Process for controlling shape of hot-rolled flat-rolled high-grade pipeline steel plate by using single-rack steckel mill

A technology of single-stand steel-steel rolling mill, which is applied in the field of shape control technology of hot-rolled flat-rolled high-grade pipeline steel plates in single-stand steel-rolling mills, and can solve the difficulty of increasing the shape and performance control of rolled pieces and the uneven temperature distribution. Uniformity and other issues, to achieve the effect of improving production capacity and economic benefits, and improving the first-time rolling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

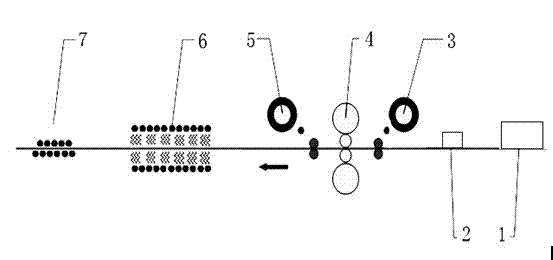

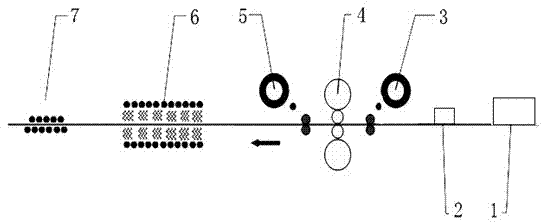

Image

Examples

Embodiment 1

[0017] A flat shape control process for hot-rolled flat-rolled high-grade pipeline steel in a single-stand furnace coil mill. The thickness is 3.2h (h is the thickness of the finished rolled piece, that is, the thickness of the billet to be warmed = 3.2 times * the thickness of the finished rolled piece), the reduction rate of the 10th pass is 18%, and the reduction rate of the 11th pass is 10%; Roll bending forces from the pass to the 10th pass are 950 tons, 900 tons, 800 tons, 700 tons, and 550 tons; the final rolling speed is 1.50m / s, and the acceleration is 0.01m / s 2 ; After the production of work rolls exceeds 800 tons, turn on the cooling water around the work rolls; if the width of the rolled piece is > 3m, use the edge shielding of the cooling system, and the cooling water ratio is 1.55; The thickness is set when more than 70% of the plastic deformation occurs, the straightening speed of the head and tail is 0.45m / s, and the straightening speed of the middle body is 0....

Embodiment 2

[0025] A flat shape control process for hot-rolled flat-rolled high-grade pipeline steel in a single-stand furnace coil mill. The thickness is 3.5h, the reduction rate of the 10th pass is 16.7%, and the reduction rate of the 11th pass is 9.7%; the bending force of the 6th pass to the 10th pass is 950 tons, 900 tons, 800 tons, 700 tons tons, 550 tons; final rolling speed is 1.50m / s, acceleration is 0.01m / s 2 ; After the production of work rolls exceeds 800 tons, turn on the cooling water around the work rolls; if the width of the rolled piece is > 3m, use the edge shielding of the cooling system, and the cooling water ratio is 1.15; The thickness is set when more than 70% of the plastic deformation occurs, the straightening speed of the head and tail is 0.5m / s, and the straightening speed of the middle body is 0.8m / s.

[0026] In this example, one piece of rolling plate X80 high-grade steel pipeline is selected. The actual size of the billet is 150*3185*8800mm, the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com