High-precision universal torque loading device and method

A torque loading and universal technology, applied in the direction of measuring devices, strength characteristics, and the use of stable torque to test the strength of materials, etc., can solve problems affecting torque analysis results, etc., to achieve wide applicability, reliable technical support, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

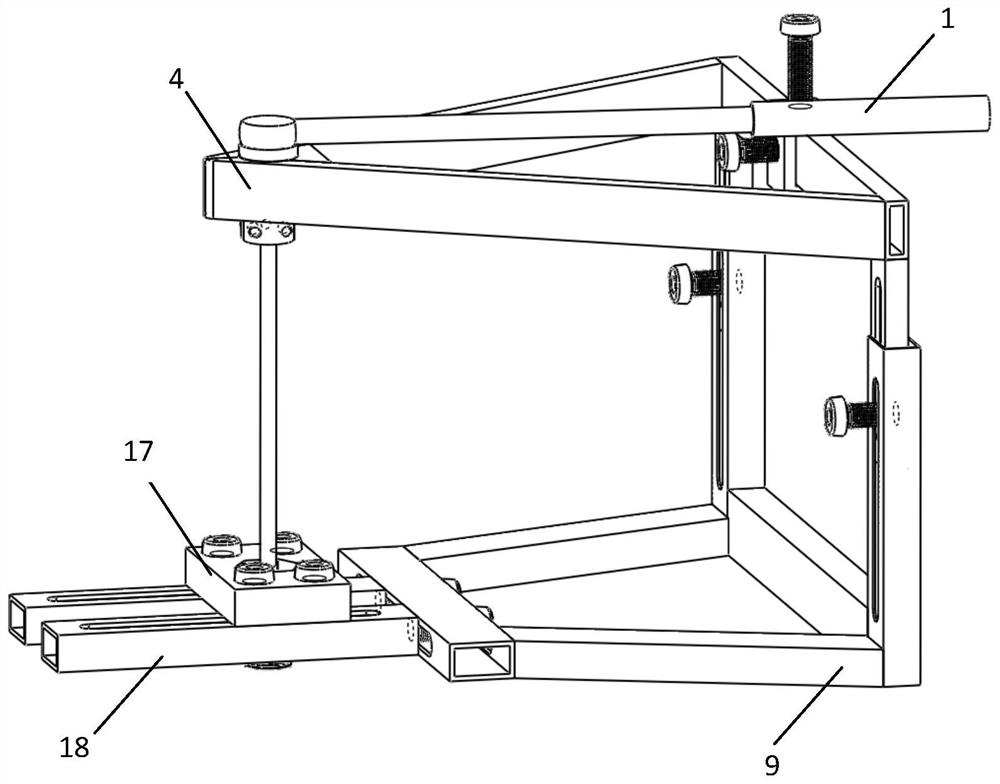

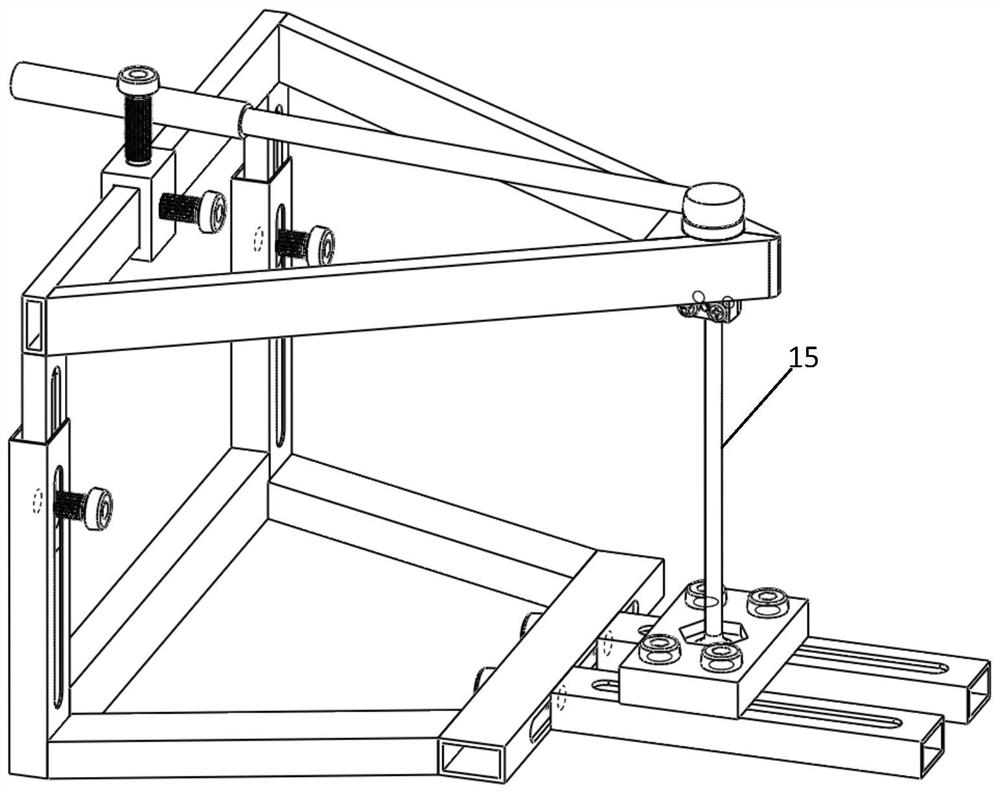

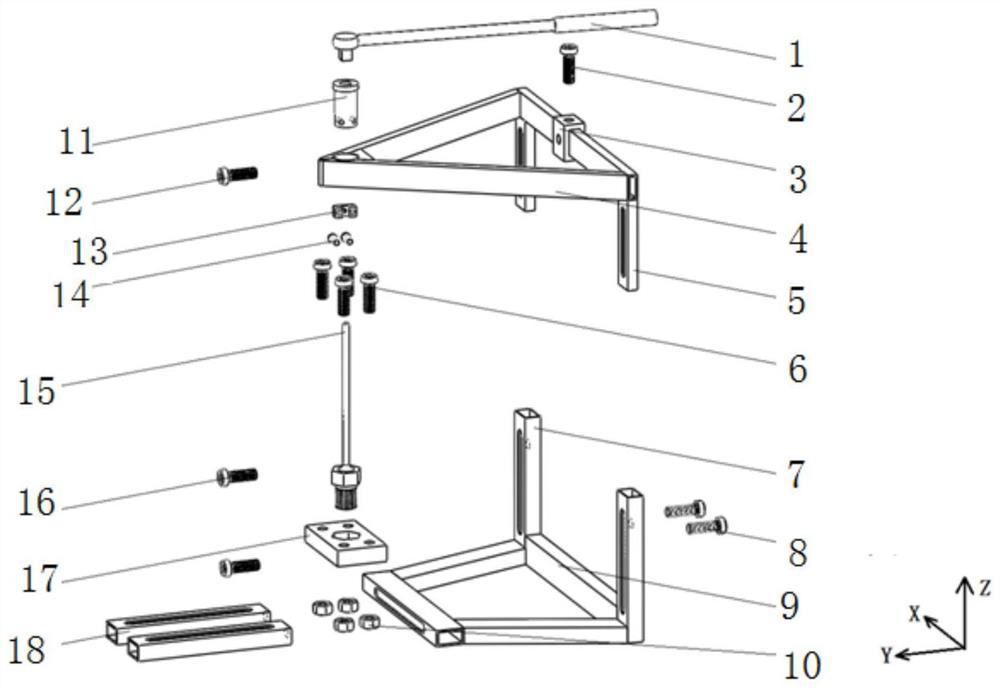

[0045] see figure 1 , figure 2 and image 3 , The high-precision universal torque loading device of this embodiment, the main components are composed of base 9, bottom slide rail 18, bottom clip 17, column assembly, upper beam 4, steering sleeve 11 and torque wrench 1, etc. The two ends of the tested piece 15 are respectively installed or stuck in the steering sleeve and the bottom clamping piece 17 .

[0046] It can be seen from the figure that the base 9 in this embodiment is an isosceles trapezoidal frame, and the upper beam 4 is an isosceles triangular frame. In other embodiments, the shape of the frame can be adjusted according to needs.

[0047] The bottom slide rail 18 is slidably connected with the base 9, and can slide and position along the X direction on the base 9; Figure 4 It can be seen from the figure that an x-direction elo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com