Resource-saving Q345 low-alloy series steel plate and production method thereof

A technology of resource saving and production method, applied in the direction of heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of product performance impact, the gain outweighs the loss, etc., to achieve the effect of improving welding performance, keeping mechanical properties unchanged, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

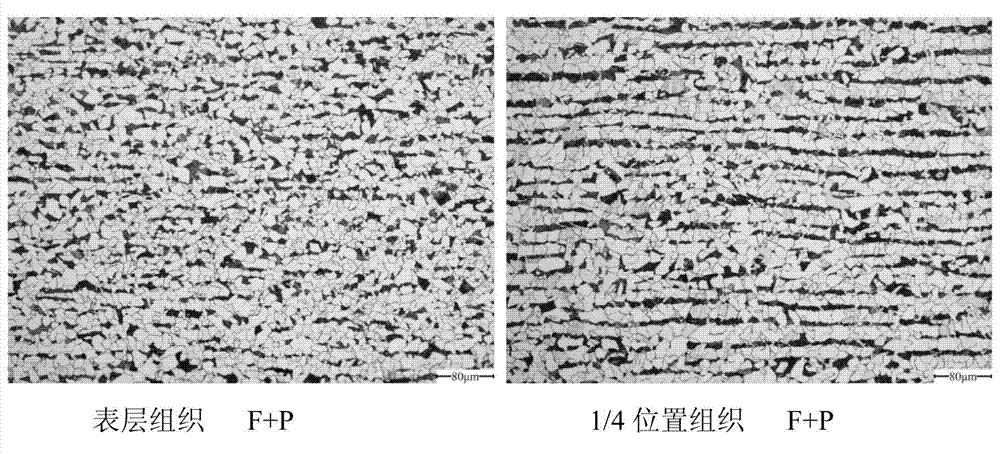

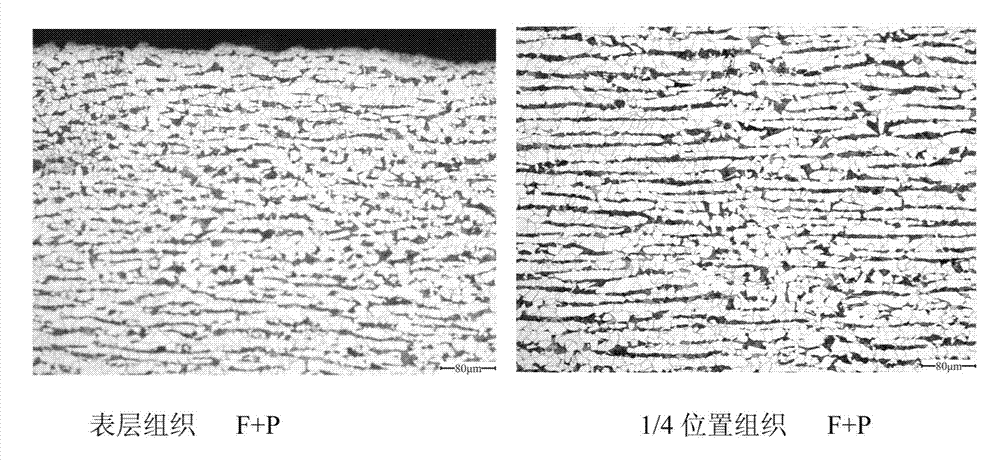

[0049] A kind of production method of resource-saving Q345C low-alloy 25nm steel plate

[0050] The steel grade Q345C adopts continuous casting slabs of 150×3000×8700mm, and the composition system is resource-saving, which reduces the Mn content. The specific mass percentage composition of each element is: C: 0.17, Si: 0.29, Mn: 1.13 , P: 0.009, S: 0.005, Alt: 0.031, the balance is Fe and unavoidable impurities.

[0051] The target thickness of the steel plate is 25 mm, and the flat rolling mode is used to roll on the steckel rolling mill. The rolling pass is 11 passes, and the two-stage control rolling process is adopted, that is, after rolling 5 passes, the intermediate billet is kept warm, and the thickness to be warmed is 66mm. The temperature control parameters at each stage of the rolling process are as follows: the slab exit temperature is 1200°C; the rolling temperature in the fully recrystallized zone is 1090°C-970°C; the rolling start temperature in the non-recrysta...

Embodiment 2

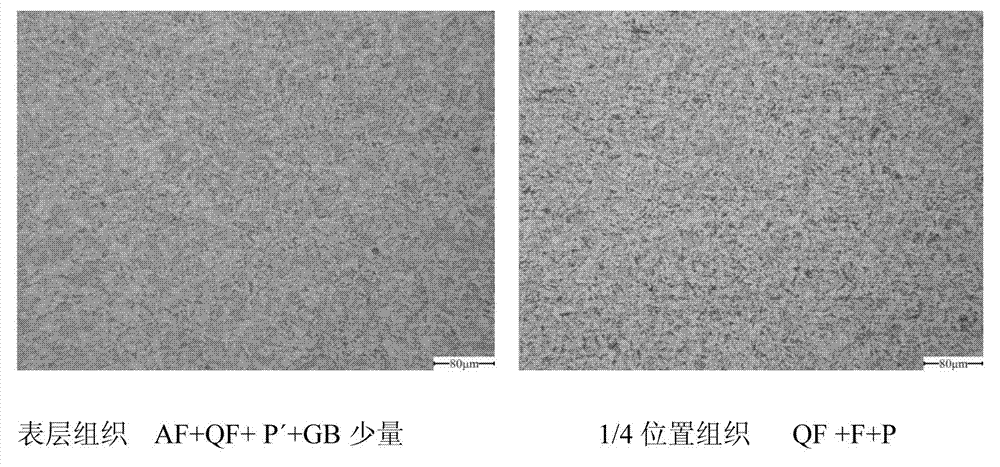

[0058] A production method of resource-saving Q345E low-alloy 16mm steel plate

[0059] The steel grade Q345C adopts continuous casting slabs of 150×2605×8525mm. The composition system is resource-saving and reduces the Mn content. The specific mass percentage composition of each element is: C: 0.17, Si: 0.28, Mn: 1.21 , P: 0.016, S: 0.008, Alt: 0.029, the balance is Fe and unavoidable impurities.

[0060] The target thickness of the steel plate is 16mm, and it is rolled on the steckel rolling mill in the flat rolling mode. 40mm. The temperature control parameters at each stage of the rolling process are as follows: the slab exit temperature is 1220°C; the rolling temperature in the fully recrystallized zone is 1065°C-1005°C; the rolling start temperature in the non-recrystallized zone is 926°C; the final rolling temperature is 805°C ℃; after rolling, the steel plate adopts the controlled cooling process, and the upper and lower headers of the laminar flow device are respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com