Method suitable for steckel mill to manufacture hot rolling steel strips of ferritic stainless steel

A technology of steckel rolling mill and stainless steel, which is applied in the field of preventing edge crack defects caused by hot rolling of SUS410S ferritic stainless steel, to achieve the effect of increasing production cost and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

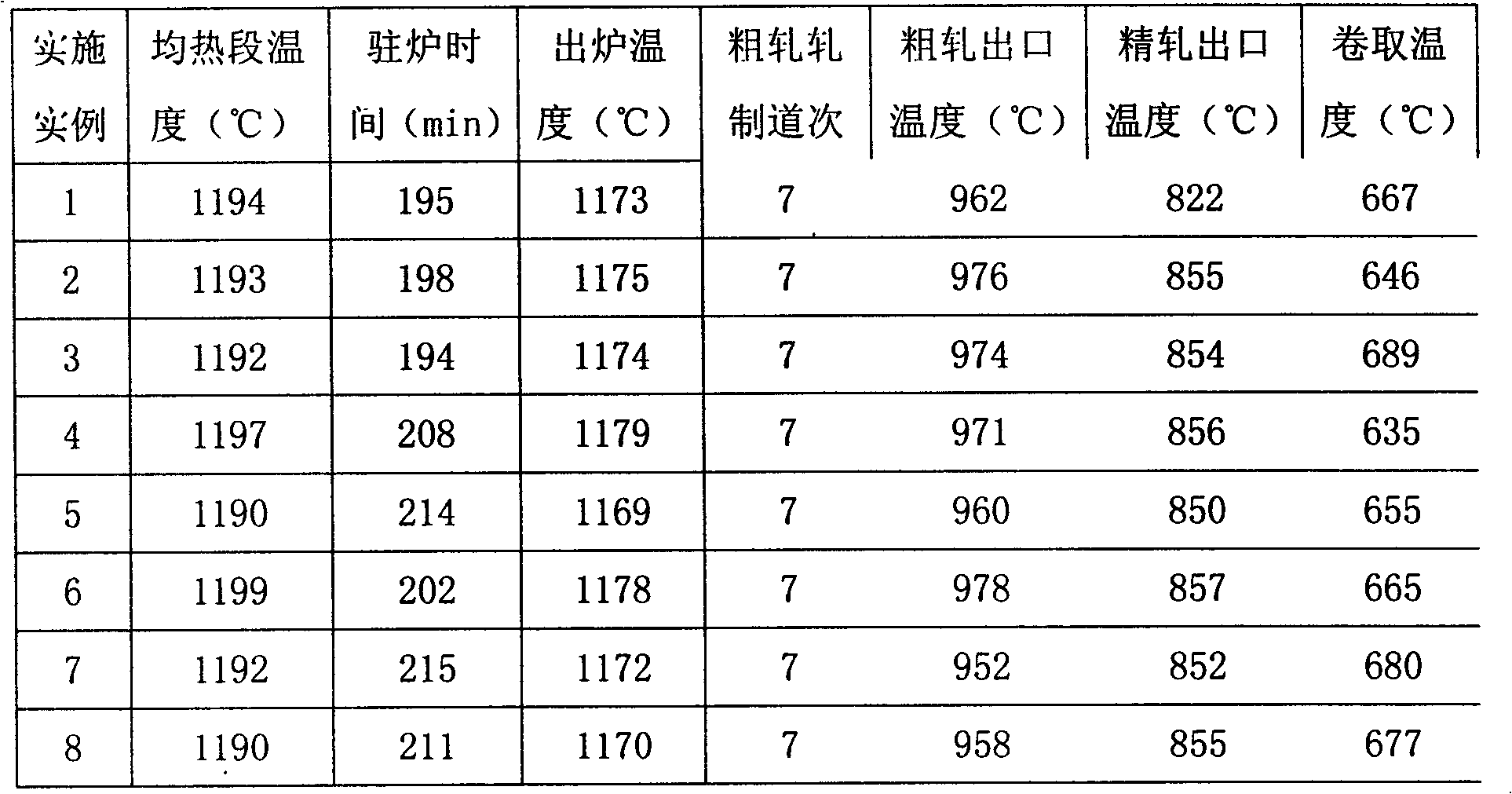

[0017] The present invention will be further described below in conjunction with embodiment:

[0018] Embodiment: in order to solve the SUS410S stainless steel hot-rolled strip edge cracking problem, adopt following technology:

[0019] 1) Smelting and continuous casting of slabs according to conventional processes (SUS410S is a typical ferritic stainless steel, and its composition is properly controlled according to the standard requirements);

[0020] 2) Hot rolling heating: the slab is heated by a walking heating furnace, and the heating temperature area is divided into four sections, which are: heat recovery section, preheating section, heating section, and soaking section; the furnace pressure is slightly positive pressure (1.0~6.0Pa), the atmosphere in the furnace is a weakly oxidizing atmosphere (the residual oxygen content is controlled at 2.0~5.0%); the temperature control of each area of the heating furnace: the temperature of the heat recovery section is ≤850°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com