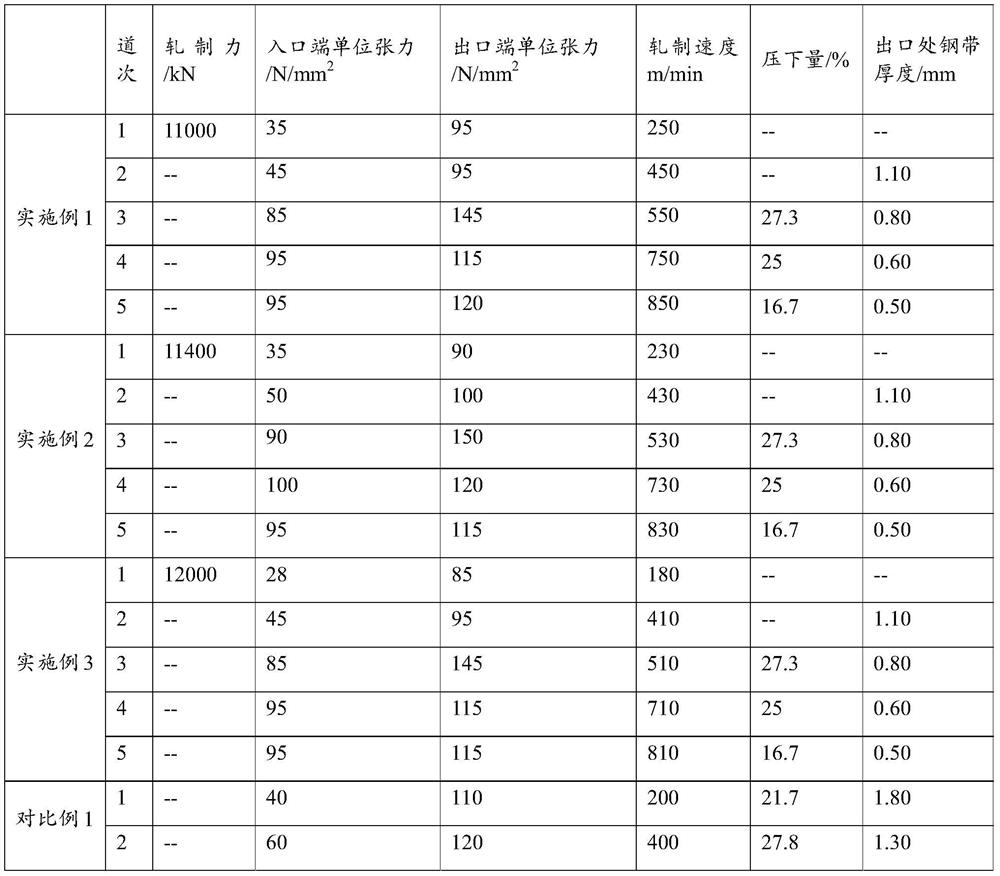

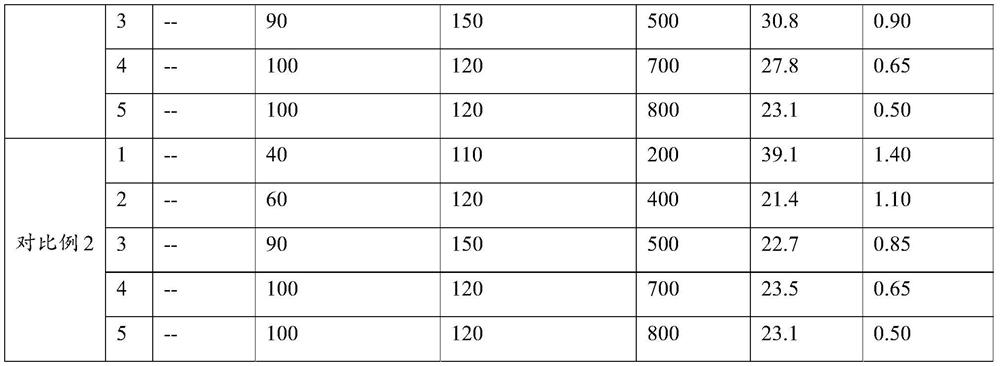

Embodiment 1~3

[0100] Embodiments 1-3: Carry out continuous pickling to the hot-rolled coil to remove the scale on its surface.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

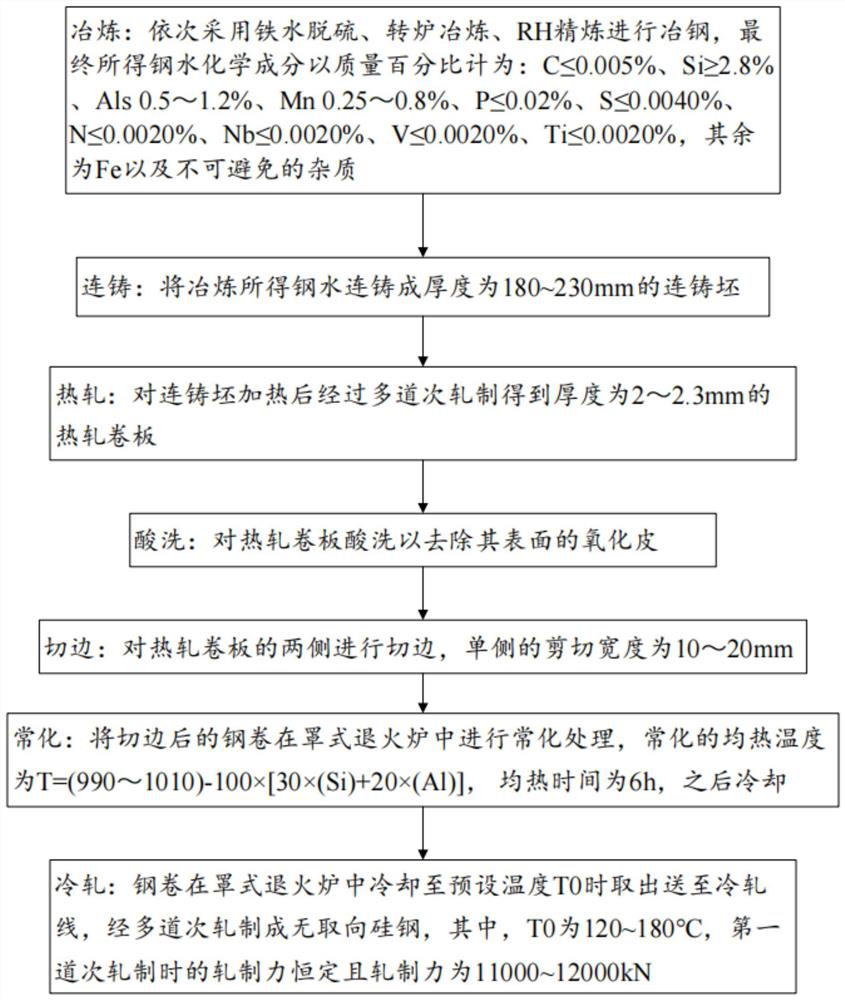

The invention discloses high-grade non-oriented silicon steel and a production method thereof. The production method comprises the steps of smelting, continuous casting, hot rolling, acid pickling, trimming, normalizing and cold rolling. The molten steel finally obtained through smelting comprises the following chemical components in percentage by mass: less than or equal to 0.005% of C, more than or equal to 2.8% of Si, 0.5-1.2% of Als, 0.25-0.8% of Mn, less than or equal to 0.02% of P, less than or equal to 0.0040% of S, less than or equal to 0.0020% of N, less than or equal to 0.0020% of Nb, less than or equal to 0.0020% of V, less than or equal to 0.0020% of Ti and the balance of Fe and inevitable impurities. In the edge cutting procedure, the two sides of the hot-rolled coil plate are subjected to edge cutting, and the shearing width of the single side is 10-20 mm; normalizing is conducted in a cover type annealing furnace, the soaking temperature T is equal to (990-1010)-100 * [30 * (Si) + 20 * (Al)], the soaking time is 6 h, and then cooling is conducted; when the steel coil is cooled to a preset temperature T0 in the cover type annealing furnace, the steel coil is taken out and sent to a cold rolling line for cold rolling, the T0 is 120-180 DEG C, and the rolling force during first-pass rolling is constant and is 11000-12000 kN. According to the method, frequent strip breakage caused by high brittleness in the cold rolling process of the high-grade non-oriented silicon steel can be avoided.

Description

technical field [0001] The invention belongs to the technical field of iron and steel smelting, relates to a production method of high-grade non-oriented silicon steel, and also relates to a high-grade non-oriented silicon steel prepared by the production method. Background technique [0002] Non-oriented silicon steel is the iron core material of the motor and generator rotor working in the rotating magnetic field, which requires good magnetic properties, including lower iron loss and higher magnetic induction. High-grade non-oriented silicon steel is one of the important materials for manufacturing various large generators. In recent years, with the continuous upgrading of motor energy consumption, the requirements for the magnetic properties of high-grade non-oriented silicon steel are getting higher and higher. [0003] According to the technical standards and technical agreements of various countries, the iron loss P 1.5 / 50 Non-oriented silicon steel ≤4.00W / kg is call...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/06C22C38/12C22C38/14C21D1/26C21D1/74C21D6/00C21D8/12C21D9/52C22C33/04

CPCC22C38/004C22C38/02C22C38/04C22C38/06C22C38/12C22C38/14C22C33/04C21D1/26C21D6/005C21D6/008C21D8/1216C21D8/1244C21D9/52C21D1/74Y02P10/20

Inventor 吴圣杰张建雷岳重祥

Owner ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com