Screwing device of truck thrust rod bolt

A thrust rod and bolt technology is applied in the field of truck thrust rod bolt tightening equipment, which can solve the problems of laborious, time-consuming and inconvenient tightening tool operation, and achieve the effects of improving assembly quality, reducing labor intensity and accurate torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

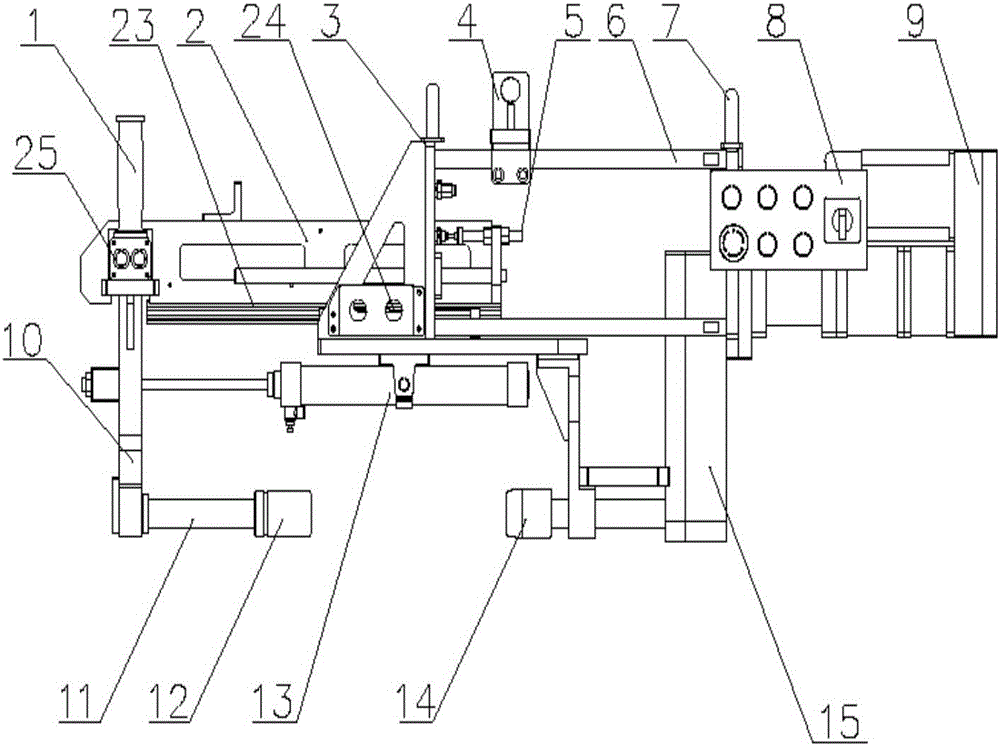

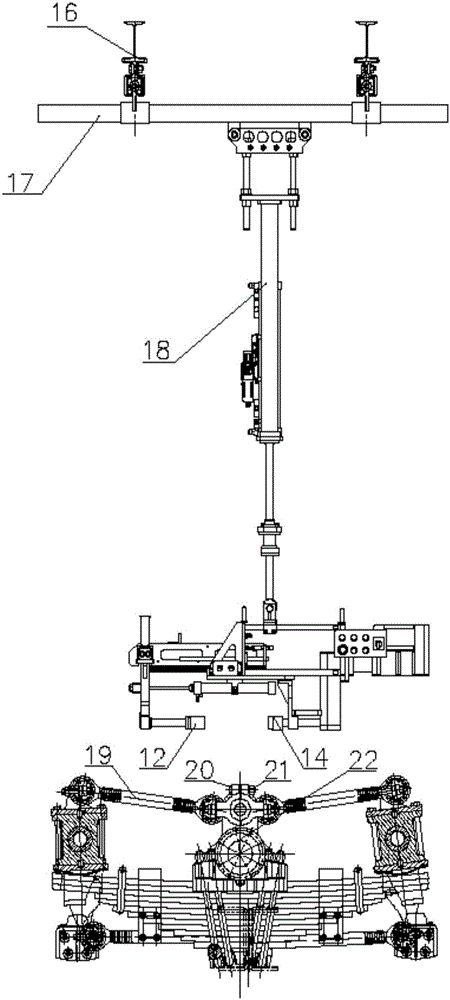

[0012] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] The tightening equipment for truck thrust rod bolts is a horizontal suspension structure as a whole, including a frame body 3, and a hanger 4 is installed on the pole 6 of the frame body 3, and the hanger 4 is hinged with the pneumatic suspension device 18, and the pneumatic suspension device 18 is another One end is connected to the vertical and horizontal slide rails 17, and the vertical and horizontal slide rails 17 are fixed by a plurality of I-beams 16, and the pneumatic suspension device 18 can move longitudinally and laterally along the vertical and horizontal slide rails 17.

[0014] A tightening shaft 9 is installed on the right end of the frame body 3, and the tightening shaft 9 transmits the motion to the offset gear b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com