Control method for limit specification steel roll hot rolling by single-stand steekle mill

A technology of the steel-steel rolling mill and the limit specification, which is applied in the field of steel rolling, and can solve the problems of increasing the difficulty of controlling the performance of the rolled piece, excessive temperature drop, performance and shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment is a control process for the performance of rolling 12.7mm*2500mm pipeline steel L415 steel coils in a single-stand furnace coil mill. °C, the tail heating temperature is 1225 °C. The rolling pass is 4+5, the second-stage rolling temperature is 960°C, the billet thickness is 4h, the final rolling temperature is 810°C, and the reddening temperature is 560°C. The reduction rate of the 8th pass is 12%, and the reduction rate of the 9th pass is 8%; the bending force coefficient is 2.5, and the final rolling speed is 2.9m / s;

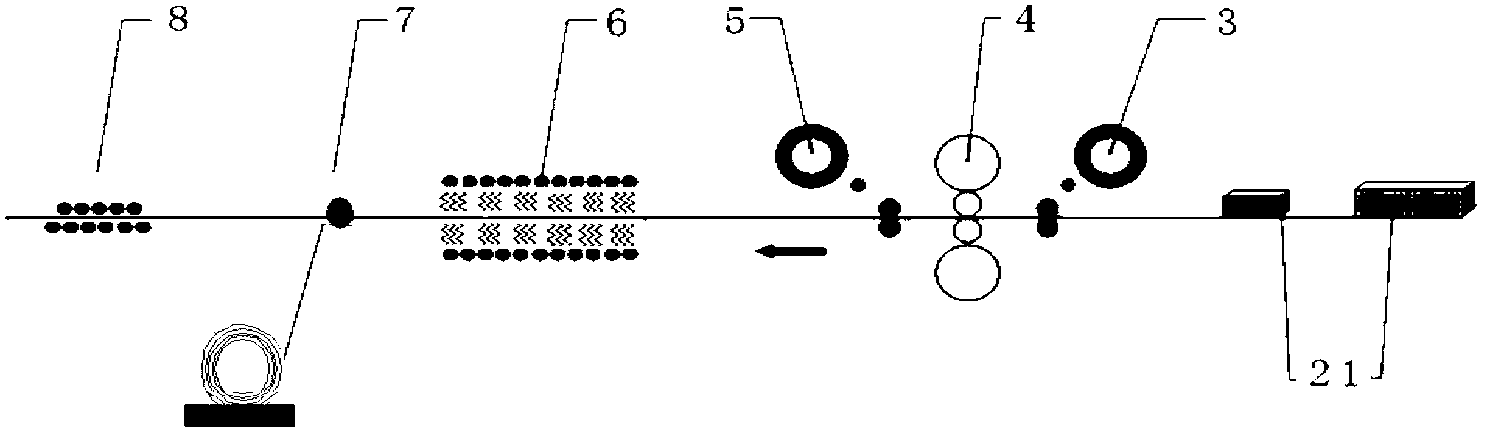

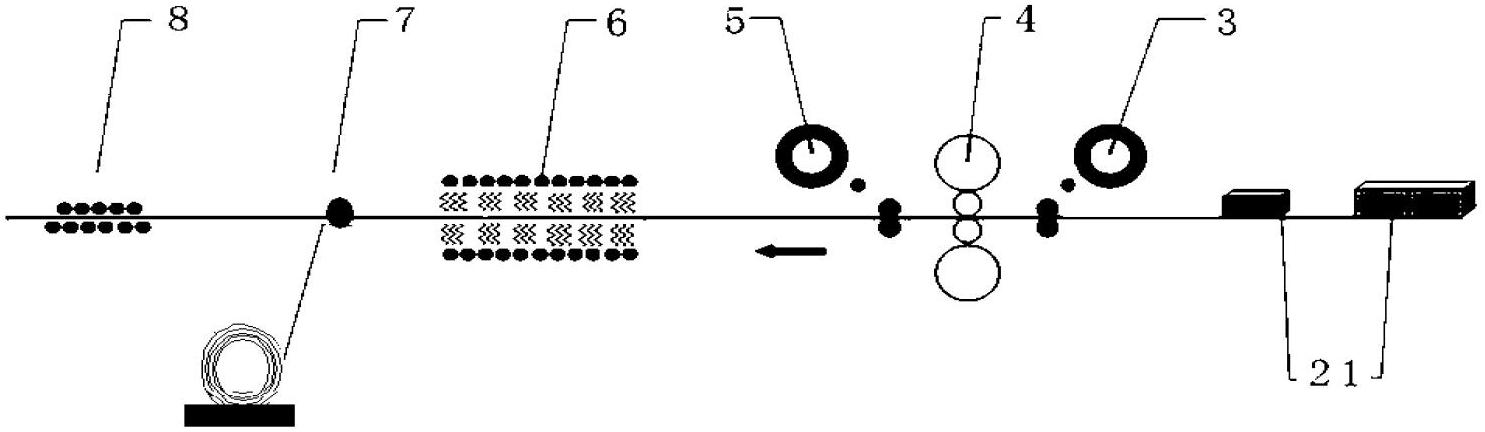

[0025] In this example, one piece of flat-rolled plate X65 pipeline steel coil is selected. The actual size of the billet is 150*2500*7100mm, the thickness of the finished product is 12.7mm, and the rolling is 11 passes, which is divided into two rolling stages: one-stage flat rolling 4 passes, 5 passes in the second stage flat rolling. The specific process is as follows, see figure 1 :

[0026] ⑴Main chemical composition design: C:...

Embodiment 2

[0033] This embodiment is a single-stand furnace coil mill hot-rolled S355 steel coil with the limit thickness and the thinnest width of 5mm*2500mm. 1200°C, the tail heating temperature is 1225°C. There are 13 rolling passes, uncontrolled rolling, the final rolling temperature is 830°C, and the reddening temperature is 650°C. The reduction rate of the 12th pass is 13%, and the reduction rate of the 13th pass is 9%; the bending force coefficient is 2.0, and the final rolling speed is 3.87m / s;

[0034] In this embodiment, one piece of rolled S355 export steel coil is selected. The actual size of the billet is 150*2500*6800mm, the thickness of the steel coil is 5mm*2500mm, and the rolling is performed in 13 passes without controlled rolling. The specific process is as follows, see figure 1 :

[0035] ⑴Main chemical composition design: C: 0.16%, Mn: 1.45%, Si: 0.25%, Nb: 0.025%, Ceq=0.42, the balance is iron; process point and mechanical property prediction: yield strength=426M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com