Patents

Literature

40 results about "Torque analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Force and Torque analysis will allow one to determine if motion of a part will occur; if the sum of forces on a part is greater than zero then it will accelerate. In this sense Force and torque analysis is a necessary and sufficient condition needed to create part motion.

Residual torque analyzer

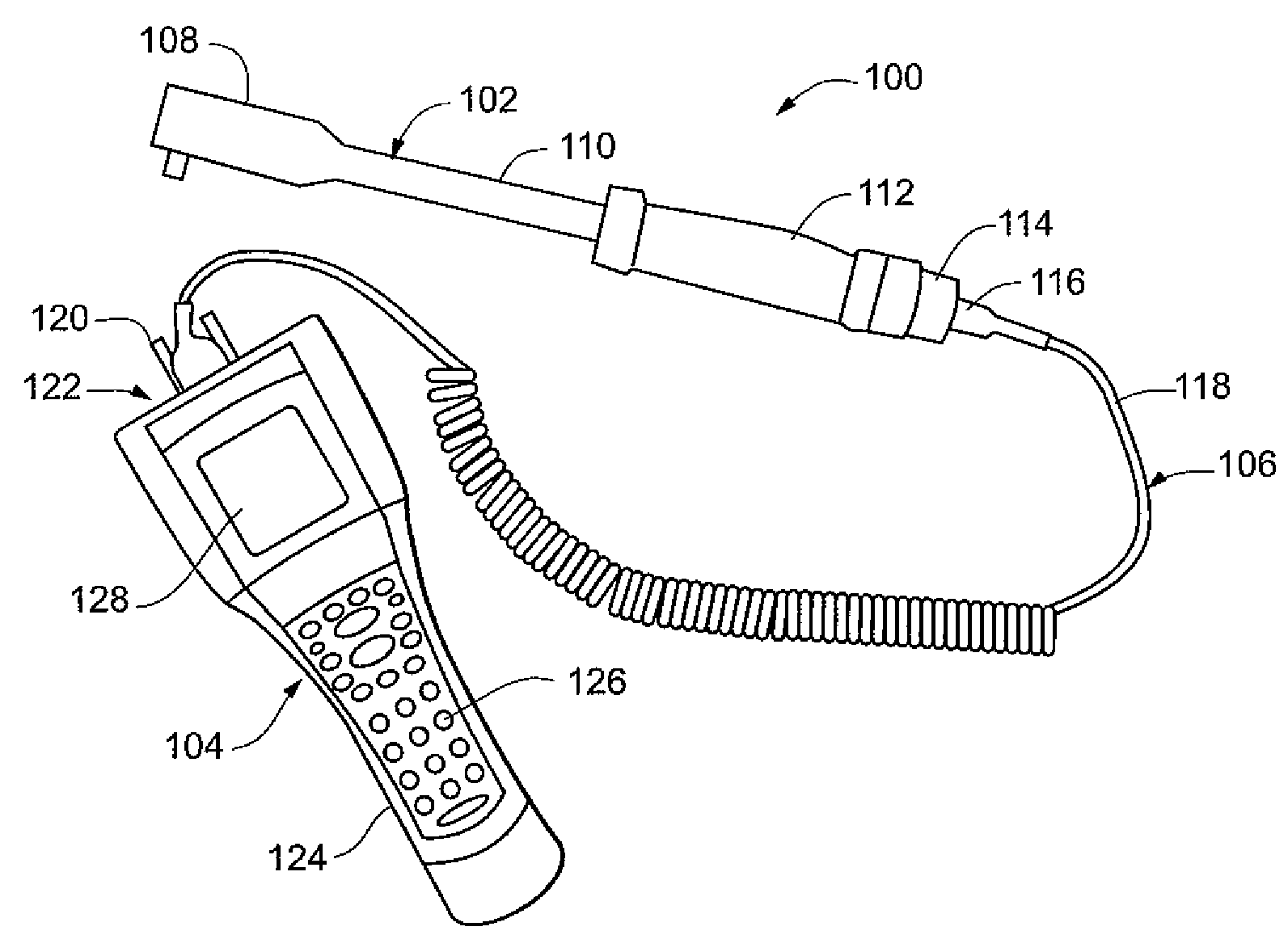

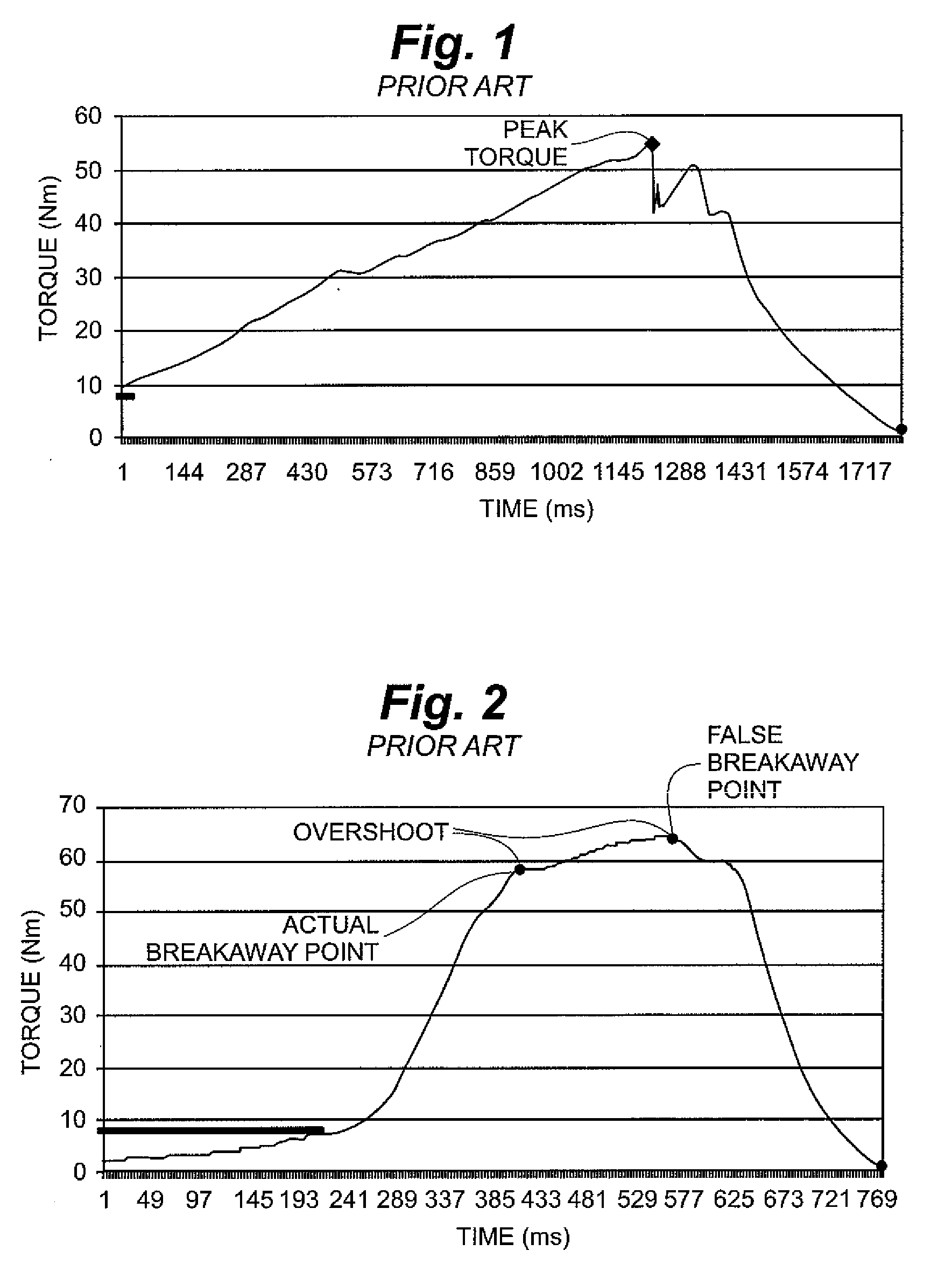

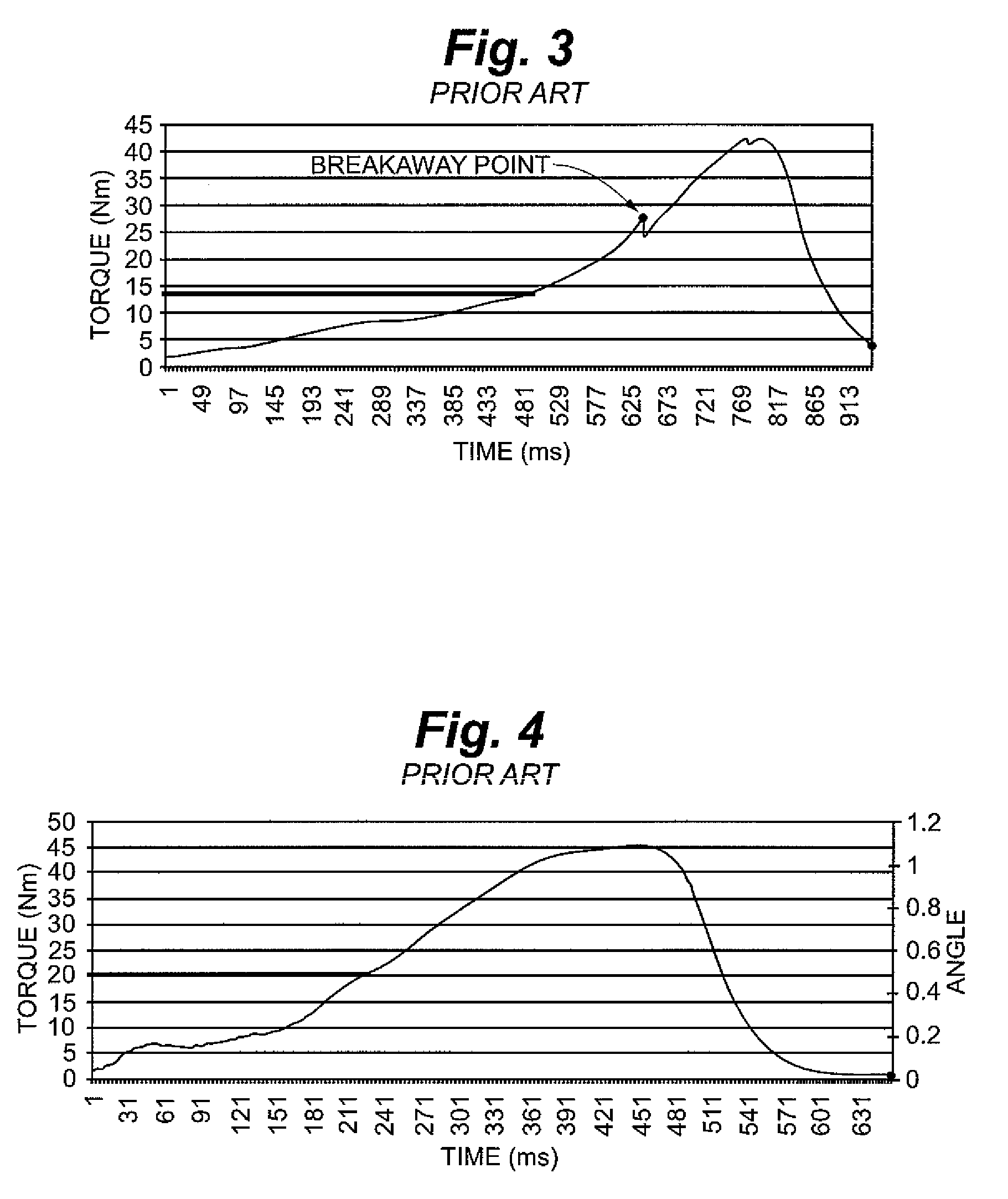

ActiveUS20090078057A1Material failureMeasurement of torque/twisting force while tighteningLoad modified fastenersGyroscopeTorque analysis

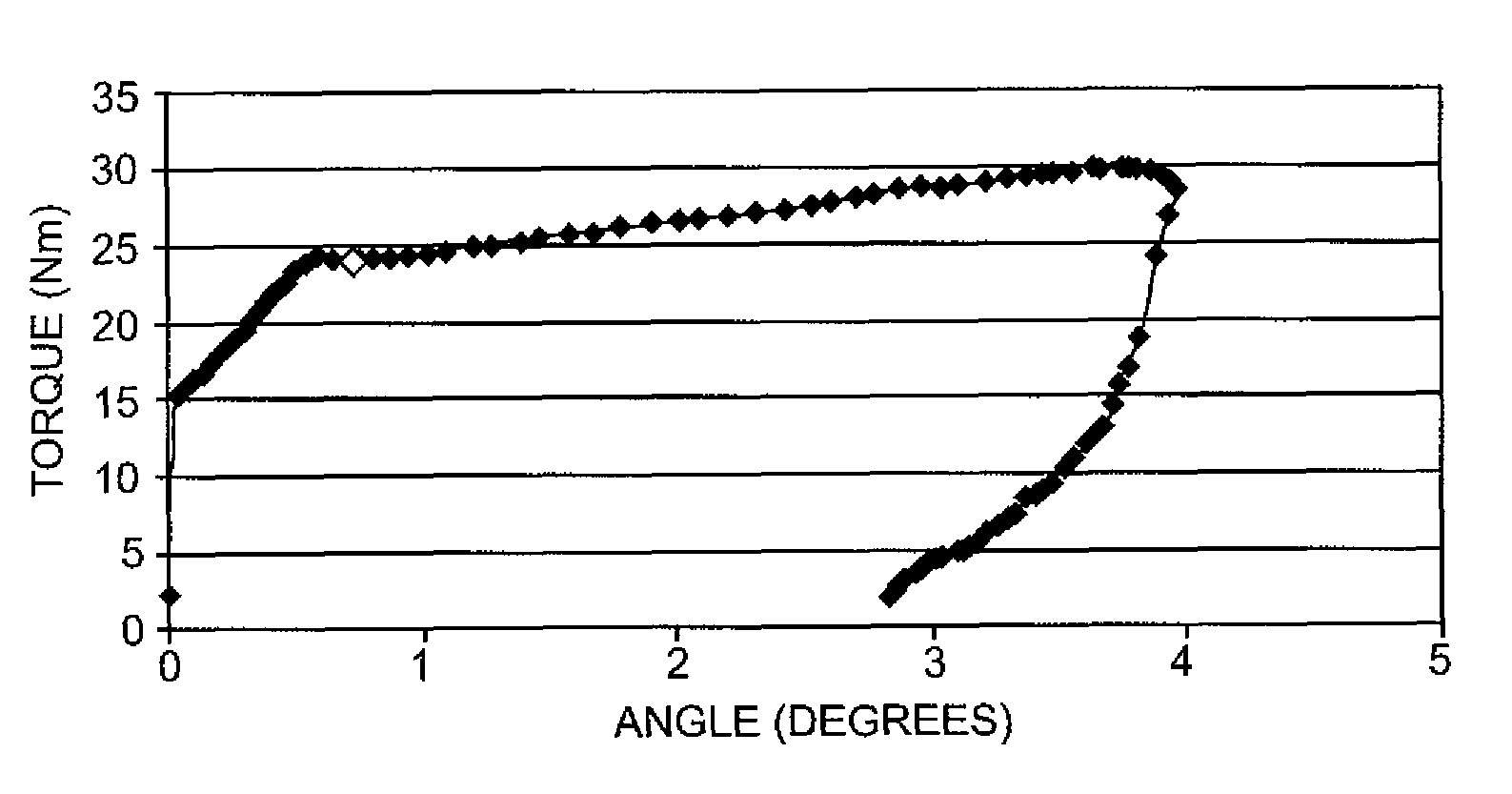

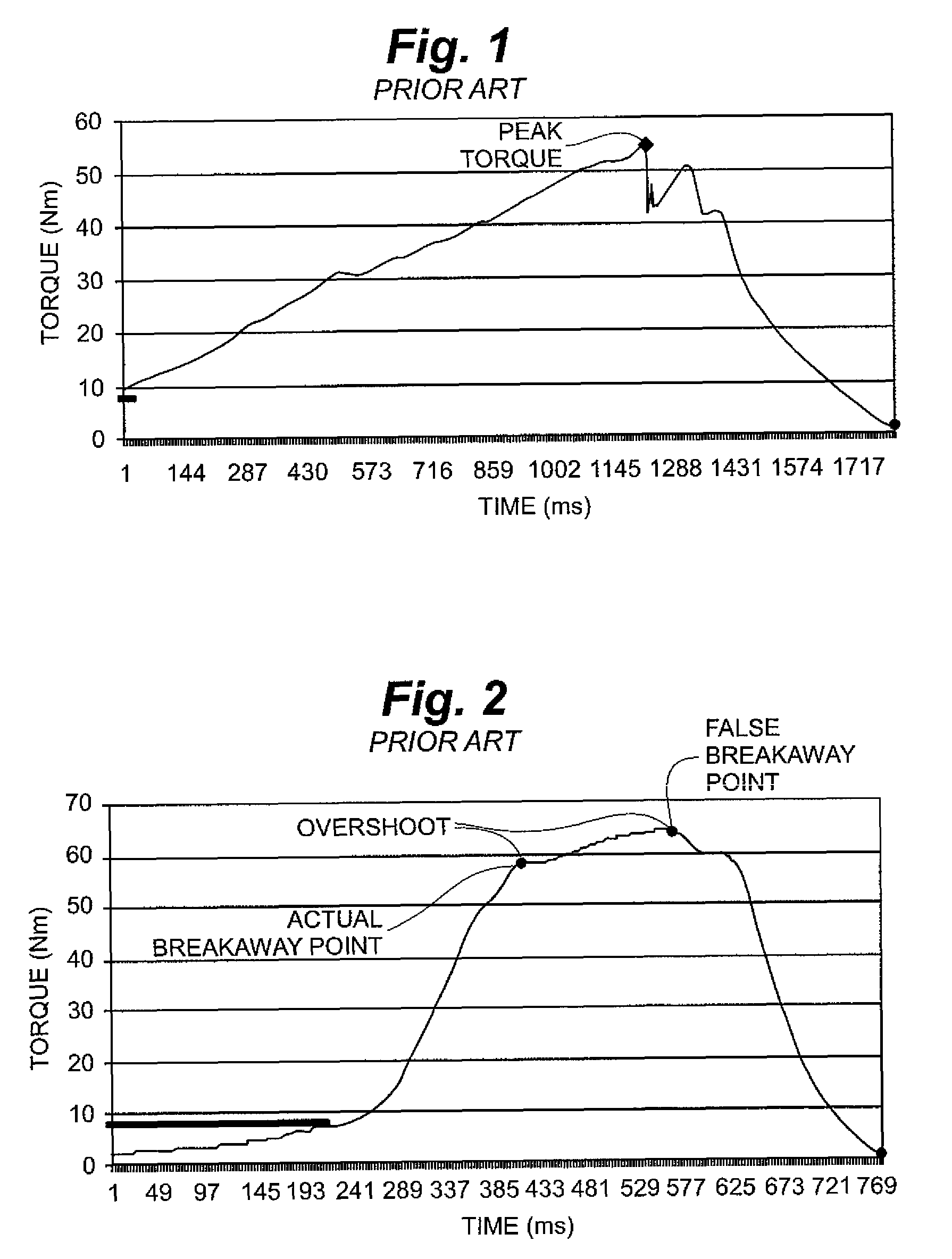

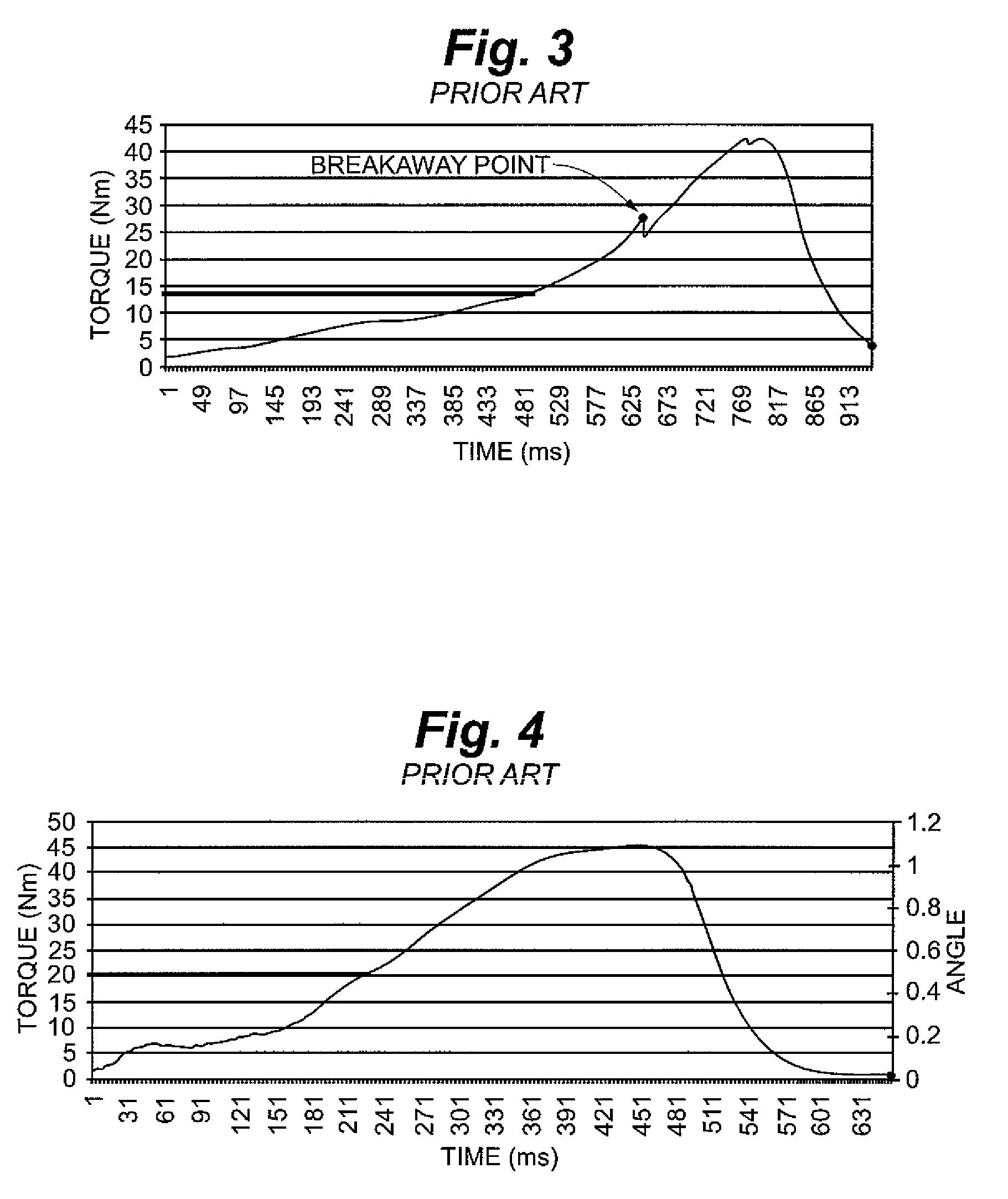

A system for detecting fastener movement and measuring a residual torque in a fastener joint, including a device for applying torque to a stationary fastener in a tightened state and measuring torque and angle of rotation. The device includes a sensing system that has a gyroscope that provides a signal corresponding to the angle of rotation of the device as it applies torque to the fastener, and a torque transducer that provides a signal corresponding to the torque applied to the fastener by the device. The device also includes a computing unit in communication with the sensing system and adapted to receive the signal corresponding to an angle of rotation of the device and the signal corresponding to the torque applied to the fastener, and determine a torque at a moment of initial movement of the fastener.

Owner:ASI DATAMYTE

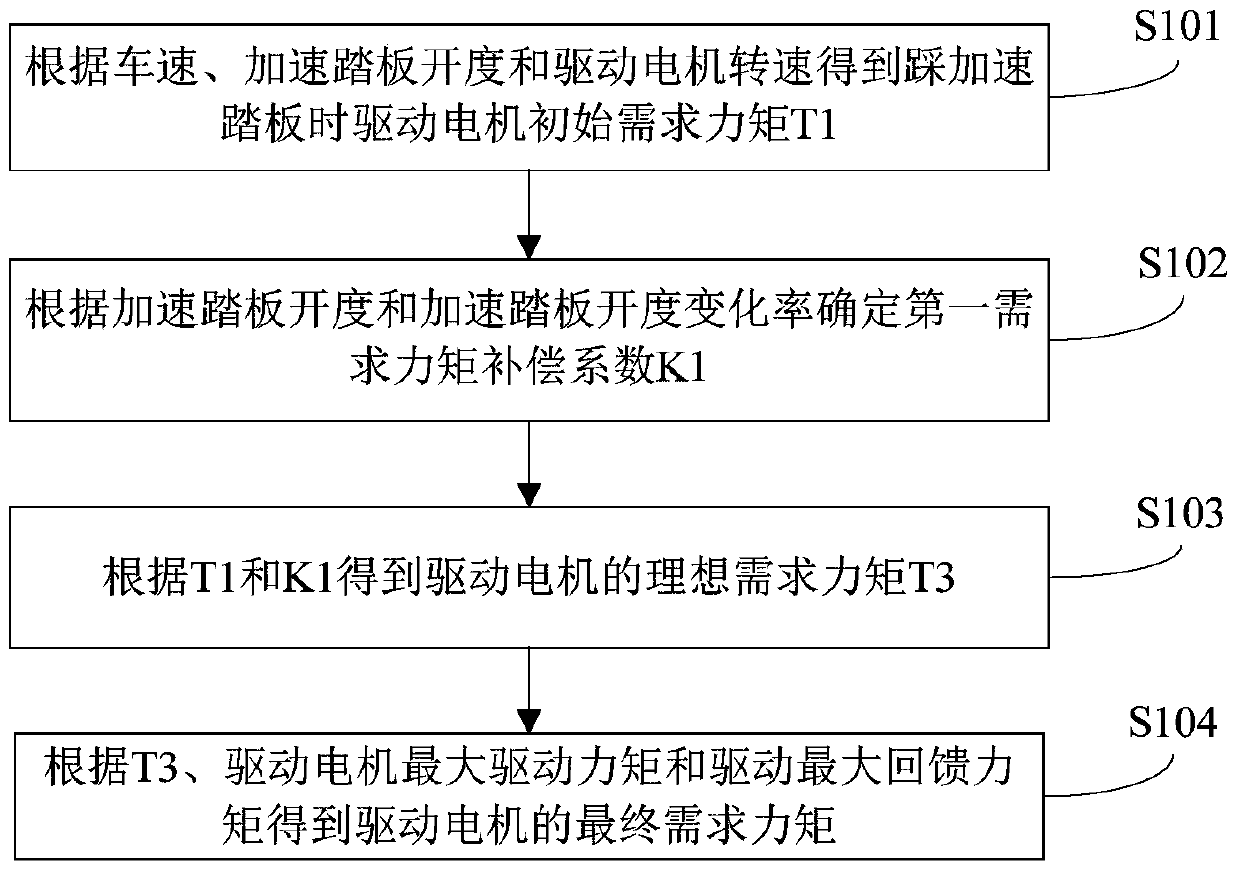

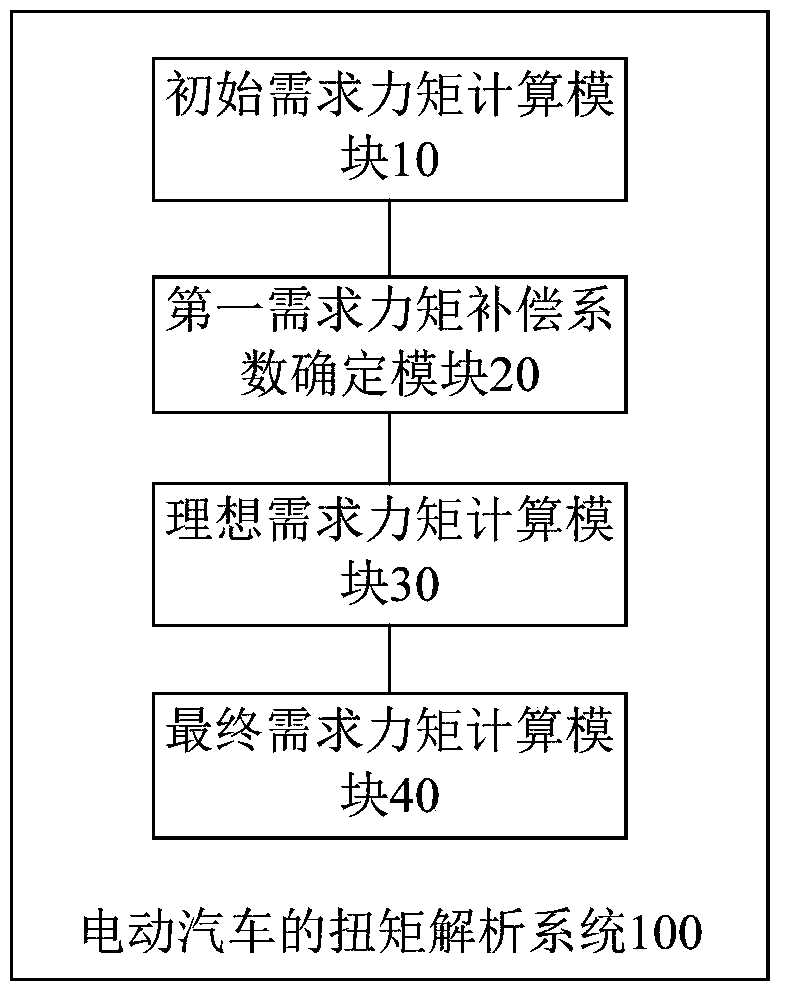

Electric car and torque analysis method and system thereof

InactiveCN106853780AImprove user experienceImprove recycling efficiencySpeed controllerElectric energy managementTorque analysisElectric machine

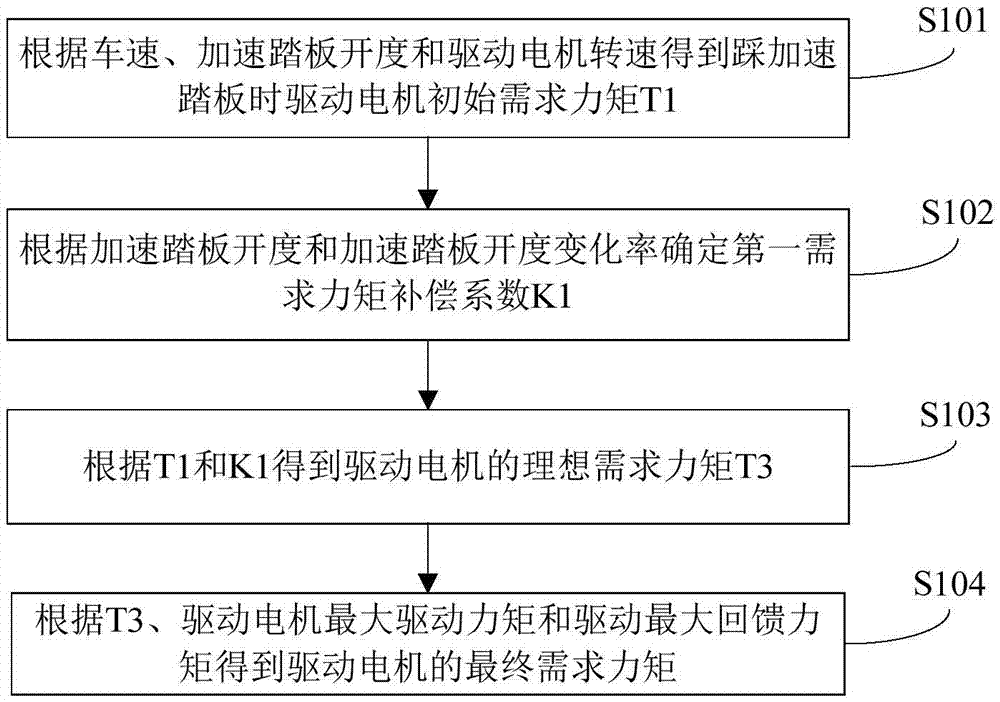

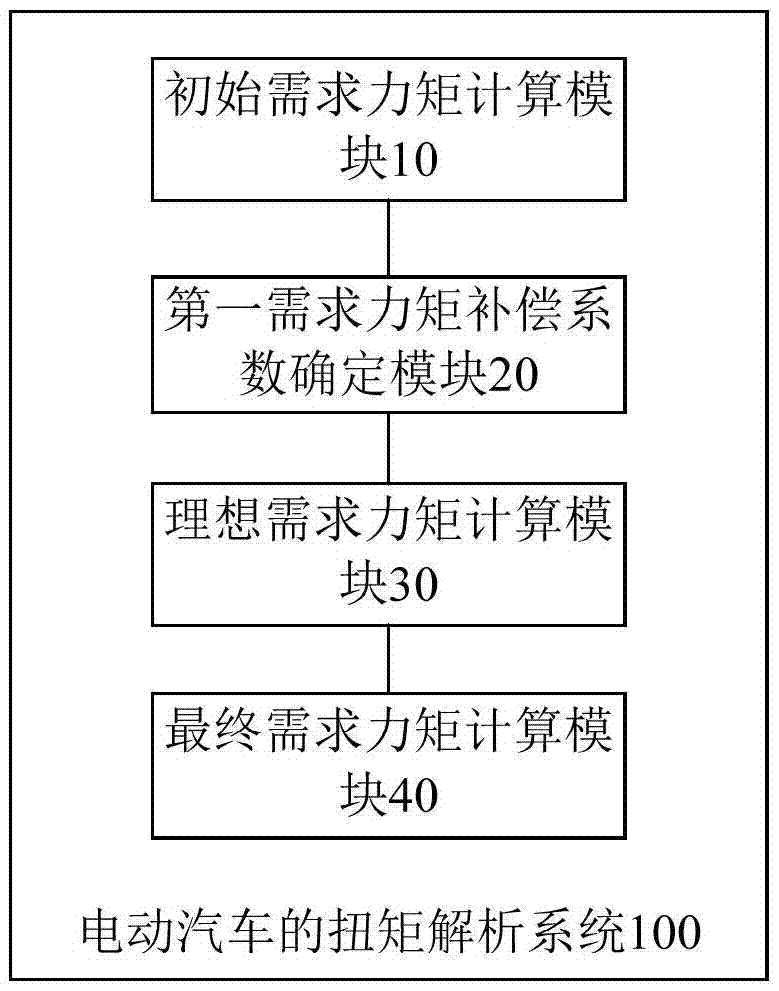

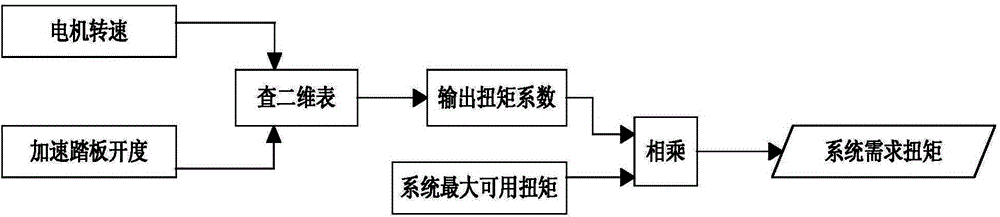

The invention discloses an electric car and a torque analysis system and method thereof. The torque analysis method comprises the following steps that according to the speed of the car, the opening degree of an acceleration pedal and the rotating speed of a driving motor, initial required torque T1 of the driving motor when the acceleration pedal is stamped is obtained; according to the opening degree of the acceleration pedal and the opening degree changing rate of the acceleration pedal, a first required torque compensation coefficient K1 is determined; according to the T1 and the K1, an ideal required torque T3 of the driving motor is obtained; according to the T3, the maximum driving torque of the driving motor and the maximum feedback torque of the driving motor, the final required torque of the driving motor is obtained. According to the torque analysis method of the electric car, it can be ensured that the torque is slowly increased when a user stamps the pedal in the using process and rapidly decreased when the user loosens the acceleration pedal, torque feedback can be performed so as to improve the energy recycling efficiency, and the user experience can be improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Torque correction coefficient calculation and torque analysis methods and systems for electric automobile

InactiveCN104859483AImprove Torque Control AccuracyGood dynamic responseSpeed controllerElectric energy managementMotor speedTorque analysis

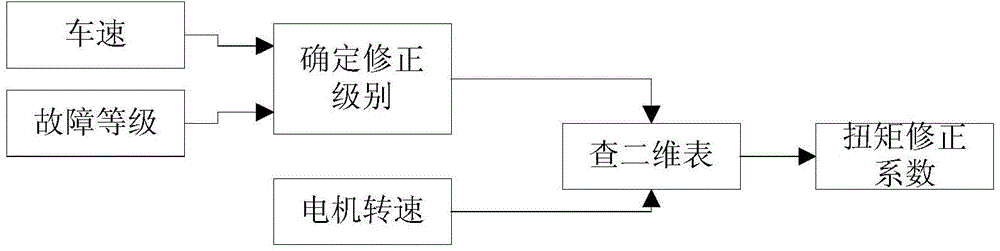

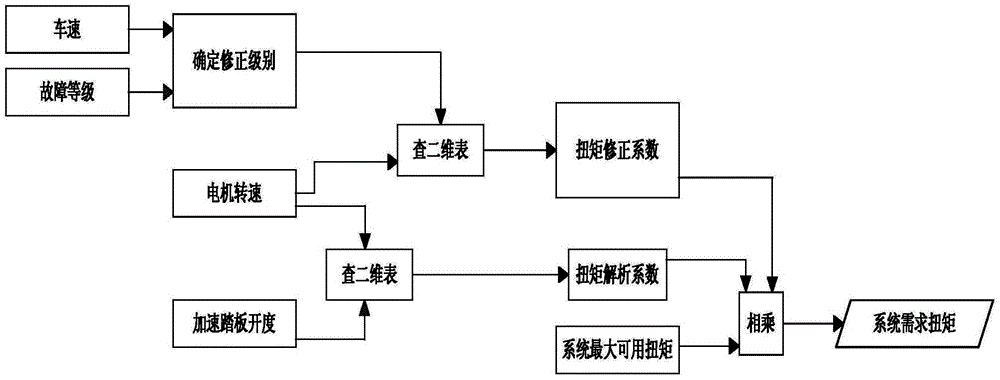

The invention provides torque corrosion coefficient calculation and torque analysis methods and systems for an electric automobile. Besides consideration of motor speeds and opening degrees of an accelerator pedal, speeds of the automobile and fault levels are comprehensively considered to determine correction coefficients and correction starting points of torque, and required torque for system analysis is corrected in real time. When the speeds of the automobile and the fault levels are different and the opening degrees of the accelerator pedal are the same, different torque corrosion coefficients can be obtained, and more accurate toque analysis coefficients are obtained; with the adoption of the scheme, more accurate and more comprehensive consideration factors are provided for actual output torque of a motor, and the torque control precision of the whole automobile is improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

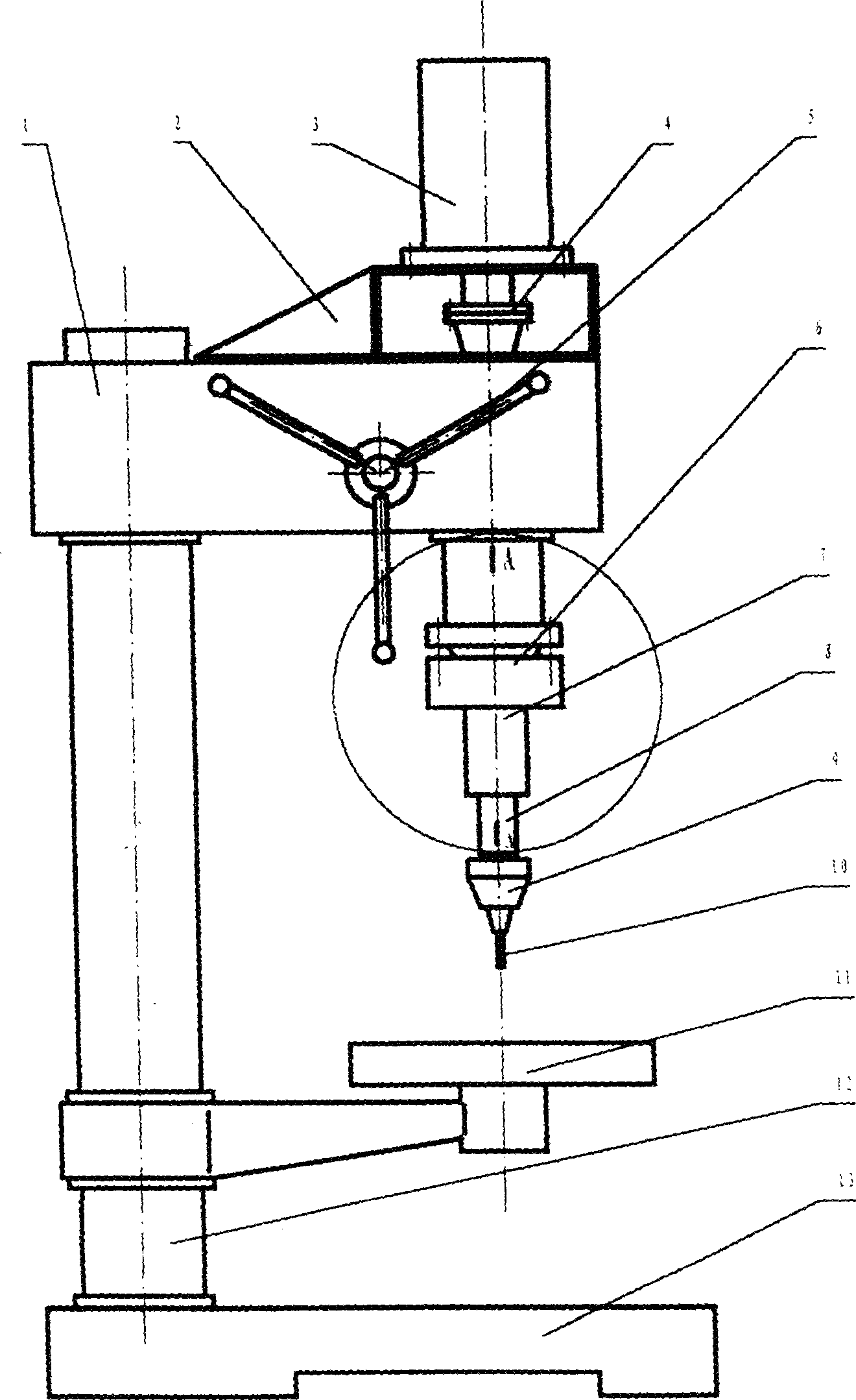

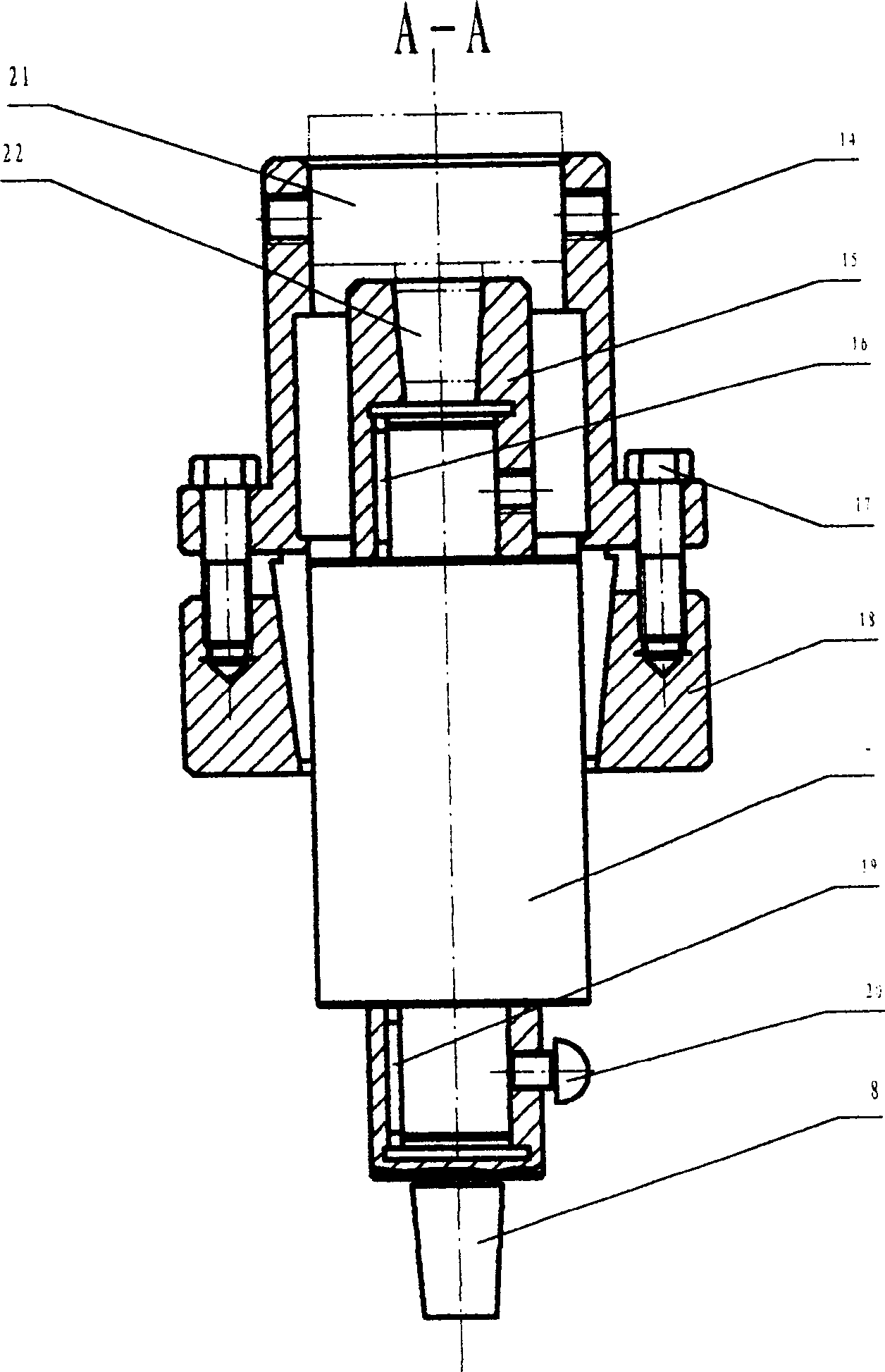

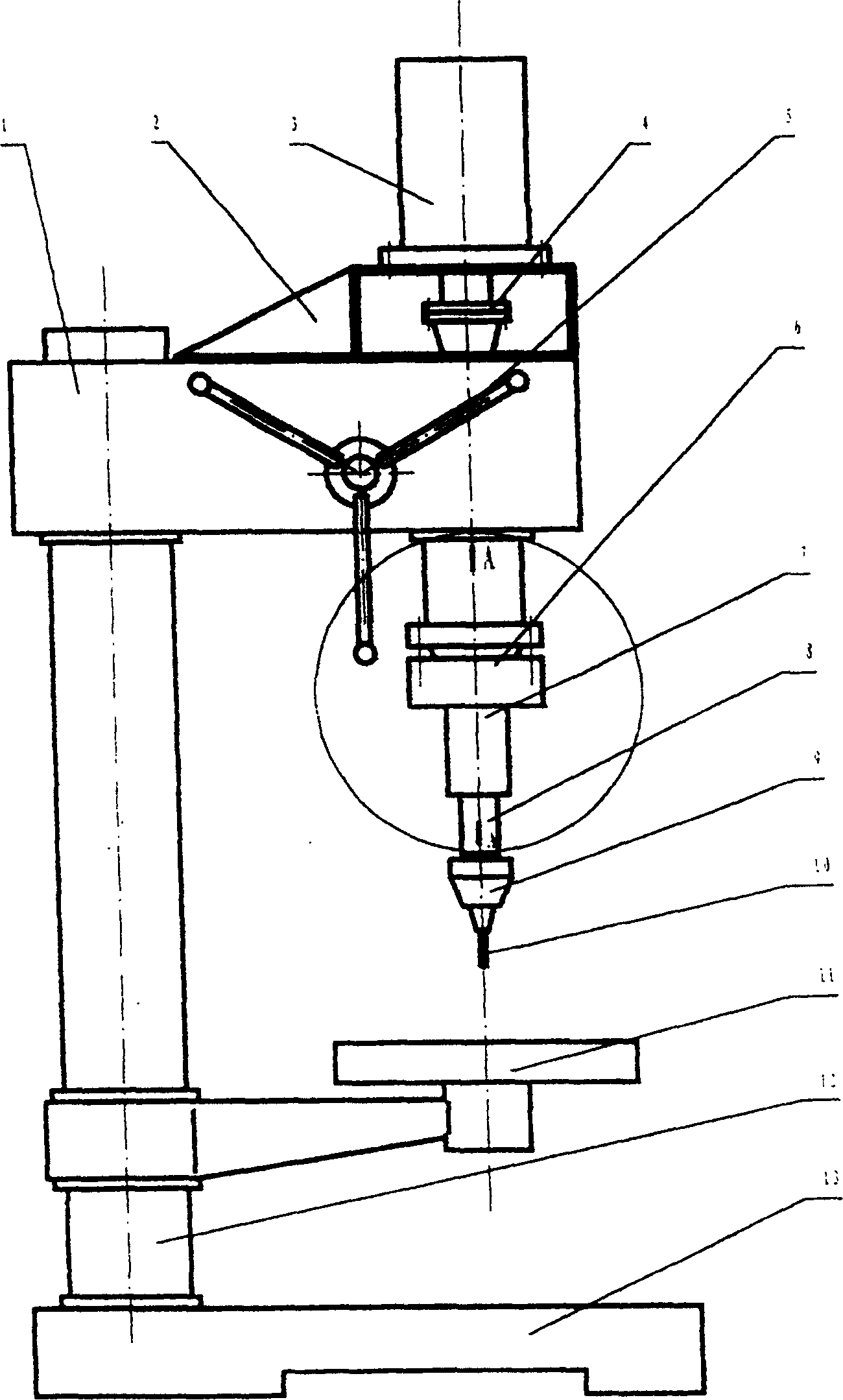

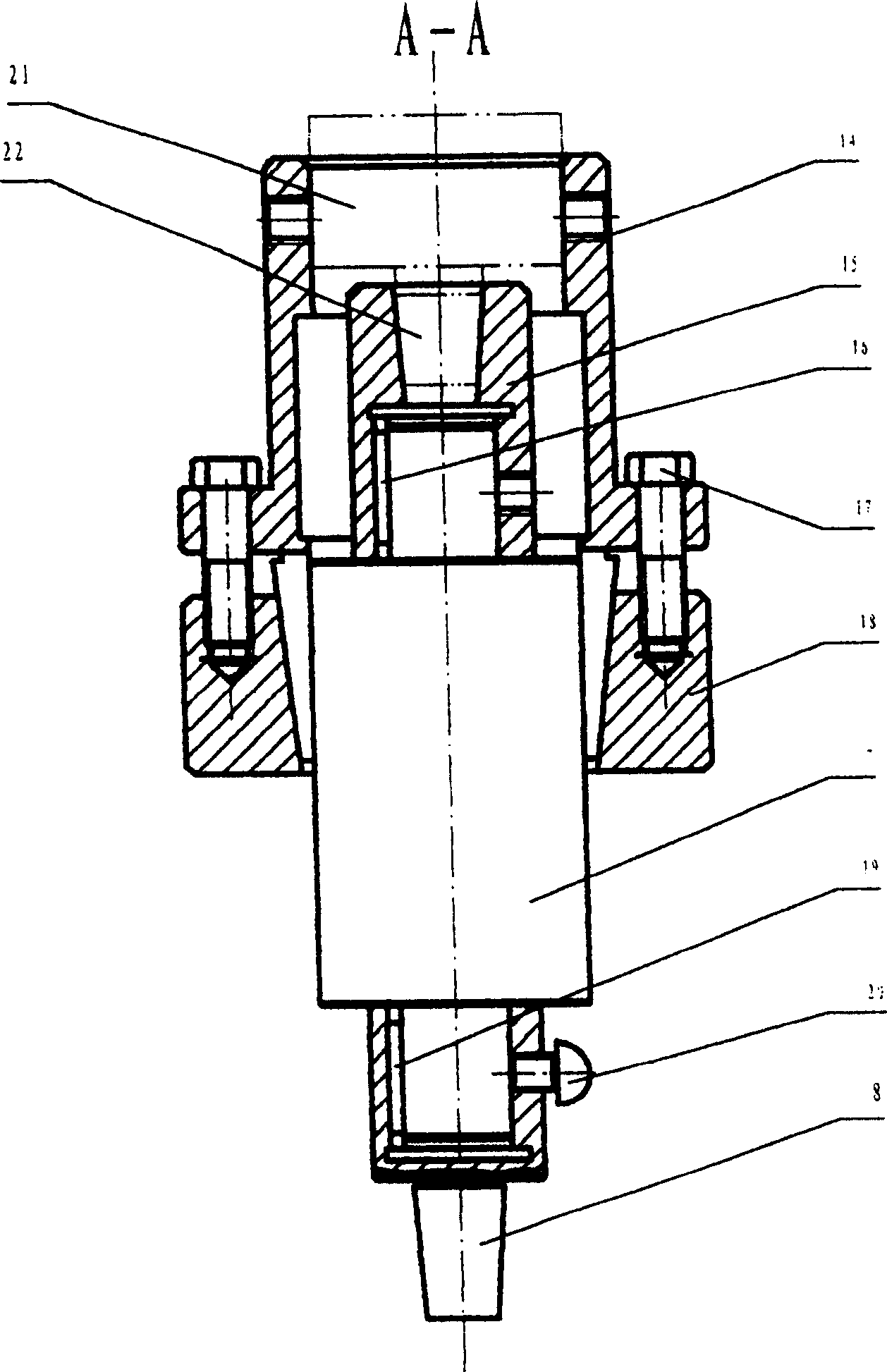

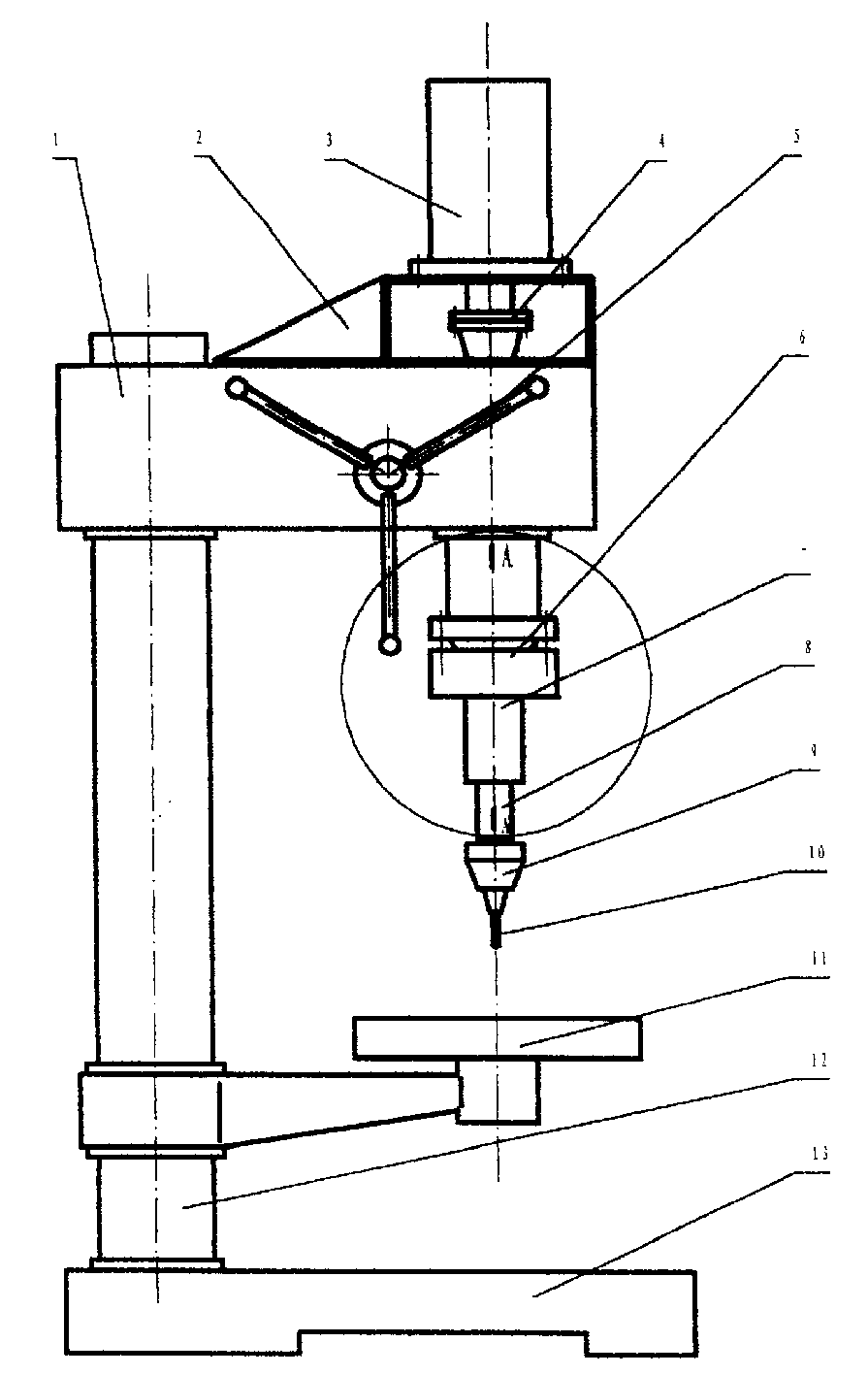

Method for on-line fault diagnosis of vibration threading and its equipment

InactiveCN1394712AEasy to installFirmly connectedAutomatic control devicesThread cutting machinesTorque analysisDiagnosis methods

The present invention relates to a vibration threading on-line fault diagnosis method and its equipment, including vibration threading machine unit, drive and control unit of stepper motor and torque measuring unit, a torque sensor and a threading torque analysis and storage system are series-connected between its main sahft input end and threading grip holder, and said torque sensor is fixedly connected with main shaft of threading machine by means of elastic holding mechanism formed from elastic holder base cover, locking cover and locking screw. Said invention adopts the stepper motor as vibration source and threaidng force source, utilzies torque sensor to receive moving force and vibration source signal transferred by main shaft of machine tool of machine unit, and unilizes the signal amplification.

Owner:JIANGSU UNIV

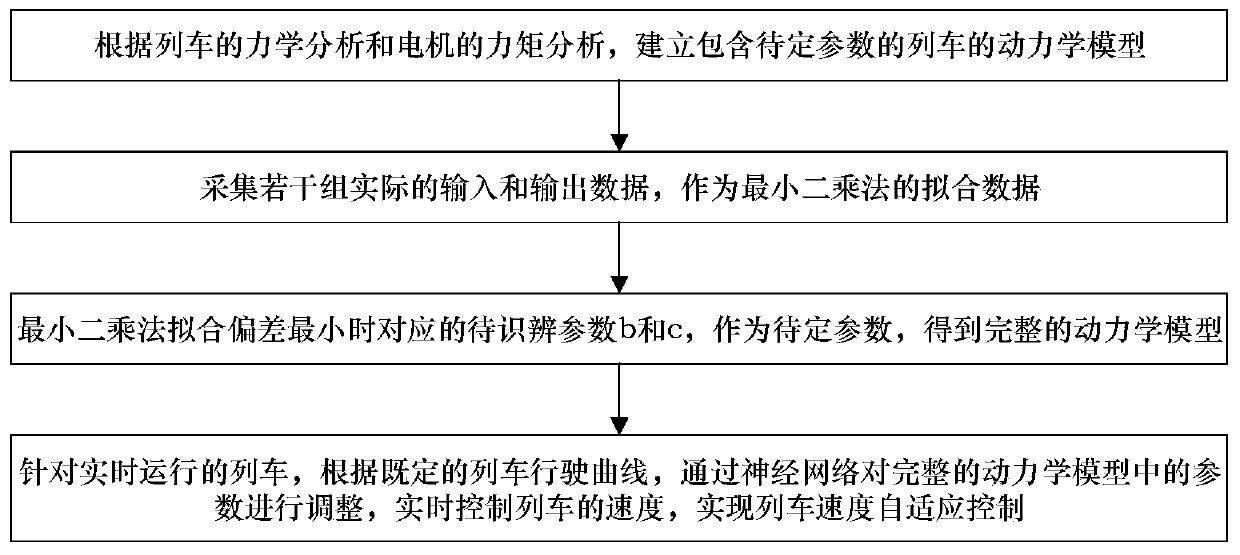

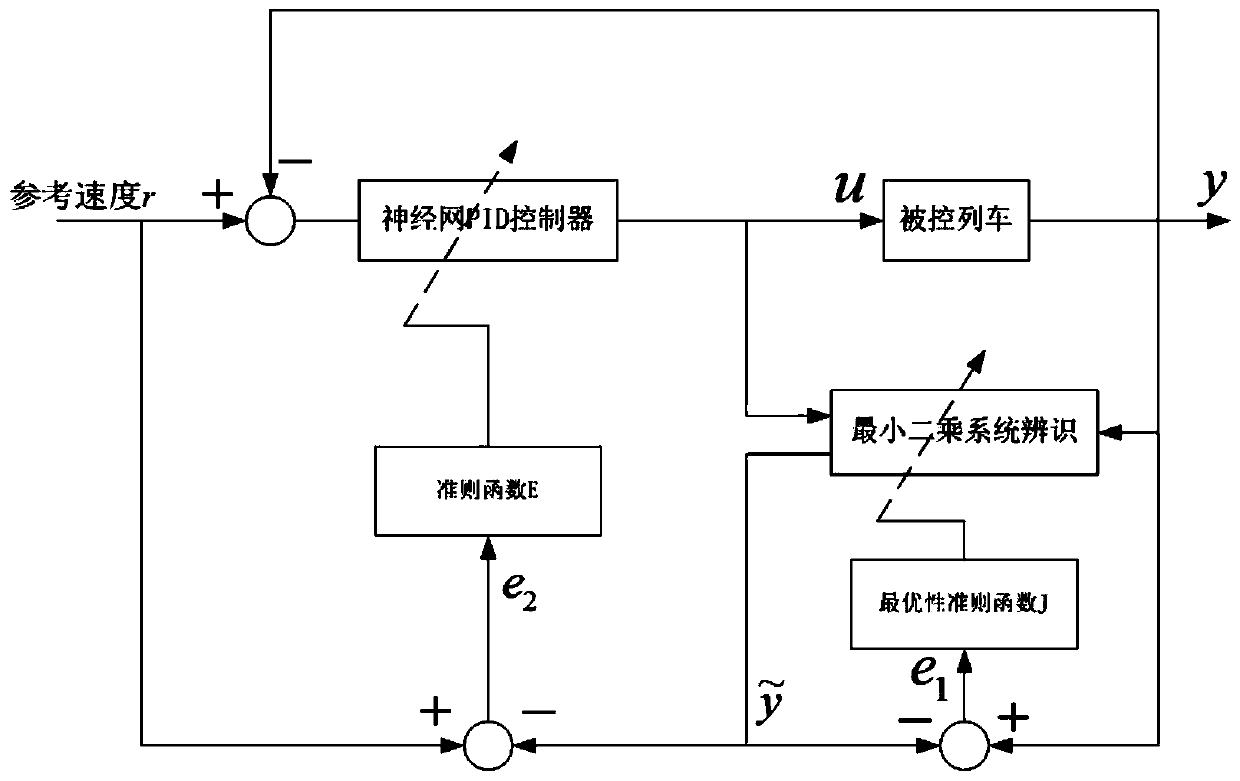

Train speed self-adaptive control method based on system parameter identification

ActiveCN110758413AConstraint learningThe identification result is accurateRailway signalling and safetyLocomotivesTorque analysisSimulation

Owner:海风智能科技(浙江)有限公司

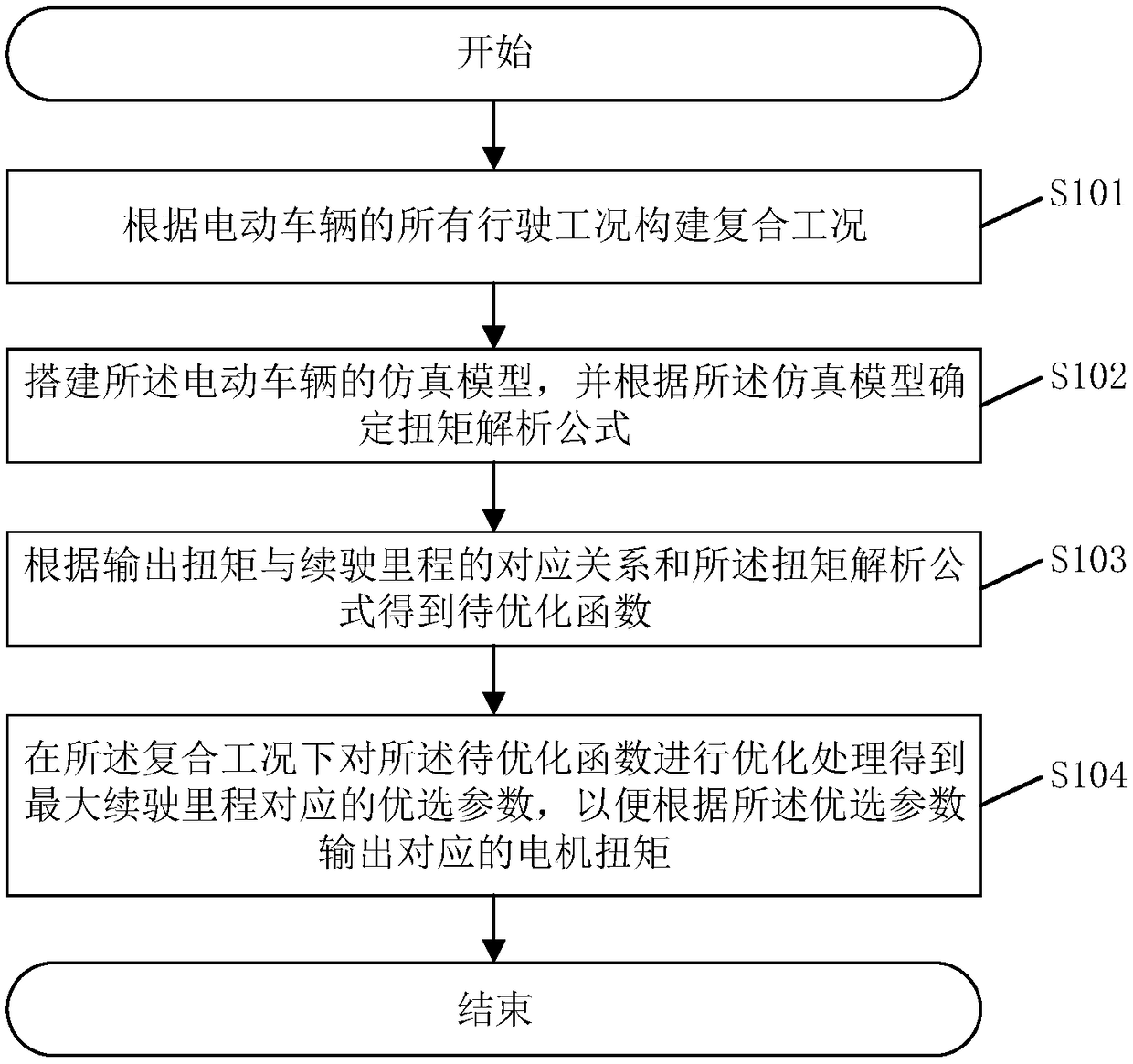

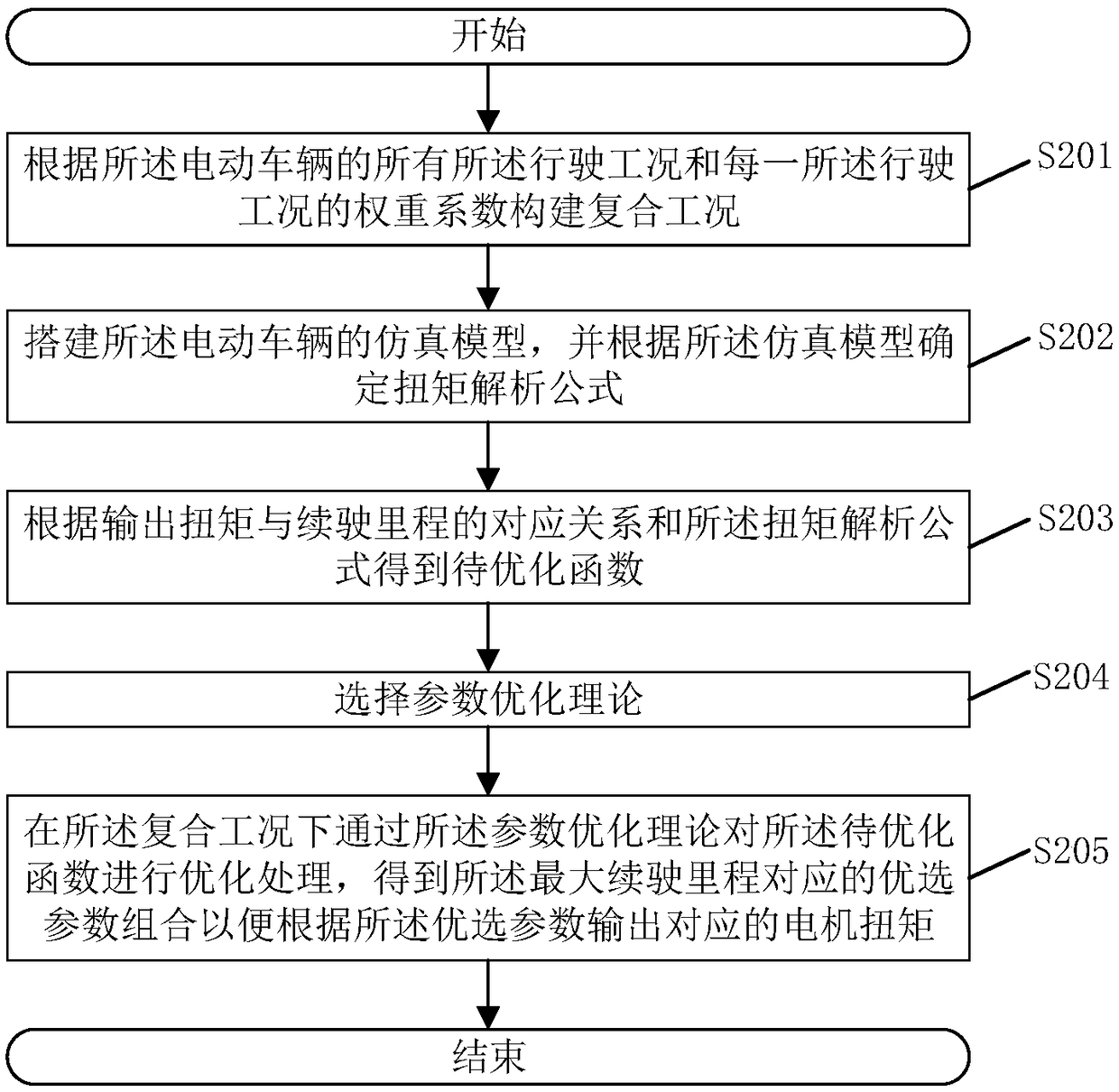

Electric vehicle motor torque output method and system and related assembly

InactiveCN109484210AImprove driving rangeStable torque outputSpeed controllerElectric energy managementTorque analysisElectric machine

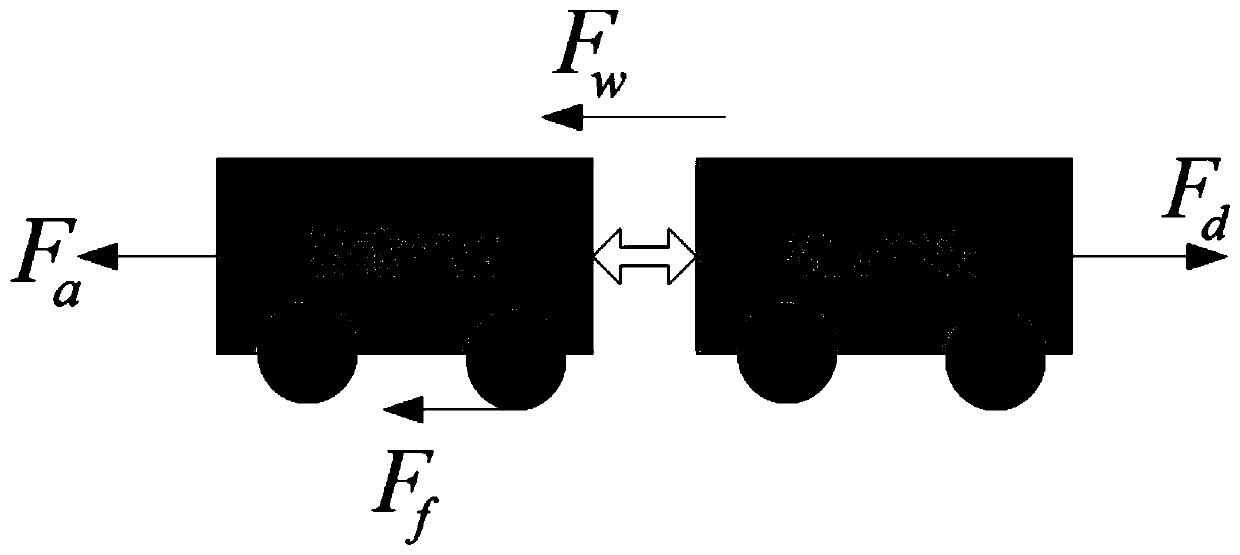

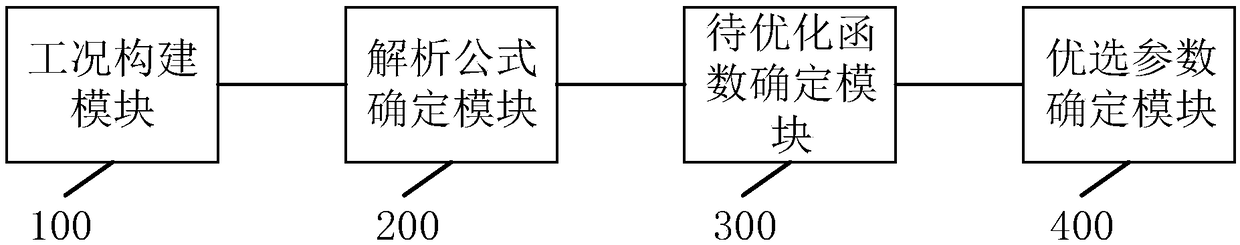

The invention discloses an electric vehicle motor torque output method. The method comprises constructing a composite working condition according to all driving conditions of an electric vehicle; constructing a simulation model of the electric vehicle and determining a torque analysis formula according to the simulation model; obtaining a function to be optimized according to the corresponding relationship between the output torque and the driving range and the torque analysis formula, wherein the optimization target of the function to be optimized is the driving range; optimizing the functionto be optimized under the composite working condition to obtain a preferred parameter corresponding to the maximum driving range to output the corresponding motor torque according to the preferred parameter. According to the method, the electric vehicle can have good driving range under different working conditions. An electric vehicle motor torque output system, a computer readable storage medium and the electric vehicle with the above advantages are further disclosed.

Owner:深蓝汽车科技有限公司

Residual torque analyzer

ActiveUS7934428B2Material failureMeasurement of torque/twisting force while tighteningLoad modified fastenersGyroscopeTorque analysis

Owner:ASI DATAMYTE

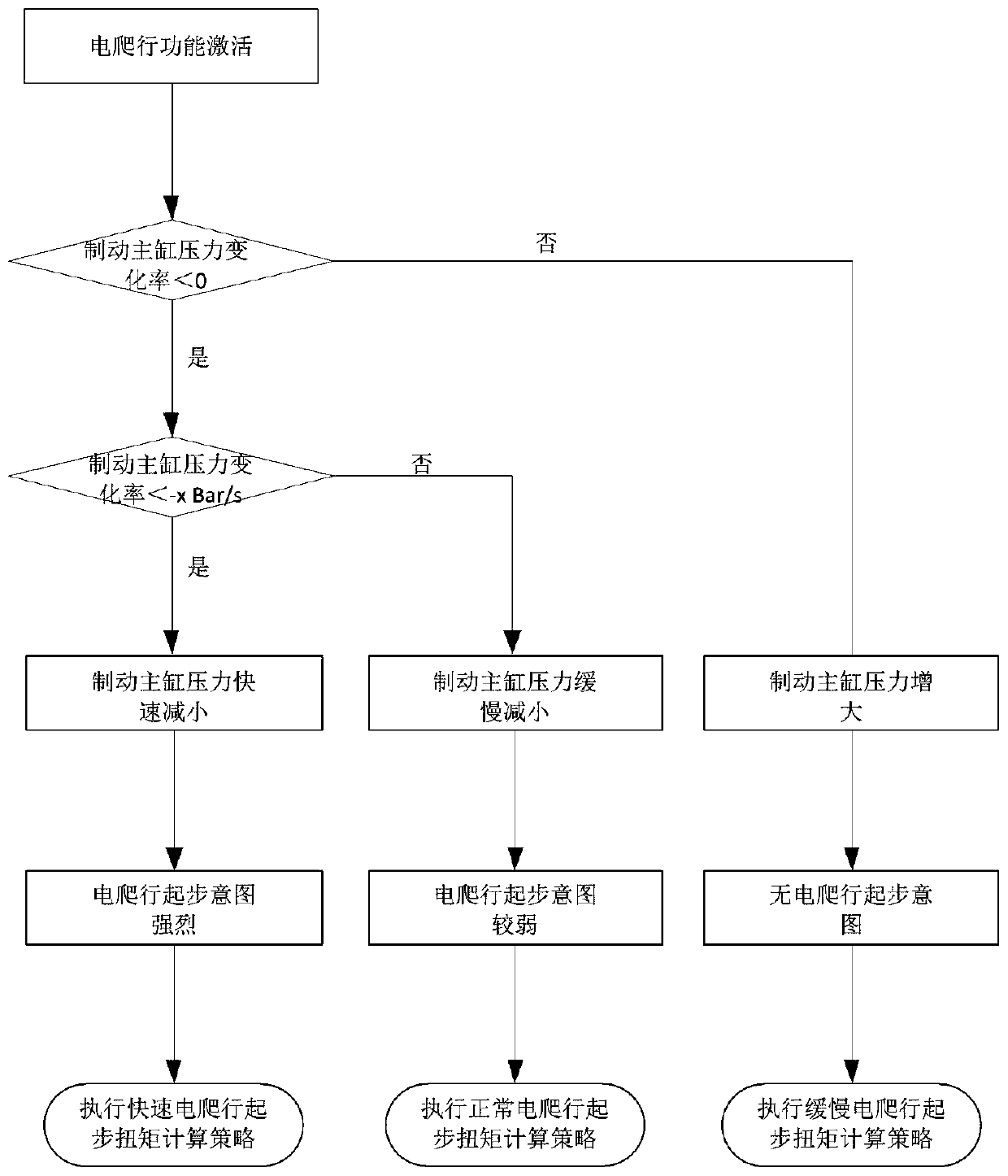

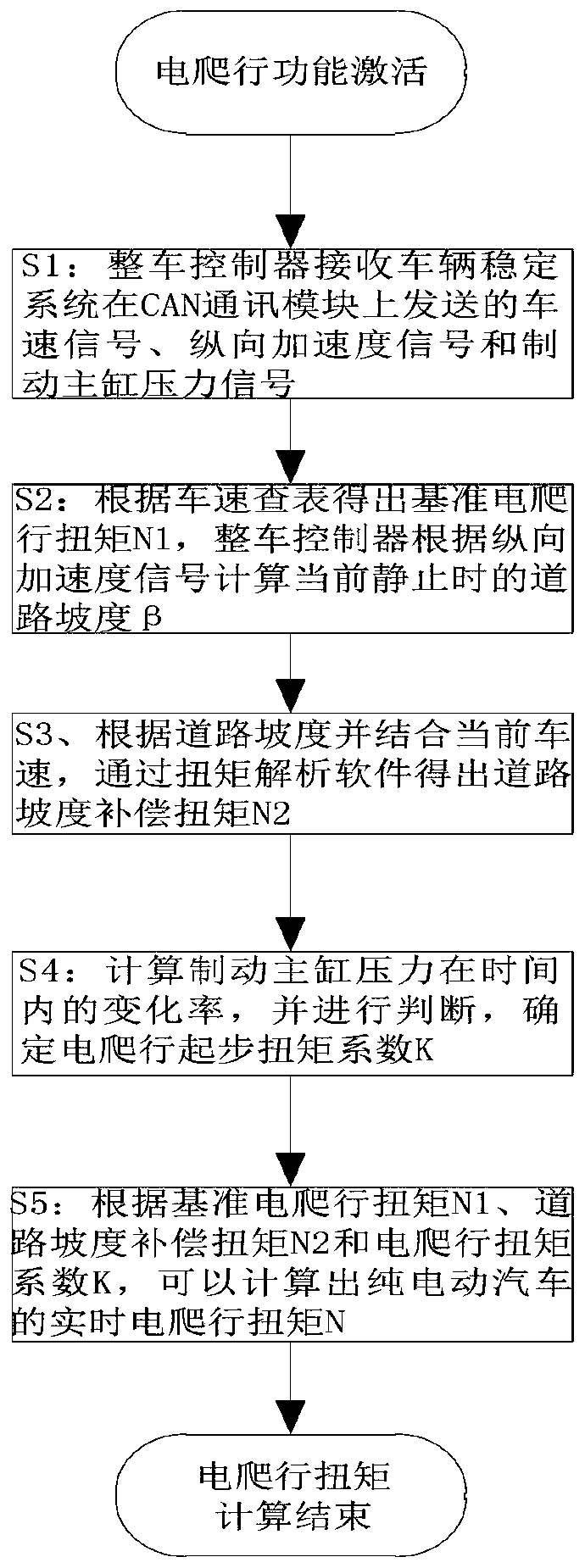

Torque control method for electric creeping starting of pure electric vehicle

PendingCN110667401AImprove controllabilitySmooth start responseSpeed controllerElectric vehicle charging technologyTorque analysisMaster cylinder

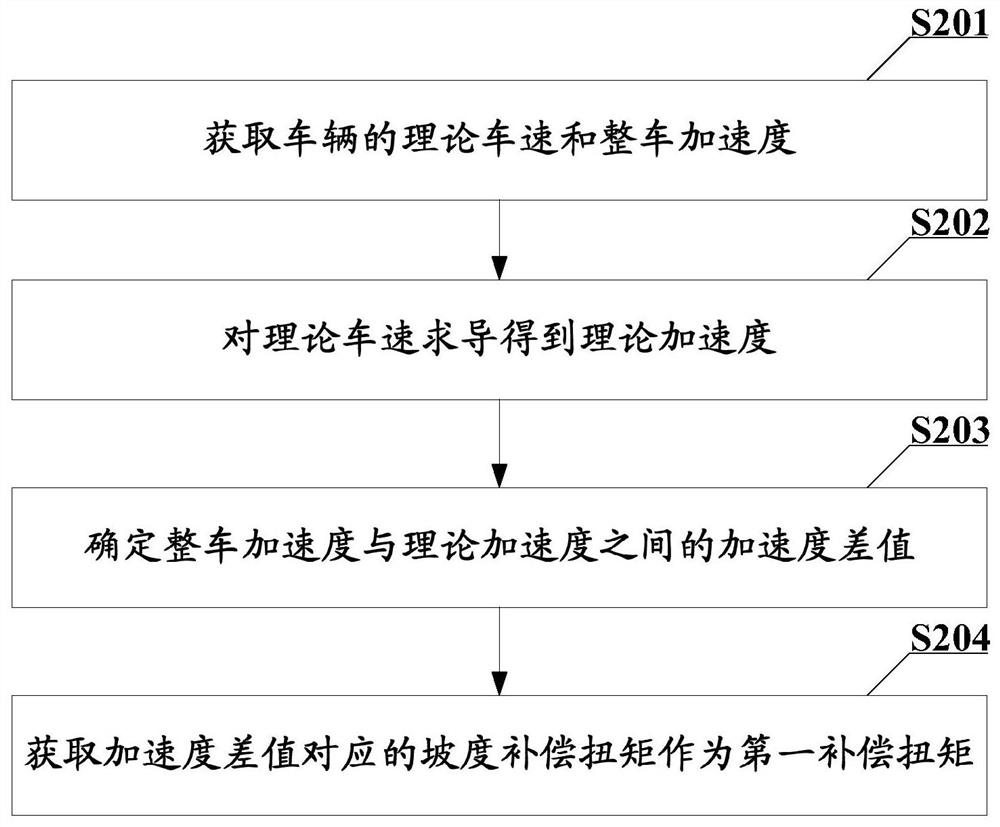

The invention discloses a torque control method for electric creeping starting of a pure electric vehicle. The torque control method for electric creeping starting of the pure electric vehicle comprises the following steps that S1, a vehicle controller receives a vehicle speed signal, a longitudinal acceleration signal, and a brake master cylinder pressure signal; S2, benchmark electric creeping torque N<1>is obtained according to vehicle speed table look-up, and the vehicle controller calculates the current road grade beta based on the longitudinal acceleration signal; S3, based on the road grade, and combined with a current vehicle speed, road grade compensation torque N<2> is obtained through torque analysis software; S4, change rate of the brake master cylinder pressure within time iscalculated for judgment to determine an electric creeping starting torque coefficient K; and S5, according to the benchmark electric creeping torque N<1>, the road grade compensation torque N<2> and the electric creeping torque coefficient K, the real-time electric creeping torque N of the pure electric vehicle is calculated, and N is equal to (N<1>+N<2>)* K. Decision-making and judgment can be made in a more humanized mode, the vehicle starting is more controllable, the vehicle starting is smooth and predictable, the problem of rotor-locking and heating of a driving motor during the electriccreeping starting is solved, and the driving comfort is improved.

Owner:上海伊控动力系统有限公司

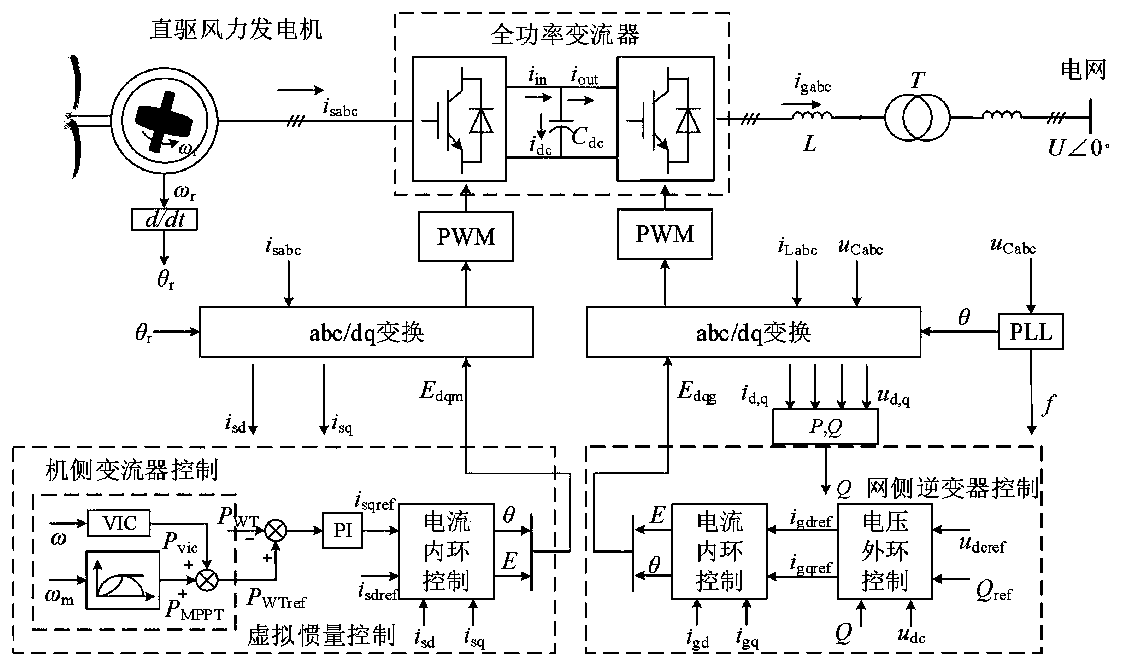

Dynamic characteristic analysis method of direct-driven wind power generation system under conventional control strategy

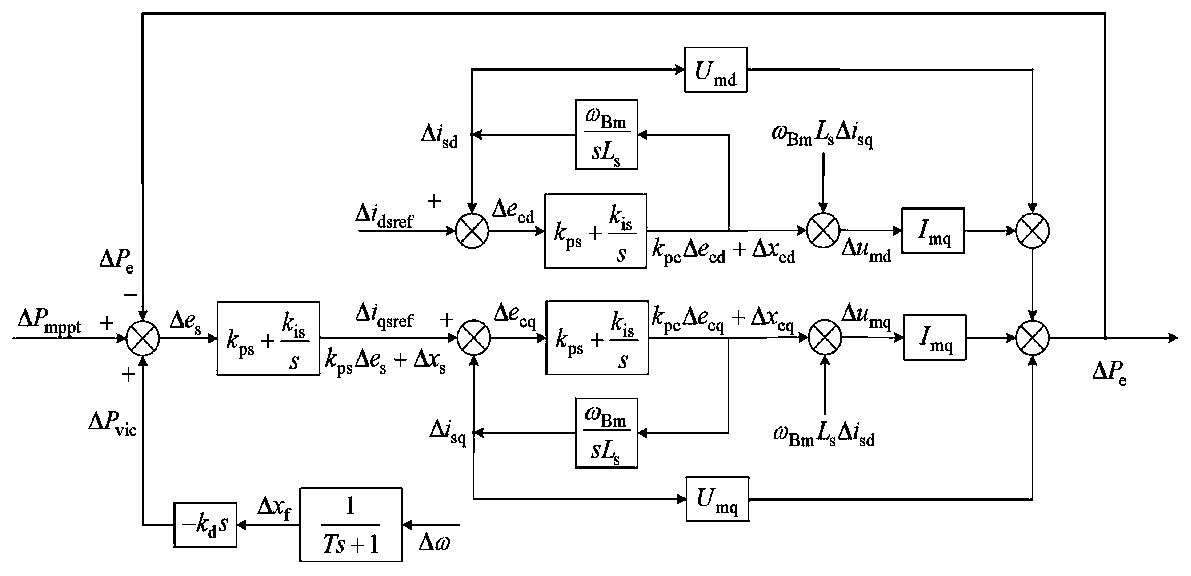

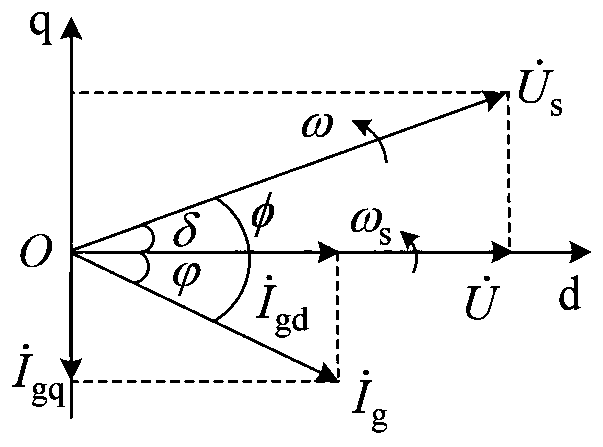

ActiveCN111342484AImprove stabilityWind motor controlSingle network parallel feeding arrangementsTorque analysisNew energy

The invention discloses a dynamic characteristic analysis method for a direct-driven wind power generation system under a conventional control strategy. The method comprises the following steps: 1, analyzing the control of the direct-driven wind power generation system, including maximum power control of a fan, control of a machine-side converter and control of a network-side inverter; 2, establishing a state space model of the direct-driven wind power grid-connected system, wherein the state space model comprises a machine-side converter system state space model and a grid-side inverter system state space model; 3, analyzing the dynamic characteristics of the system by using an electrical torque analysis method, and calculating equivalent dynamic characteristic parameters of the system; 4, simulating, verifying and analyzing a conclusion. Characteristic problems of the wind power generation system can be simply and quickly analyzed, new energy grid-connected safe operation is guided,and faults are reduced.

Owner:HUNAN UNIV OF TECH

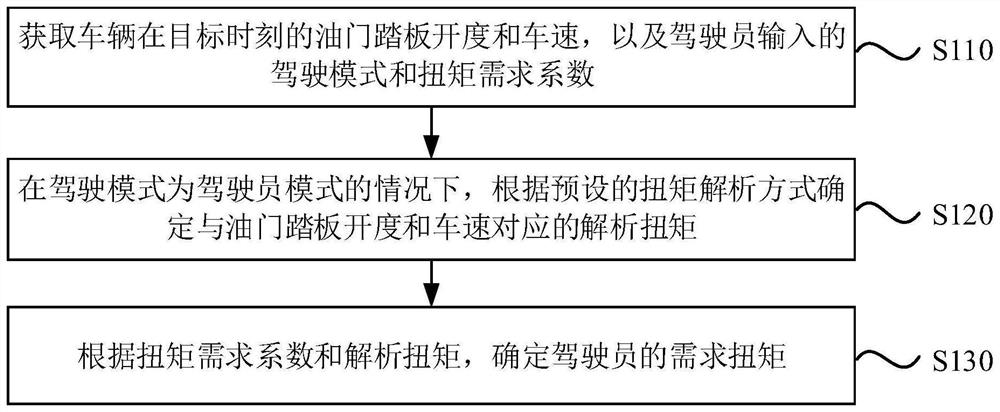

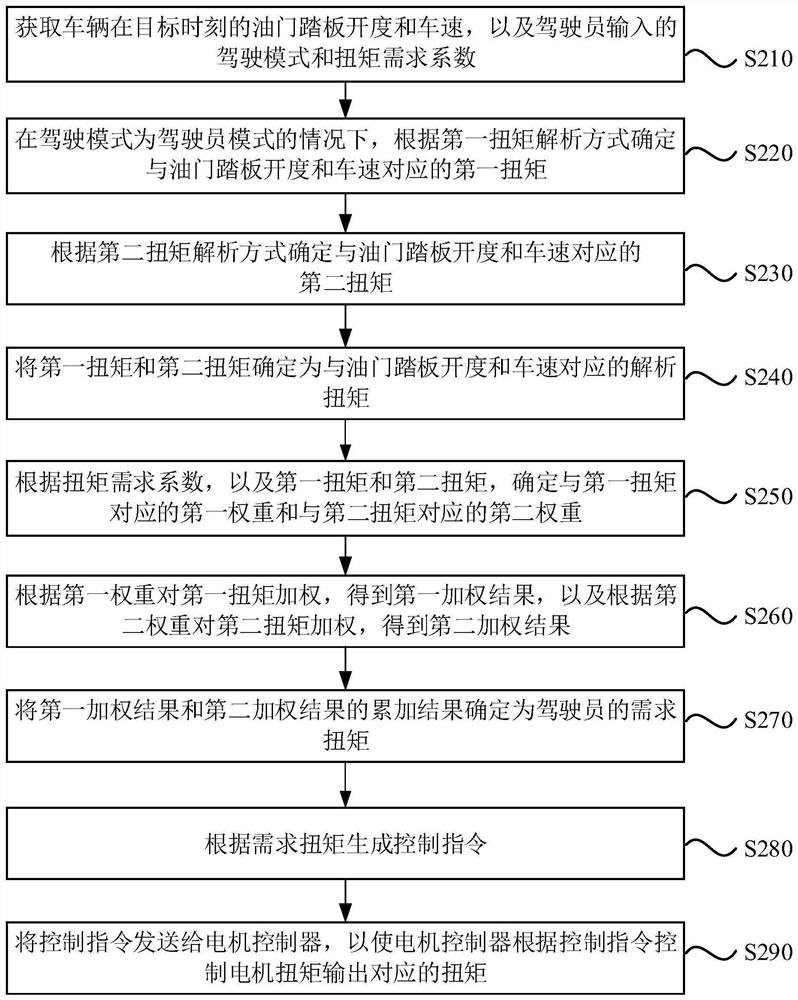

Demand torque determination method and device, vehicle and storage medium

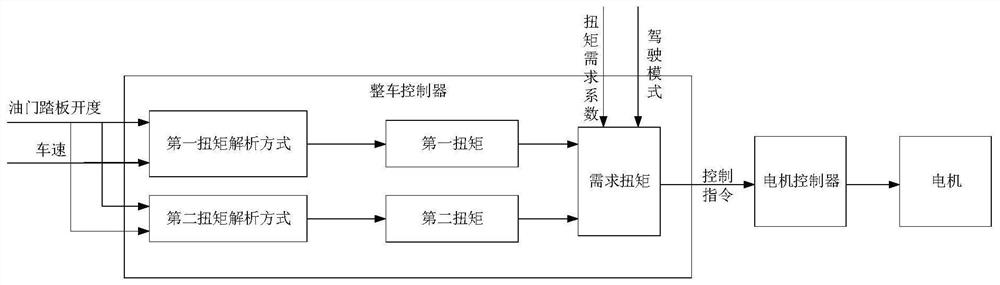

ActiveCN113335077AMeet individual needsEasy to operateSpeed controllerDriver interactionsTorque analysisDriver/operator

The embodiment of the invention discloses a demand torque determination method and device, a vehicle and a storage medium. According to the method, when a driving mode input by a driver is a driver mode, an analysis torque corresponding to the opening degree of an accelerator pedal and the vehicle speed is determined through a preset torque analysis mode, and then the demand torque of the driver is obtained according to the analysis torque and a torque demand coefficient input by the driver. According to the method of the invention, the driver only needs to input the two parameters of the driving mode and the torque demand coefficient, the torque meeting the demand of the driver can be obtained according to the preset torque analysis mode, the individual demand of the driver is met, the driver does not need to set other parameters, and the operation of the driver is simplified.

Owner:ROX MOTOR TECH CO LTD

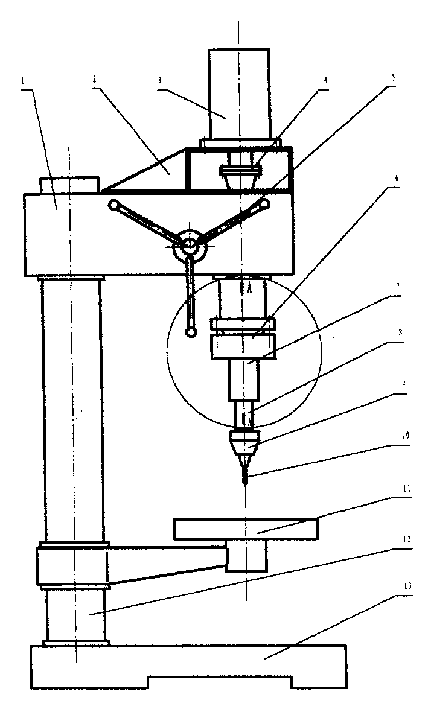

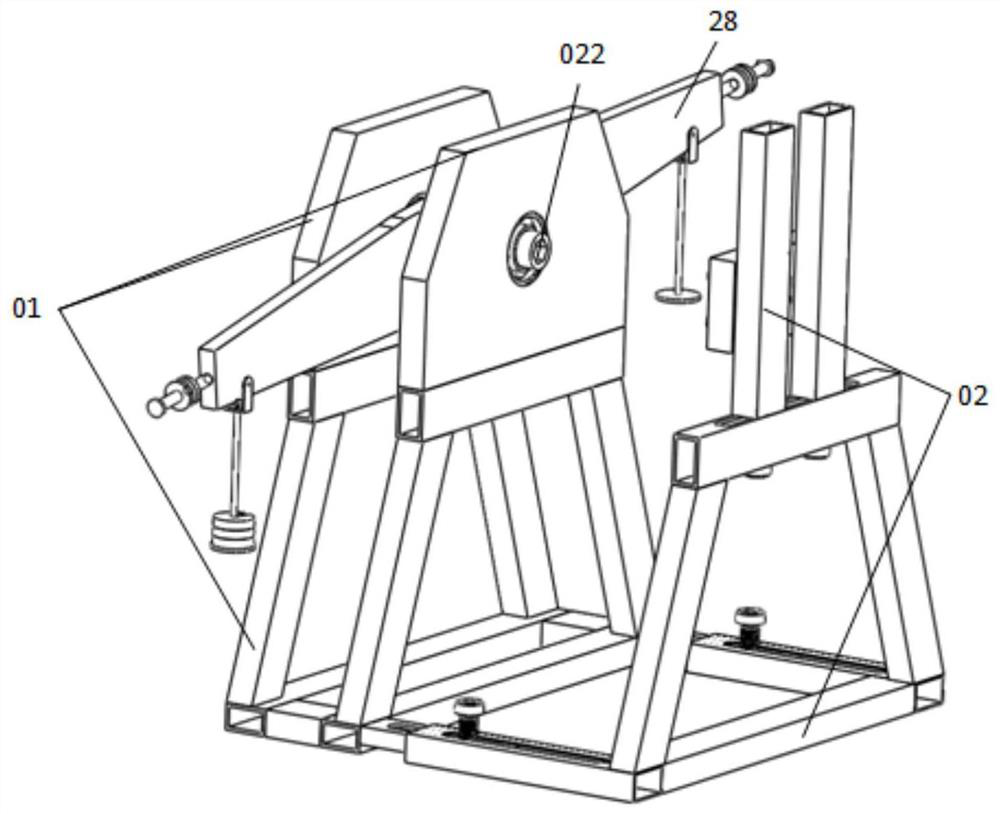

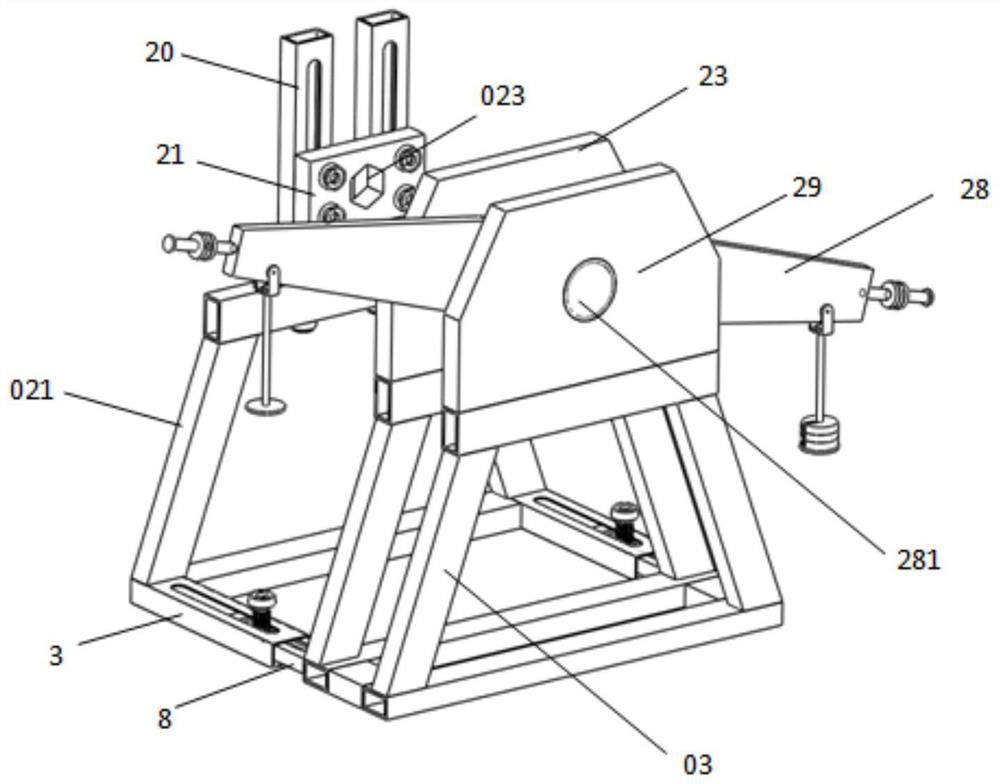

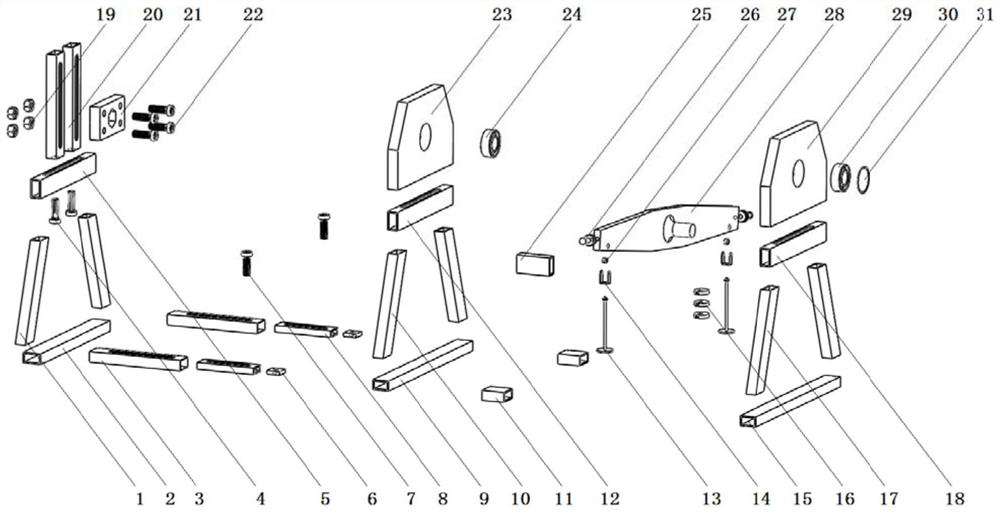

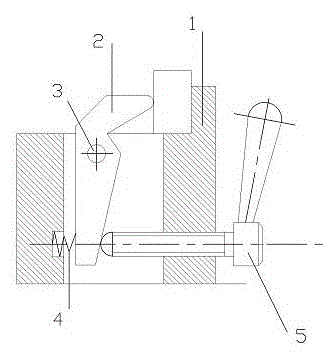

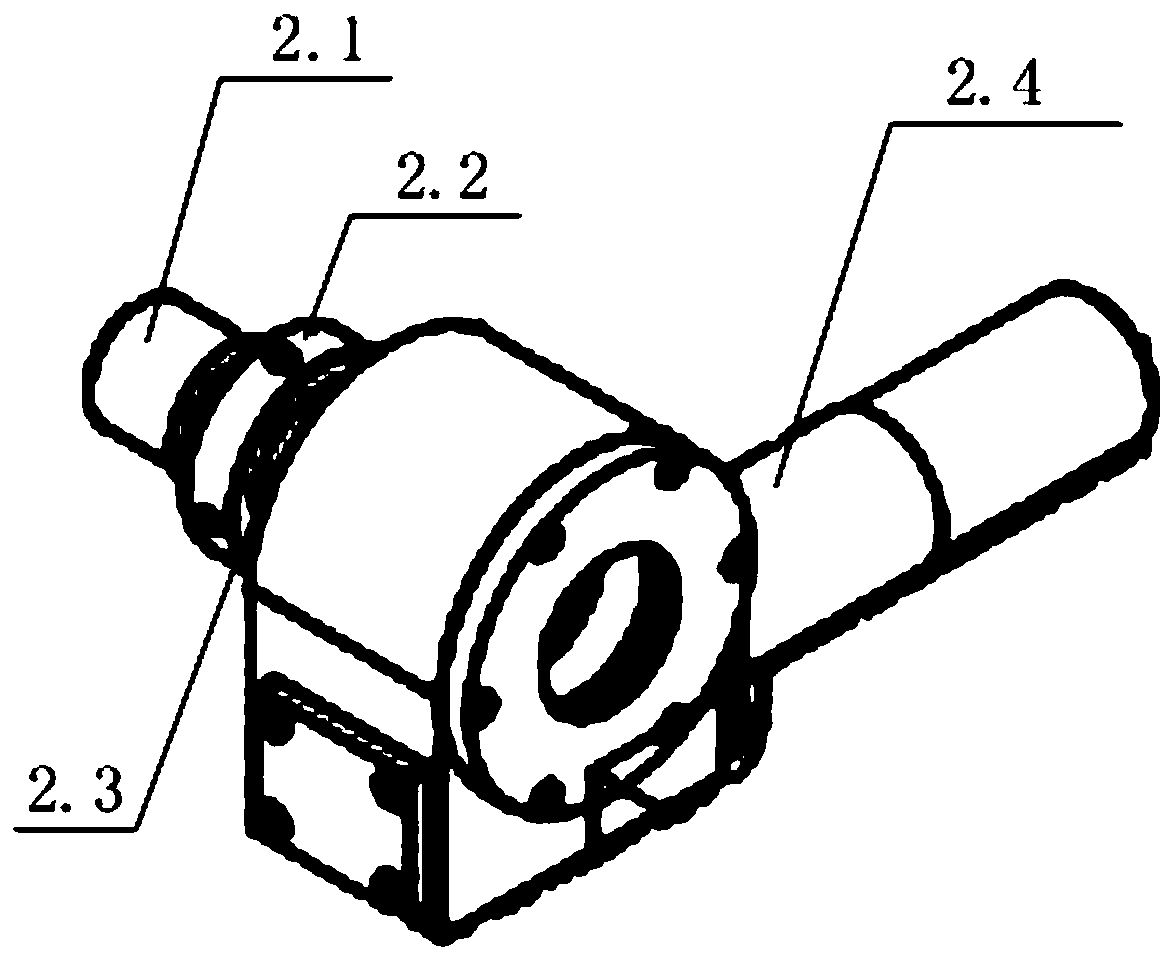

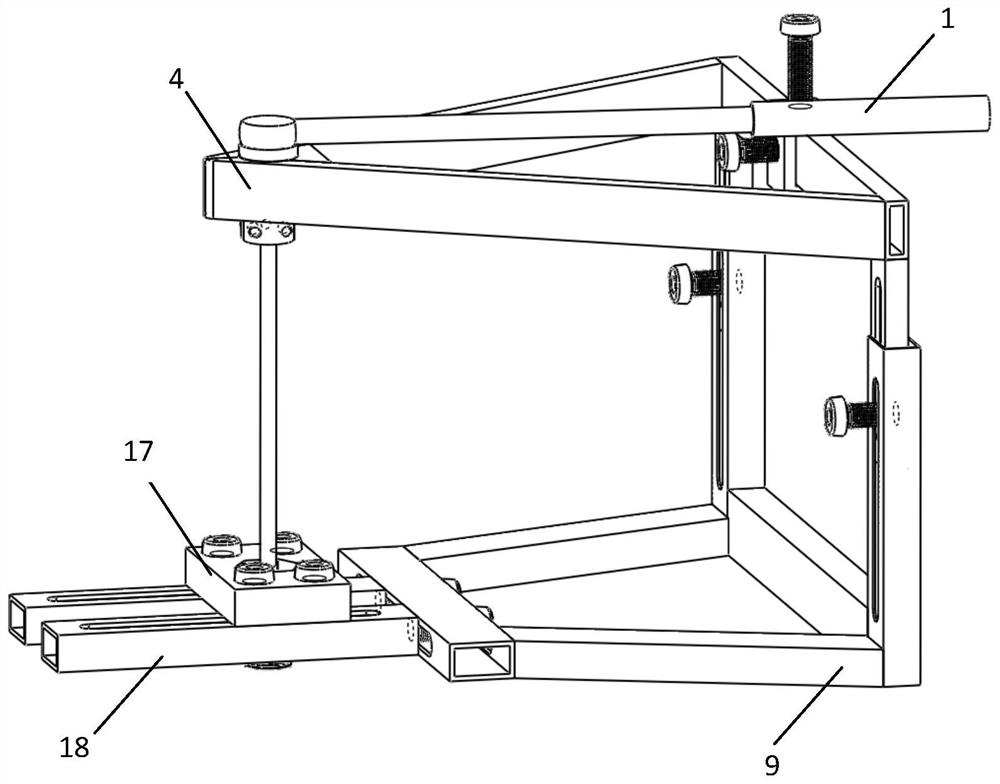

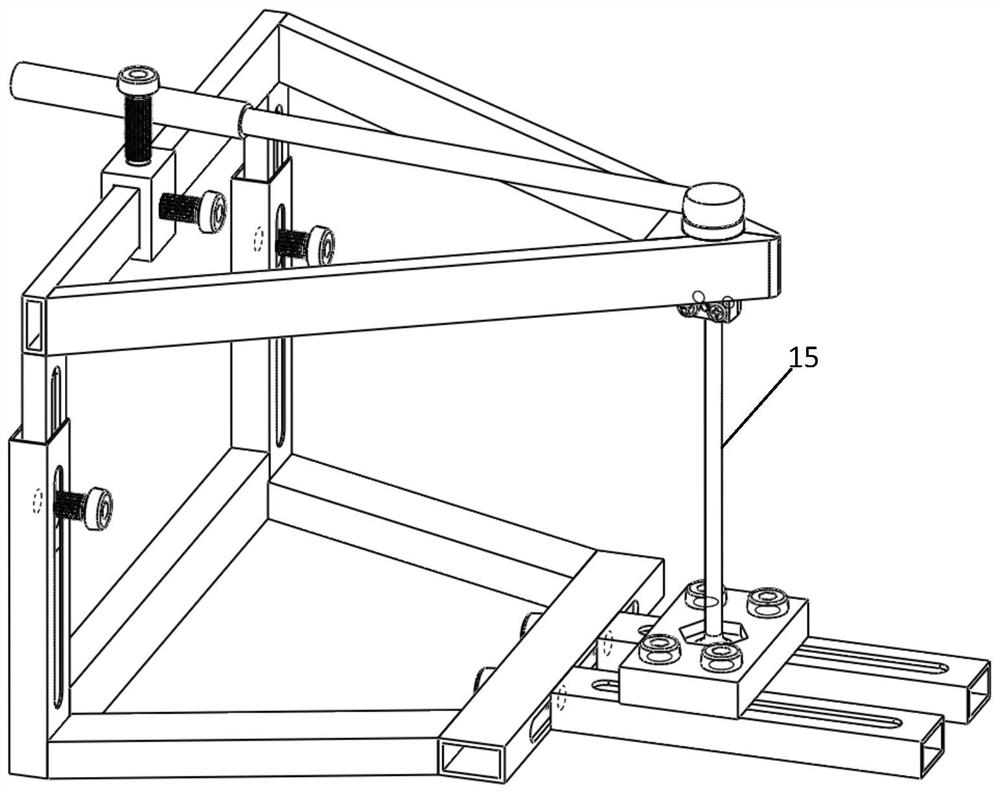

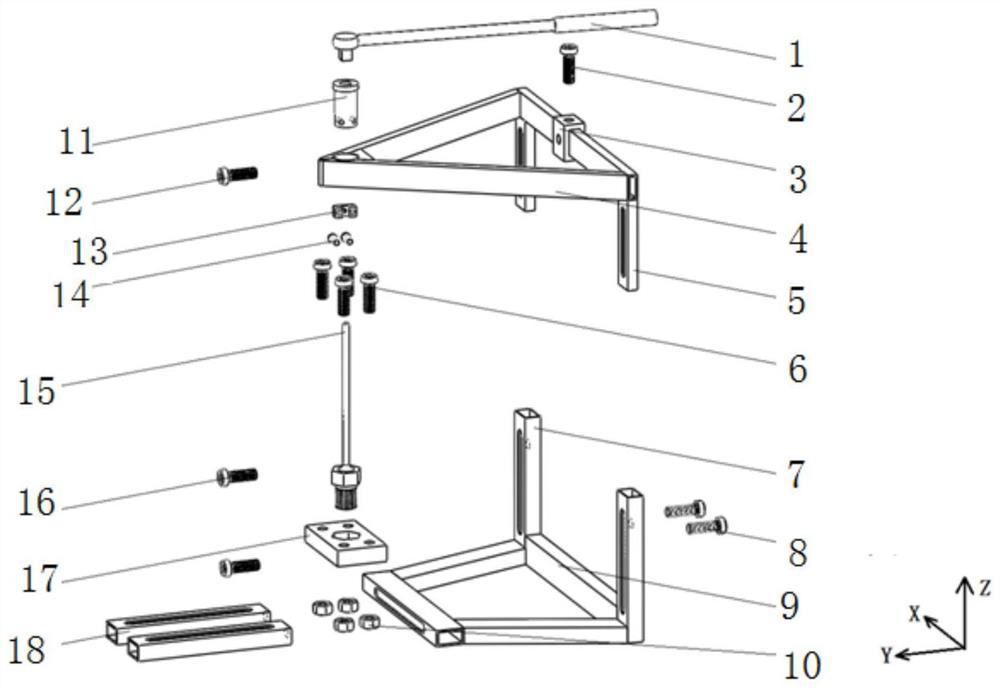

Pure torque loading device and method based on lever principle

PendingCN112179788AWide applicabilityReduce manufacturing costMaterial strength using steady torsional forcesTorque analysisEngineering

The invention relates to a pure torque loading device and method based on the lever principle, can be used for constant-value pure torque stable loading of columnar objects, and aims to solve the problem that the torque analysis result is affected due to the fact that mechanical values such as stretching, compressing and bending are inevitably introduced into an existing torque applying device. The device comprises a force arm supporting assembly and a twisted workpiece mounting assembly, the force arm is fixed to the force arm supporting assembly, one end of a twisted workpiece is installed in a hole with a force arm spreading function, the other end of the twisted workpiece is installed on a positioning block of the twisted workpiece mounting assembly, and the xyz-direction position of the positioning block is adjustable. The pure torque loading device based on the lever principle can apply a pure torque value to a pipeline and a part, other mechanical indexes such as stretching, compression and bending are not brought in, the quantitative and stable torque loading and maintaining functions are achieved, a new torque loading thought can be provided for most objects needing torqueloading, and reliable technical guarantee is provided for product development.

Owner:西安航天计量测试研究所

Simple screw clamping mechanism

The invention relates to a tool clamp in machining, and in particular to a simple screw clamping mechanism. The simple screw clamping mechanism comprises a base. A vertical hollow part is formed on the base, and a clamping block is arranged in the hollow part. The upper end of the clamping block is fixed to the hollow part of the base through a locating pin. The lower end of the clamping block is connected with one side of the base through a spring, and a handle is arranged at the position, opposite to the spring, of the other side of the base. The handle rotates inwards to compress the clamping block, the clamping block is driven to clamp a workpiece, and the clamping function is achieved. Conversely, the handle rotates outwards, elastic force is generated on the clamping block by the spring at this moment, the clamping block is driven to loosen the workpiece, and the workpiece is rapidly mounted and demounted. Furthermore, due to the fact that the locating pin is arranged at the end close to the workpiece, torque analysis shows that the workpiece can be clamped only through small force of the handle on the clamping block, and therefore the labor saving effect can be achieved.

Owner:CHONGQING JIANAN IND & TRADE

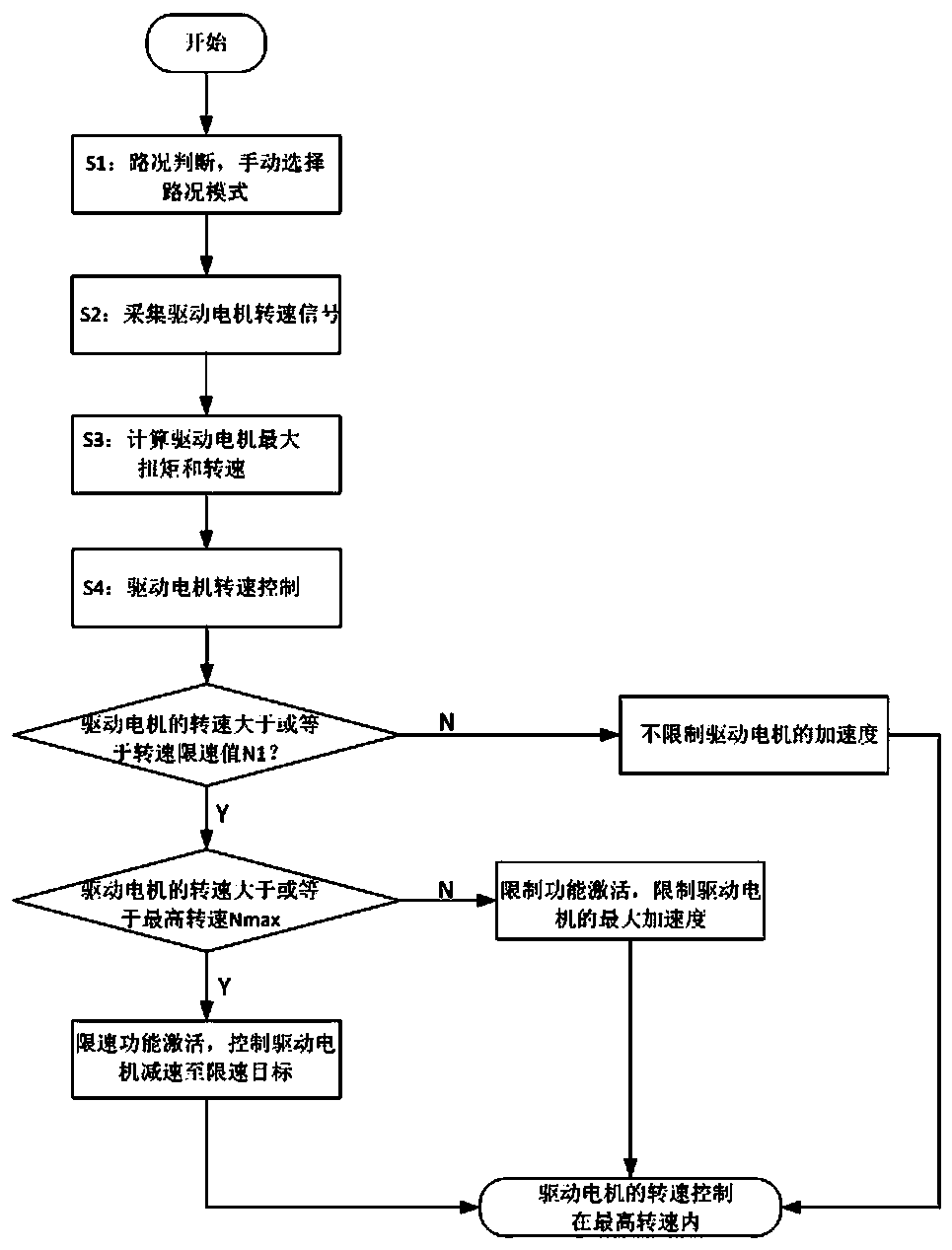

Rotation speed control method for preventing overspeed of motor of pure electric logistics vehicle

ActiveCN109687810AAvoid damageImprove securitySpeed controllerElectric motor controlMaximum torqueTorque analysis

The invention discloses a rotation speed control method for preventing overspeed of a motor of a pure electric logistics vehicle. The rotation speed control method adopts the pure electric logistics vehicle, a whole vehicle controller, a power source controller, the driving motor, a motor rotation speed sensing module and torque analysis software; the whole vehicle controller, the power source controller, the driving motor and the motor rotation speed sensing module are all installed on the pure electric logistics vehicle, and the torque analysis software is installed on the whole vehicle controller. The rotation speed control method comprises the steps of S1, judging road conditions; S2, acquiring a rotating speed signal of the driving motor; S3, calculating the maximum torque and rotating speed of the driving motor; S4, controlling the rotating speed of the driving motor. The method has the advantages that the closed-loop speed feedback precision is high, overspeed is effectively avoided, a good speed limiting effect is achieved, damage to mechanical structures of vehicles is avoided, the safety factors of drivers are greatly increased, and the method adapts to different road conditions and is applicable to a wide range of vehicle modes and great in market prospect.

Owner:上海伊控动力系统有限公司

Bolt centering control method for power transmission line bolt fastening robot

InactiveCN111168367AHigh precisionImprove securityProgramme-controlled manipulatorMetal working apparatusTorque analysisClassical mechanics

The invention discloses a bolt centering control method for a power transmission line bolt fastening robot. The method comprises the following steps that according to a deflection angle between a sleeve and a nut, a deviation angle threshold value theta < max > is set, and according to the dimension of the deflection angle, feeding of a mechanical arm is controlled, specifically, almost no deviation exists between central axes of the sleeve and the nut, a deviation only exists between hexagons, the mechanical arm is directly controlled to carrying out feeding, and the nut is rotated, so that the hexagon of the nut is aligned with the hexagon of the sleeve; an angular deviation exists between the sleeve and the nut, the deviation angle is theta ( the absolute value of the theta is less thanor equal to the theta < max>), and according to a known deviation angle theta <1> and feeding depth delta, a deviation angle theta <2> can be obtained; the value of the theta <2> is calculated and monitored, and once the value reaches a target value range, the sleeve is used for rotating the bolt, so that the hexagon of the nut is aligned with the inner hexagon of the sleeve; and once the deviation angle between the sleeve and the nut is too large, and the the absolute value of the theta is larger than the theta < max>, the mechanical arm needs to be adjusted again for alignment. According tothe method, the bolt centering task of the robot is automatically completed through compliance control, torque analysis and other methods, a traditional manual remote control mode is replaced, and the precision is higher.

Owner:新昌县新明实业有限公司 +1

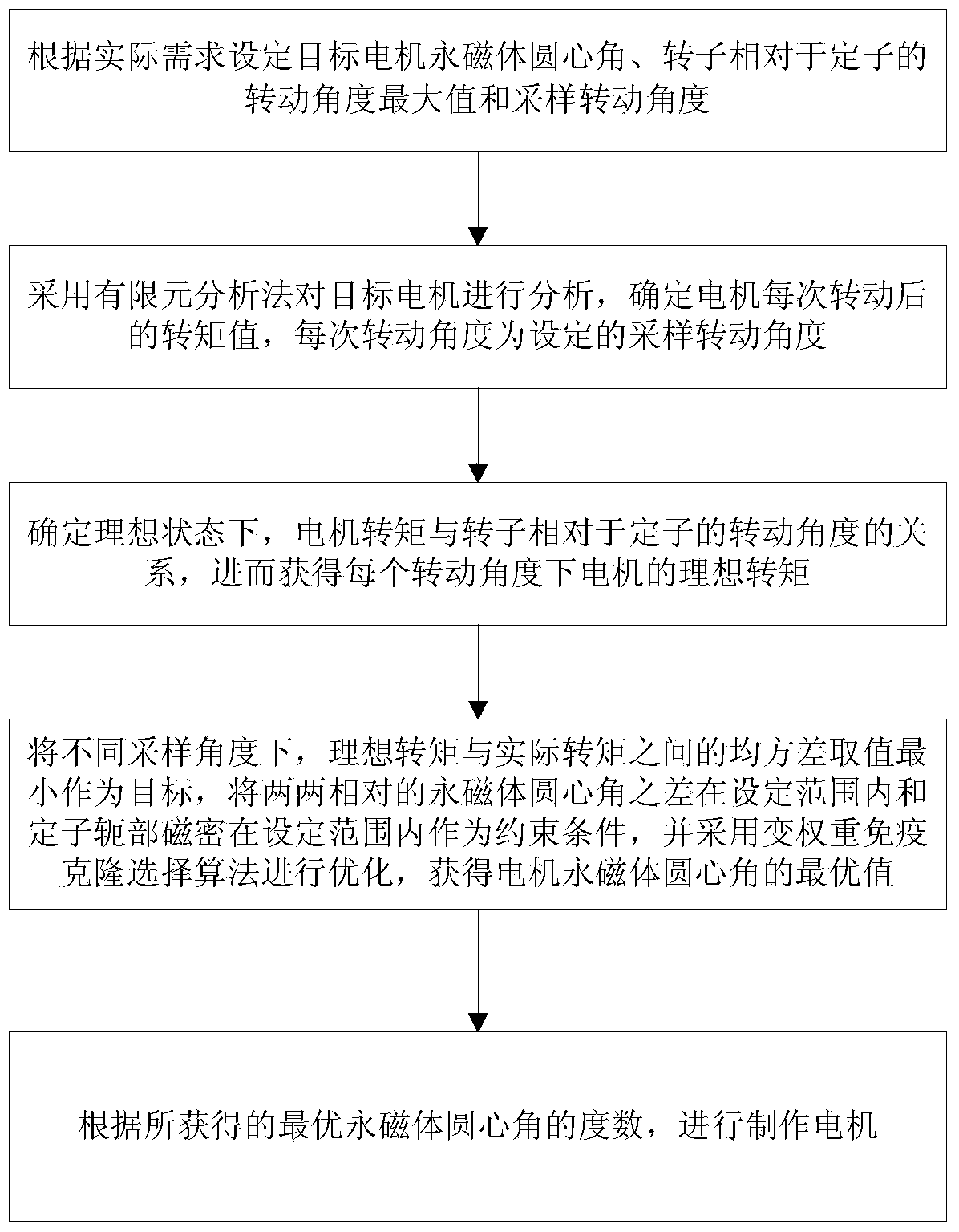

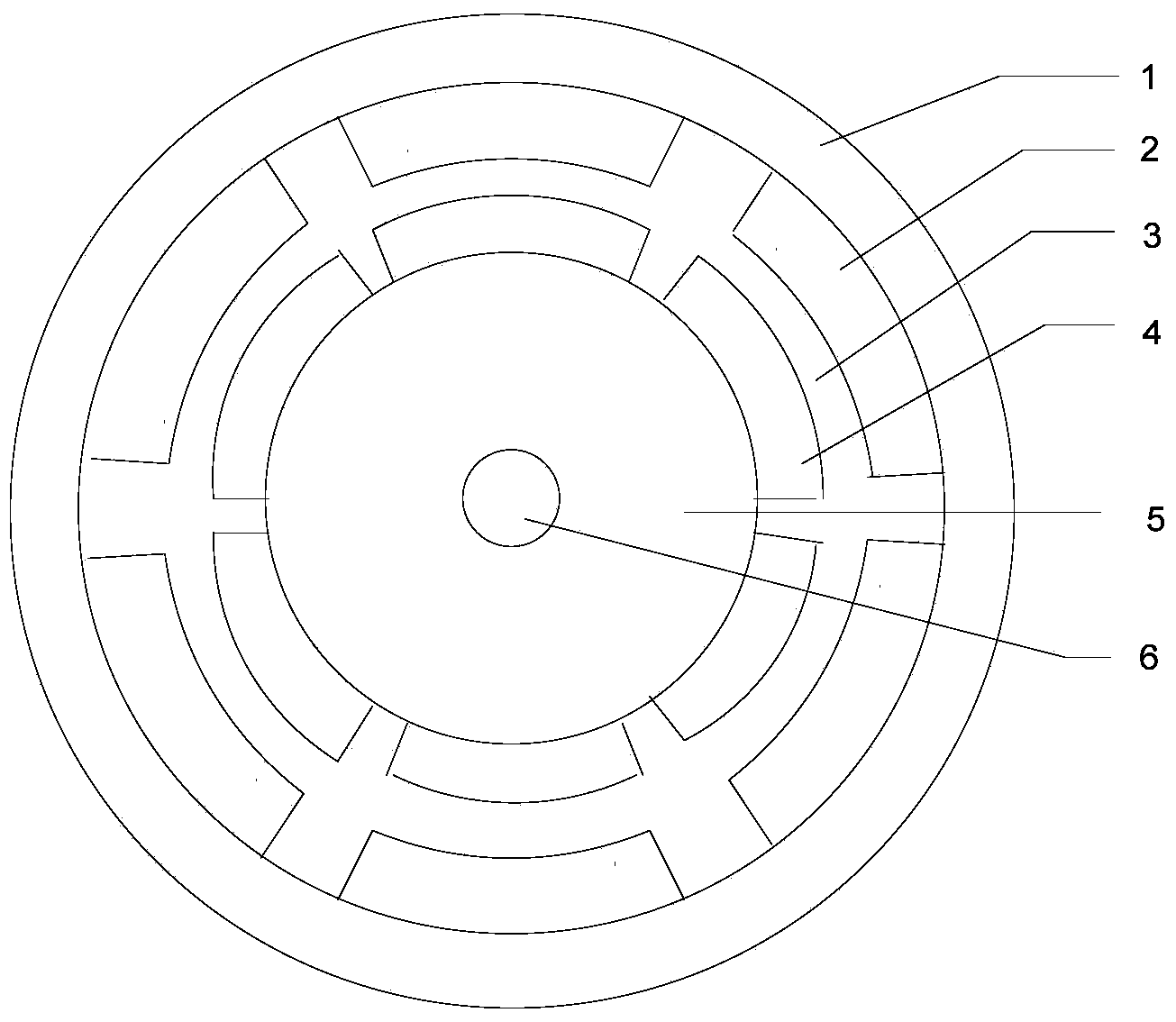

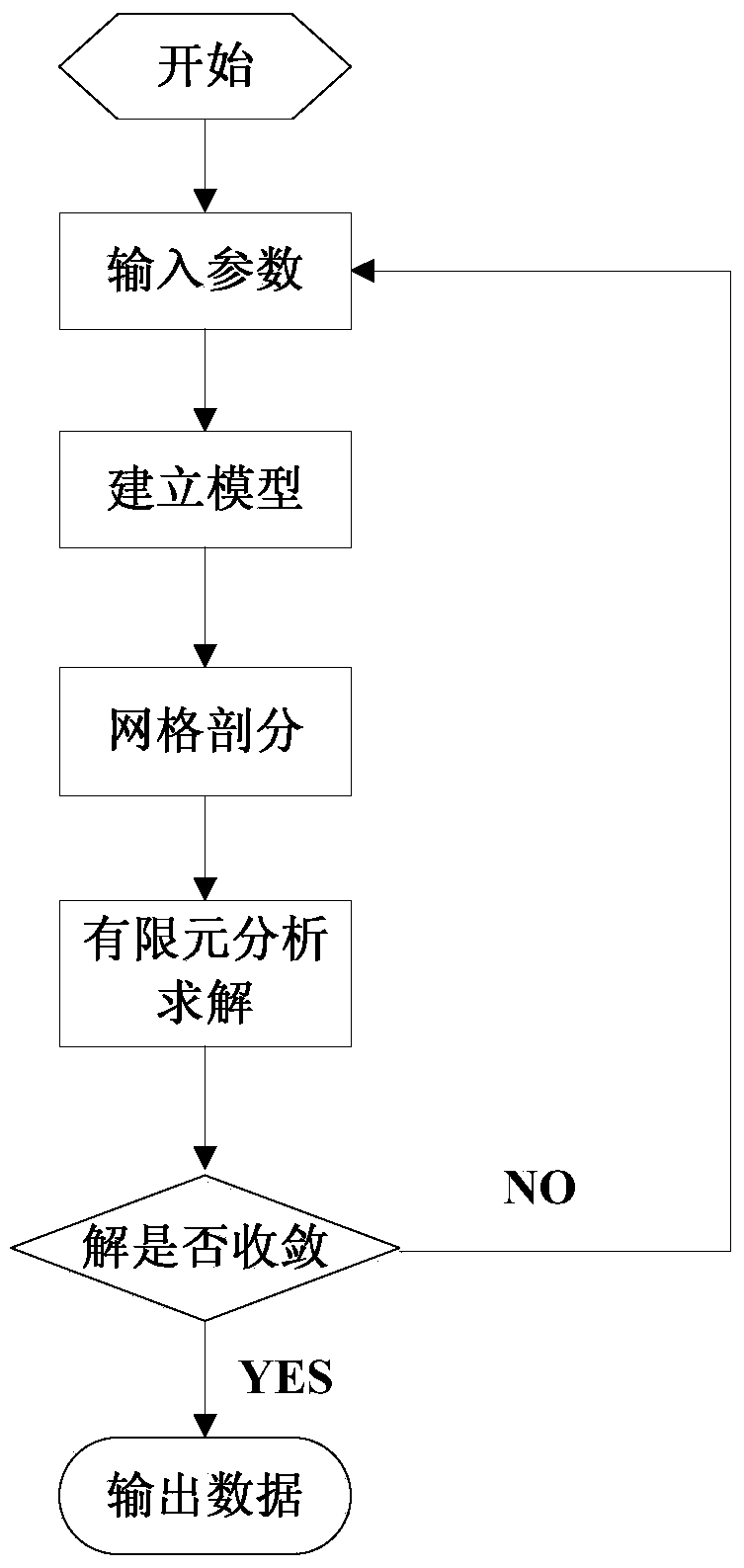

Novel torque motor structure parameter optimization method

ActiveCN104038135AReduce mistakesFast convergenceElectronic commutation motor controlVector control systemsClonal selection algorithmImmune clonal selection algorithm

The invention provides a novel torque motor structure parameter optimization method, and belongs to the field of motor intelligent optimization design. A finite element analysis system is used for conducting modeling and torque analysis on introduced structural parameters to replace traditional motor mathematical model analysis and calculation, so that errors of calculating results are small, and the accuracy is high. A weight value changing immune clonal selection algorithm is provided, after a weight value changing mechanism is used, the weight between single objective functions can be continuously adjusted along with operation of the algorithm, wherein the weights of the single objective functions close to the design demand can be changed to be small, and the weights of the single objective functions deviating from the design demand can be continuously increased. Accordingly, the convergence rate of the algorithm is increased, a large amount of unnecessary optimizing time is saved, and the optimization result is obtained more quickly. In addition, the algorithm can effectively keep the diversity of a population, global searching and local searching can be achieved simultaneously, early-maturing of evolution and falling into local minimal values of searching can be prevented, and complex non-linear problems can be solved.

Owner:东能(沈阳)能源工程技术有限公司

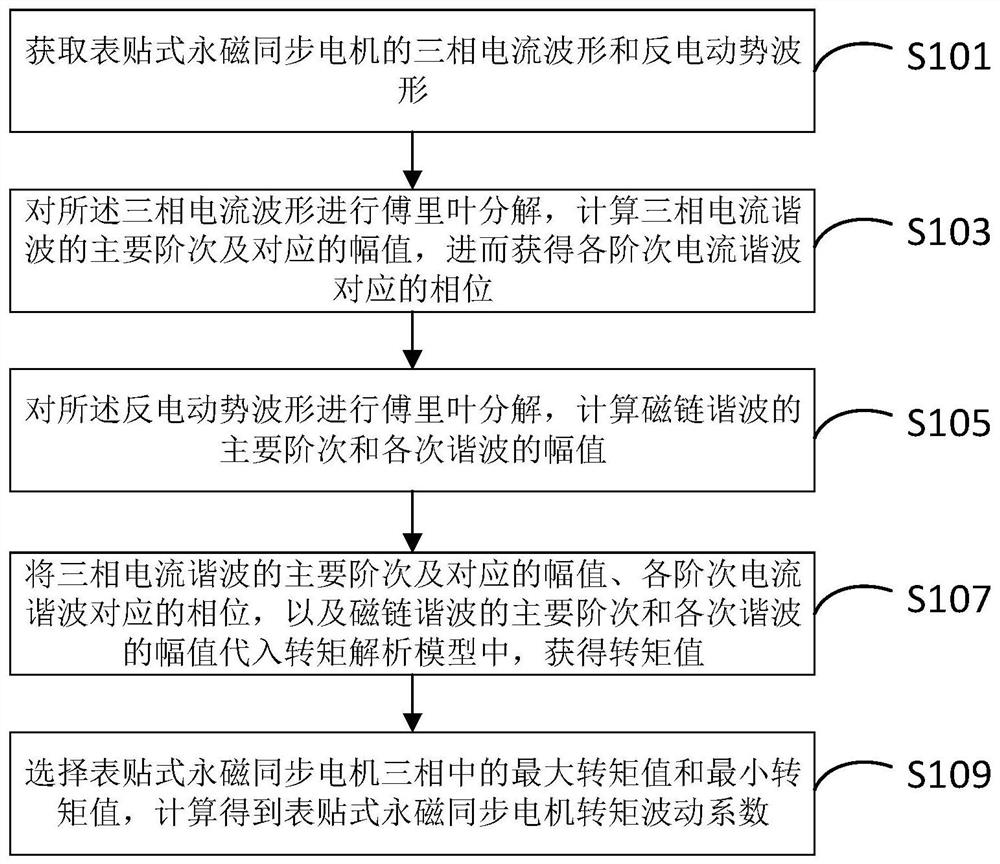

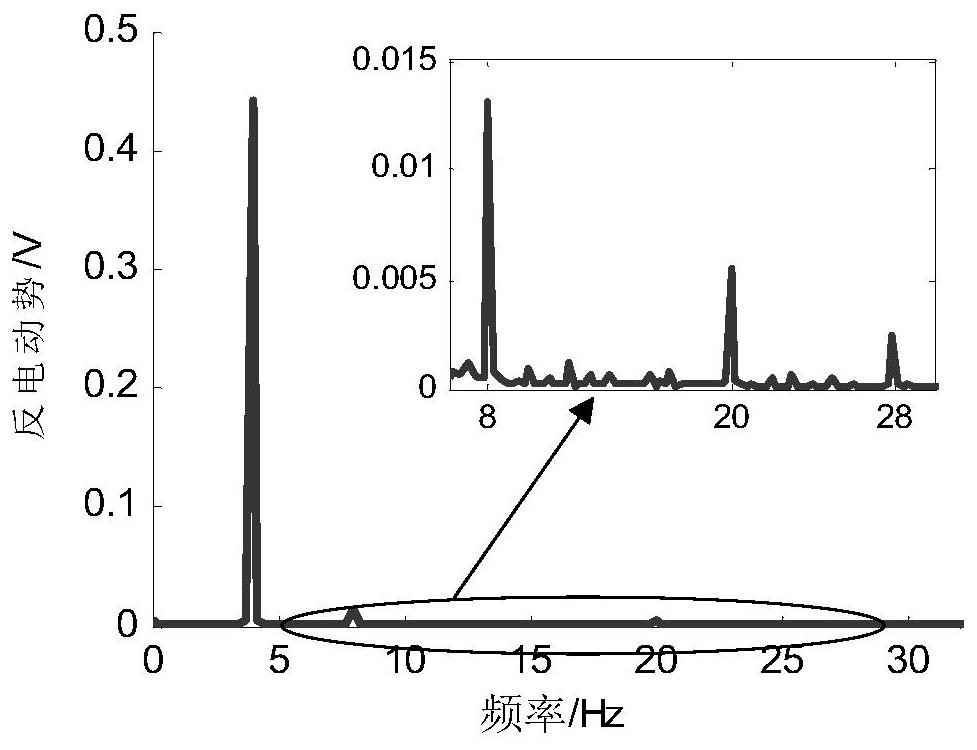

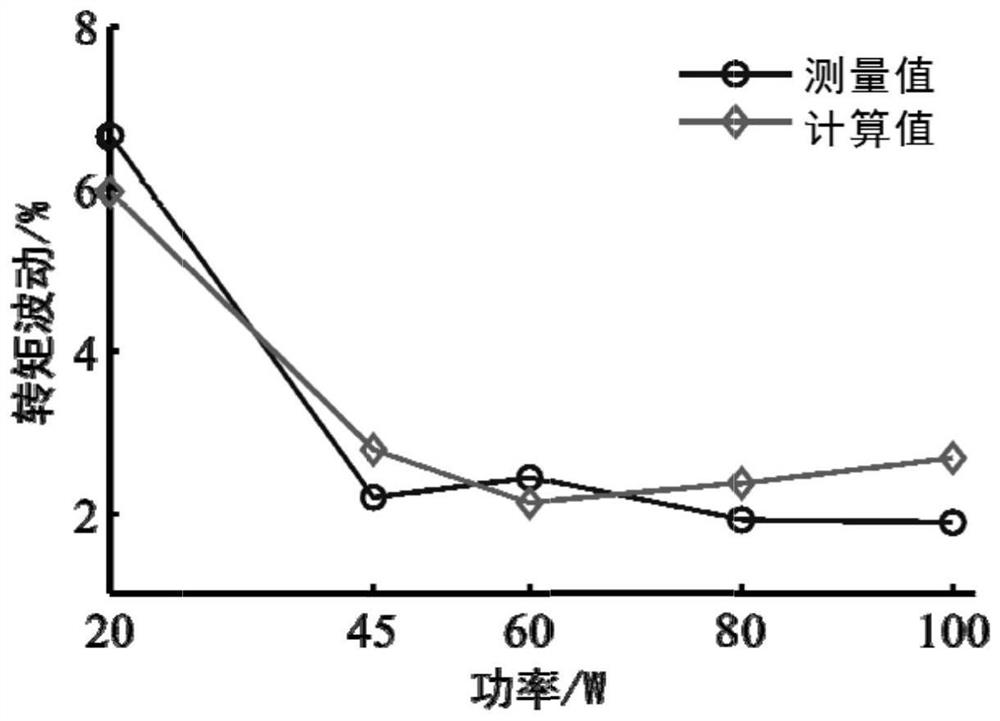

Method and device for calculating torque ripple coefficient of surface-mounted permanent magnet synchronous motor

InactiveCN111740653AAccurate calculationVerify validityTorque ripple controlElectric motor controlPhase currentsPermanent magnet synchronous motor

The invention discloses a method and device for calculating a torque ripple coefficient of a surface-mounted permanent magnet synchronous motor. The method comprises the following steps of acquiring athree-phase current waveform and a back electromotive force waveform of the surface-mounted permanent magnet synchronous motor; carrying out Fourier decomposition on the three-phase current waveform,calculating the main order and the corresponding amplitude of three-phase current harmonics, and then obtaining the phase corresponding to each order of current harmonics; carrying out Fourier decomposition on the back electromotive force waveform, and calculating the main order of the flux linkage harmonic and the amplitude of each harmonic; substituting the main order and the corresponding amplitude of the three-phase current harmonic, the phase corresponding to each order of current harmonics, the main order of a flux linkage harmonic wave and the amplitude of each harmonic wave into a torque analysis model to obtain a torque value; and selecting a maximum torque value and a minimum torque value in the three phases of the surface-mounted permanent magnet synchronous motor, and calculating to obtain a torque ripple coefficient. The method is helpful for monitoring the torque ripple degree of the permanent magnet synchronous motor under the actual working condition and carrying outfault prediction according to the change of the torque ripple degree.

Owner:ZHEJIANG SCI-TECH UNIV

High-precision universal torque loading device and method

PendingCN112255117APrevent bending factorWide applicabilityMaterial strength using steady torsional forcesTorque analysisControl engineering

The invention provides a high-precision universal torque loading device and method, and solves the problem that a torque analysis result is influenced by inevitable introduction of mechanical values like stretching, compression and bending of an existing torque applying device. The device comprises a base, a lower bottom sliding rail, a lower bottom clamping piece, a stand column assembly, an upper beam, a steering sleeve, a torque wrench and a positioning block. The lower bottom sliding rail is in sliding connection with the base and can slide and be positioned on the base in the X direction;the lower bottom clamping piece is connected with the lower bottom sliding rail in a sliding mode and can slide and be positioned on the lower bottom sliding rail in the y direction. The stand columnassembly can stretch out and draw back in the z-direction and be positioned. The two ends of the stand column assembly are fixedly connected with the base and the upper beam. In the torque loading process, by adjusting the position of the lower bottom clamping piece in the X-Y direction, bending factors caused by deviation of a measured piece in the vertical direction in the machining or using process are prevented. A new torque loading thought can be provided for most objects needing torque loading, and a reliable technical guarantee is provided for product development.

Owner:西安航天计量测试研究所

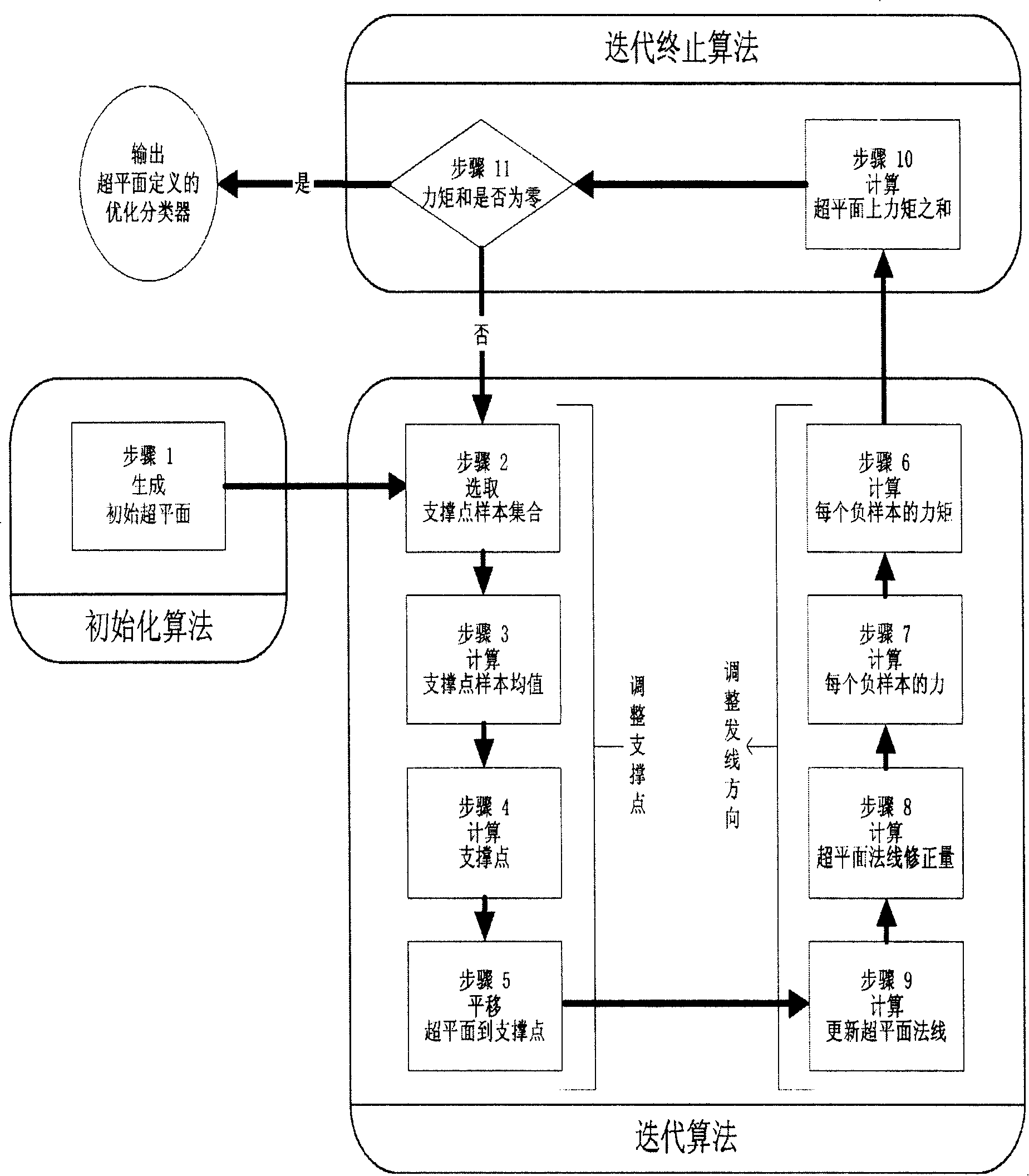

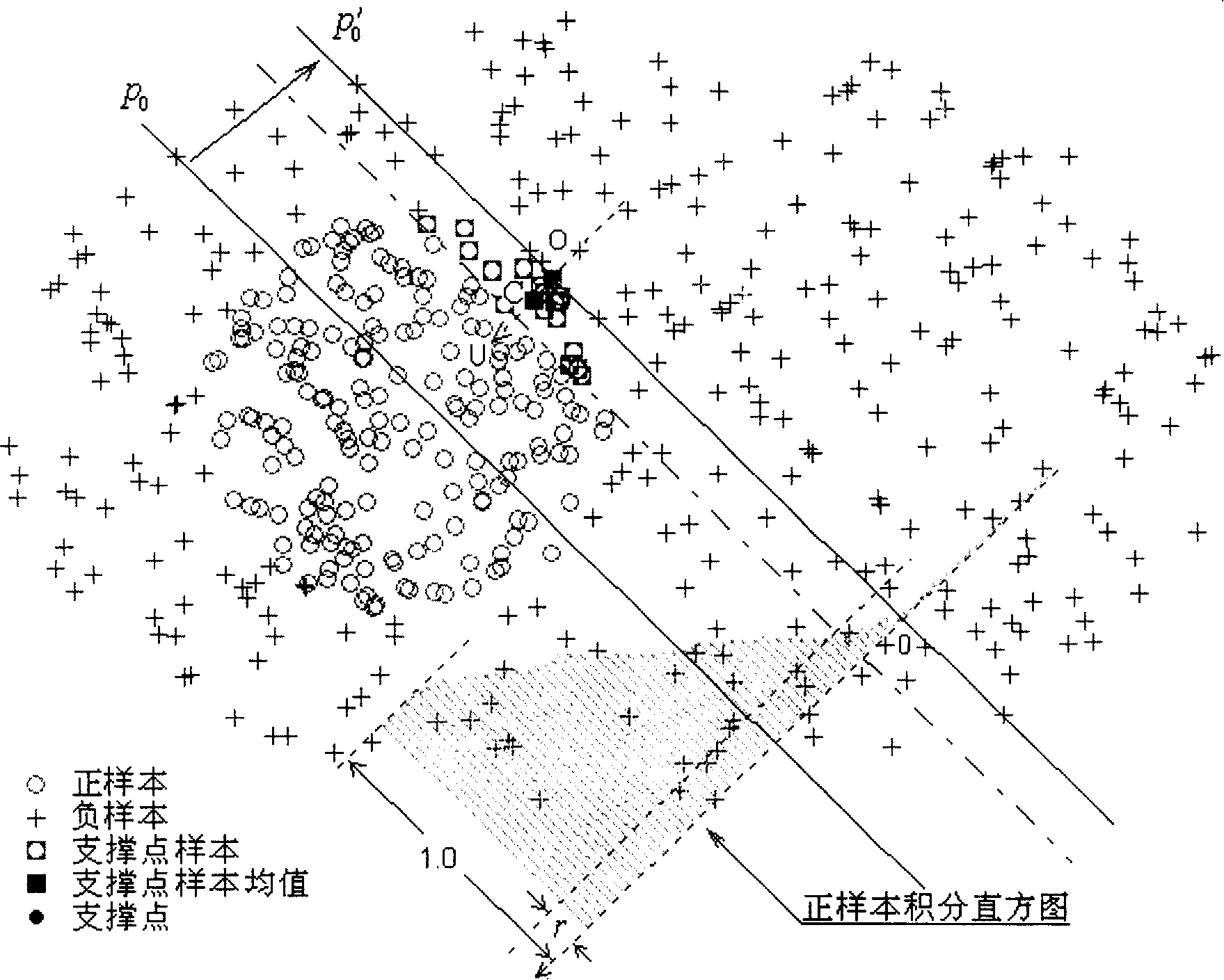

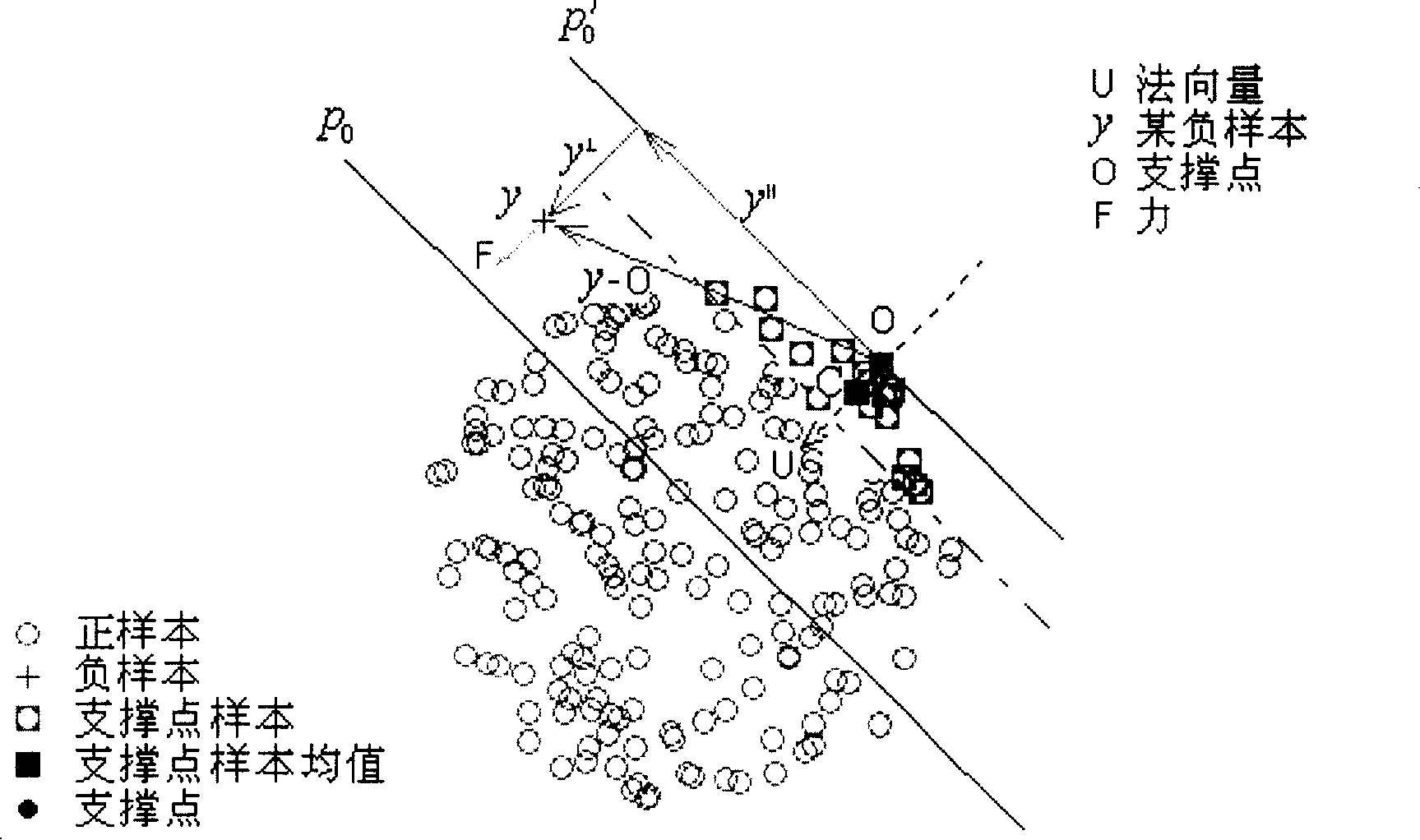

Method for analyzing and training linear classifier based on torque

InactiveCN101226520ADigital computer detailsCharacter and pattern recognitionPattern recognitionFace detection

The invention discloses a method for training linear classifier based on torque analysis, which uses an initialization method to generate a hyperplane in data space, processes iterate training on the initialized linear classifier based on torque analysis, stops the training according to iterate ending conditions to obtain one linear classifier with local optimization. The invention uses torque analysis to build linear classifier with wide application in pattern recognition, which leads physical force and torque concepts into machine learning, to train one linear classifier with local optimization. The classifier trained by the inventive method can reach local minimum correct reject rate. The invention has wide application of computer vision fields as face detection and vehicle detection, with significant theory and practical values.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

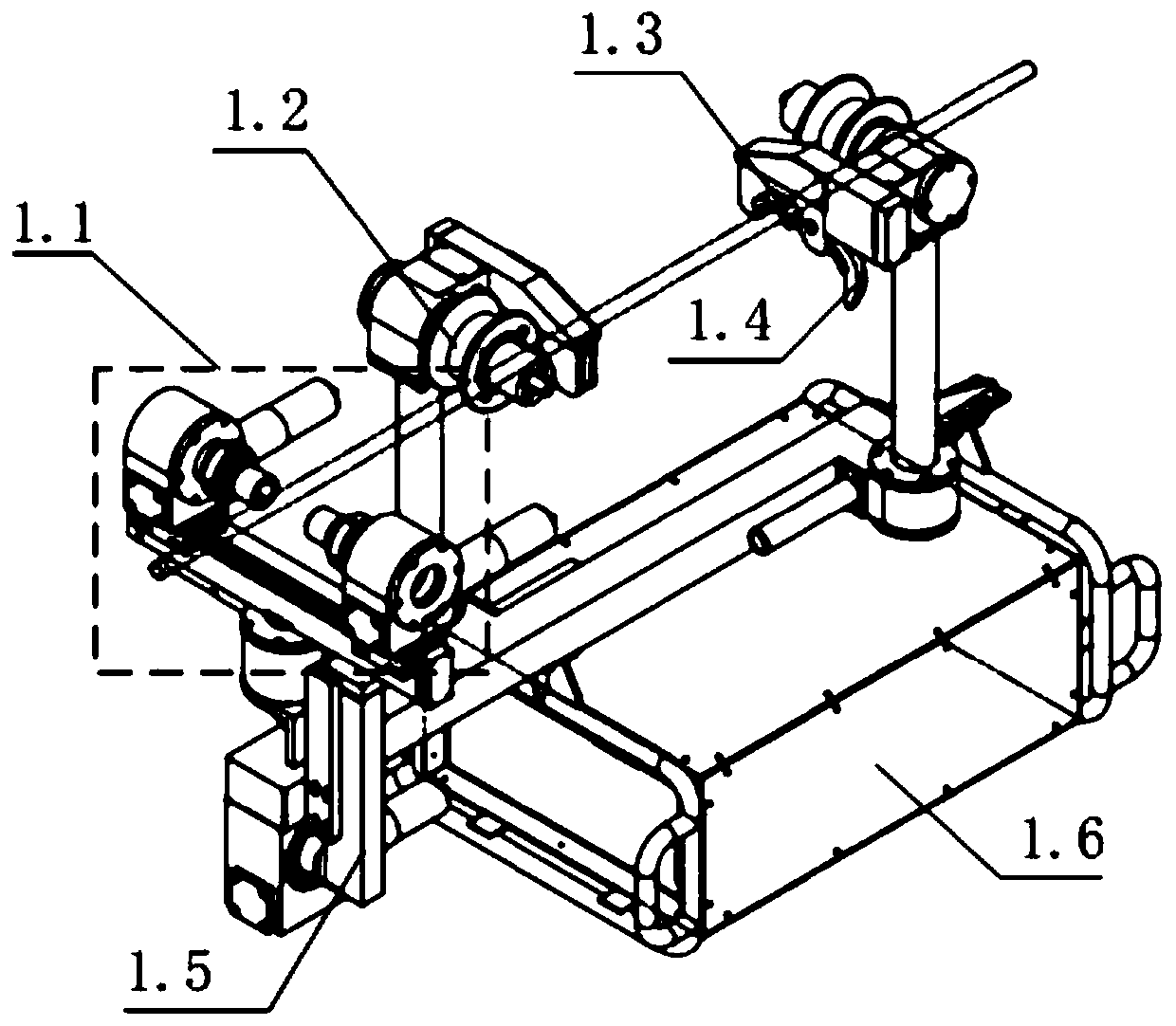

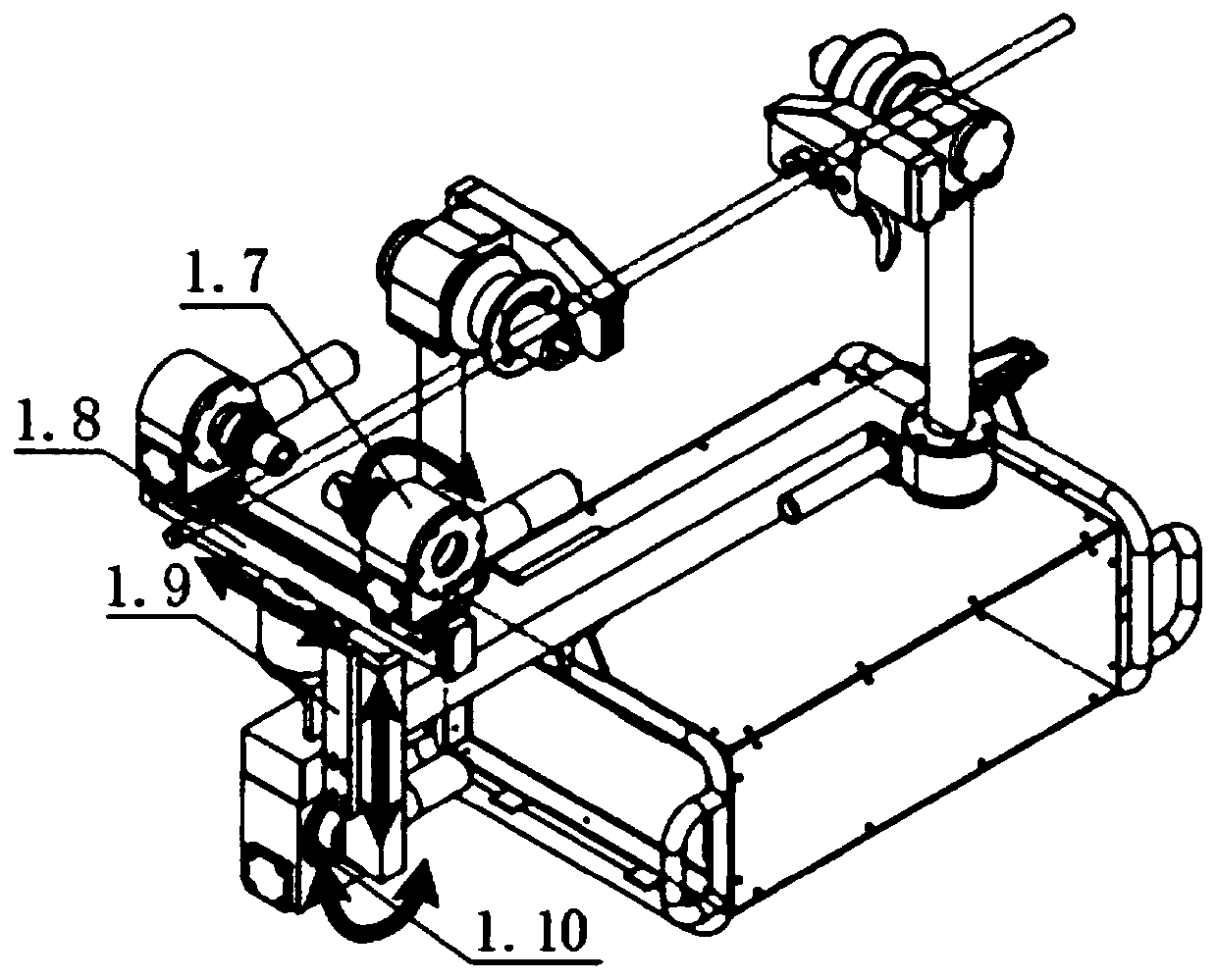

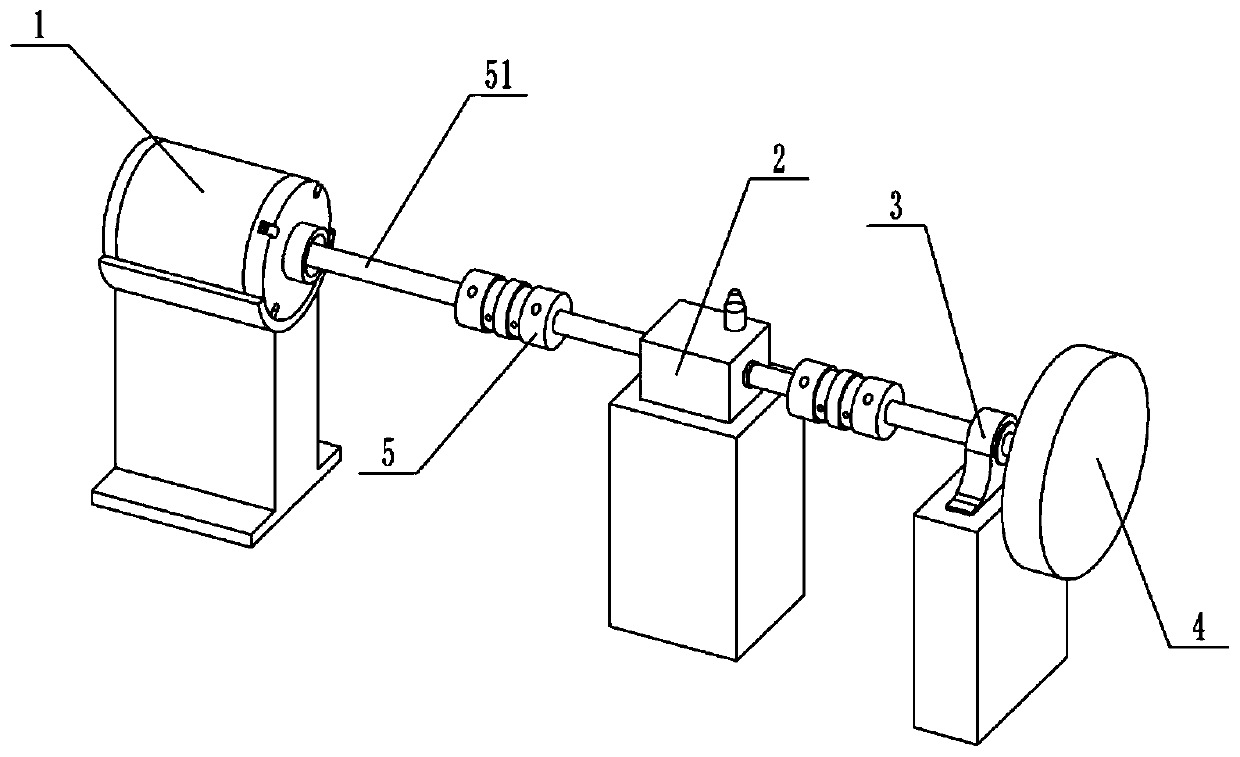

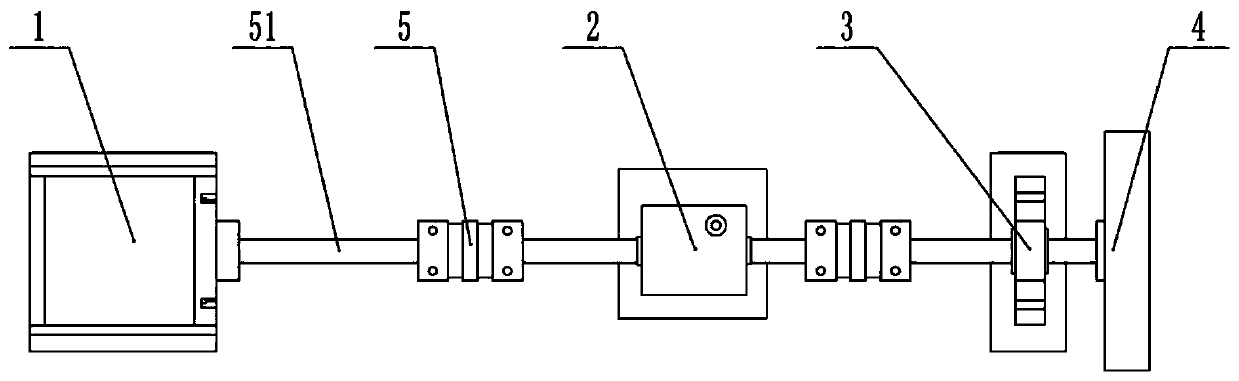

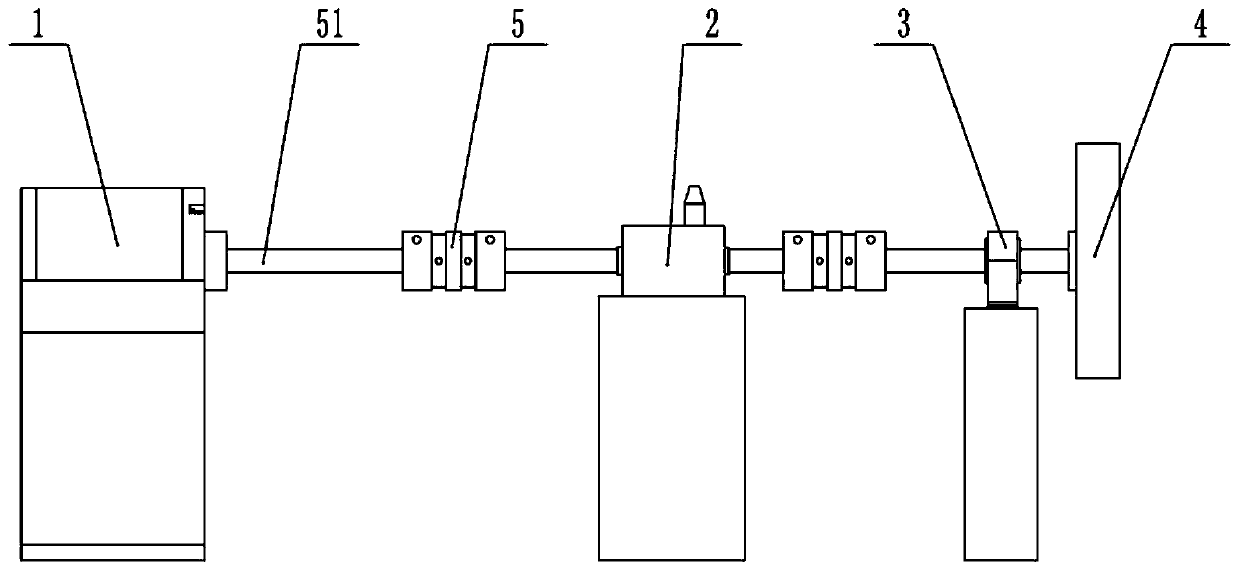

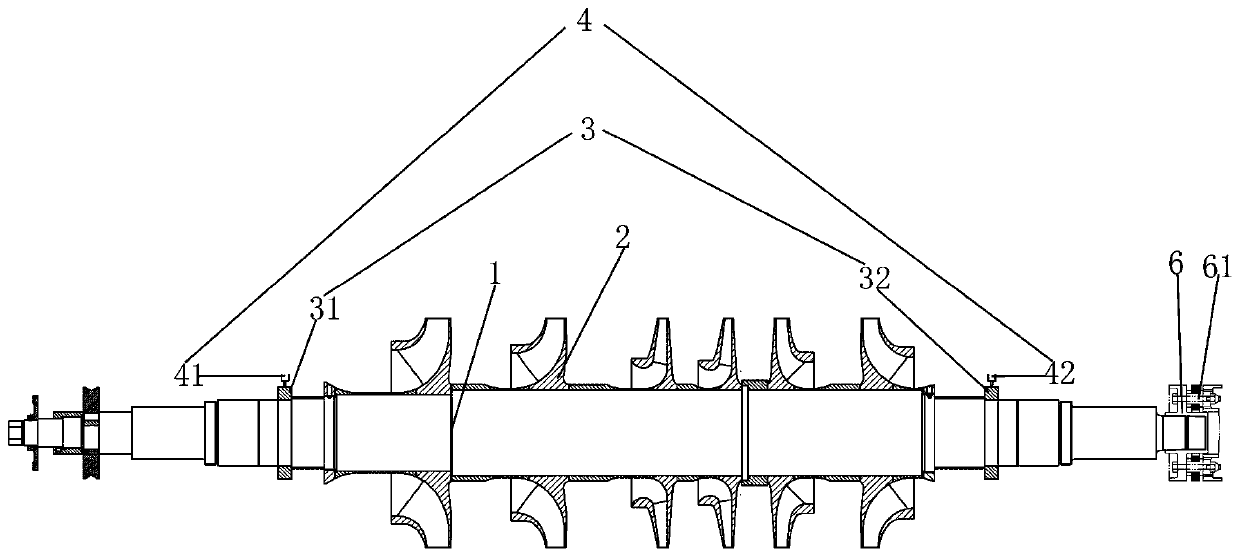

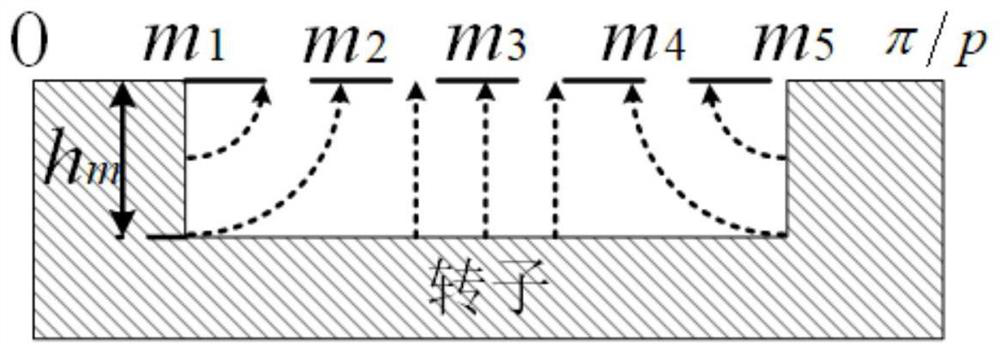

Electromagnetic harmonic oscillating tooth transmission torque characteristic analysis system and analysis method thereof

ActiveCN111207871AGuaranteed single variableAccurate measurementMachine part testingApparatus for force/torque/work measurementTorque analysisCoupling

The invention belongs to the field of transmission, and particularly relates to an electromagnetic harmonic oscillating tooth transmission torque analysis system and an analysis method thereof. The electromagnetic harmonic oscillating tooth transmission torque analysis system comprises an electromagnetic harmonic oscillating tooth transmission device body and an end cover. A pressure sensor is arranged on the surface of a flexible gear. The system further comprises a torque tester, a coupling and a flywheel. Racks are correspondingly arranged on the electromagnetic harmonic oscillating tooth transmission device body and the torque tester, the electromagnetic harmonic oscillating tooth transmission device body, the torque tester and the flywheel are connected through output shafts, and theoutput shafts are fixed through the coupling. A camera and a plurality of illuminating lamps are arranged on the end cover. Each illuminating lamp is provided with an independent control circuit, andthe control circuits are closed after the electromagnetic harmonic oscillating tooth transmission device body and the end cover are installed. Compared with a traditional analysis system of the electromagnetic harmonic oscillating tooth, the scheme combines the results of stress analysis and the torque tester, the electromagnetic harmonic oscillating tooth can be reliably analyzed by utilizing a common torque tester, and the accuracy of transmission torque is increased to the maximum extent.

Owner:YANSHAN UNIV

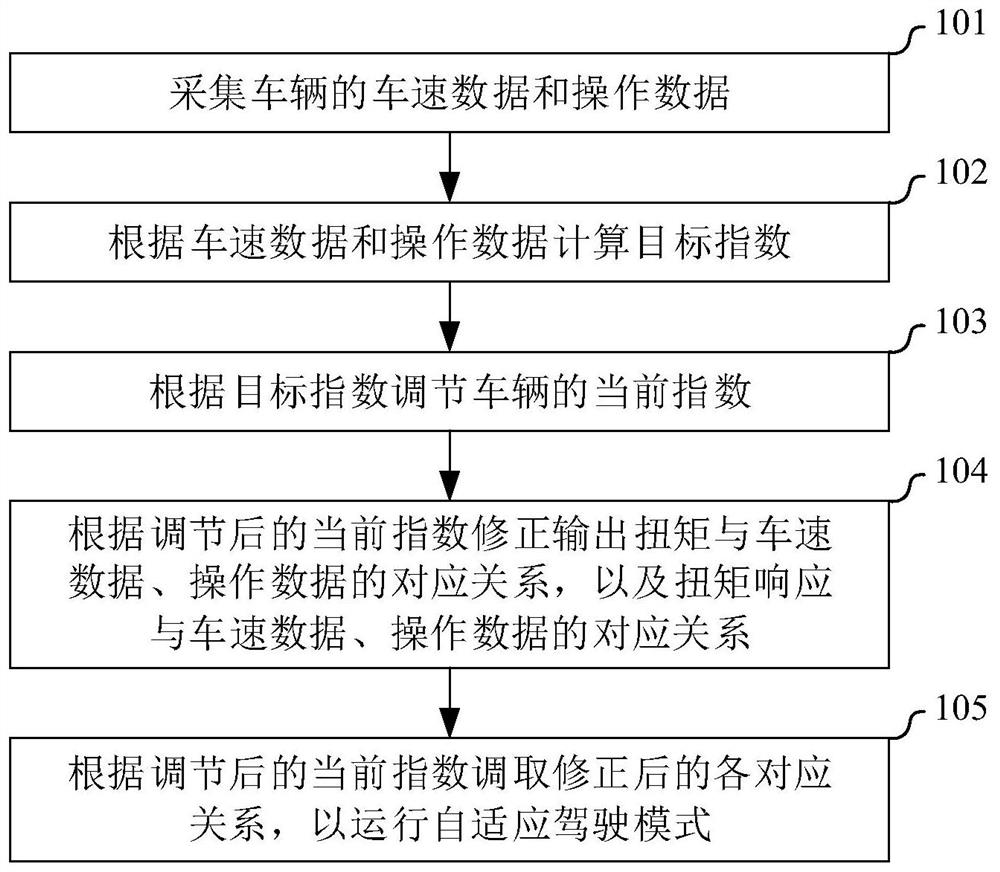

Self-adaptive driving mode control method and device

The invention relates to a self-adaptive driving mode control method and device, and a computer readable storage medium. The control method comprises the following steps: collecting vehicle speed data and operation data of a vehicle are collected; calculating a target index according to the vehicle speed data and the operation data; adjusting the current index of the vehicle according to the target index; correcting the corresponding relation between the output torque and the vehicle speed data and the operation data and the corresponding relation between the torque response and the vehicle speed data and the operation data according to the adjusted current index; and calling the corrected corresponding relations according to the adjusted current indexes so as to operate the self-adaptive driving mode. According to the invention, adaptive learning can be carried out according to the driving style and the driving habit of the driver, and the torque analysis and the torque filtering of the vehicle can be adjusted in real time, so that personalized driving requirements of different users and different road conditions can be met.

Owner:WM SMART MOBILITY (SHANGHAI) CO LTD

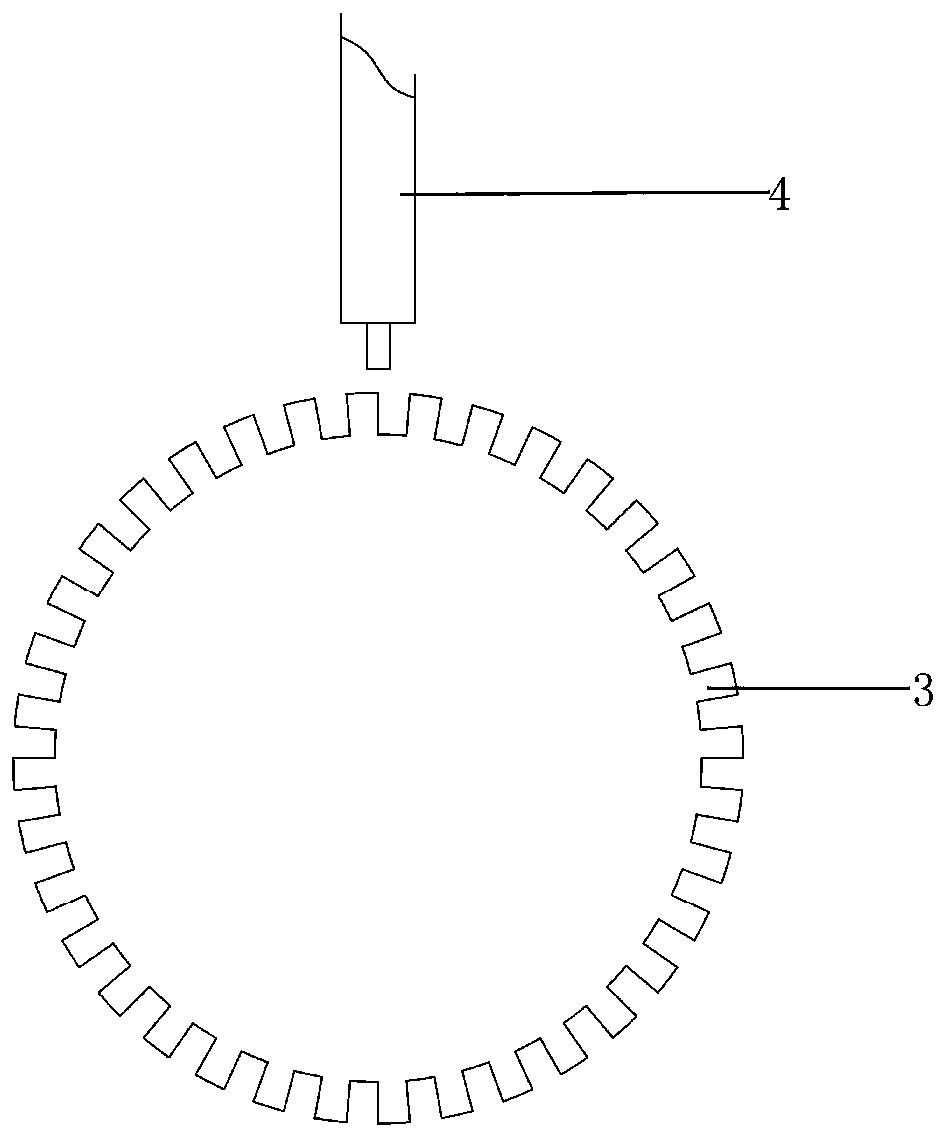

Centrifugal compressor torque monitoring device

ActiveCN108005939BTorque monitoringTimely detection of power changesPump componentsPump controlTorque analysisData information

The invention relates to a centrifugal compressor torque detection device, which relates to the technical field of structural design of centrifugal compressor safety maintenance machinery, and is used for monitoring the torque change of the rotor of the centrifugal compressor. At the position of the end, grooves are arranged at equal angular intervals along the circumferential direction of the torque indexing plate; the phase probe is matched with the torque indexing plate and arranged on the casing to detect the torque change of the torque indexing plate and generate the first signal; The torque analysis device is electrically connected with the phase probe, and is used to receive, calculate and analyze the first signal, obtain the torque and rotational speed of the rotor of the centrifugal compressor, and obtain the power of the centrifugal compressor according to the torque and rotational speed. The invention can obtain the responsible equipment for the torque change through the power change, distinguish the power change caused by the failure of the driving equipment or a certain compressor, and provide accurate data information for the decision maker to determine the responsible equipment for maintenance at the first time.

Owner:SHENYANG TURBO MASCH CORP

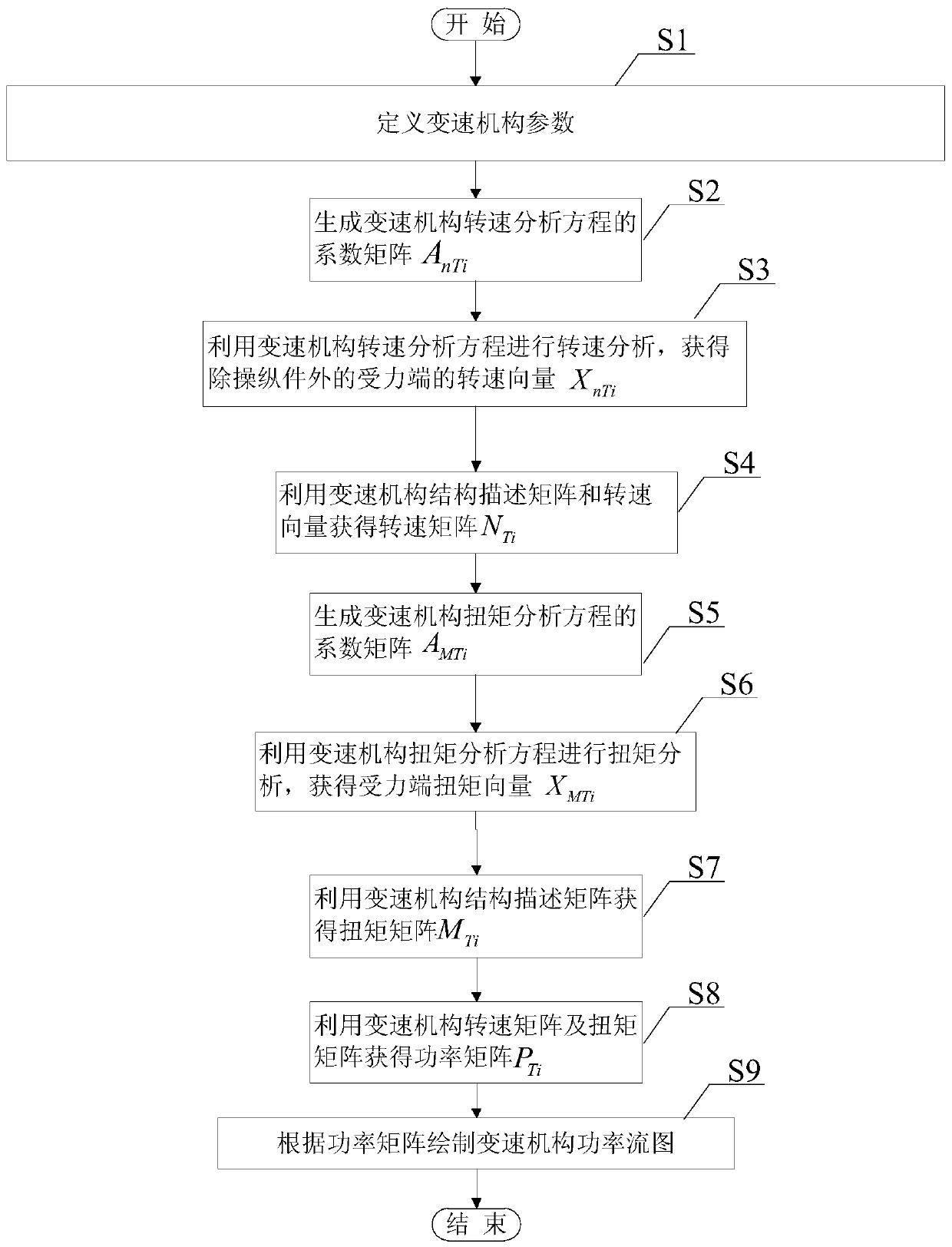

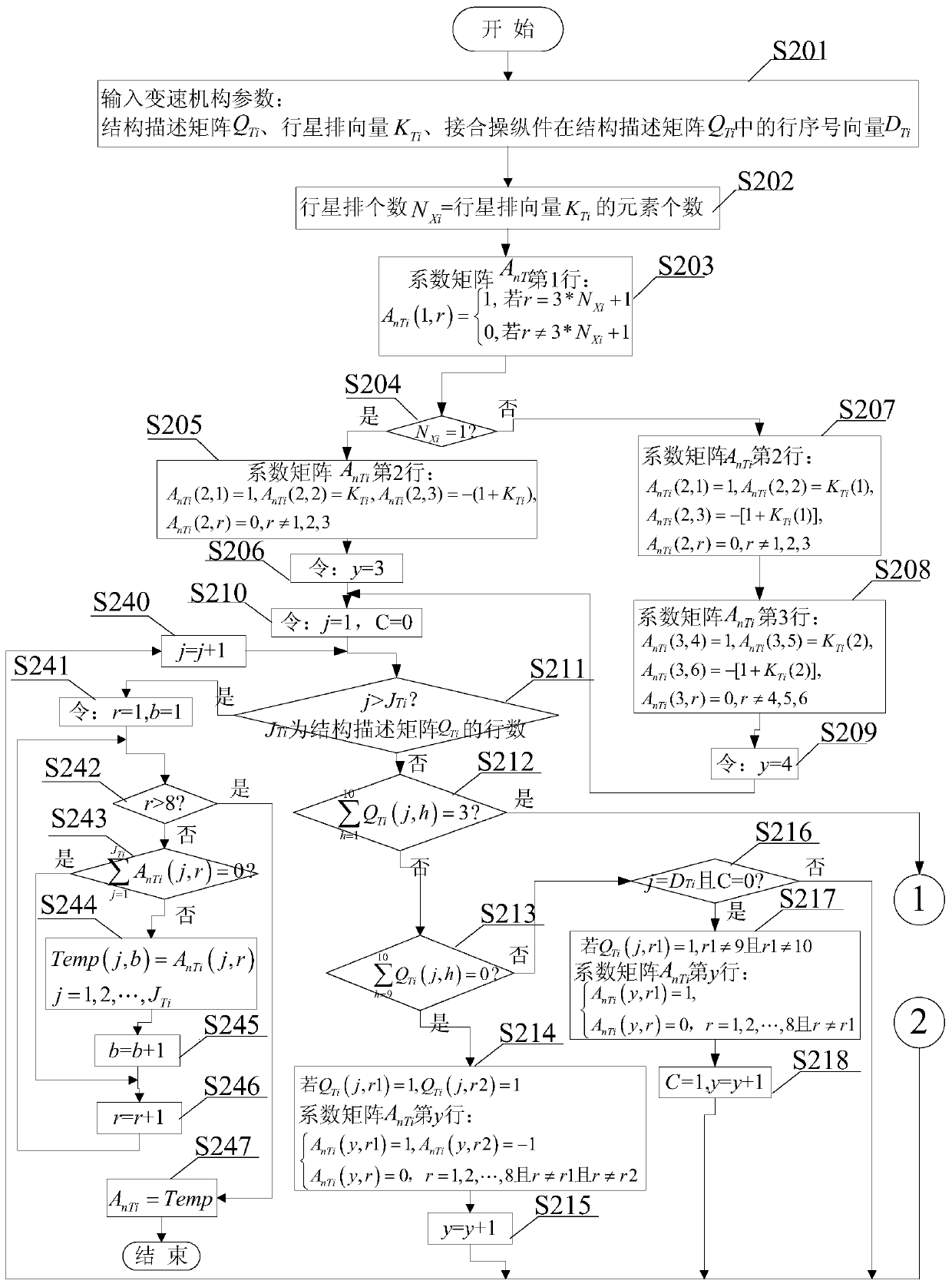

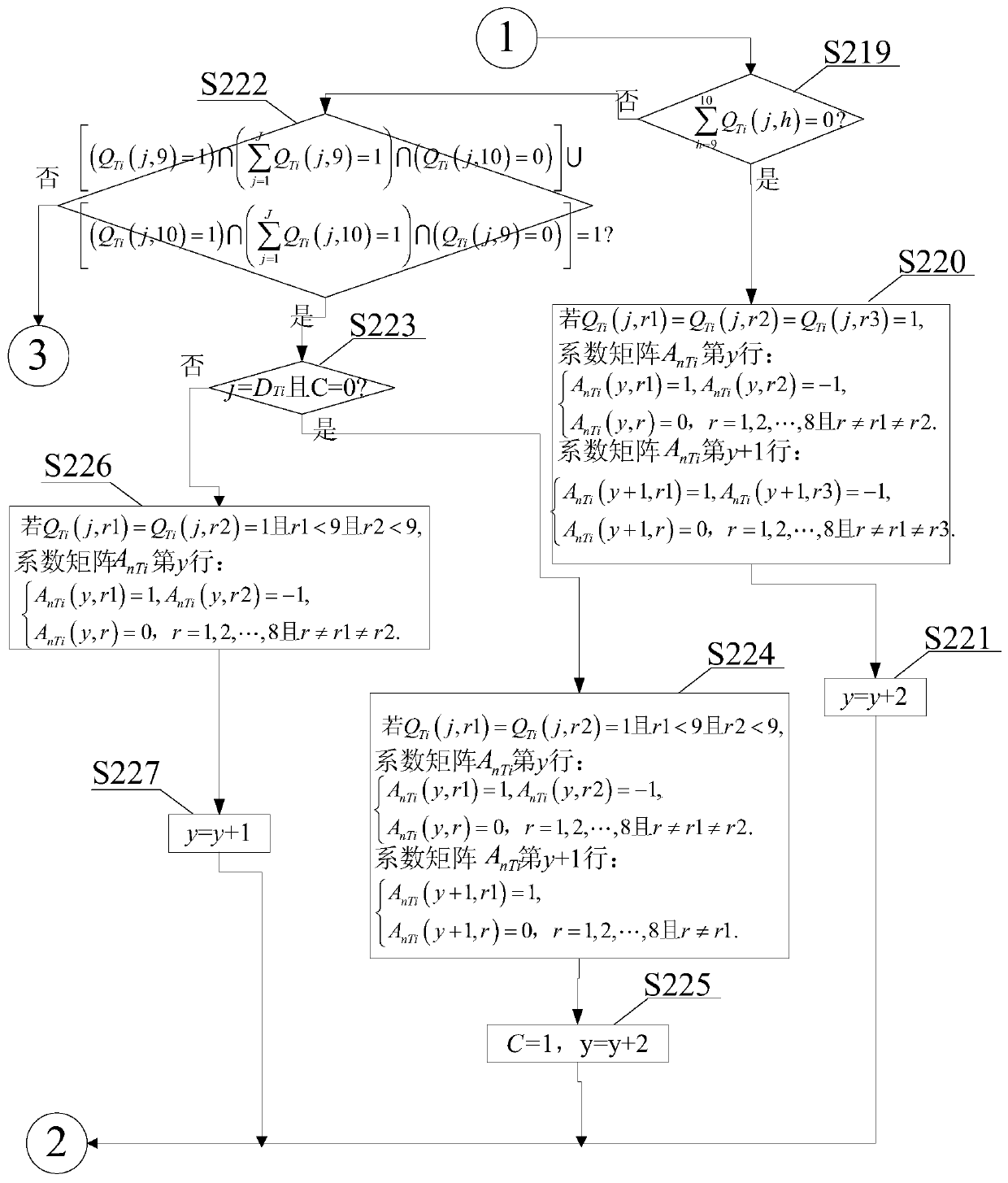

A general analysis method for the power flow of the transmission mechanism of an electric drive vehicle

ActiveCN106257260BLow costImprove work efficiencyMachine gearing/transmission testingDesign optimisation/simulationTorque analysisPower flow

The invention relates to an analytical method for power circulation of an electric drive vehicle speed change mechanism. The method comprises the steps that parameters of the speed change mechanism are defined; a coefficient matrix of a rotational speed analysis equation of the speed change mechanism is constructed; rotational speed vectors of all stressed ends, except operation parts, relative to the input end are acquired; a structural description matrix of the speed change mechanism and the rotational speed vectors are utilized for generating a rotational speed matrix; a coefficient matrix of a torque analysis equation of the speed change mechanism is constructed; the torque analysis equation of the speed change mechanism is subjected to torque analysis, and torque vectors of all the stressed ends relative to the input end are acquired; a torque matrix is generated; the rotational speed matrix and the torque matrix are utilized for generating a power matrix; a power flow graph of the speed change mechanism is drawn. Through the analytical method, rotational speed analysis, torque analysis and power flow analysis of any speed change mechanism can be carried out in a programmed mode, and design efficiency is effectively improved.

Owner:CHINA NORTH VEHICLE RES INST

Method for on-line fault diagnosis of vibration threading and its equipment

InactiveCN1264637CEasy to detectImplement fault diagnosisAutomatic control devicesThread cutting machinesControl cellEngineering

The present invention relates to a vibration threading on-line fault diagnosis method and its equipment, including vibration threading machine unit, drive and control unit of stepper motor and torque measuring unit, a torque sensor and a threading torque analysis and storage system are series-connected between its main sahft input end and threading grip holder, and said torque sensor is fixedly connected with main shaft of threading machine by means of elastic holding mechanism formed from elastic holder base cover, locking cover and locking screw. Said invention adopts the stepper motor as vibration source and threaidng force source, utilzies torque sensor to receive moving force and vibration source signal transferred by main shaft of machine tool of machine unit, and unilizes the signal amplification.

Owner:JIANGSU UNIV

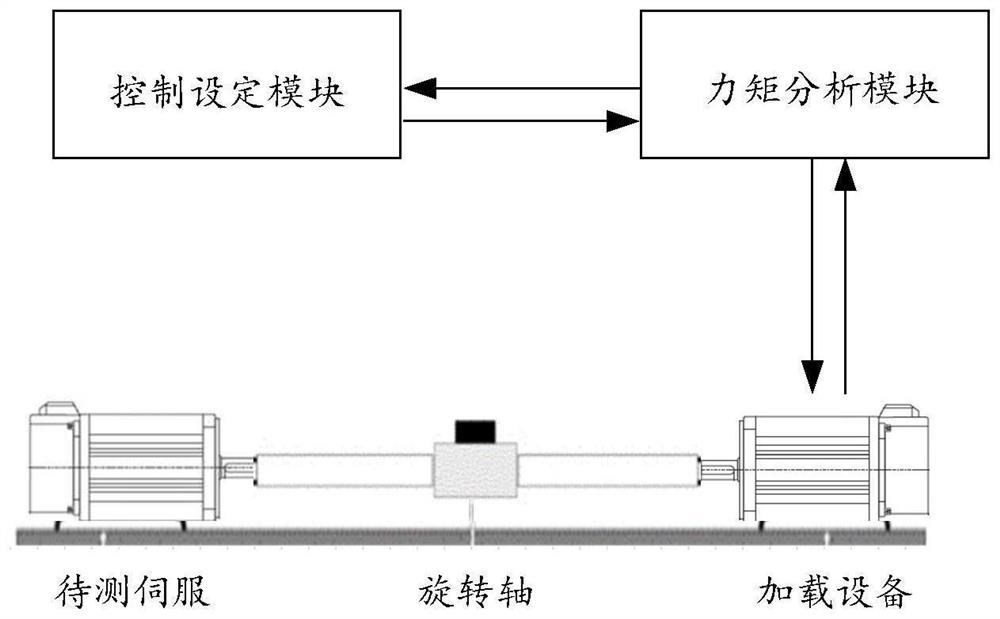

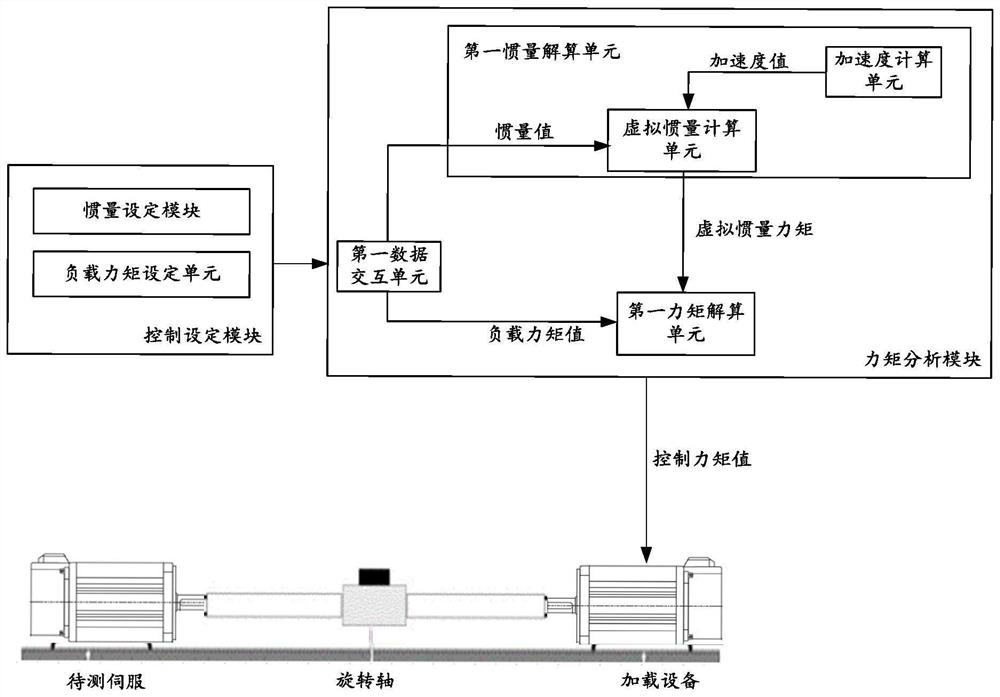

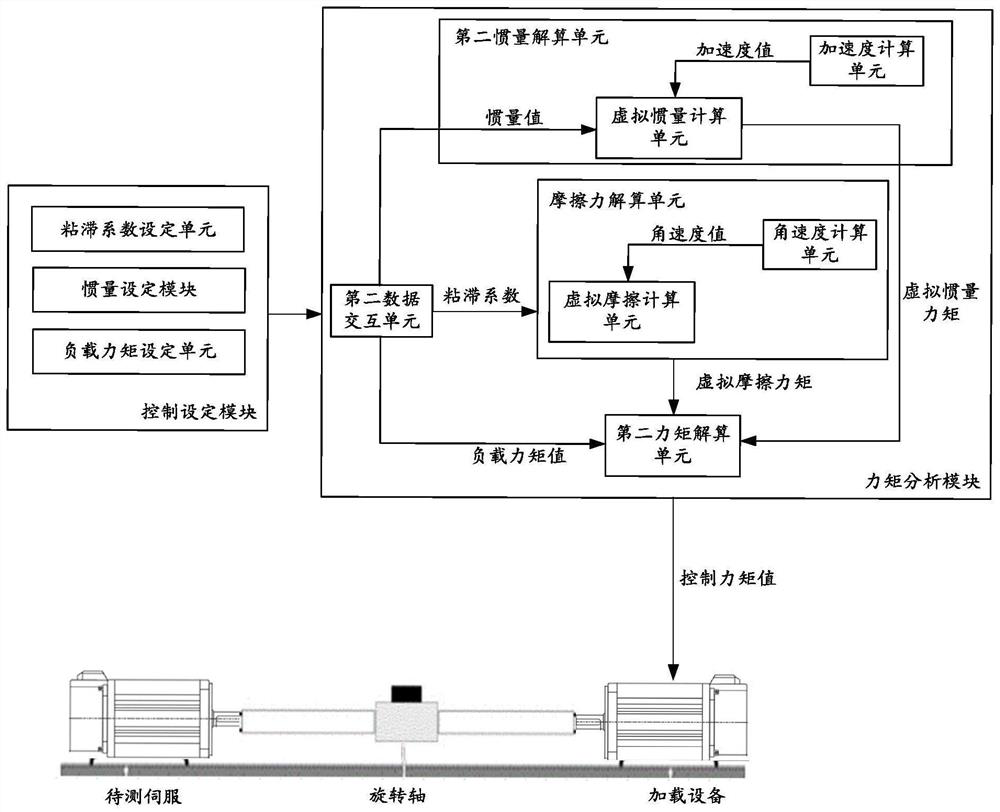

Servo test system

A servo test system comprises a control setting module, a torque analysis module and a loading device, and the loading device is connected with a servo to be tested through a rotating shaft. The control setting module is used for determining an inertia value and a load torque value for testing the to-be-tested servo, and sending the inertia value and the load torque value of the to-be-tested servo to the torque analysis module; the torque analysis module is used for acquiring an acceleration value of a rotating shaft of the servo to be tested in real time, determining a control torque value according to the received inertia value, the load torque value and the acquired acceleration value, and sending the control torque to the loading equipment; and the loading equipment is used for receiving the control torque value and loading the control torque corresponding to the control torque value to the servo to be tested connected with the rotating shaft of the loading equipment. According to the invention, the inertia value and the load torque value for testing the to-be-tested servo are converted into the corresponding control torque to realize the simulation test, so that the test requirements of variable inertia and variable load in the servo test process can be realized.

Owner:GUANGDONG KOSSI INTELLIGENT TECH CO LTD

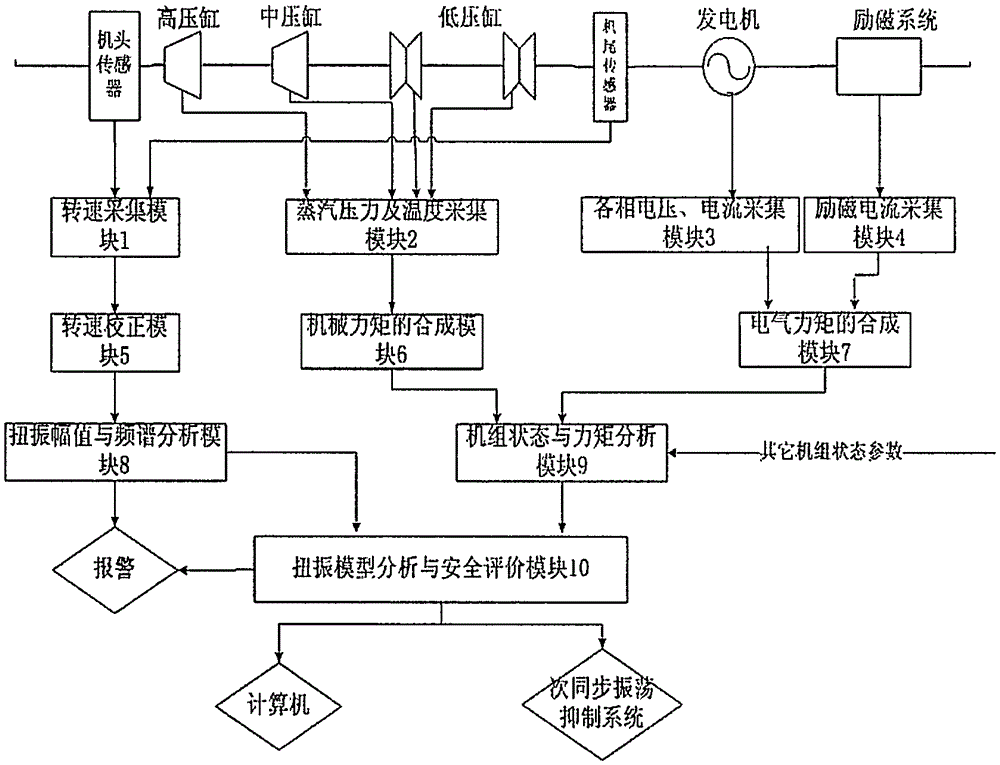

Method and System for Detection and Analysis of Subsynchronous Oscillation Signals of Large Generating Sets

ActiveCN103245913BImprove reliabilityImprove accuracyDynamo-electric machine testingTorque analysisTorsional oscillations

The invention provides a method and a system for detecting and analyzing subsynchronous oscillation signals of a large generator set. The method comprises the steps as follows: rotating speed signal collection and correction, torsional oscillation amplitude and frequency spectrum analysis, generator set status signal collection and analysis, and torsional oscillation model analysis and safety evaluation. The system comprises three parts of a torsional oscillation amplitude and frequency spectrum analysis module, a generator set status and torque analysis module, and a torsional oscillation model analysis and safety evaluation module. The mechanical quantity and the electrical quantity of the generator set are taken as signals, extracted during oscillation and taken as analysis objects, so that not only are the reliability and the accuracy of the signals are enhanced, but also subsynchronous oscillation of the generator set can be deeply analyzed on the basis of detection signals, the oscillation frequency, amplitude and reason of the generator set, and the temperature, the torsional stress, the deformation and the loss accumulation of shafting can be comprehensively analyzed, and good foundation work is laid for a subsequent restrain system.

Owner:SHANGHAI JIAO TONG UNIV

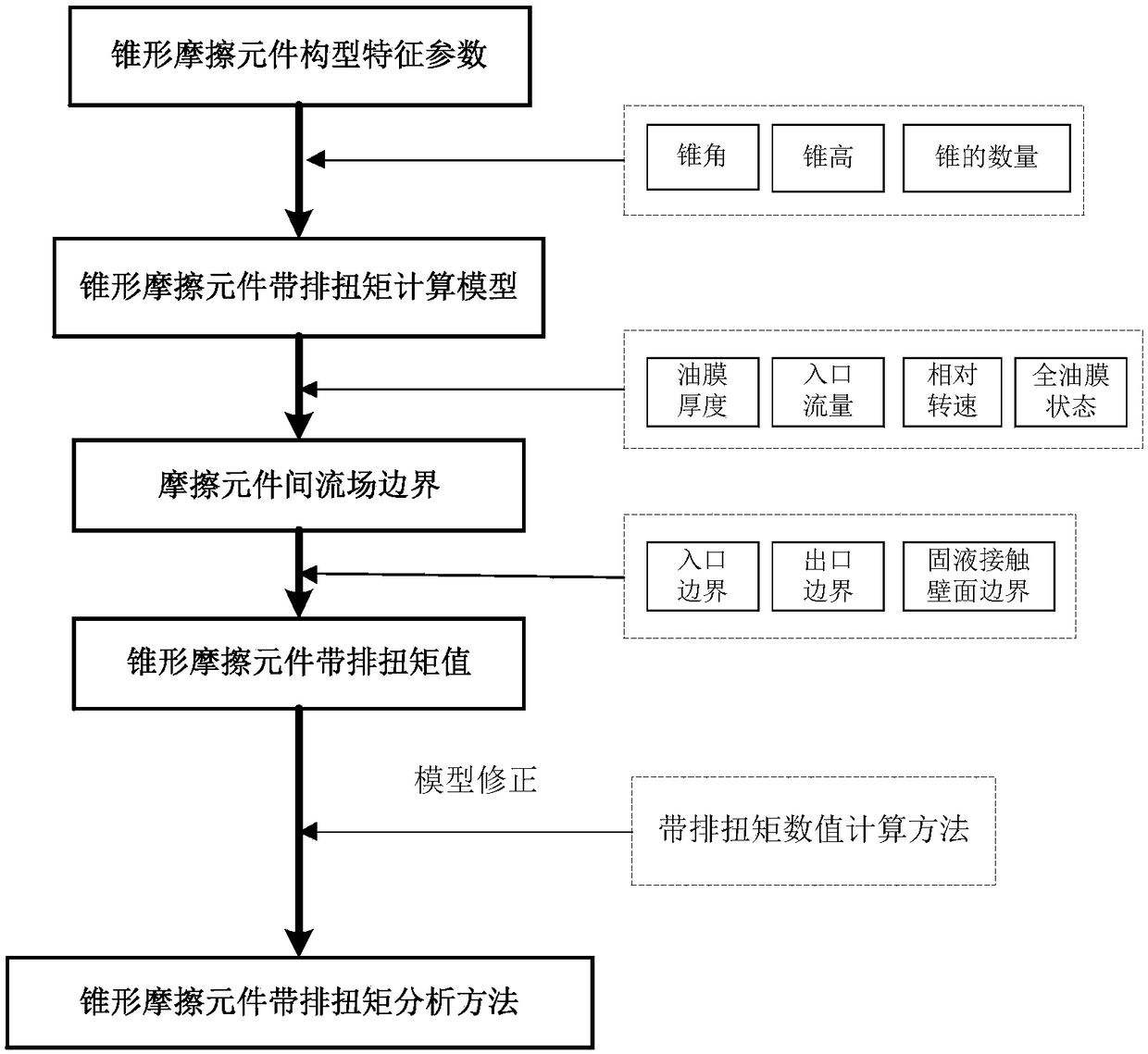

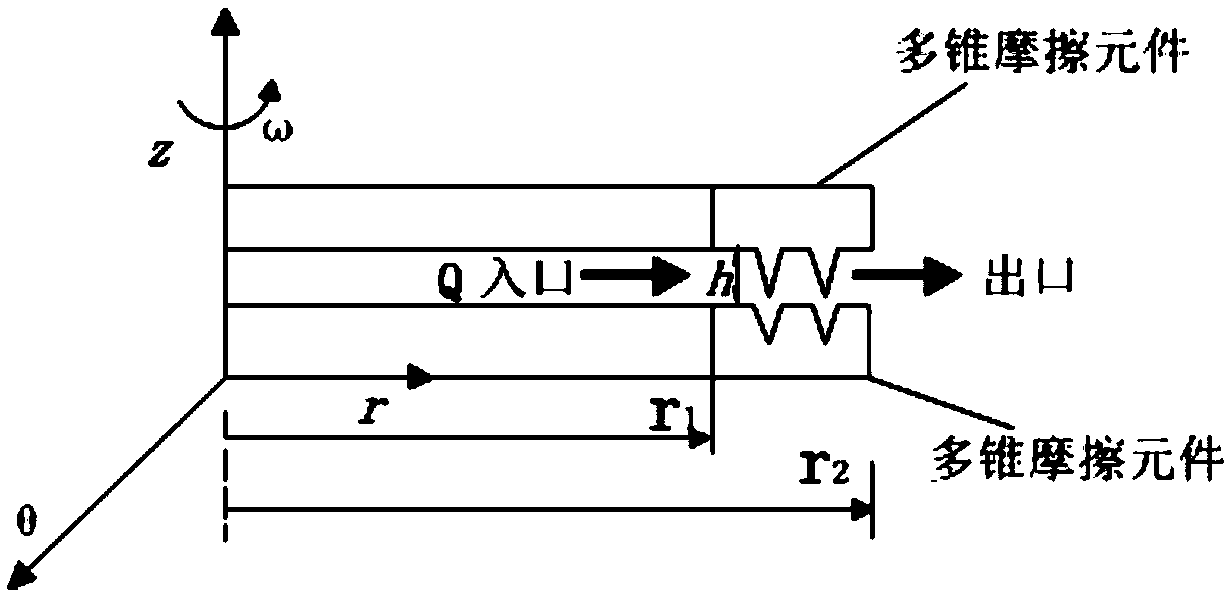

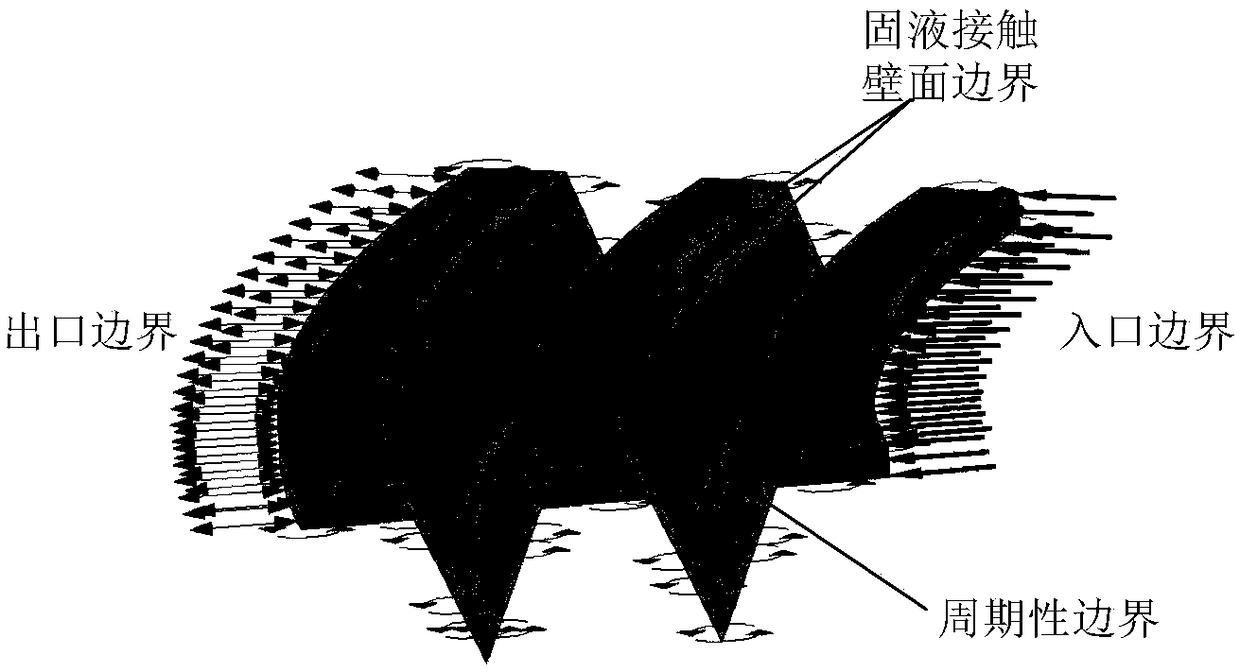

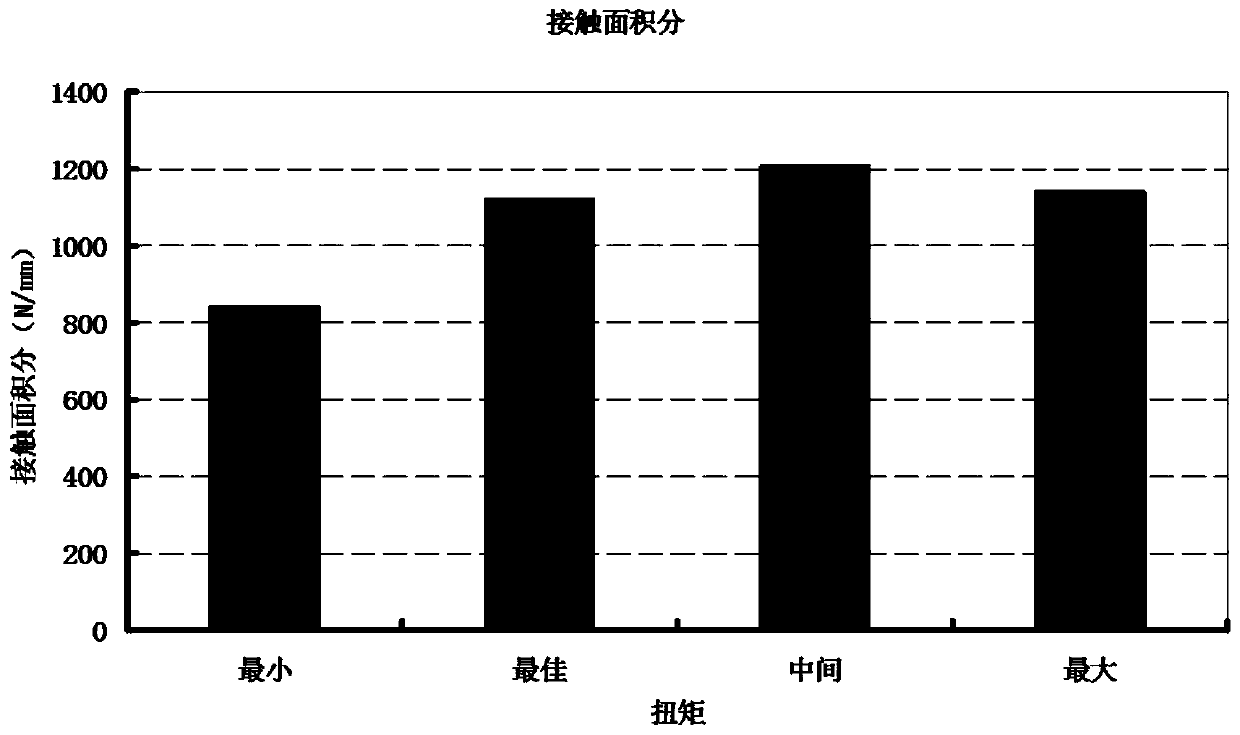

A method for analyzing belt row torque of conical friction element

InactiveCN109271682AImprove accuracyGeometric CADDesign optimisation/simulationLow speedTorque analysis

A method for analyzing belt row torque of conical friction element includes: establishing belt-row torque analysis model of conical friction element, determining flow field boundary between conical friction elements and modifying calculation model of belt-row torque of conical friction element, according to the loss of the tapered friction element in idle state, establishing the analysis model ofthe tapered friction element torque by considering the configuration characteristic parameters of the tapered friction element and the working conditions of the tapered friction element, such as the clearance of the tapered friction element, the flow rate of lubricating oil and the relative rotational speed, etc, determining the boundary of the flow field between the conical friction elements, using the finite element method to calculate the torque of tapered friction element, and modifying the model of tapered friction element by comparing with the numerical calculation method, and developping a new method of tapered friction element torque analysis. The method can be used not only to calculate the torque of tapered friction element at low speed but also to evaluate the loss of tapered friction element at different configurations and working conditions, which can be used as the basis for the design of comprehensive performance of tapered friction element.

Owner:BEIHANG UNIV

An analysis and evaluation method for gas sealing threads of tubing in high temperature and high pressure gas wells

ActiveCN108982076BImproves seal integrityAvoid failureMachine part testingVibration testingTorque analysisHermetic seal

The invention discloses an analysis and evaluation method for hermetic seal thread of a tubing of a high-temperature high-pressure gas well. The hermetic seal applicability of a limit tolerance samplein the condition load and stress correction environment under different make-up torques is tested and evaluated by analyzing the make-up torque of the hermetic seal thread according to down-hole workenvironment characteristics of the high-temperature high-pressure gas well and structural characteristics of the thread; according to analysis on the make-up torque of the hermetic seal thread, the limit tolerance and torque are selected to analyze hermetic seal finite elements under the condition load spectrum, and the down-hole condition load spectrum sealing after make-up of the hermetic sealthread is analyzed; and thread dynamic-load anti-fatigue analysis in the gas production process of a down-hole tubing string is analyzed, an applicability test and evaluation process is determined according to links likely to fail in analysis, and the applicable reliability of the thread is evaluated and analyzed comprehensively. The method can be widely applied to high-temperature high-pressure gas wells as well as unconventional multi-segment high cracking gas wells, especially to evaluate selection and applicability of threads of well-completion tubing strings of deep and ultradeep wells inTarim and southwest oil and gas fields.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

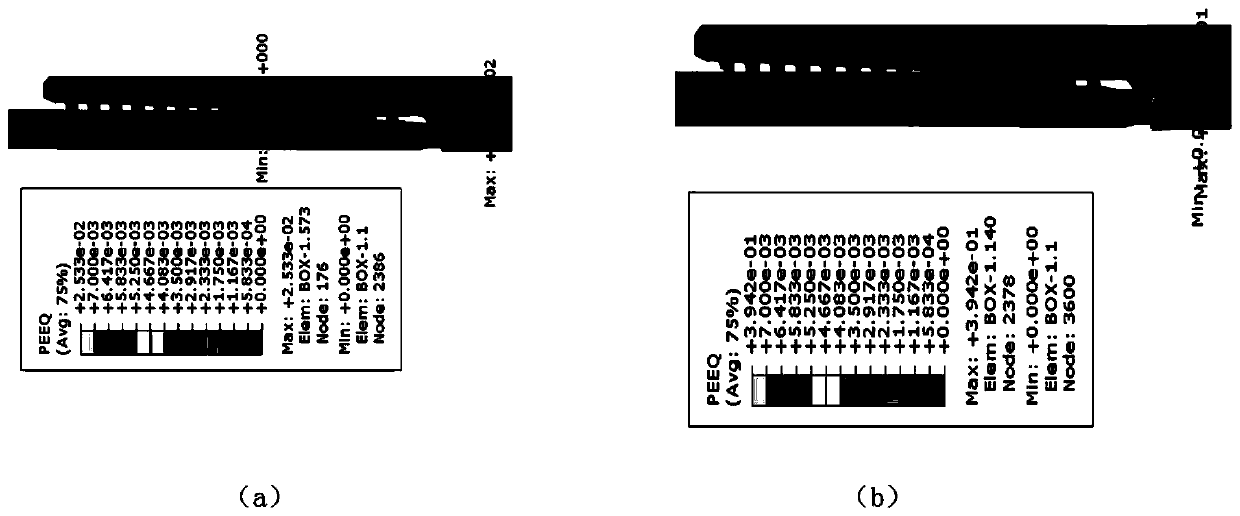

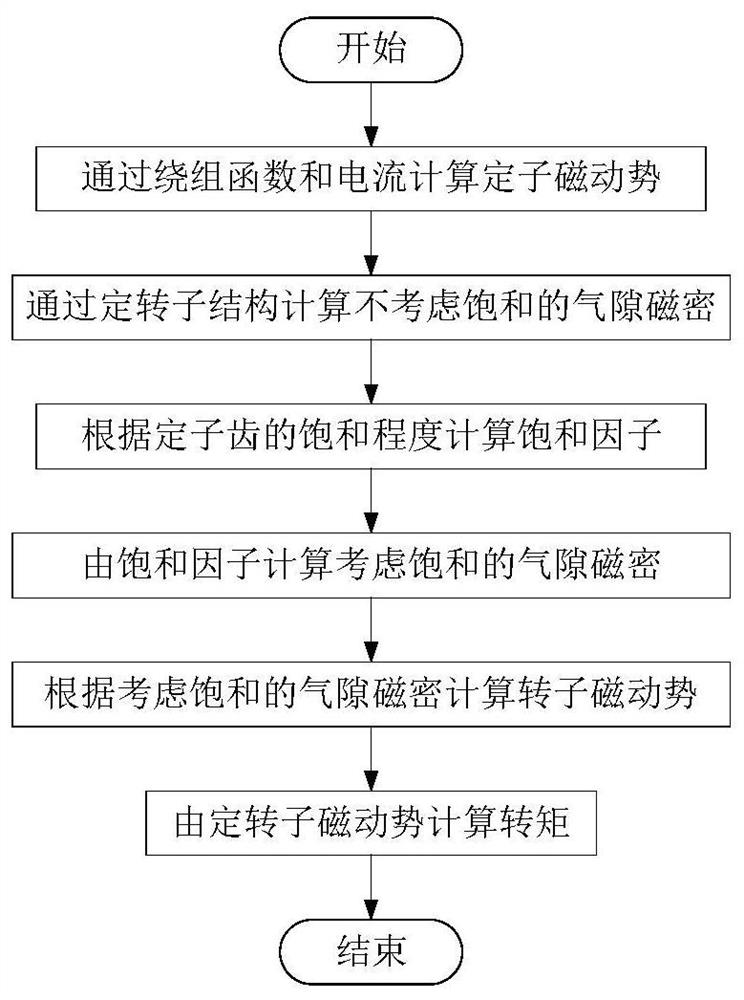

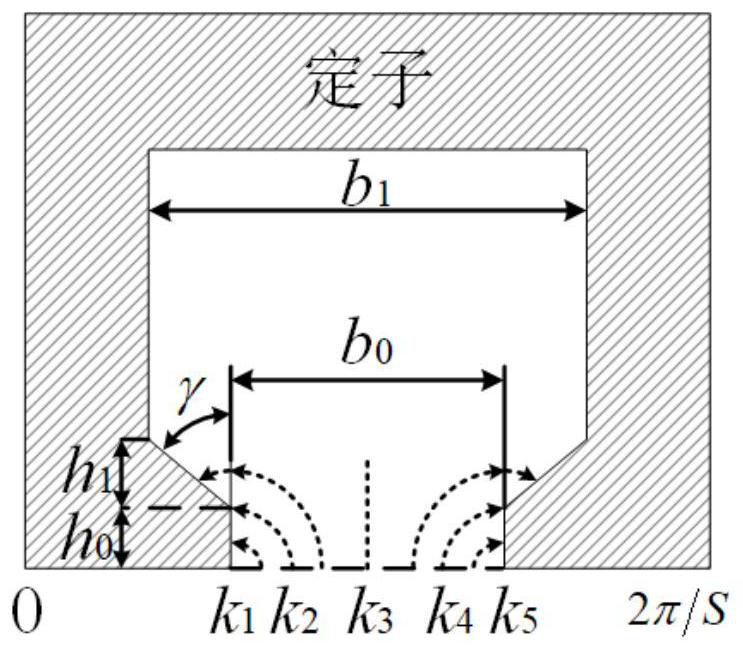

Torque analysis method of synchronous reluctance motor considering magnetic saturation

InactiveCN113037171AHigh precisionImprove the efficiency of torque calculationElectronic commutation motor controlAC motor controlSynchronous reluctance motorTorque analysis

The invention discloses a torque analysis method of a synchronous reluctance motor considering magnetic saturation. The method comprises the following steps of: 1, calculating air gap flux density; concretely, calculating through a winding function, stator magnetomotive force, stator slotting and a rotor structure to obtain air gap flux density without considering magnetic saturation; 2, for the magnetic saturation of the stator core, calculating a saturation factor of each stator tooth part by adopting an iteration method, and calculating the air gap flux density considering the magnetic saturation according to the saturation factor and the air gap flux density not considering the saturation; and 3, calculating the torque, concretely calculating the reluctance torque through the stator magnetomotive force, the rotor magnetomotive force and the air gap flux density considering magnetic saturation. According to the method, the torque of the offset asymmetric synchronous reluctance motor considering stator tooth saturation is analyzed for the first time, and the scheme can be expanded to other motors.

Owner:JIANGSU UNIV

Electric vehicle and its torque analysis method and torque analysis system

InactiveCN106853780BImprove user experienceImprove recycling efficiencySpeed controllerElectric energy managementTorque analysisElectric machine

The invention discloses an electric car and a torque analysis system and method thereof. The torque analysis method comprises the following steps that according to the speed of the car, the opening degree of an acceleration pedal and the rotating speed of a driving motor, initial required torque T1 of the driving motor when the acceleration pedal is stamped is obtained; according to the opening degree of the acceleration pedal and the opening degree changing rate of the acceleration pedal, a first required torque compensation coefficient K1 is determined; according to the T1 and the K1, an ideal required torque T3 of the driving motor is obtained; according to the T3, the maximum driving torque of the driving motor and the maximum feedback torque of the driving motor, the final required torque of the driving motor is obtained. According to the torque analysis method of the electric car, it can be ensured that the torque is slowly increased when a user stamps the pedal in the using process and rapidly decreased when the user loosens the acceleration pedal, torque feedback can be performed so as to improve the energy recycling efficiency, and the user experience can be improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

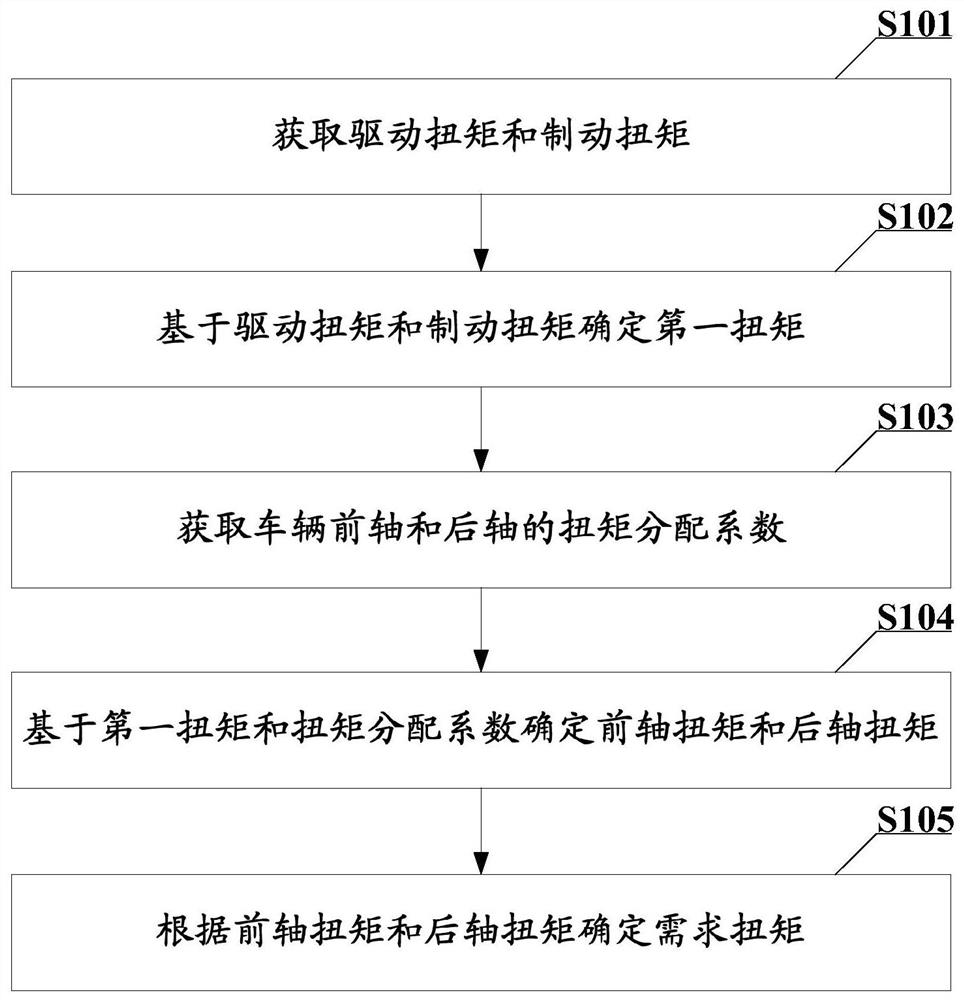

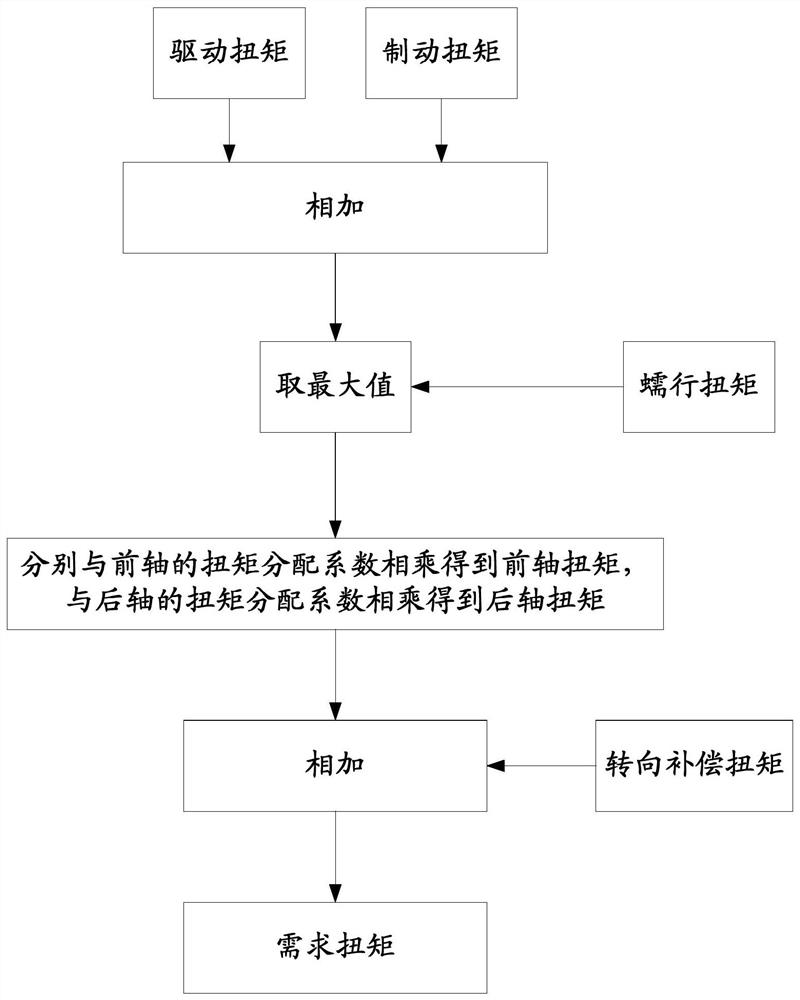

A torque analysis method, device, vehicle controller and vehicle

Embodiments of the present application provide a torque analysis method, device, vehicle controller, and vehicle. By obtaining the driving torque, braking torque, and torque distribution coefficients of the front and rear axles, the second torque is determined based on the driving torque and the braking torque. A torque, and according to the first torque, the torque distribution coefficient of the front axle and the torque distribution coefficient of the rear axle, the front axle torque and the rear axle torque are obtained, and then the required torque is determined. The entire torque analysis process relies on the driving torque and braking torque, and assigns a reasonable torque distribution coefficient between the front axle and the rear axle, so that the final required torque is more reasonable and the driving experience of the vehicle is better.

Owner:四川阿尔特新能源汽车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com