Patents

Literature

33results about How to "Stable torque output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Screw capping head

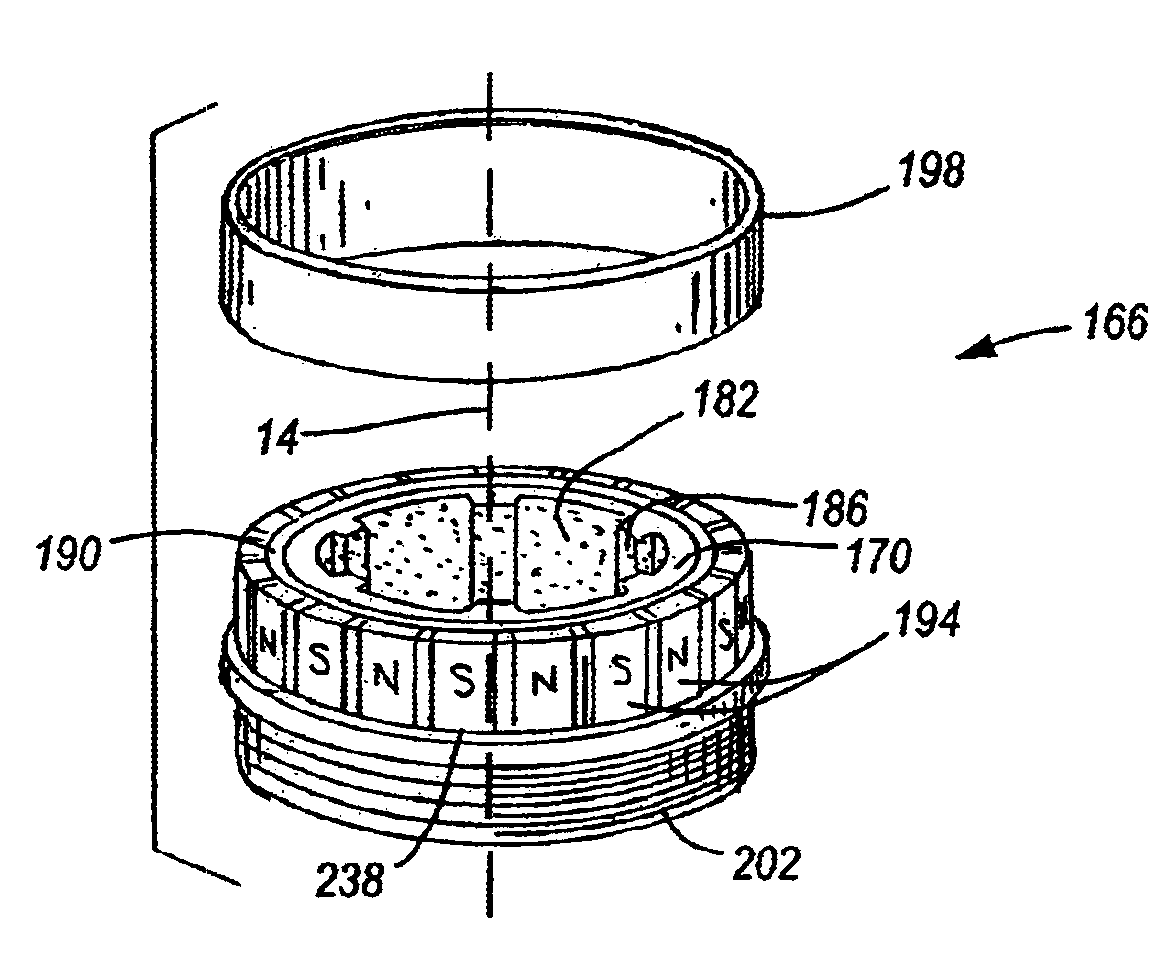

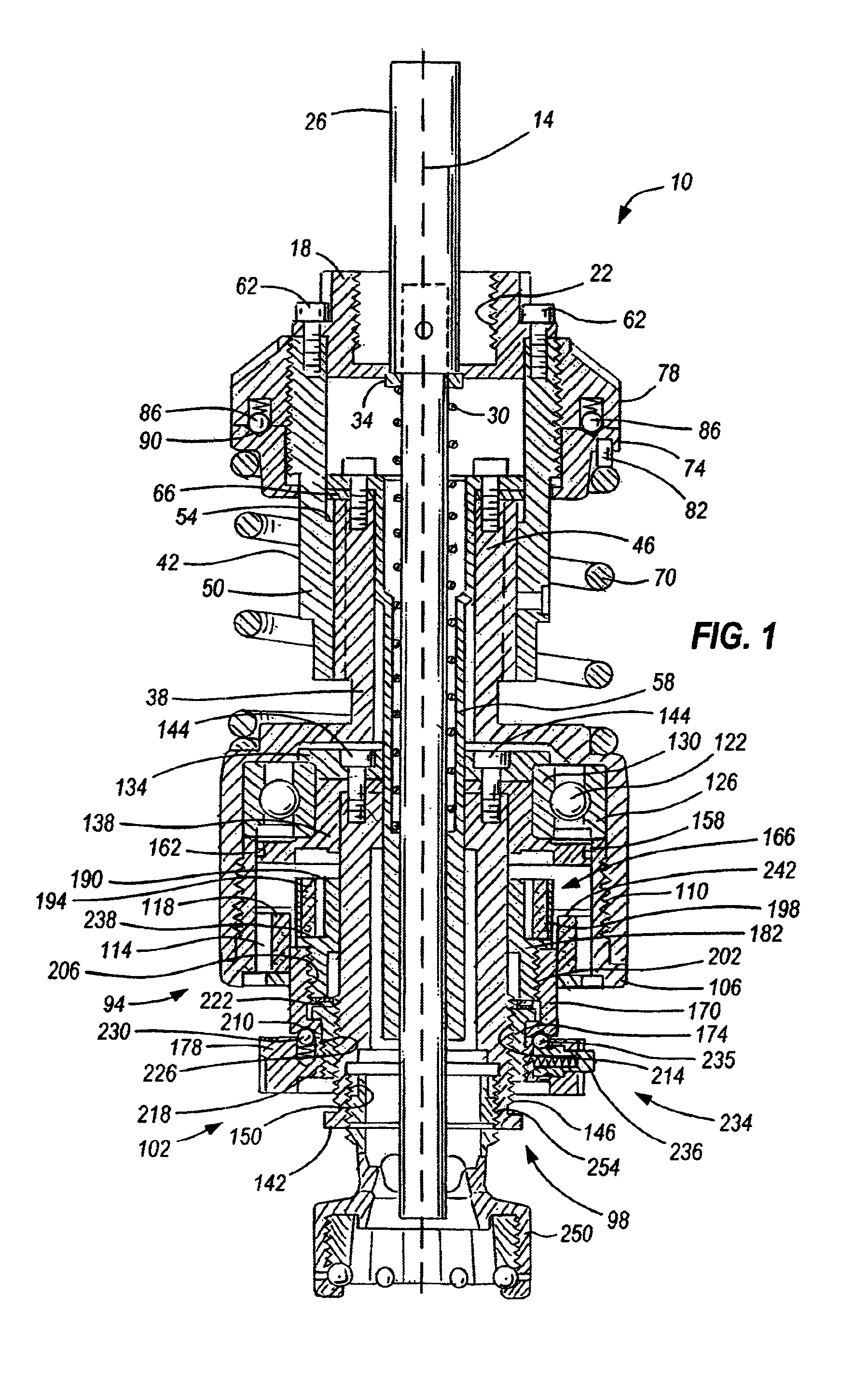

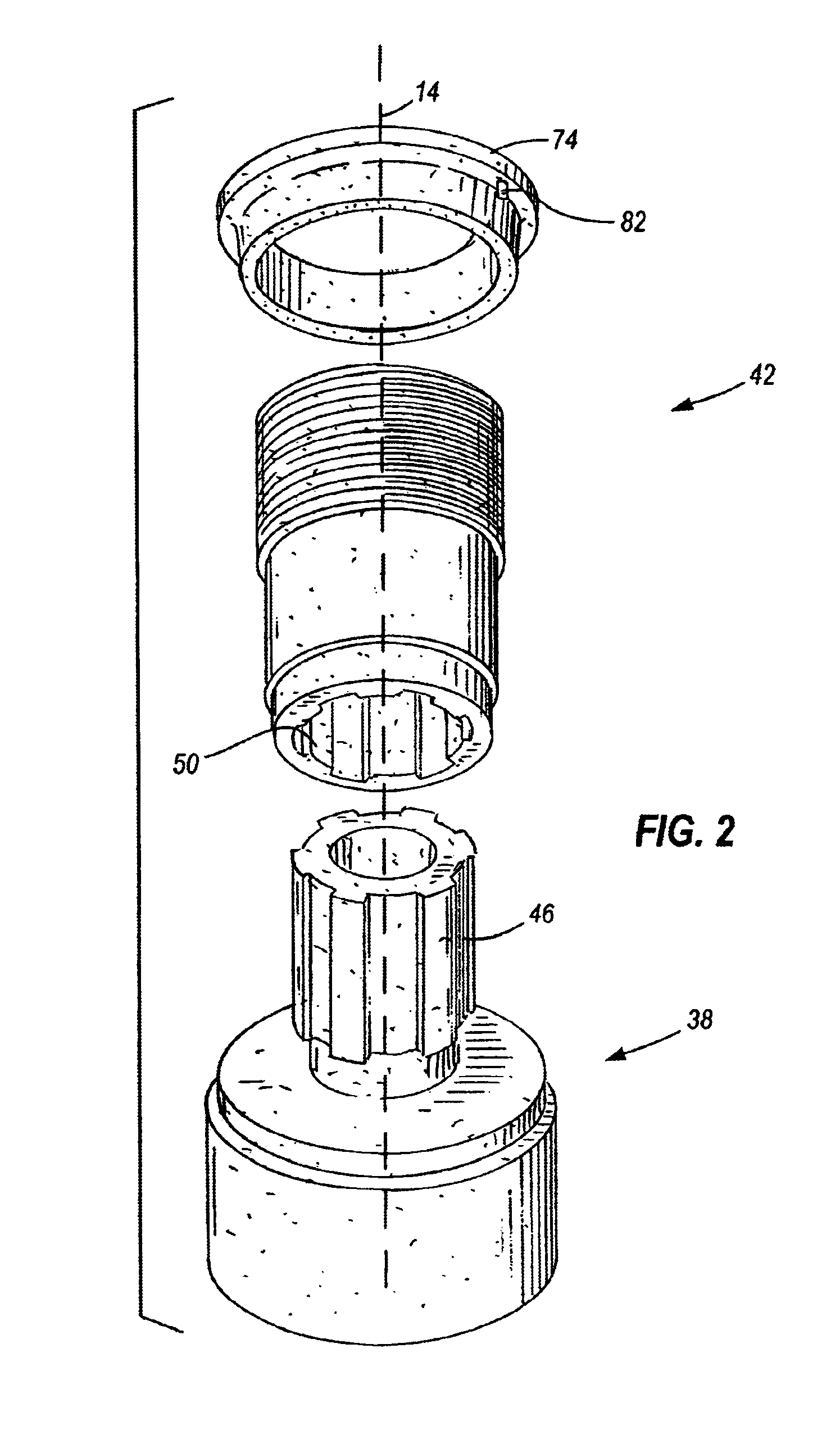

InactiveUS6941724B2Stable torque outputProlong useful lifeCapsThreaded caps applicationLinear relationshipMagnet

A screw capping head for use in a rotary capping machine includes a housing defining a longitudinal axis, a spindle rotatably carried by the housing, a first ring of magnets fixed within the housing, and a second ring of magnets coupled to the spindle for rotation with the spindle. The second ring of magnets is movable, without the use of tools, in the longitudinal direction with respect to both the spindle and the first ring of magnets to achieve a plurality of nested positions with respect to the first ring of magnets. The first and second rings of magnets define a magnetic torque coupling between the housing and the spindle, the strength of the torque coupling varying in a substantially linear relationship to the nested positions of the first and second rings of magnets.

Owner:KHS USA

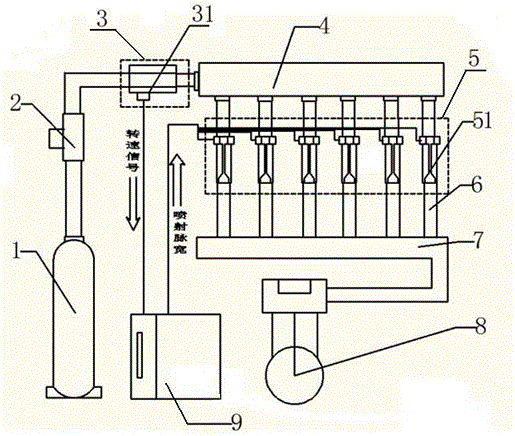

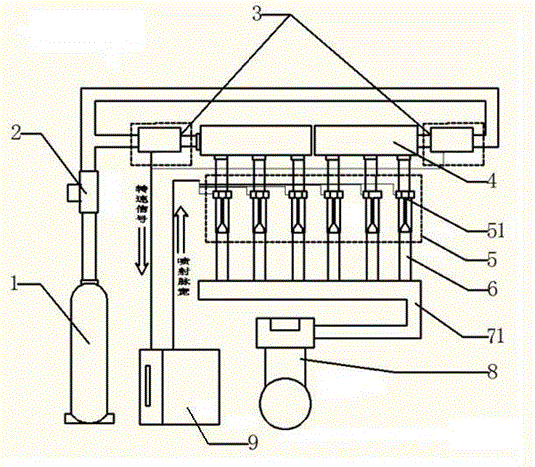

System and method for controlling uniformity of gas injection amount of natural gas engines for vehicles

InactiveCN105840372AImprove uniformityMaintain stable torque outputFuel injection apparatusMachines/enginesSpray nozzleProcess engineering

The invention discloses a gas injection quantity uniformity control system and control method of a natural gas engine for a vehicle, which includes an ECU, a natural gas supply bottle and an injection system equal to the number of cylinders of the engine, and each injection system includes at least one gas rail and The injection unit connected to the ECU has a metering unit between the air inlet of each air rail and the high-pressure solenoid valve. Each metering unit includes a millisecond-level rotameter connected to the ECU. The millisecond-level The rotameter can measure the transient flow of natural gas at the millisecond level. After adopting the above-mentioned structure and method, the uniformity of natural gas injection volume can be significantly improved, the control problem caused by the consistency of nozzles in the natural gas engine control system can be solved, the state of the injection system can be monitored in real time, and the stable torque output of the natural gas engine can be maintained, which is beneficial The development of in-cylinder direct injection lean-burn natural gas engine is applicable to natural gas engines of various displacements.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

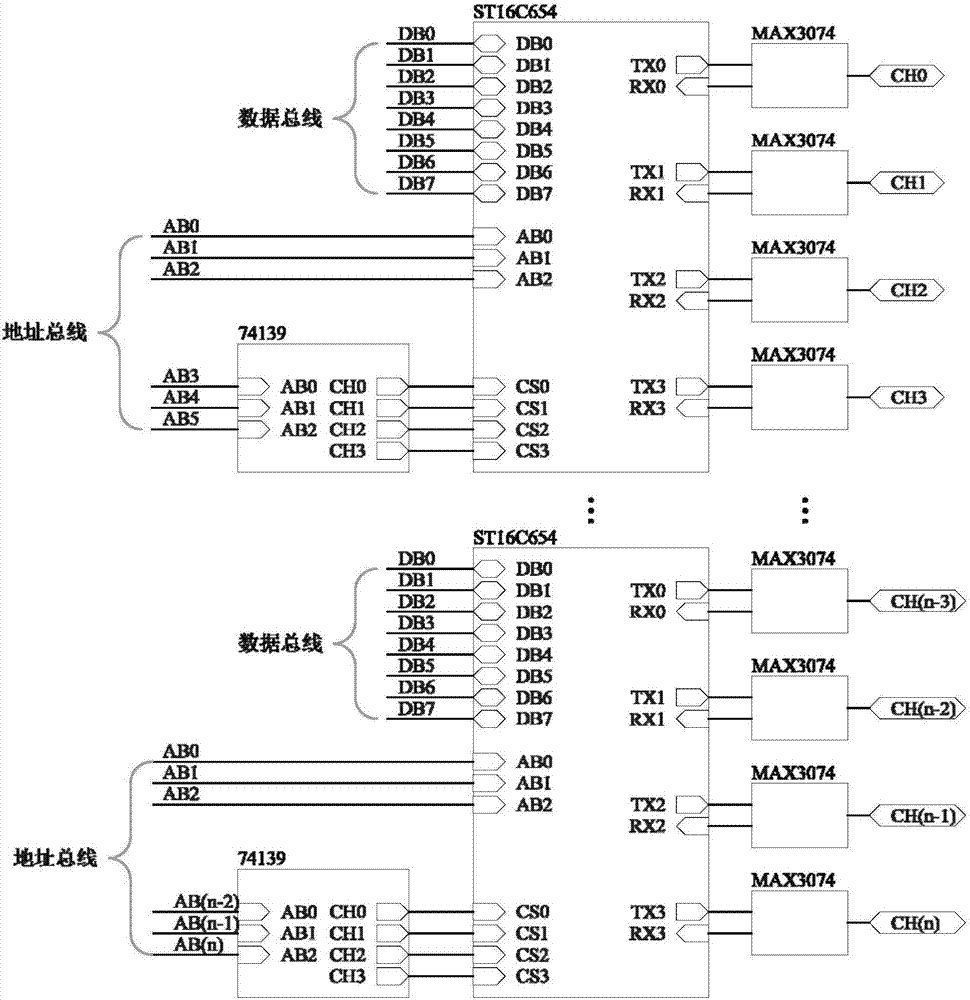

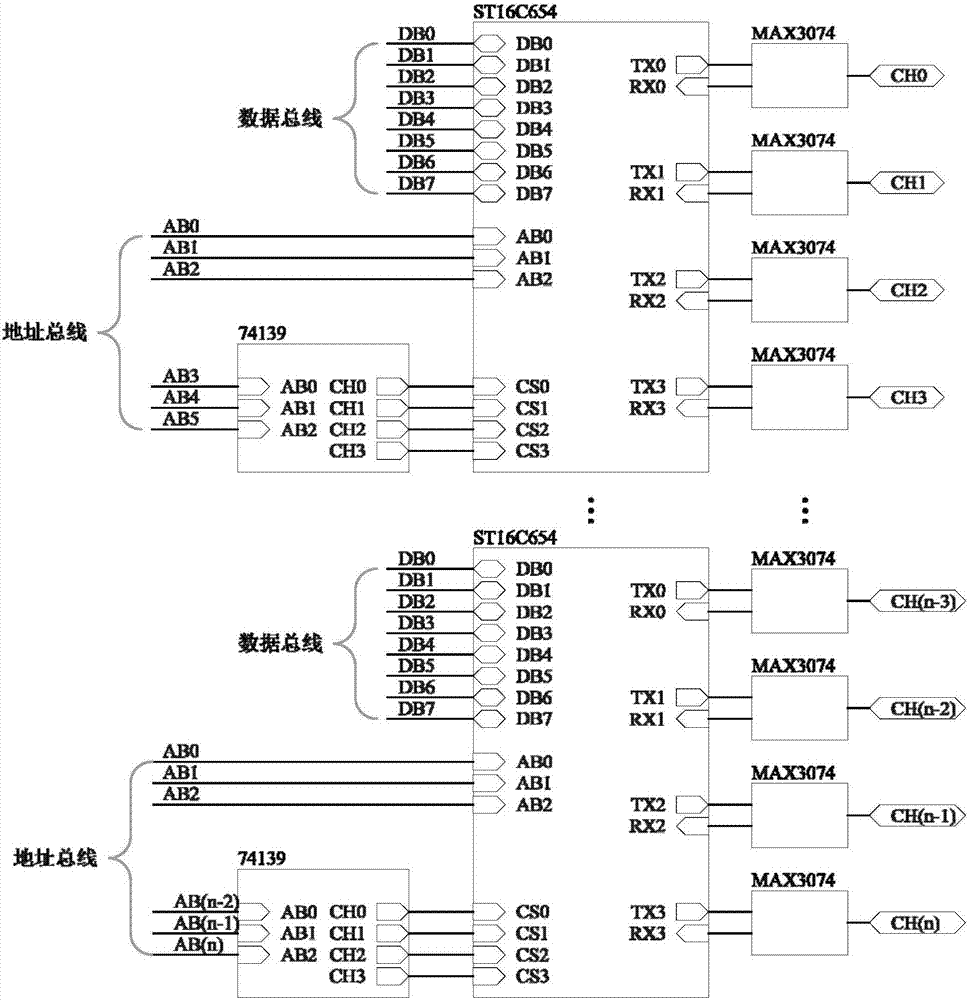

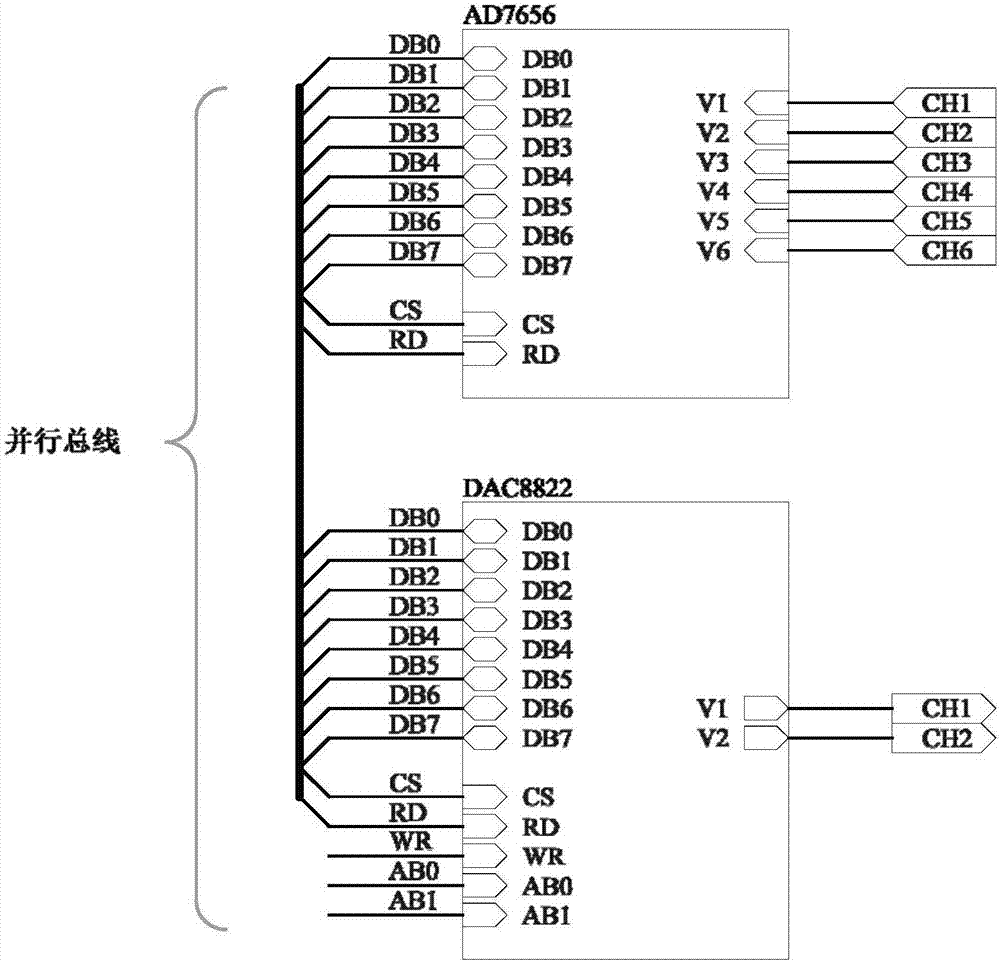

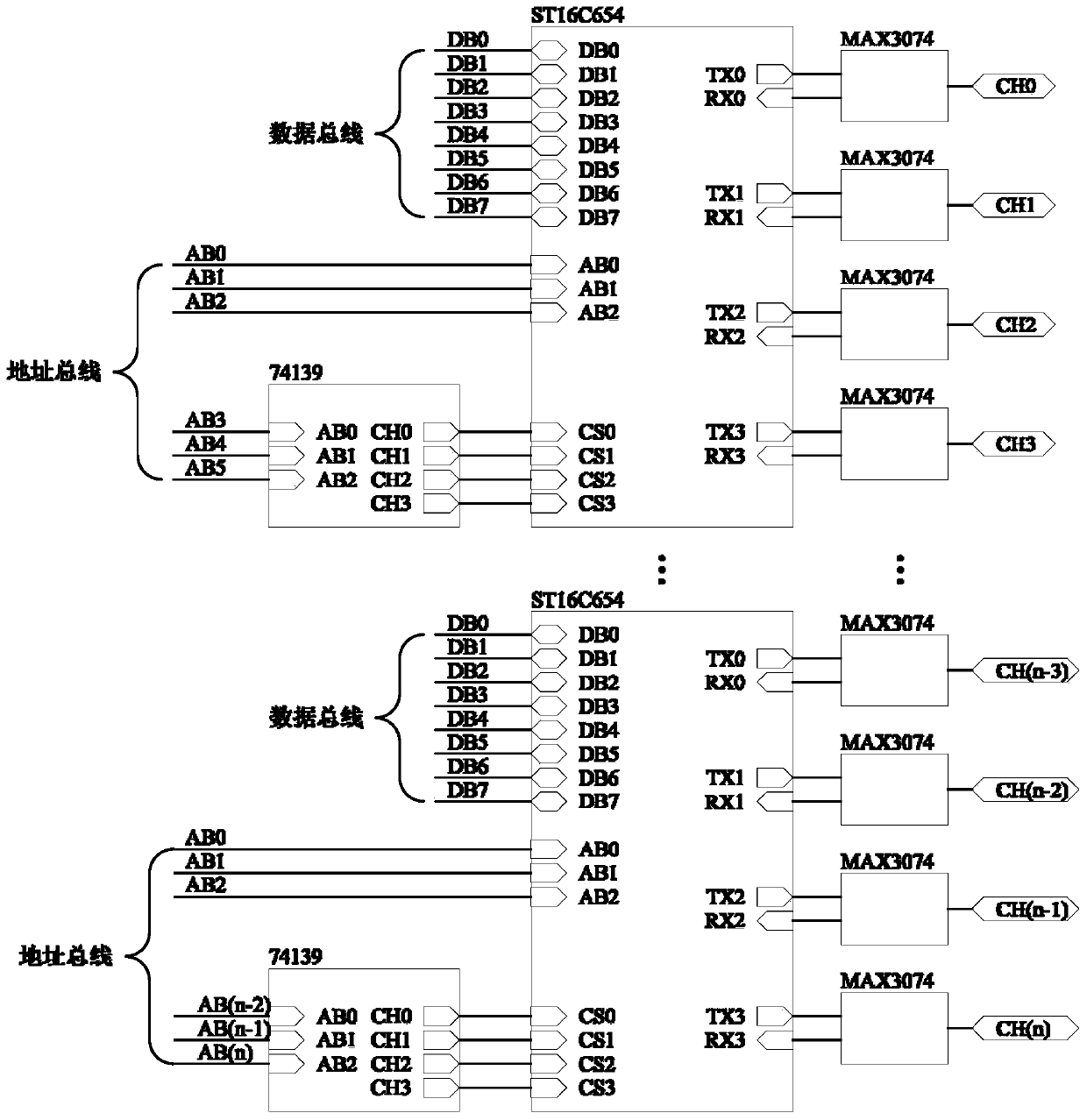

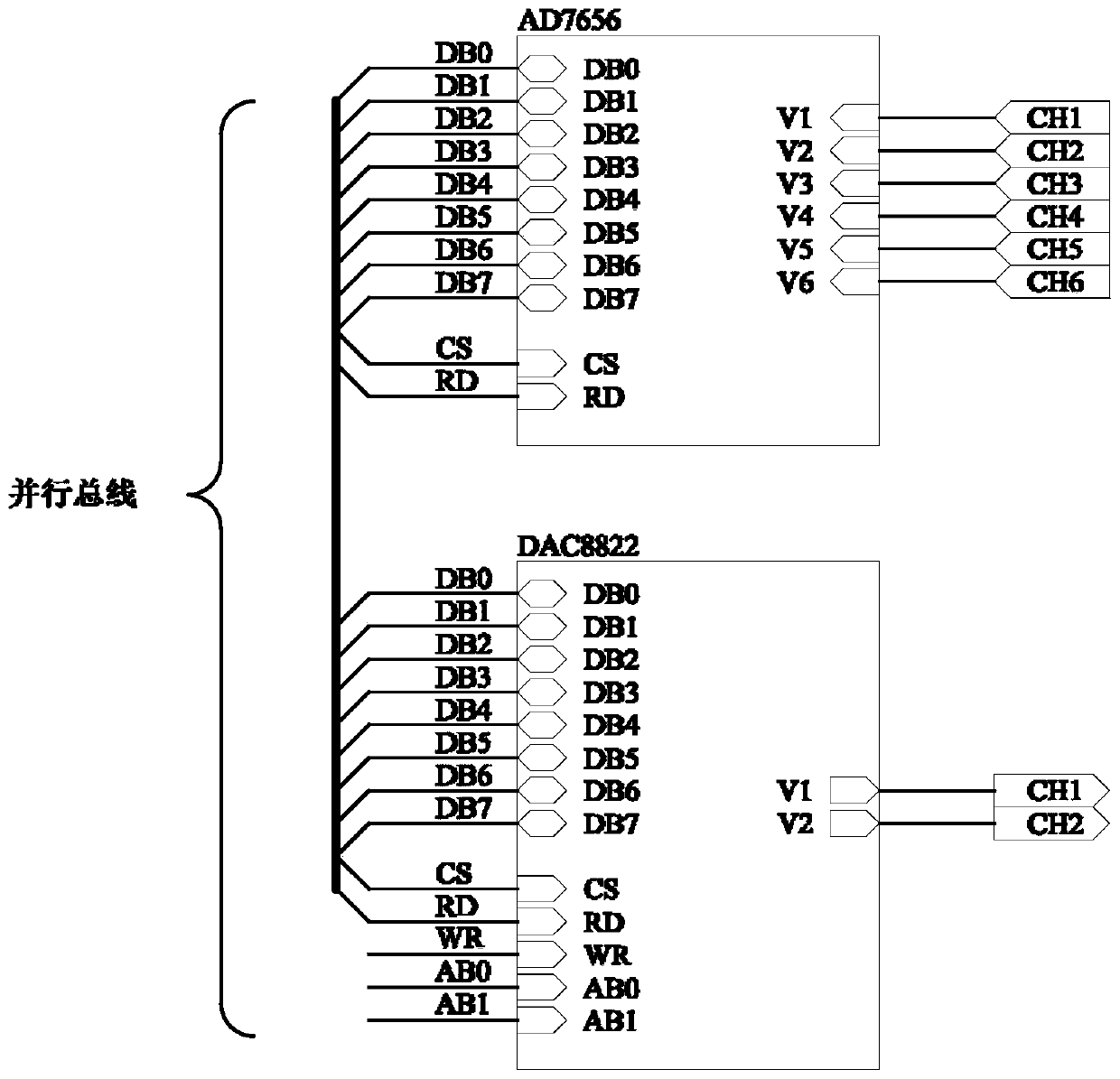

Vector control method and control system for controlling motor rotation, and stable console

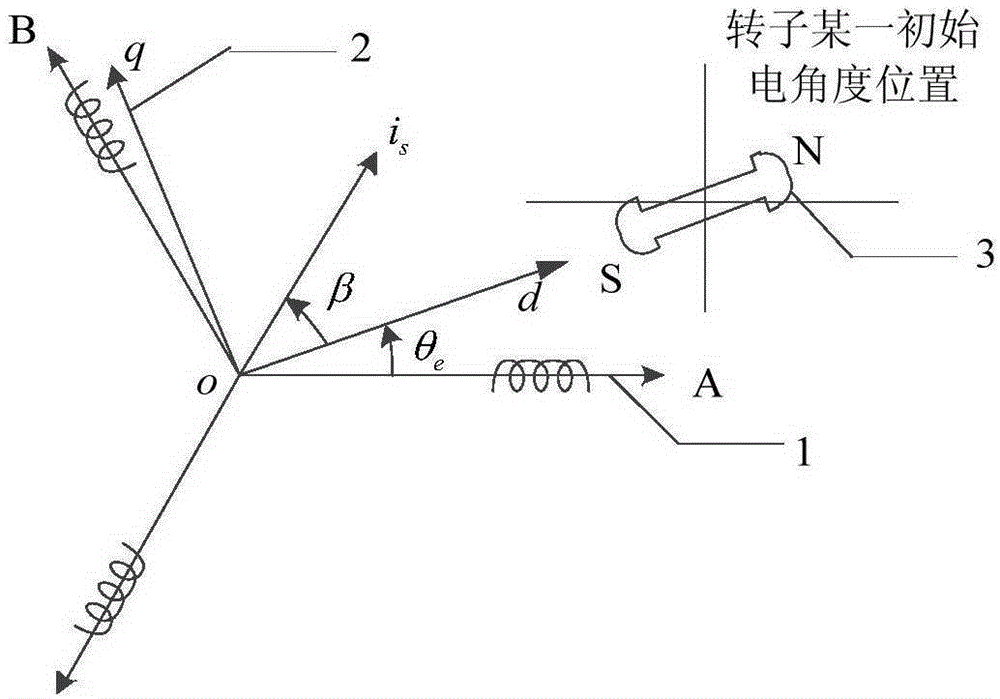

InactiveCN107147341ARelieve pressureEliminate the effects of induced electromotive forceAC motor controlVector control systemsElectricityControl vector

The invention relate to a vector control method for controlling motor rotation. The vector control method comprises the following steps of judging whether an electrical angle absolute initial value exists or not; if the electrical angle absolute initial value does not exist, obtaining a current electrical angle value, a quadrature-axis voltage control quantity, a direct-axis voltage control quantity, and an electrical angle absolute initial value at the initial mode; if the electrical angle absolute initial value exists, obtaining an angle value of an absolute angle position sensor, and obtaining the current electrical angle value according to the angle value of the absolute angle position sensor and the electrical angle absolute initial value; and obtaining the duty ratio of output PWM according to the current electrical angle value, the quadrature-axis voltage control quantity and the direct-axis voltage control quantity, so as to control rotation of the motor.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

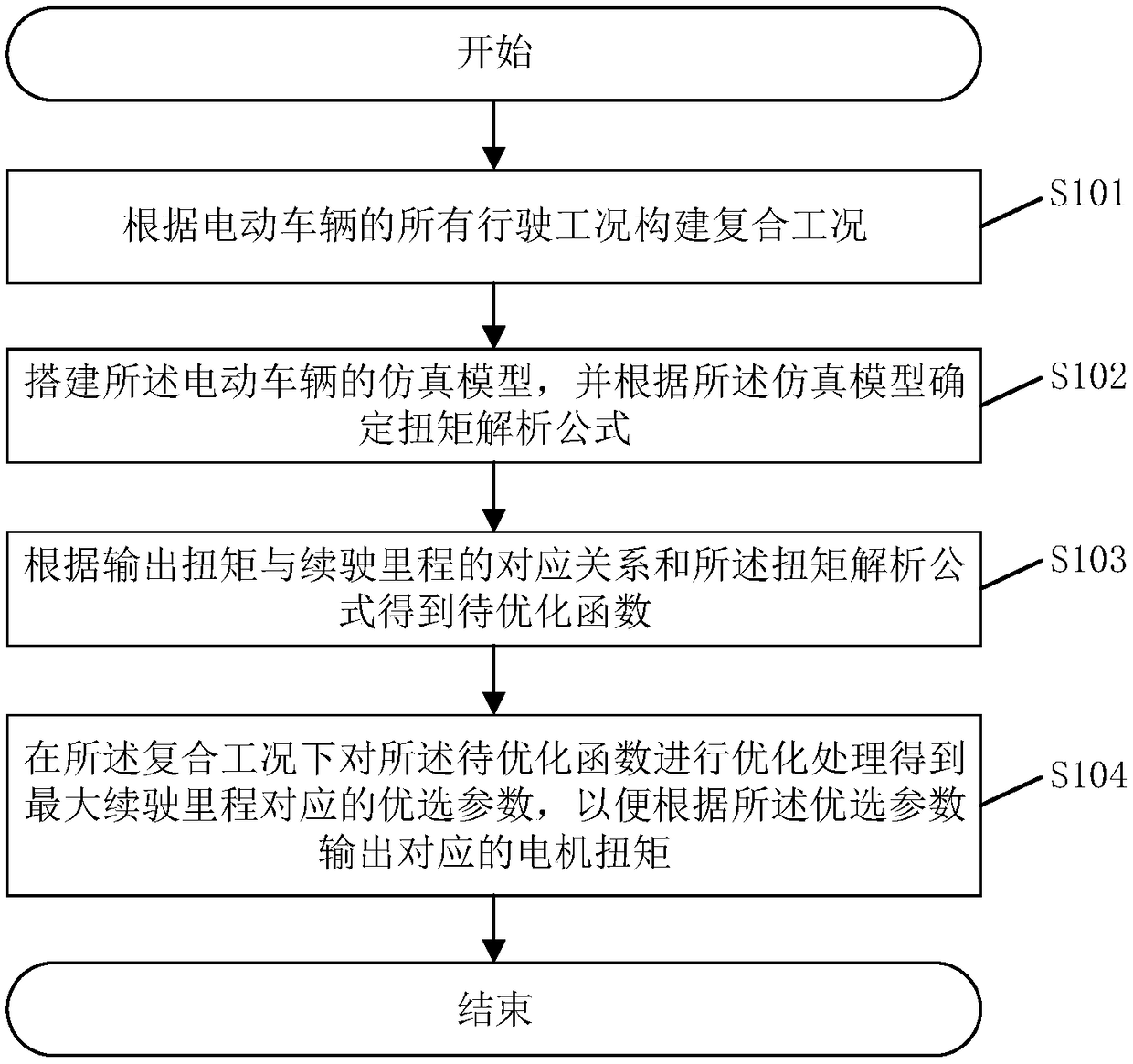

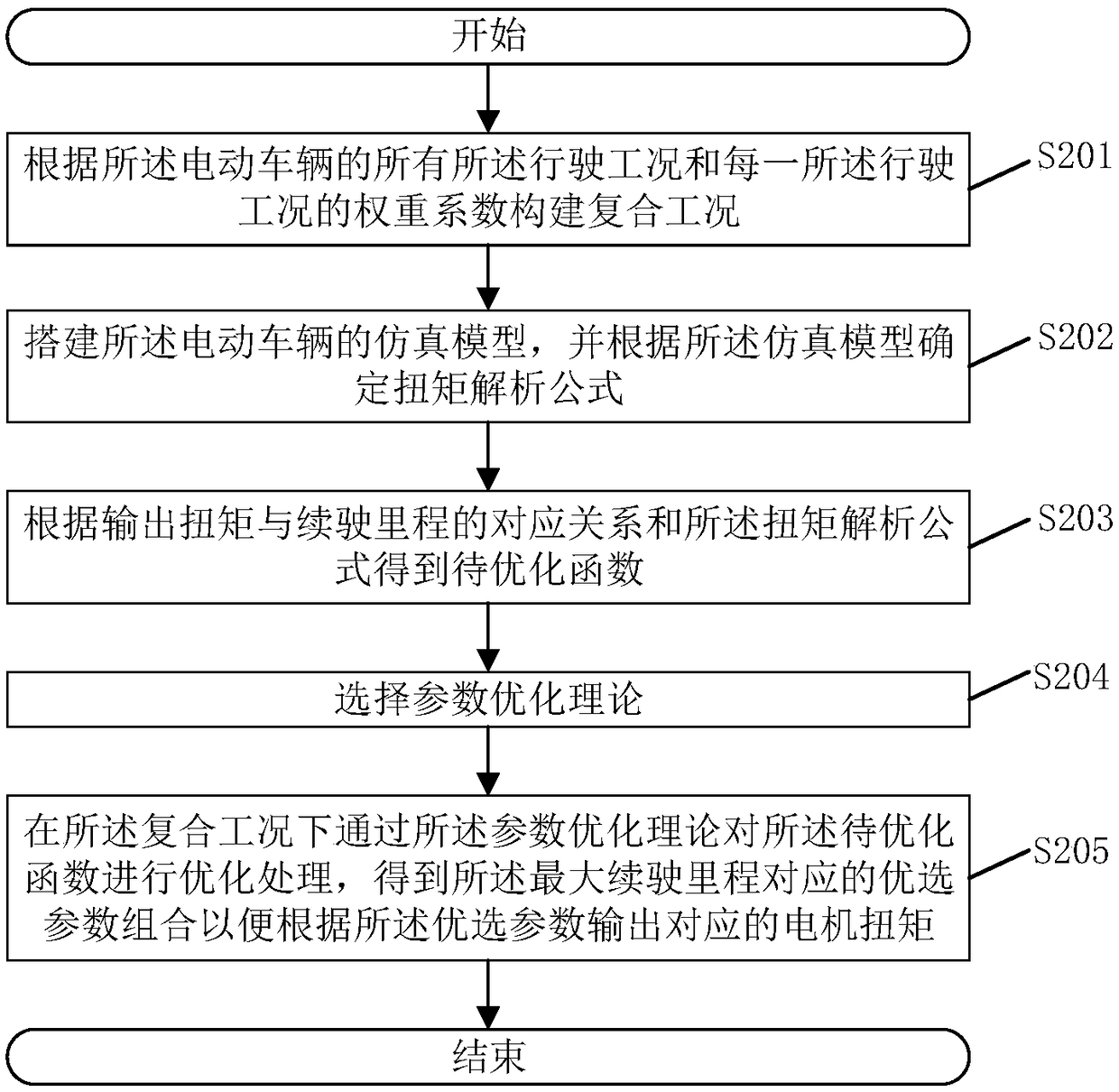

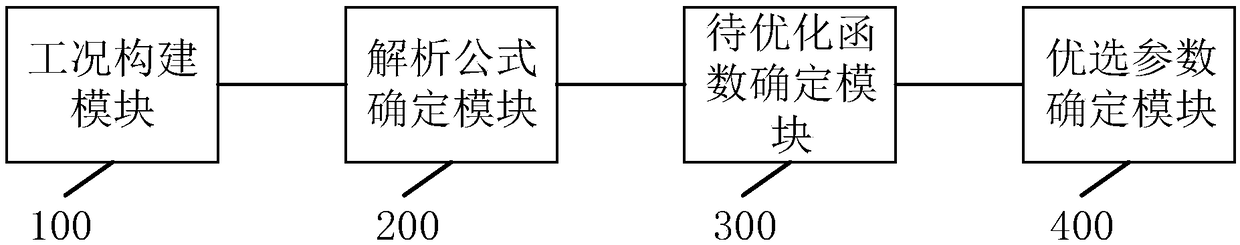

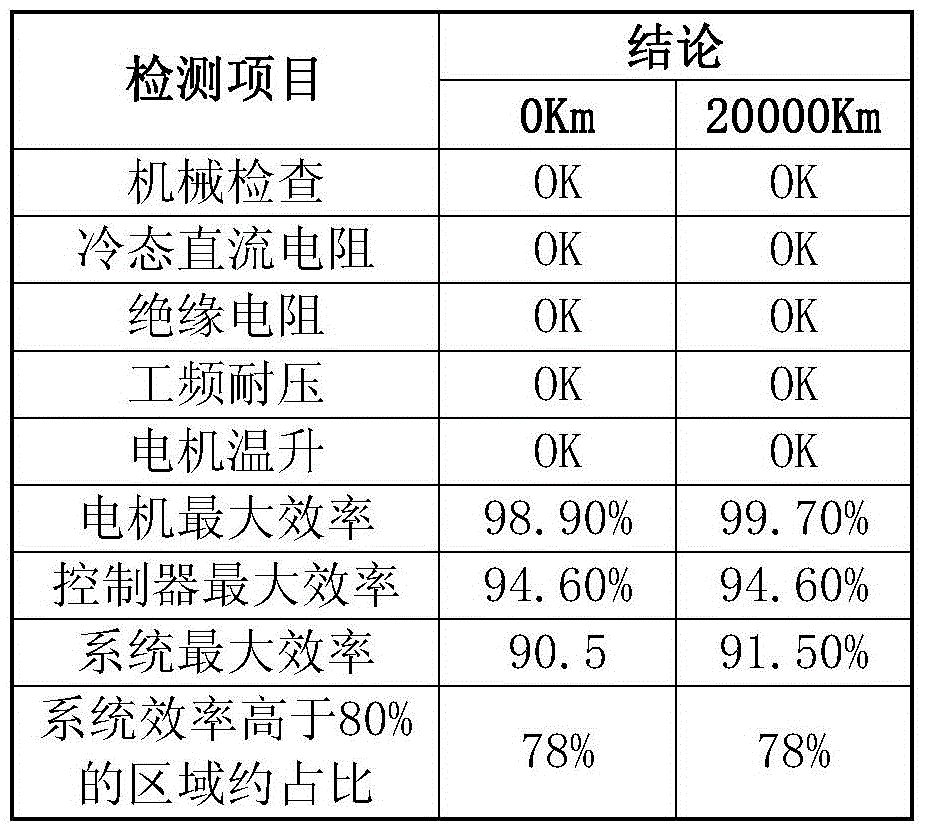

Electric vehicle motor torque output method and system and related assembly

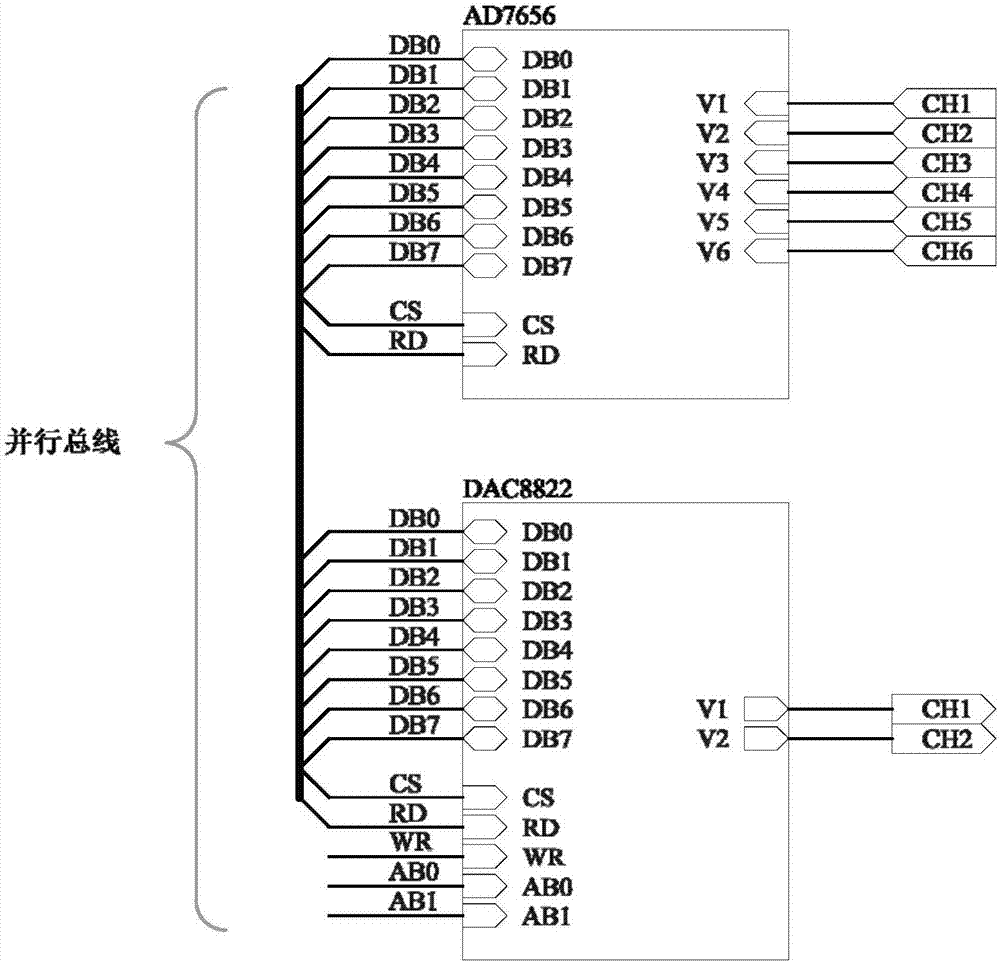

InactiveCN109484210AImprove driving rangeStable torque outputSpeed controllerElectric energy managementTorque analysisElectric machine

The invention discloses an electric vehicle motor torque output method. The method comprises constructing a composite working condition according to all driving conditions of an electric vehicle; constructing a simulation model of the electric vehicle and determining a torque analysis formula according to the simulation model; obtaining a function to be optimized according to the corresponding relationship between the output torque and the driving range and the torque analysis formula, wherein the optimization target of the function to be optimized is the driving range; optimizing the functionto be optimized under the composite working condition to obtain a preferred parameter corresponding to the maximum driving range to output the corresponding motor torque according to the preferred parameter. According to the method, the electric vehicle can have good driving range under different working conditions. An electric vehicle motor torque output system, a computer readable storage medium and the electric vehicle with the above advantages are further disclosed.

Owner:深蓝汽车科技有限公司

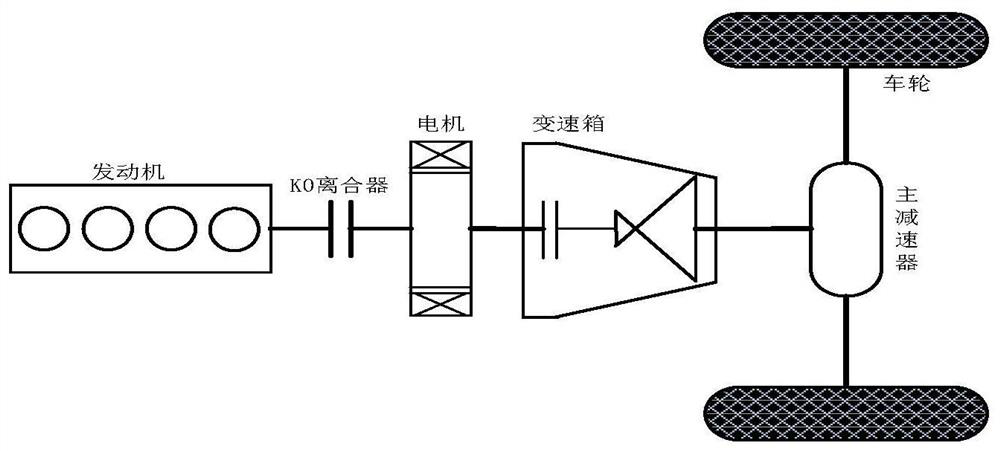

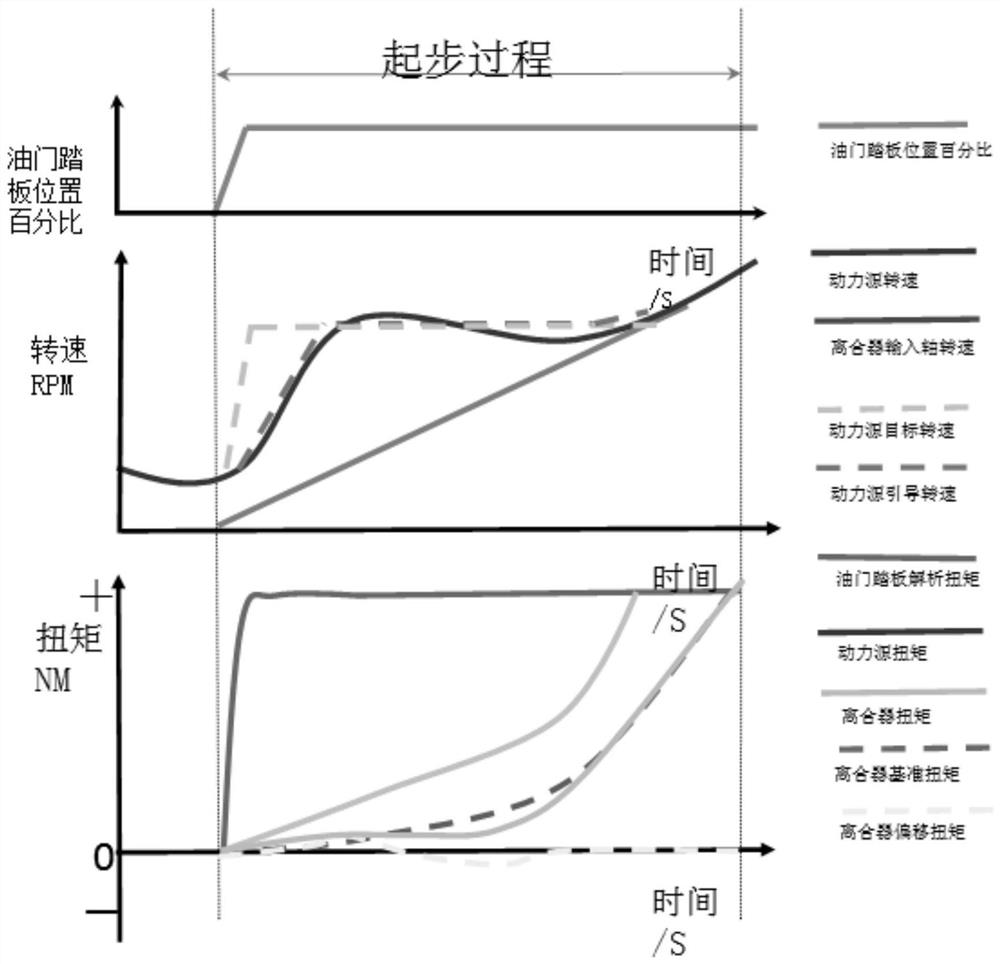

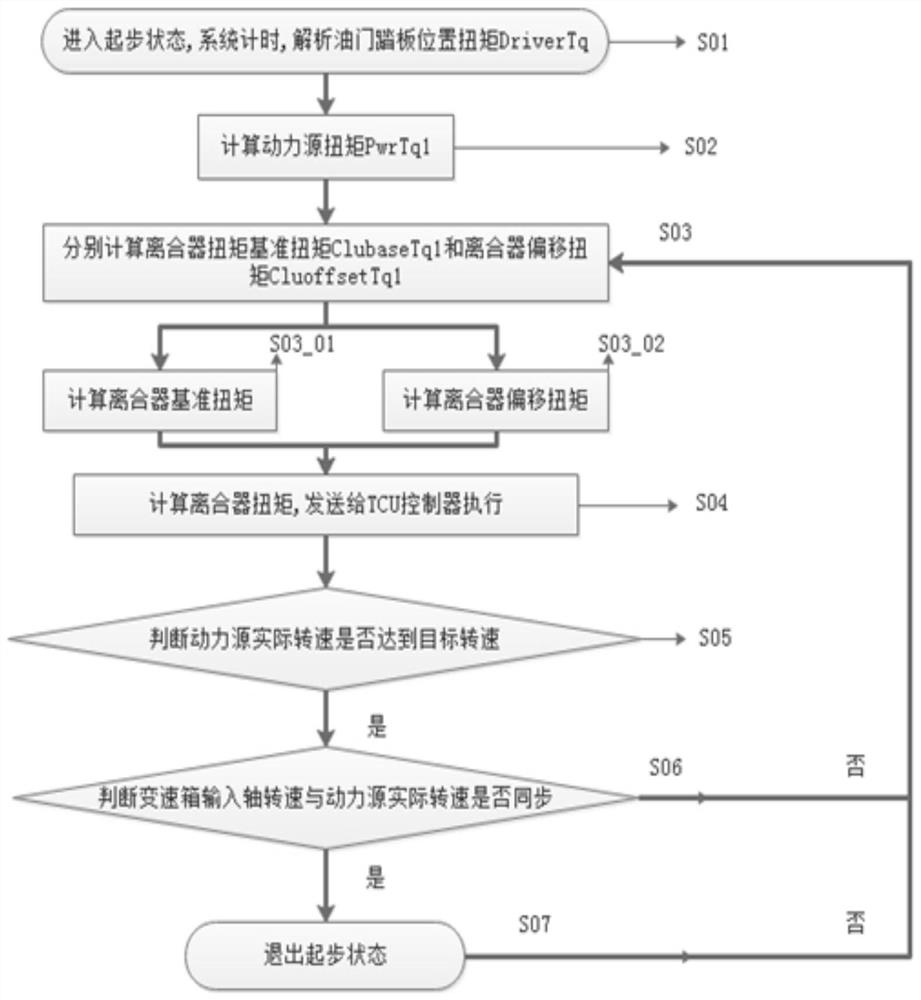

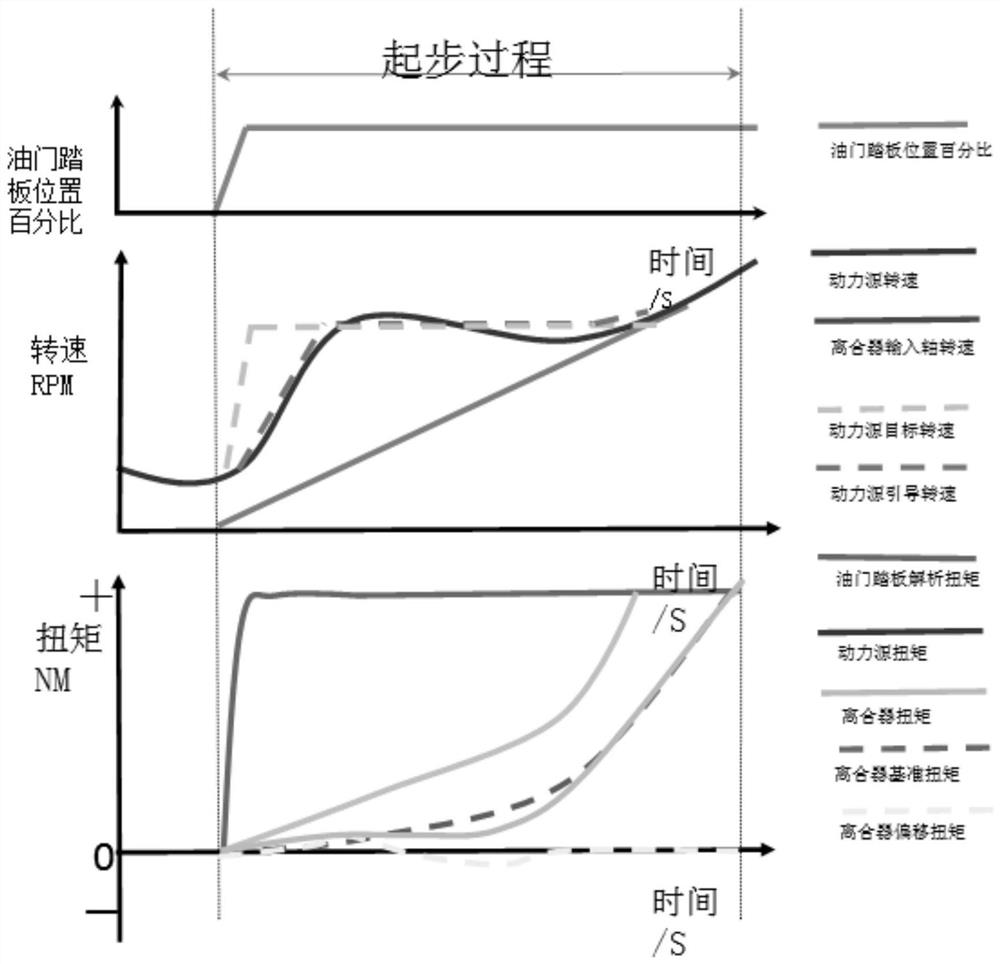

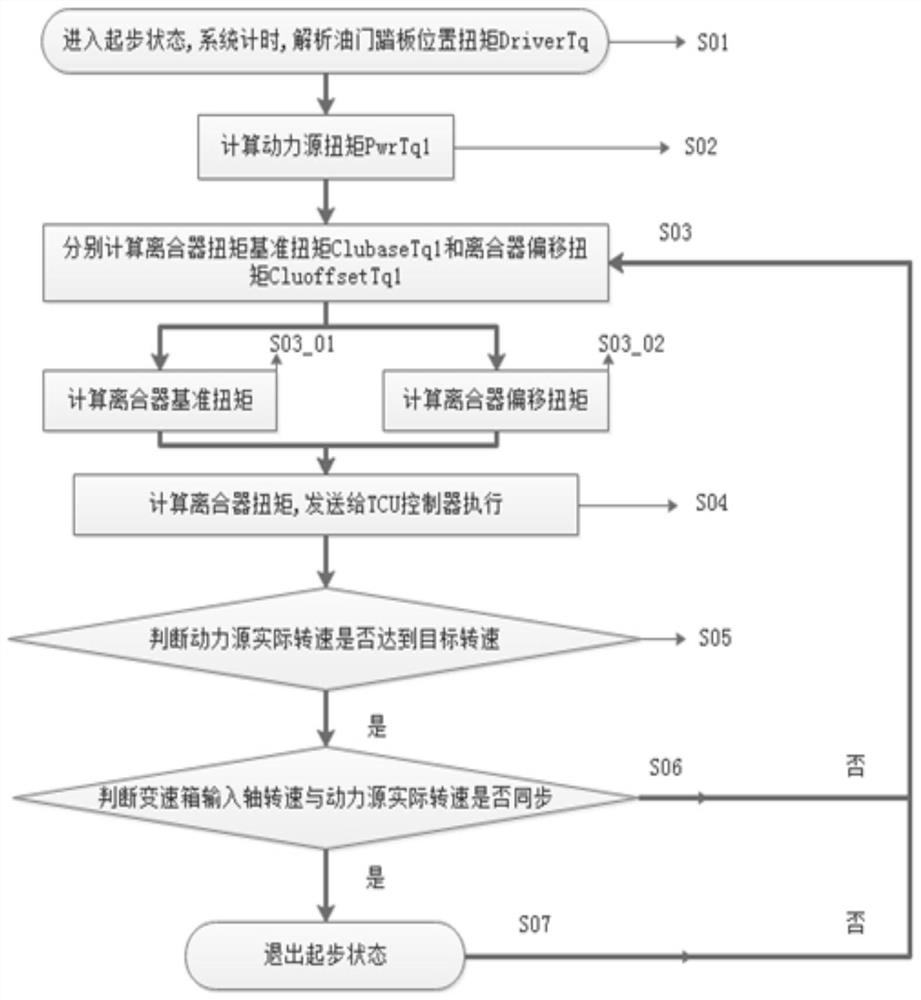

Vehicle starting control method and system and vehicle

The invention provides a vehicle starting control method and system and a vehicle, and the method comprises the steps that when it is detected that the vehicle has a starting demand, a whole vehicle power control unit PCU controls a power source torque and a clutch torque slope, and the power source torque, a clutch reference torque and a clutch offset torque act together to control the starting demand of the vehicle; finely the target transmission torque of the clutch is adjusted in real time according to the actual rotating speed of the power source, and the power source end rotating speed is guided to rise to the target rotating speed along with the guiding rotating speed until the power source rotating speed is synchronous with the gearbox input shaft rotating speed. According to the method, the power source end and the clutch load end are controlled, the fluctuation of the rotating speed of the power source end is weakened through the combined action of the clutch reference torque and the clutch offset torque, the stable torque output is ensured, and the good starting smoothness and dynamic property of the vehicle are obtained. Due to the fact that complex calculation is not needed, power assembly torque output and clutch transmission torque are determined, rotating speed fluctuation caused by PID closed-loop control is weakened, different stages of rotating speed rising do not need to be refined, and therefore control and calibration are easier.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

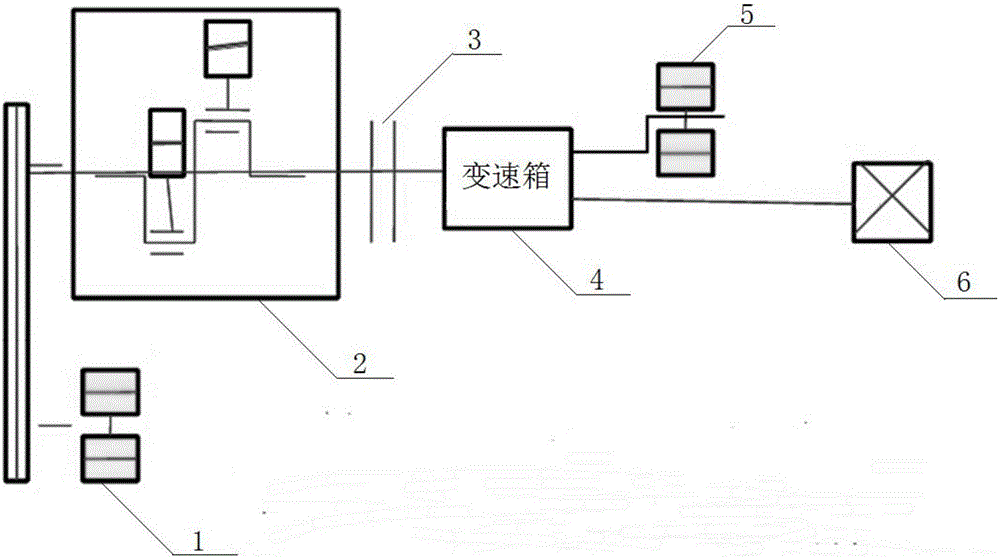

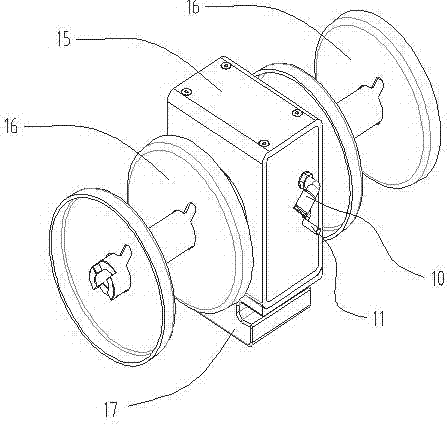

BSG hybrid power system with drive motor additionally arranged on output shaft of gearbox

InactiveCN105691181AImprove efficiencyIncrease the degree of mixingHybrid vehiclesGas pressure propulsion mountingLow speedElectric machine

The invention discloses a hybrid power system with a BSG and a drive motor arranged on an output shaft of a gearbox and a control method thereof. The system is formed by sequentially connecting the BSG, an ICE, a clutch, the gearbox, the drive motor and a front drive shaft, wherein the drive motor is connected to the output shaft of the gearbox through a gear and has a fixed speed ratio, and the BSG is arranged at the front end of an engine and is connected to the engine through a belt. The invention further discloses the control method of the hybrid power system with the BSG and the drive motor arranged on the output shaft of the gearbox. According to the hybrid power system with the BSG and the drive motor arranged on the output shaft of the gearbox and the control method thereof, the drive motor directly drives the output shaft of the gearbox to rotate through the gear and drives a vehicle to travel; the motor has low speed and large torque, and the efficiency of the motor is obviously higher than the efficiency of the engine at low speed.

Owner:海博瑞德(北京)汽车技术有限公司

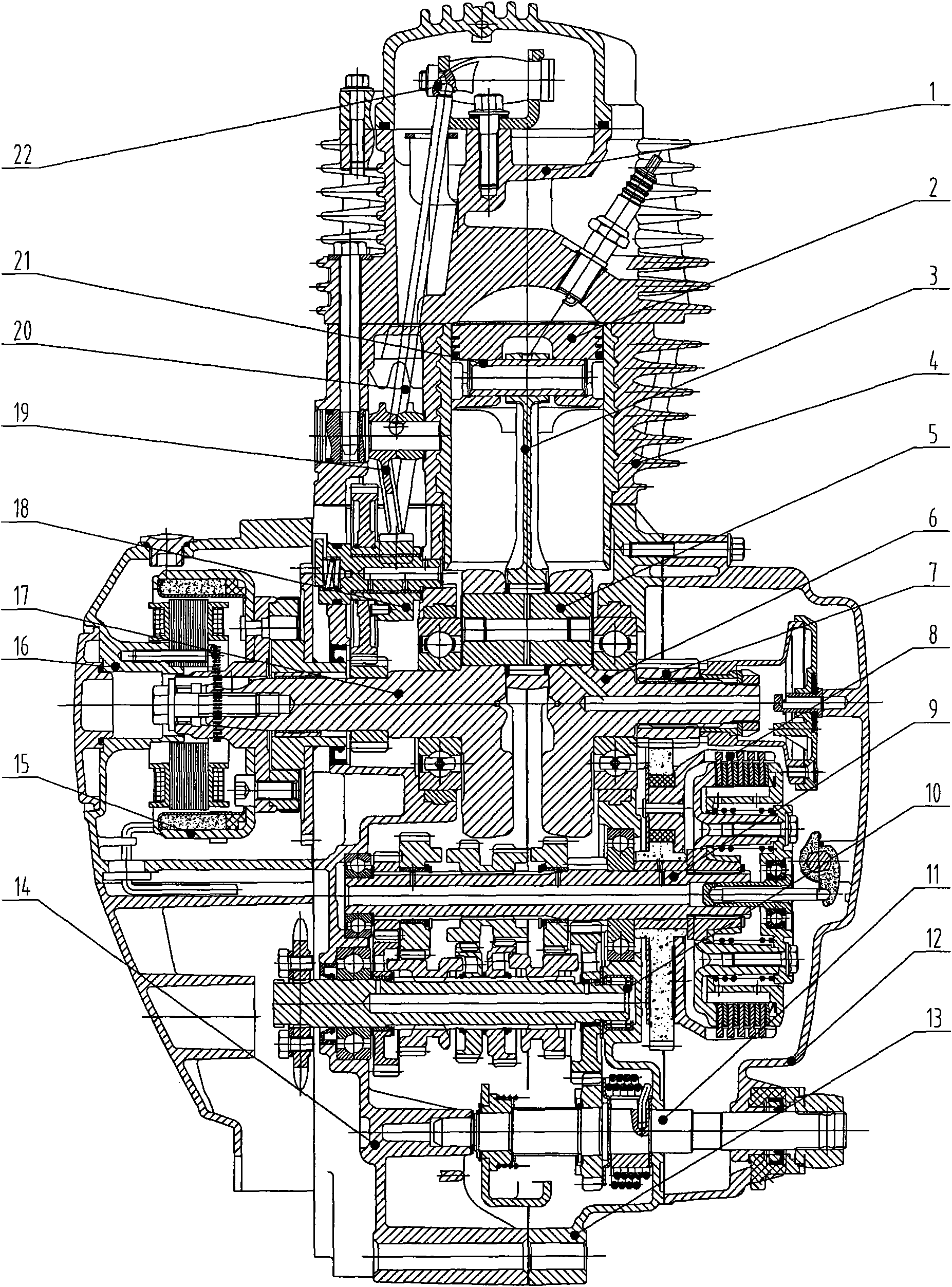

Engine for motorcycle

InactiveCN101798967AReduce working speedSmall cross-sectional area designValve arrangementsCylinder headsMaximum torqueCylinder head

The invention provides an engine for a motorcycle. For the engine, the diameter of a gas inlet of a cylinder head is 21 to 23millimeters, and the diameter of a gas outlet is 19 to 21 millimeters; the eccentricities of left and right cranks are 30.5 to 32.5 millimeters, and the centre distances of mounting holes on both ends of a connecting rod are 104.5 to 105.5 millimeters; the height of a cylinder body is 75.5 to 77.5 millimeters, the internal diameter of a cylinder sleeve is 54 to 56 millimeters, and the height of the cylinder sleeve is 101 to 103 millimeters; the diameter of an upper end opening of a gas inlet tube is 24 to 26 millimeters, and the diameter of a lower end opening of the gas inlet tube is 21 to 23 millimeters; and the length of a convex hull of a rotor of a magnetic motor is 13 to 18 millimeters, and the included angle between the center of the convex hull and a keyway of the rotor of the magnetic motor is 50 to 60 degrees. The engine has the advantages of effectively improving gas-intake efficiency of the engine, increasing an operating stroke of the engine, reducing rotating speeds of the cranks in all strokes and the rotating speed section of the maximum torque point of the engine, ensuring that the engine can output big torques at the middle / low rotating speed and improving reliability and durability of the engine.

Owner:重庆动源摩托车配件销售有限公司

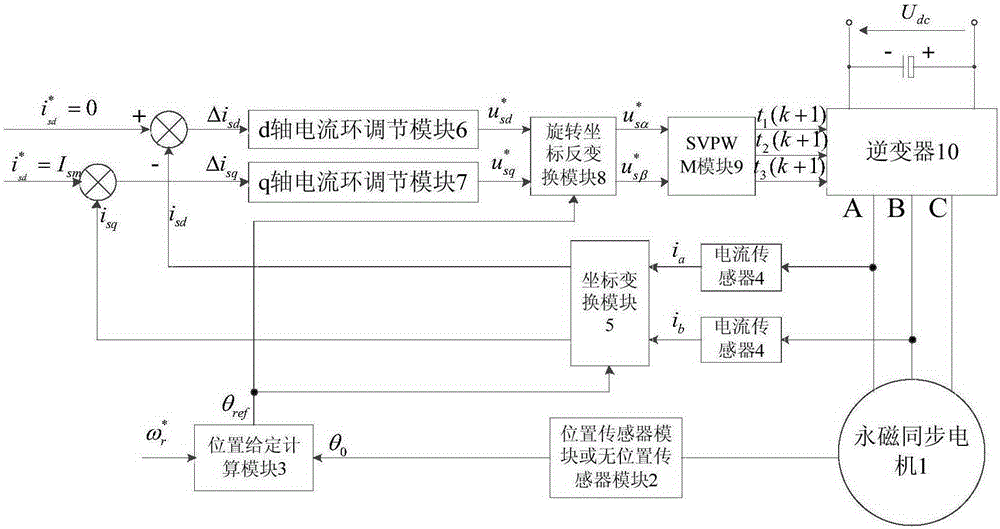

Micro-step drive control method of permanent magnet synchronous motor

InactiveCN105207558ASimple structureStrong control robustnessElectronic commutation motor controlVector control systemsPermanent magnet synchronous motorClosed loop

The invention provides a micro-step drive control method of a permanent magnet synchronous motor. The method comprises the steps that a current position of a permanent magnet synchronous motor rotor is detected through a position sensor, and the position of the rotor at the next moment is obtained through calculation; a current value of a permanent magnet synchronous motor stator is detected, and a stator three-phase current of the permanent magnet synchronous motor and a current component under a two-phase static coordinate system are obtained; a current component under a synchronous rotating coordinate system is obtained according to the position of the permanent magnet synchronous motor at the next moment and the current component under the two-phase static coordinate system; a current difference value is obtained finally, a reference voltage, an SVPWM reference input voltage and the three-phase PWM duty ratio under the synchronous rotating coordinate system are generated, a drive voltage of a next cycle is obtained, and drive is completed. By means of the micro-step drive control method of the permanent magnet synchronous motor, the defect that for an existing closed-loop control scheme, when the situations that load inertia is large, control is not stable is overcome, good positioning performance for a large inertial load is achieved, the robustness is strong, the reliability is high, and the control effect is good.

Owner:BEIJING INST OF CONTROL ENG

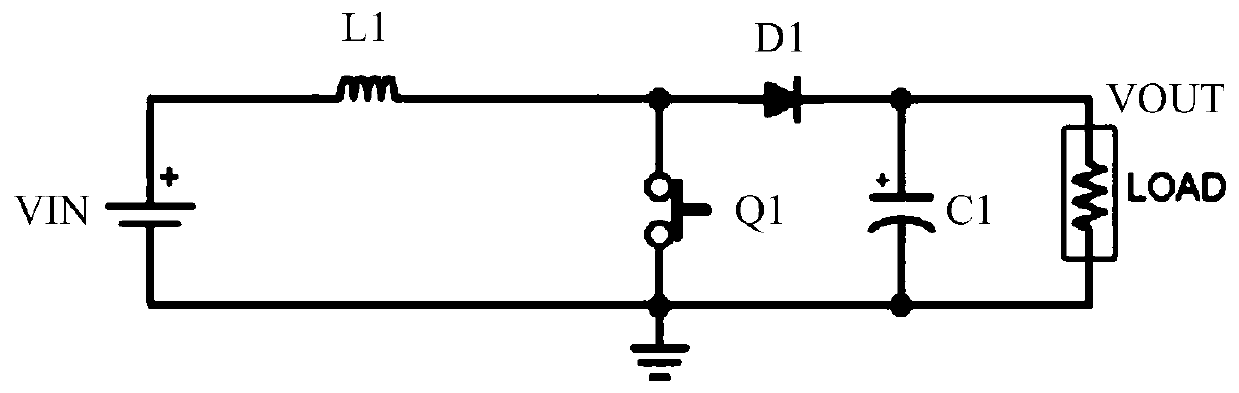

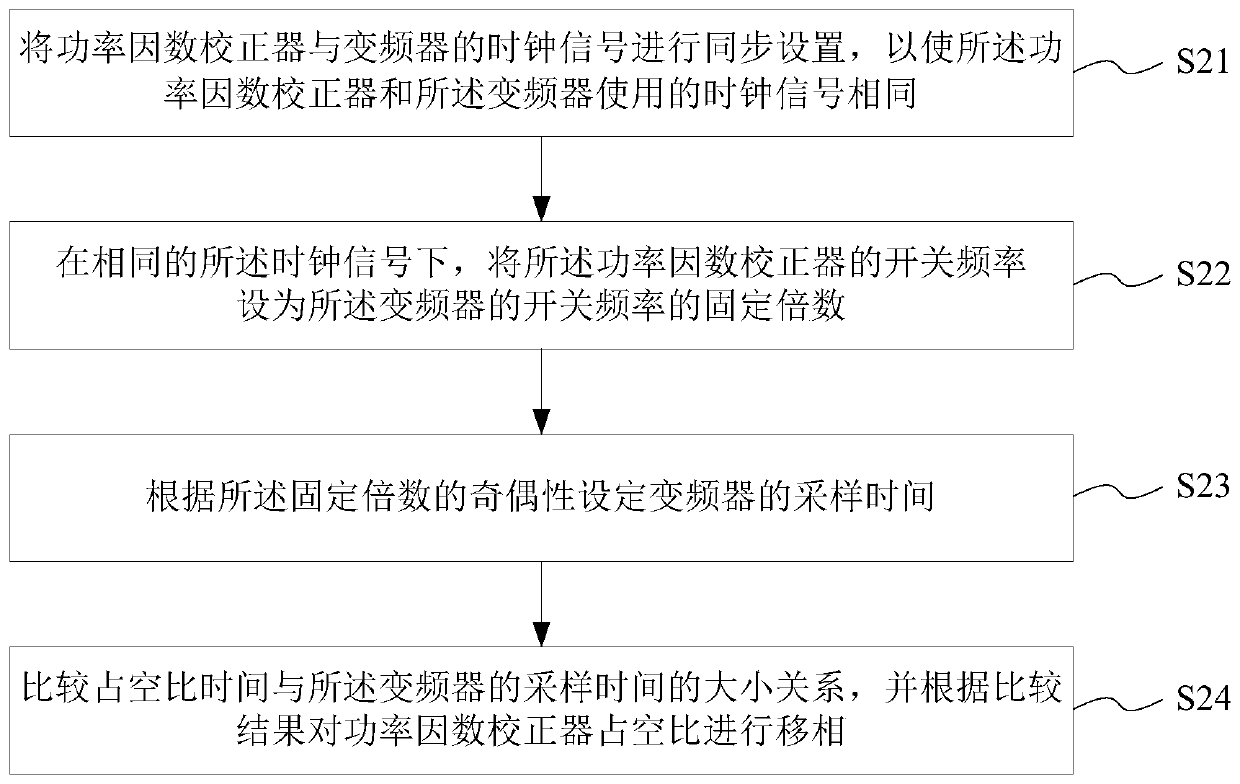

Duty ratio design method and system for eliminating current sampling interference, medium and equipment

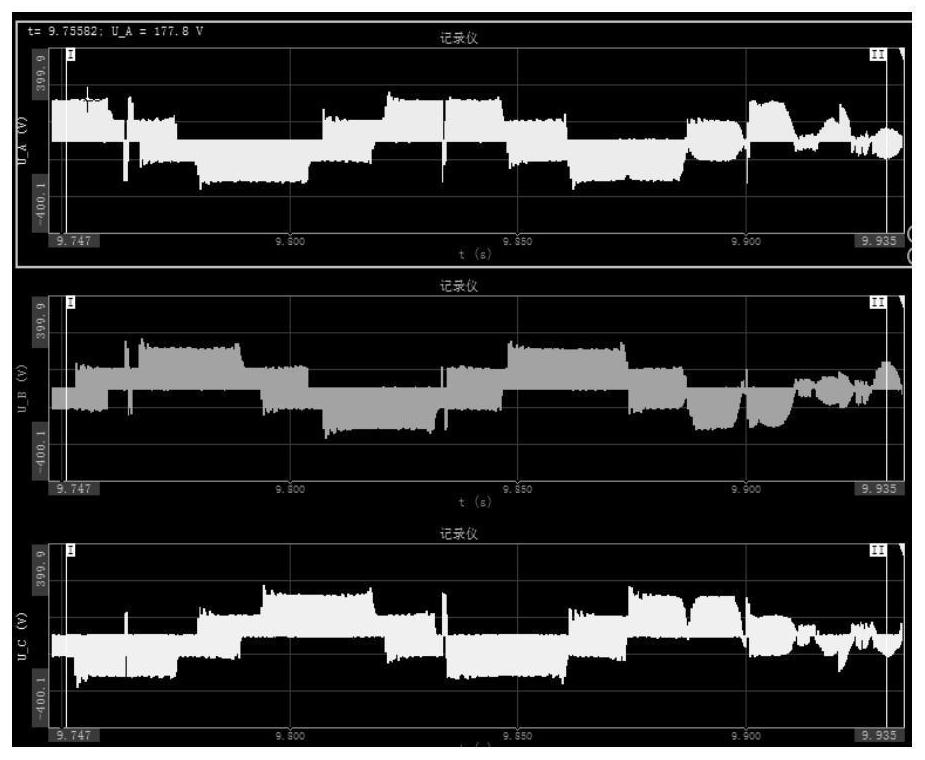

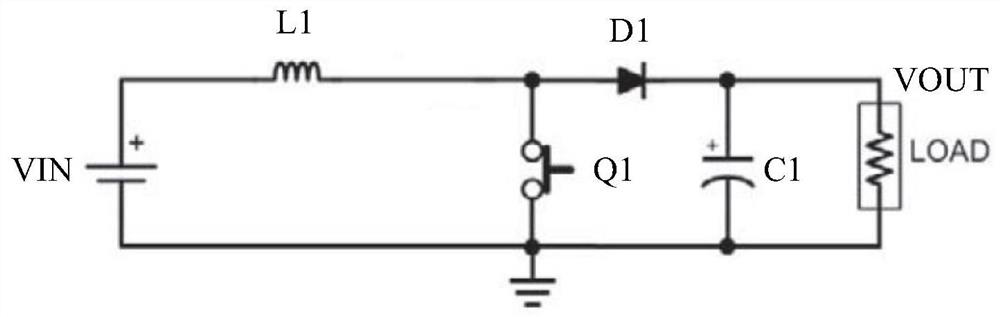

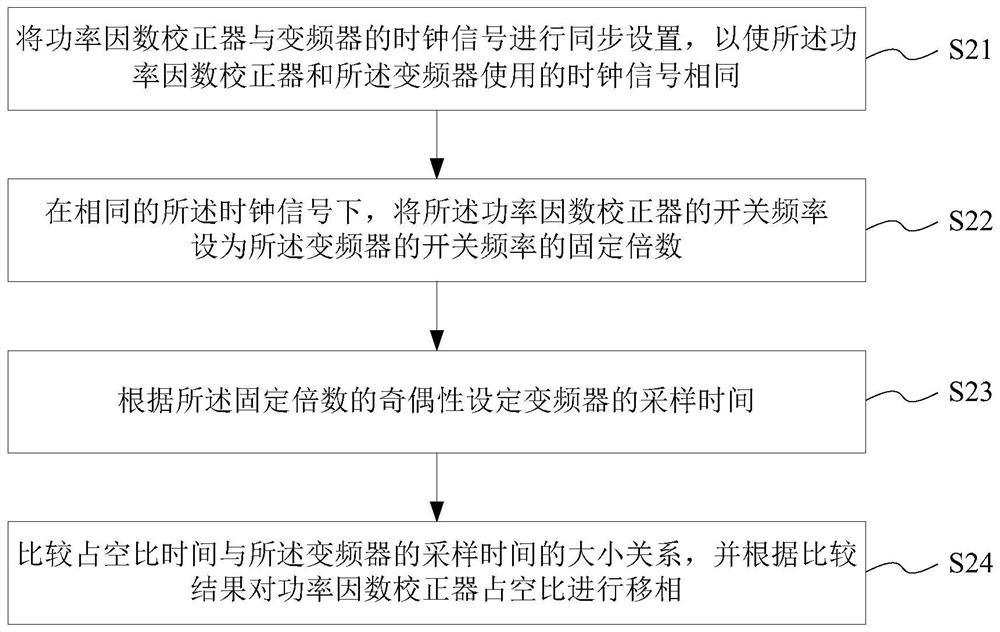

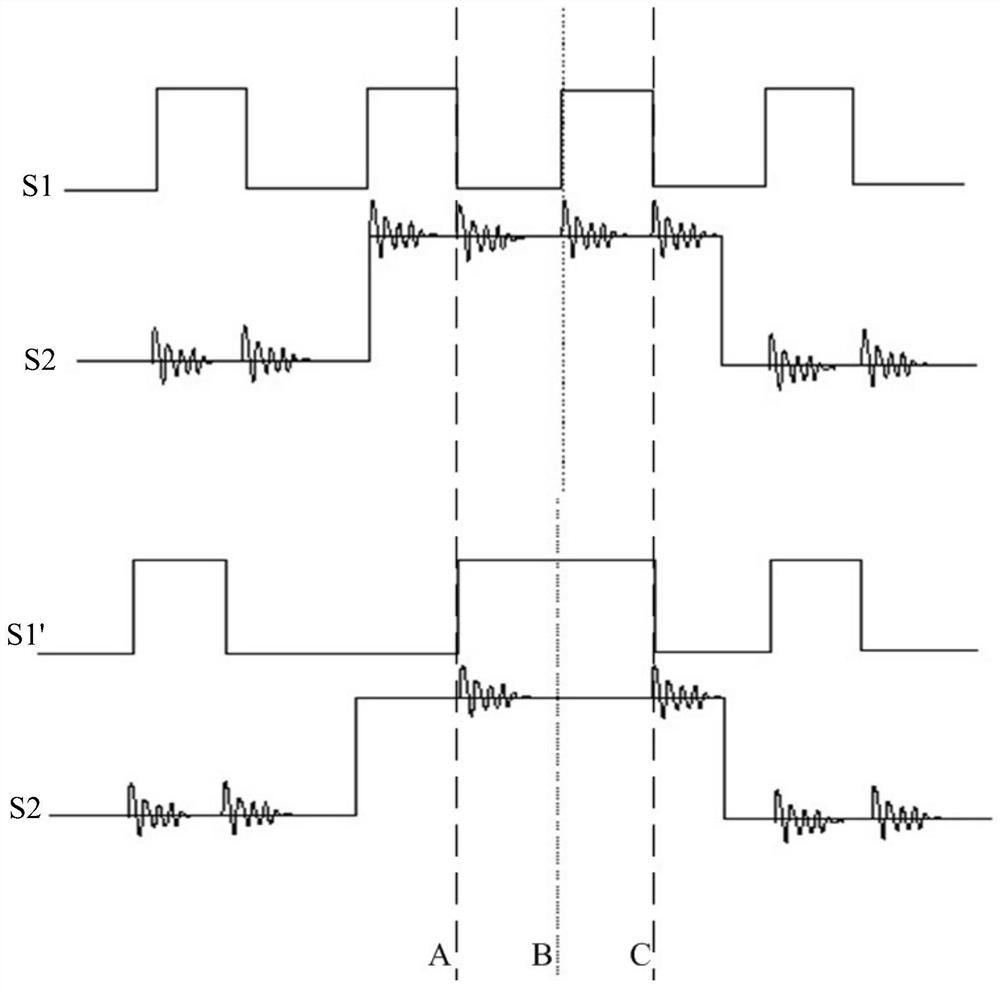

ActiveCN110798050AThe sampling value is accurateImprove accuracy and precisionEfficient power electronics conversionPower conversion systemsPower factor correctorFrequency changer

The invention provides a duty ratio design method and system for eliminating current sampling interference, a medium and equipment. The duty ratio design method for eliminating current sampling interference comprises the following steps: synchronizing the clock signal of a power factor corrector with the clock signal of a frequency converter to enable the clock signals used by the power factor corrector and the frequency converter to be the same; under the same clock signal, setting the switching frequency of the power factor corrector to be a fixed multiple of the switching frequency of the frequency converter; setting the sampling time of the frequency converter according to the parity of the fixed multiple; and obtaining the size relationship between the duty ratio time and the samplingtime of the frequency converter through comparison, and performing phase shift on the duty ratio of the power factor corrector according to the comparison result, wherein the duty ratio time and theduty ratio of the power factor corrector are determined according to the switching period of the power factor corrector. Through the PFC duty ratio control method provided by the invention, the problem of current sampling interference generated in an occasion where the PFC and the frequency converter are used at the same time is solved.

Owner:RUKING EMERSON CLIMATE TECH SHANGHAI CO LTD

Device and method for controlling moment

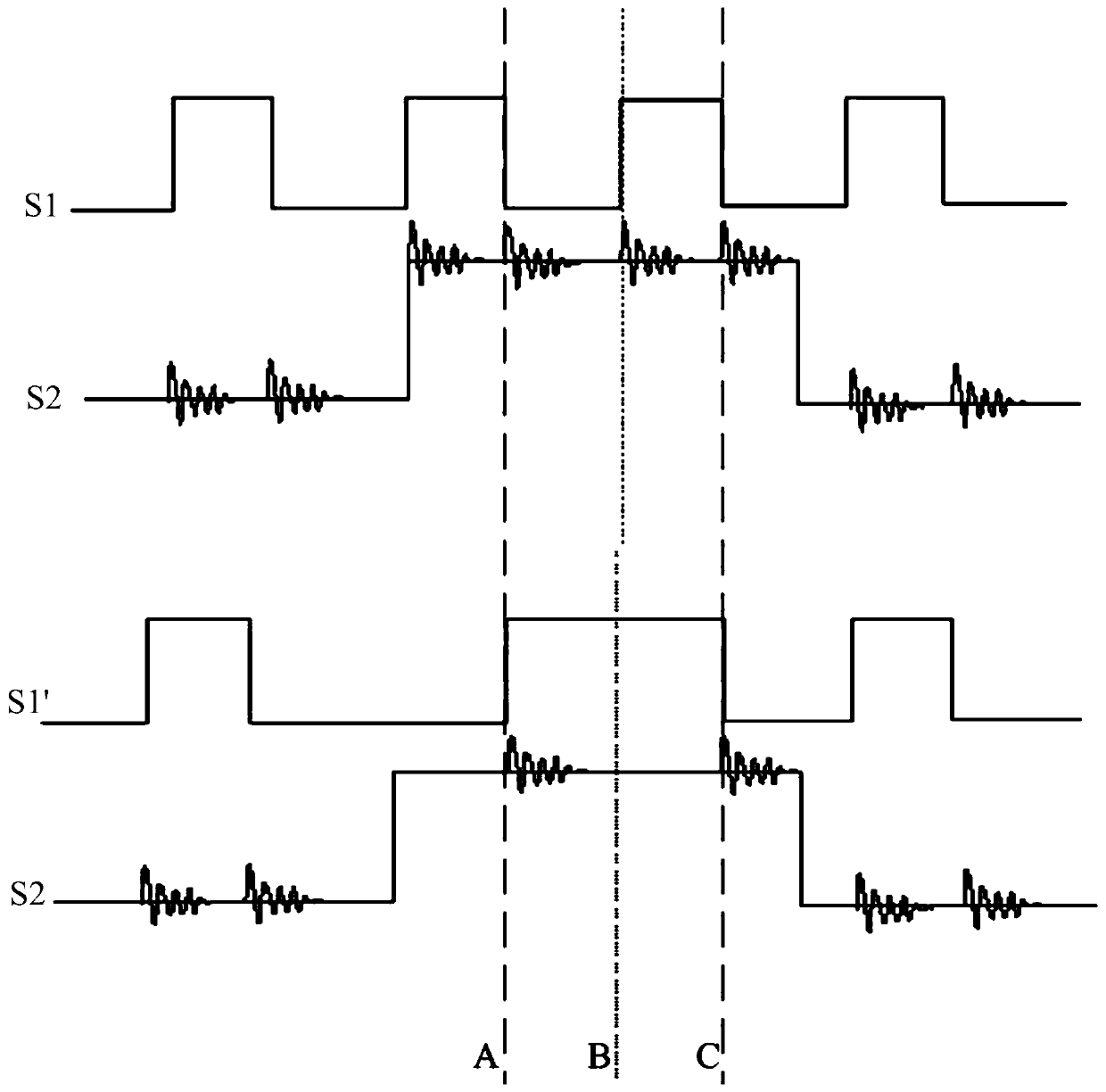

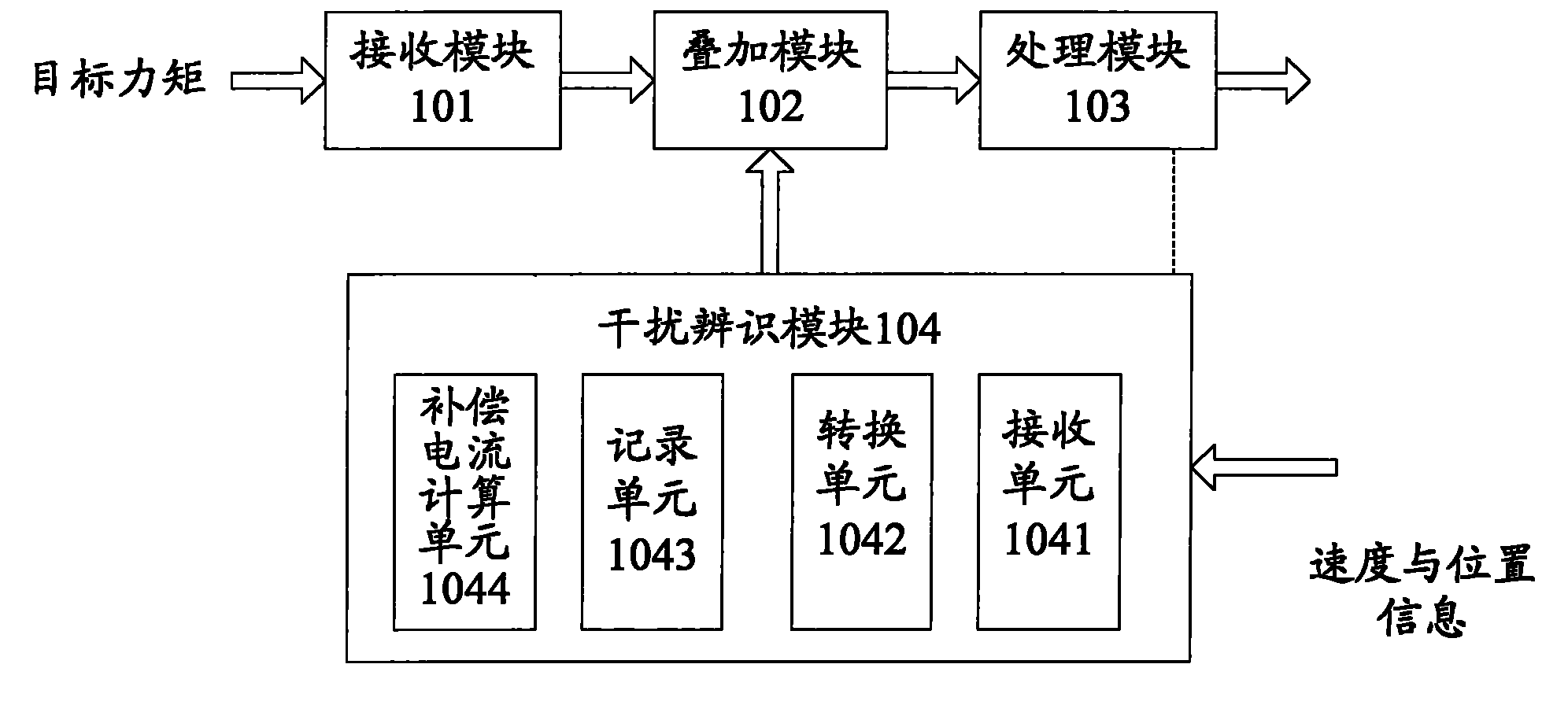

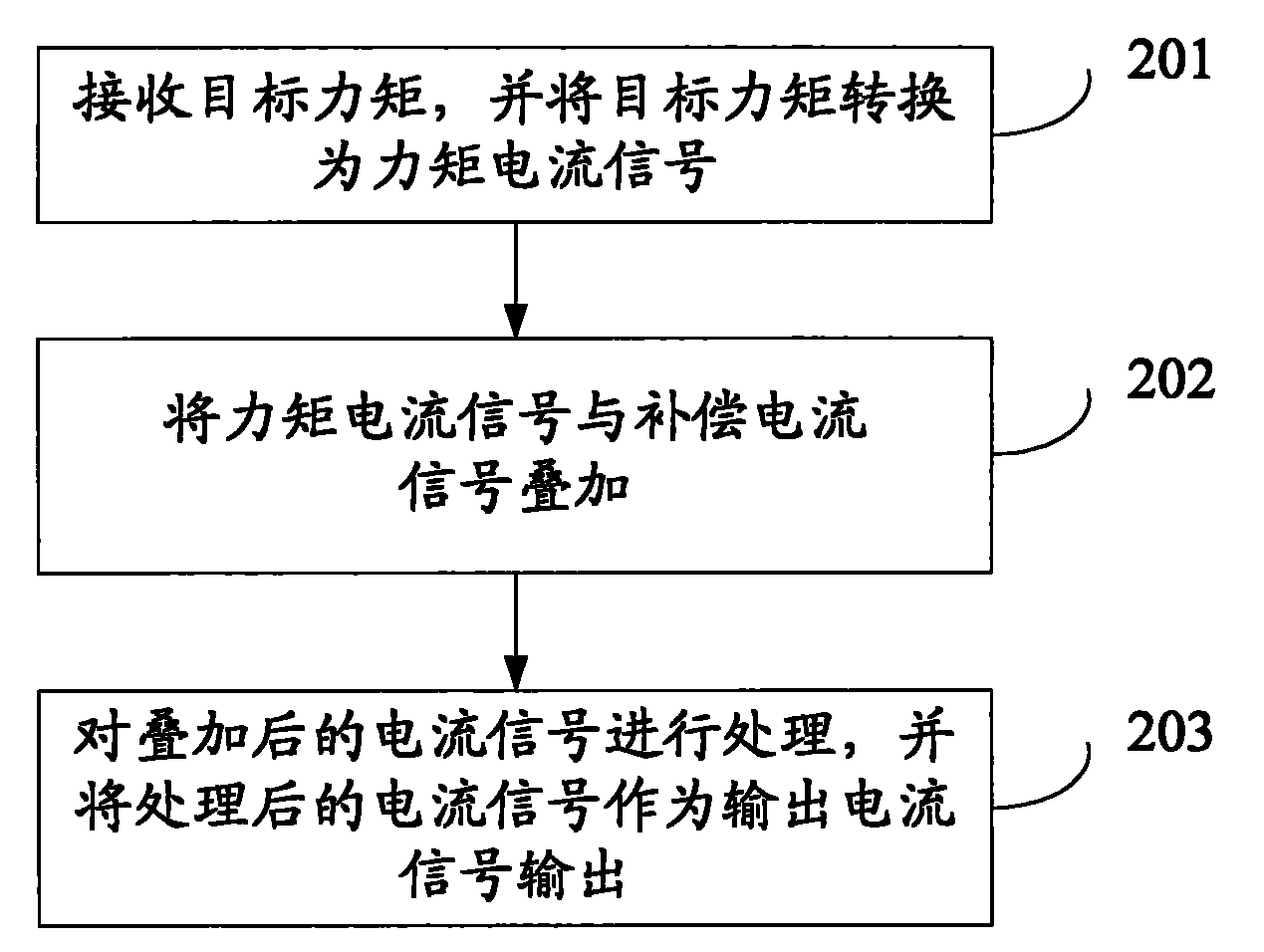

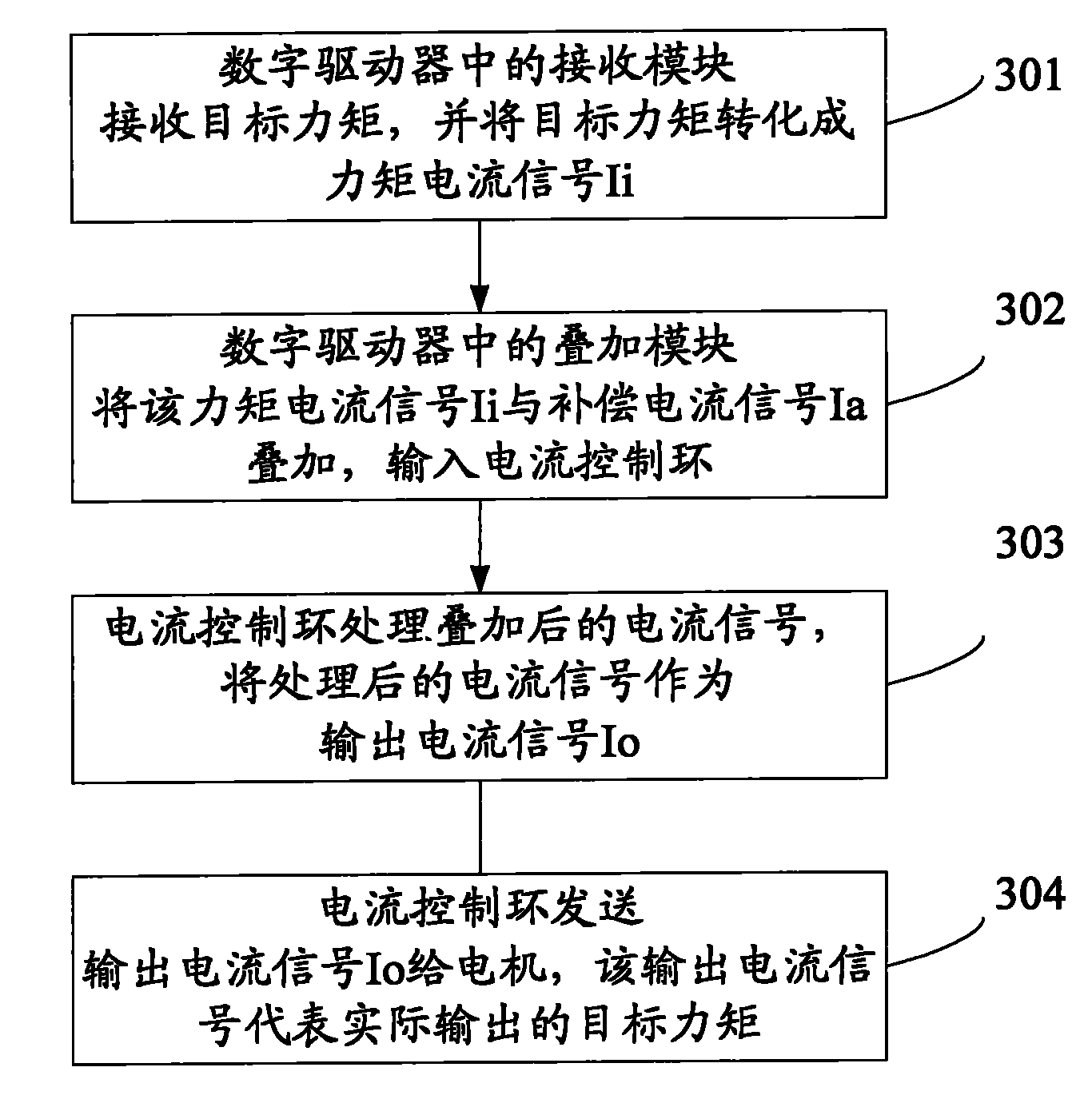

InactiveCN102063134AStable torque outputGuaranteed response speedMechanical power/torque controlSpeed/accelaration controlElectric machineryComputer module

The invention discloses a device and method for controlling a moment and belongs to the field of control. The device comprises a receiving module, an overlapping module, a processing module and an interference identification module. In the invention, moment ripples are subjected to active compensation, the systematic interference is effectively inhibited, the stable output of the moment of a motor is realized, the speed of responding to the moment is guaranteed, the systematic delay is avoided, a force sensor is not required, and the anti-interference capability is strong in the engineering.

Owner:BEIHANG UNIV

Active vibration damping method for torsional vibration of engine-motor coupling system

InactiveCN109677396AReduce torque fluctuationReduce instabilityHybrid vehiclesStarter generatorDamping torque

The invention provides an active vibration damping method for the torsional vibration of an engine-motor coupling system and belongs to the field of engine control. The method comprises the steps of firstly installing a torque sensor assembly applied to a hybrid engine; calculating the integrated output torque of a power system, the desired torque of the engine and the desired torque of an ISG (Integrated Starter Generator) motor by a vehicle control unit according to throttle opening signals at any time; obtaining the vibration damping torque of the ISG motor according to the difference valuebetween the desired torque and the actual output torque of the engine and obtaining the integrated output torque of the power system by combining with the desired torque of the ISG motor; and carrying out closed-loop control on the integrated output torque to obtain the control quantity of the ISG motor and realize active vibration damping. The method provided by the invention has the beneficialeffects that the torque fluctuation of the power system can be reduced; the torsional vibration of a drive system is reduced; and the risk that a shaft system of the drive system is broken due to thevibration is reduced.

Owner:TSINGHUA UNIV

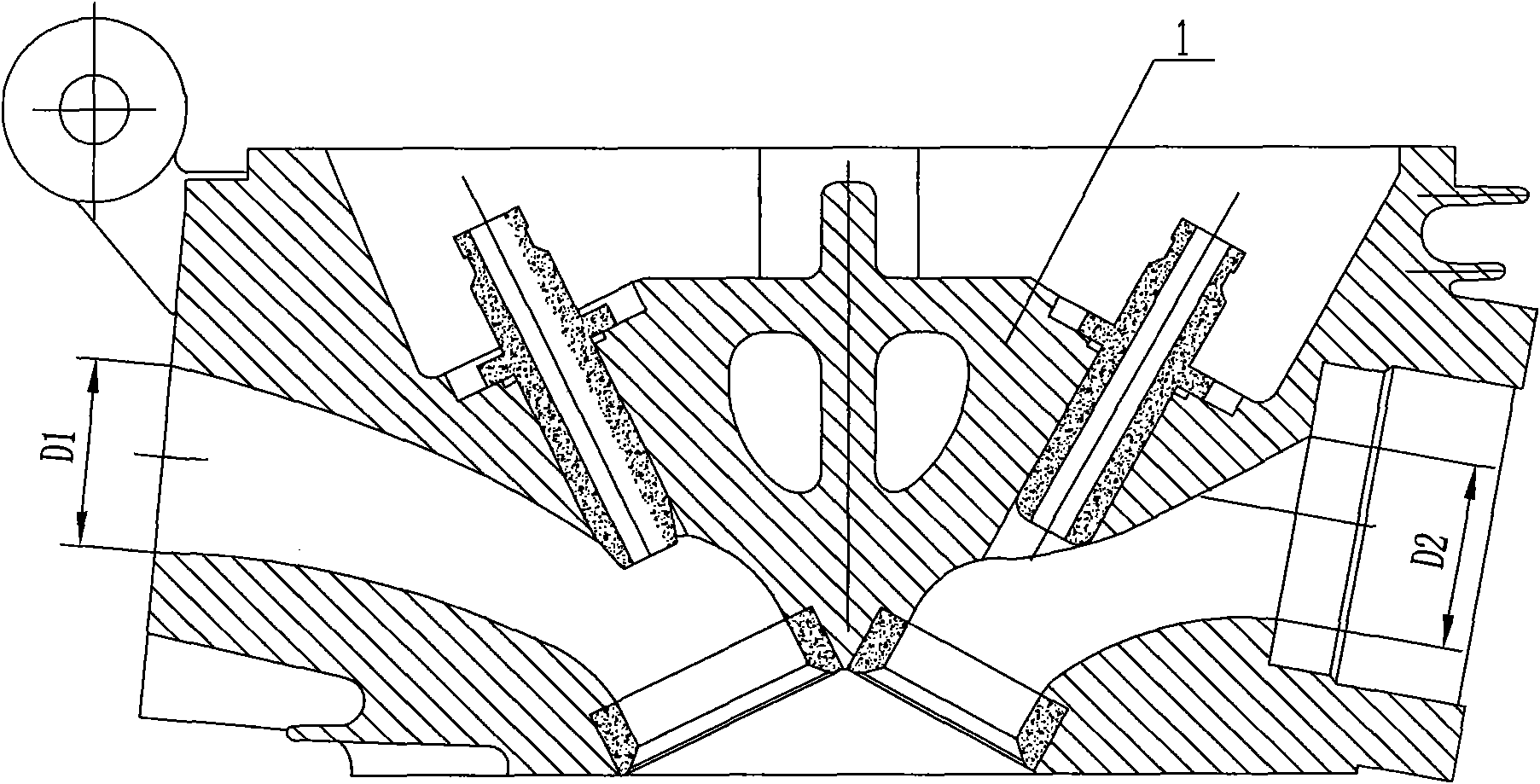

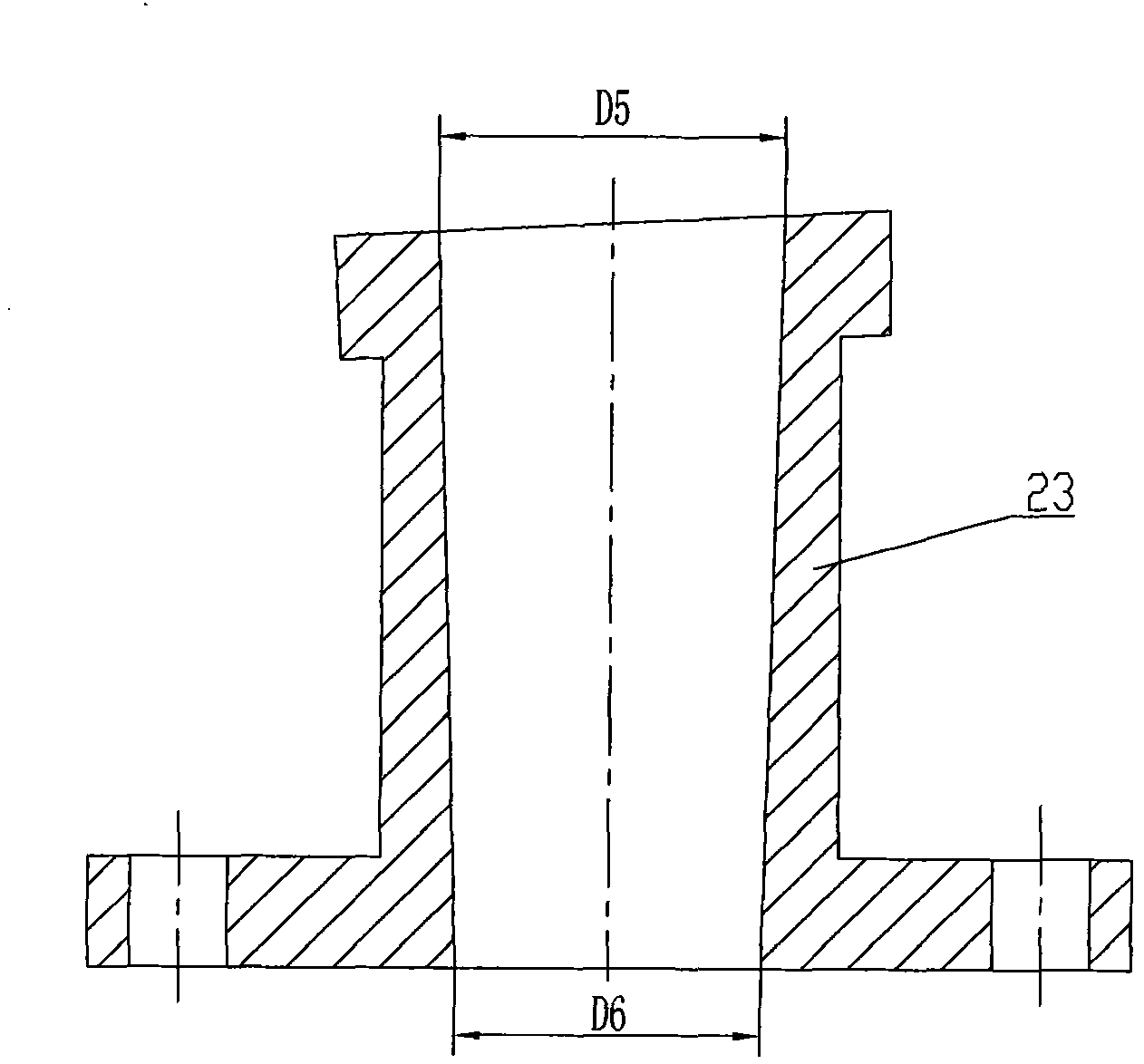

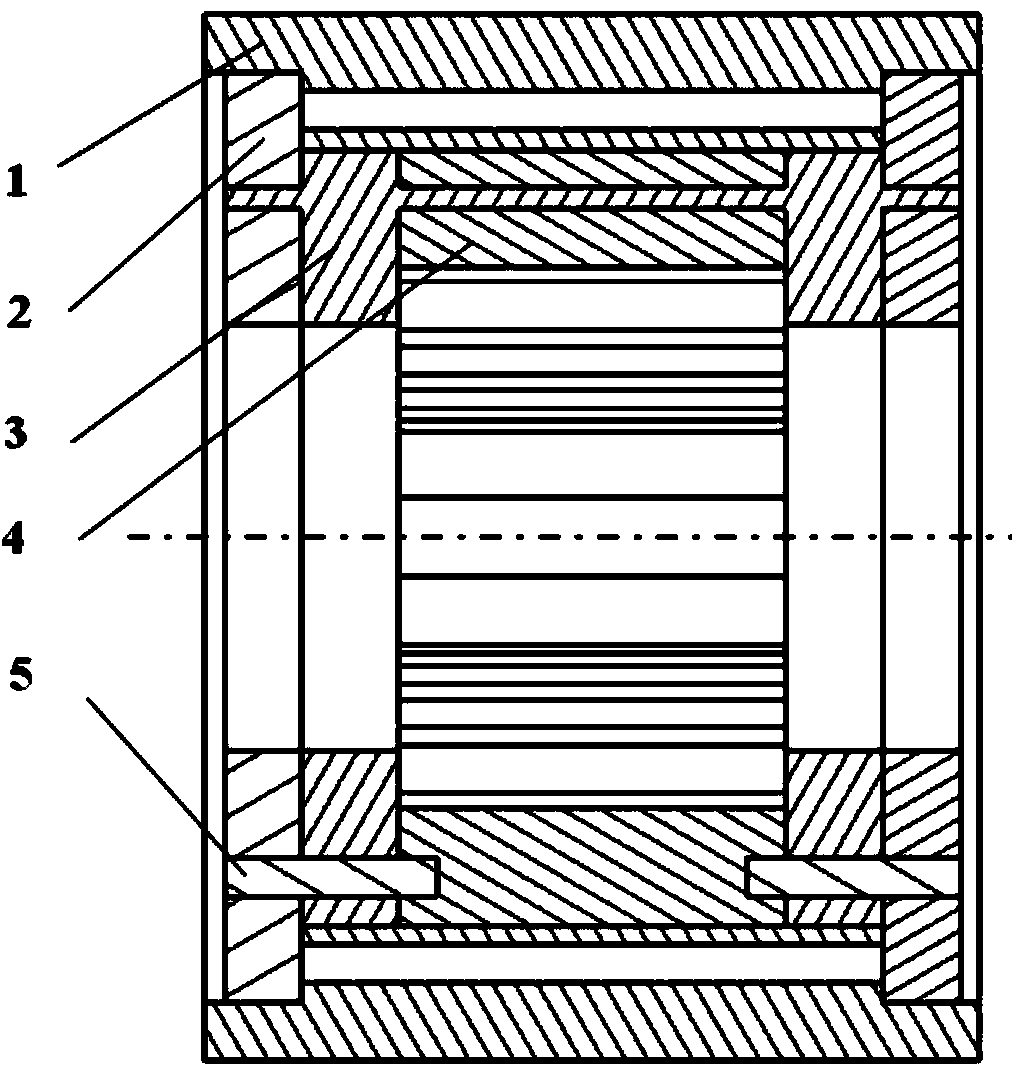

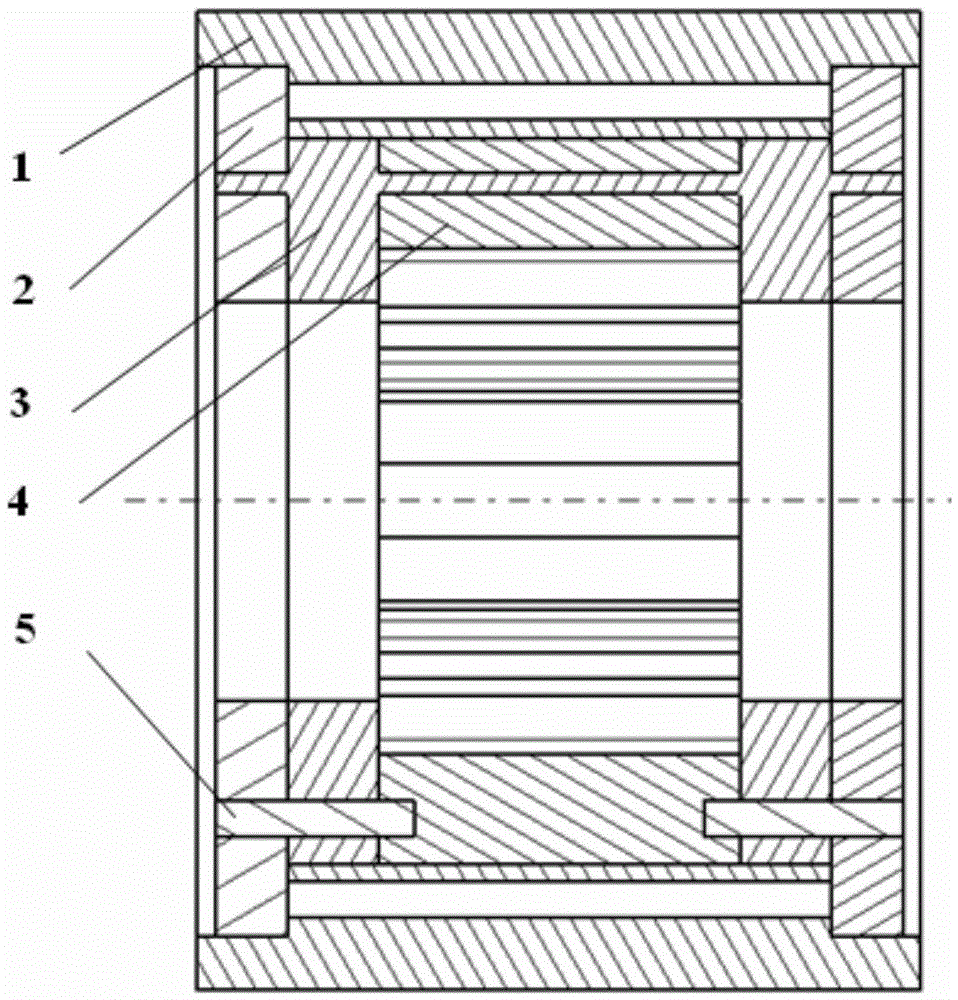

Water-cooled motor stator iron core fixing structure and fixing method thereof

ActiveCN103956837AStable torque outputAchieve fixationMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectric machineEngineering

The invention discloses a water-cooled motor stator iron core fixing structure and a fixing method thereof. According to the fixing structure, a stator iron core and a water channel pressing plate are connected rigidly by utilizing steel pins and colloid injected into a shell, the water channel pressing plate and the stator iron core, the water channel pressing plate is also connected with the shell rigidly, and therefore fixation of the stator iron core is achieved. The fixing structure enables air gaps between a stator and a rotor of a water-cooled motor to be more even and motor torque output to be stable, and noise can be lowered effectively. According to the fixing method of the water-cooled motor stator iron core fixing structure, the hot press fitting technology does not need to be adopted, only a common press fitting technology is needed, the technology is simple, and assembling cost can be reduced. When the hot press fitting technology is adopted, the risks of uneven deformation exist in heating and cooling deformation processes, the unevenness can be transmitted to the air gaps between the stator and the rotor, and the performance of the motor is further influenced, but no mentioned risks exist in the fixing method of the water-cooled motor stator iron core fixing structure.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

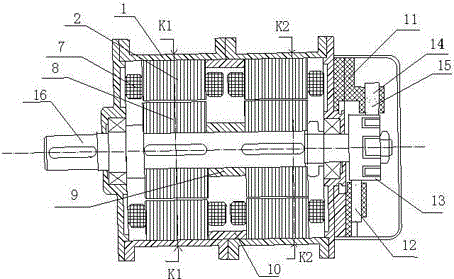

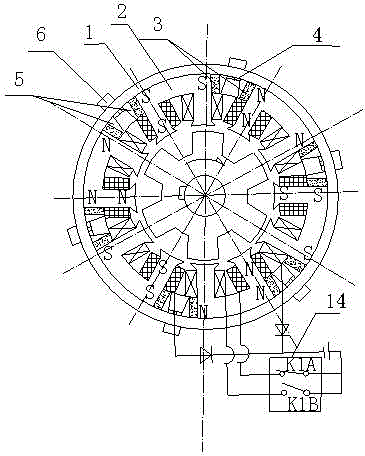

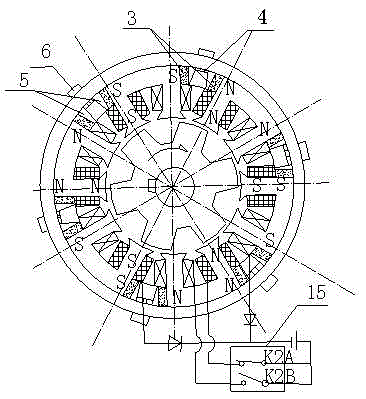

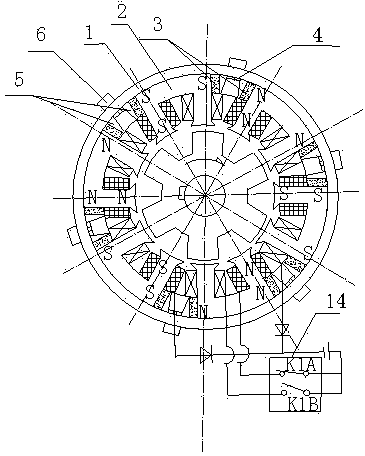

Loop superposition magnetic circuit switch reluctance direct current motor

ActiveCN105978275AImprove energy efficiencyImprove power densitySynchronous machine detailsHigh power densityPhysics

The invention discloses a loop superposition magnetic circuit switch reluctance direct current motor. The motor comprises a stator unit and a rotor unit arranged in the stator unit. The stator unit comprises a number of split stator iron core laminations arranged in a cabinet, stator windings wound on the salient poles of the stator iron core laminations, stator permanent magnets, and an iron-magnetically permeable wedge assembly used for fixing the stator iron core laminations and the stator permanent magnets. A stator permanent magnet of the same polarity is placed on the ring direction surface of both ends of each independent stator iron core lamination. A stator iron core lamination and a stator permanent magnet form a unipolar stator iron core lamination single body. After a stator winding on the salient pole of a stator iron core lamination is energized, an electromagnetic field generated by the winding of the phase and a permanent magnetic field are superimposed, strengthened and applied on the rotor. The rotor is in a non-winding non-magnet salient pole type structure. The loop superposition magnetic circuit switch reluctance direct current motor provided by the invention uses the structure, and has the advantages of high work efficiency, low power consumption, high power density, smooth operation and excellent comprehensive performance.

Owner:冯西川

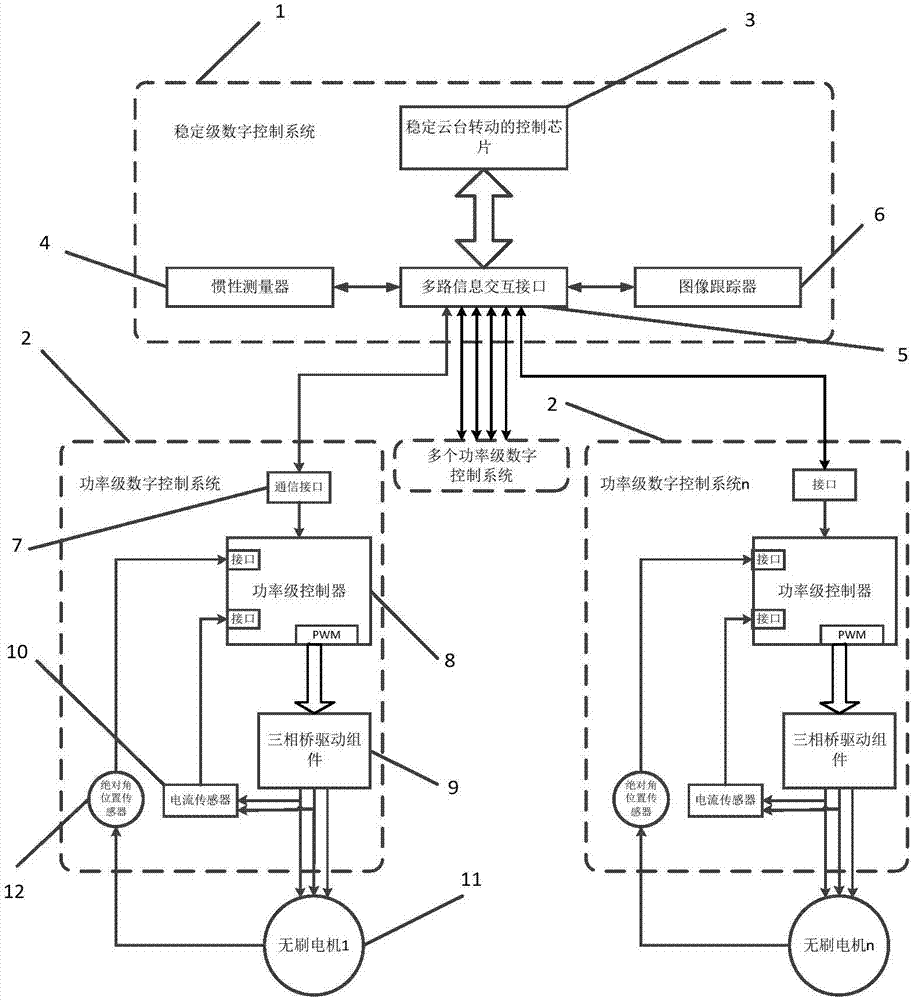

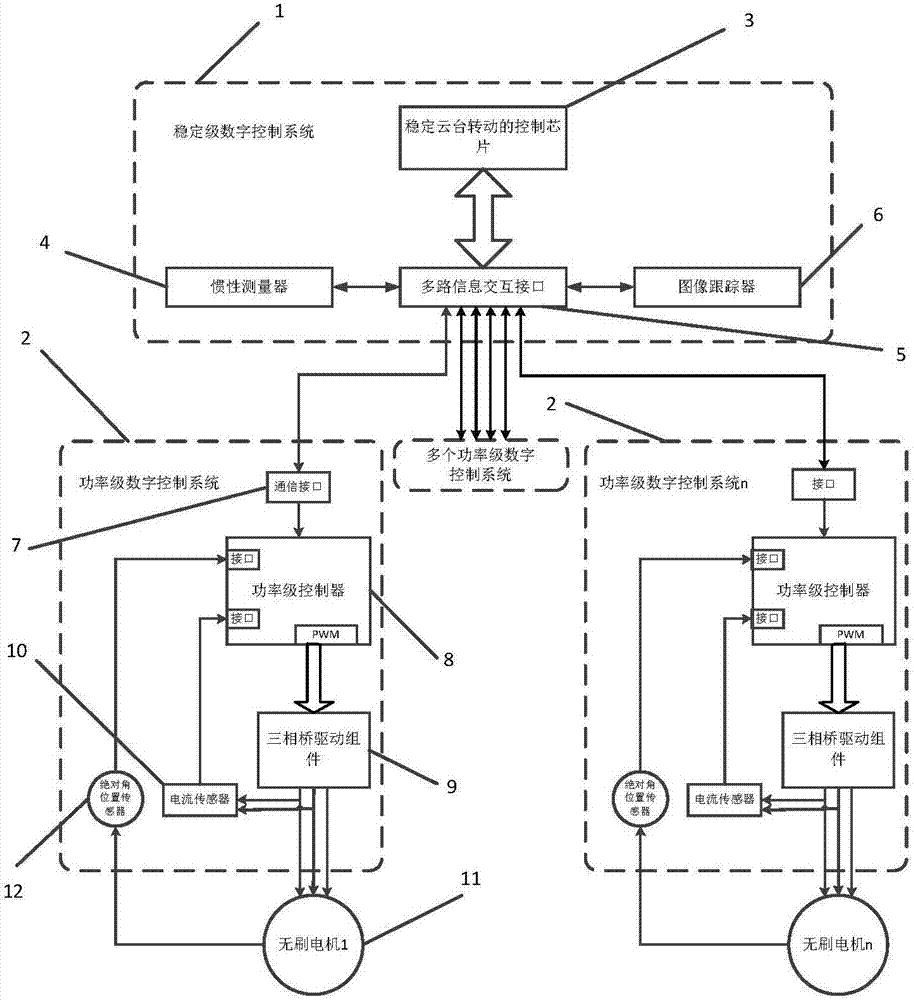

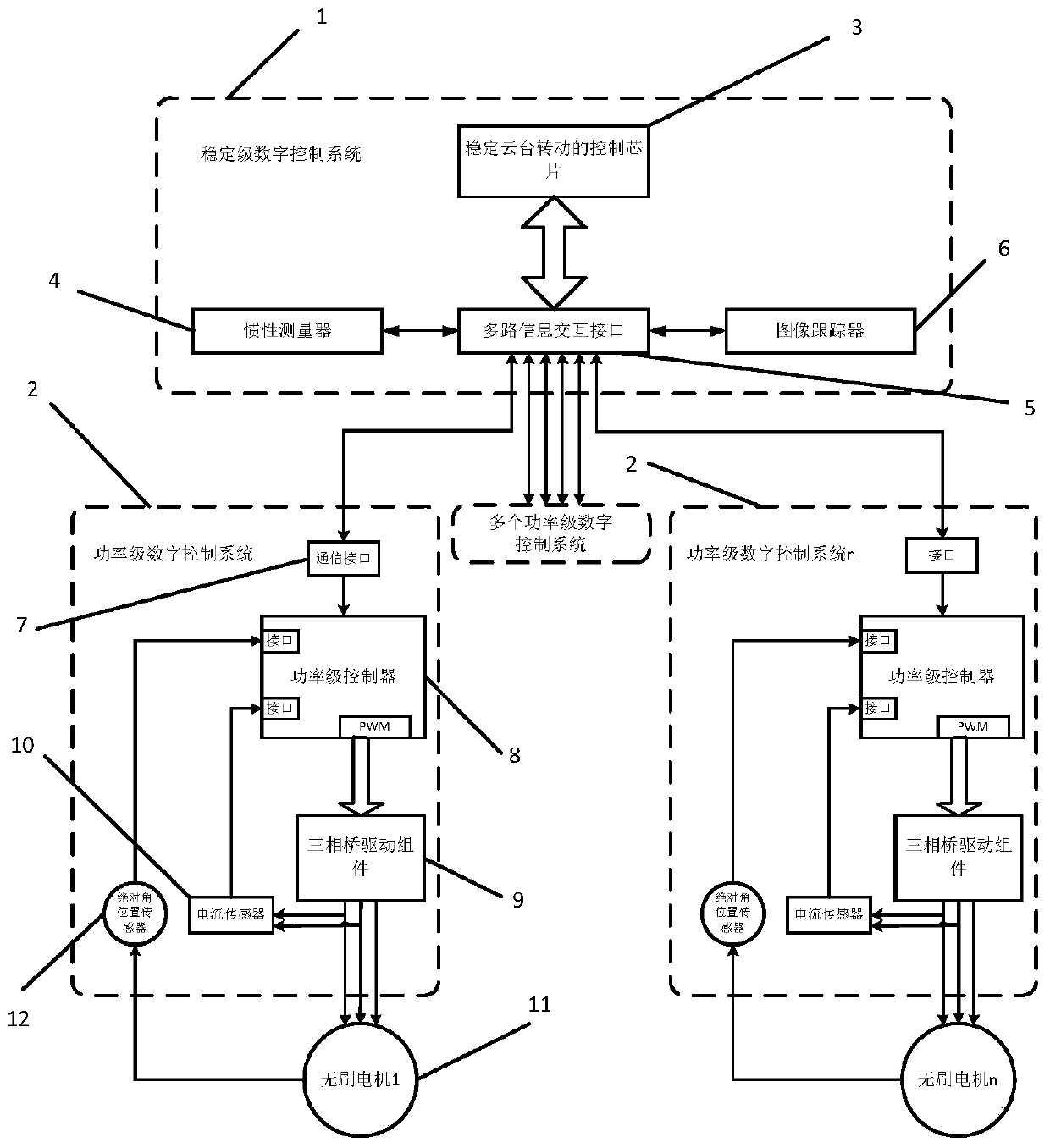

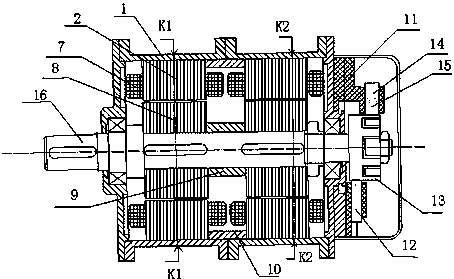

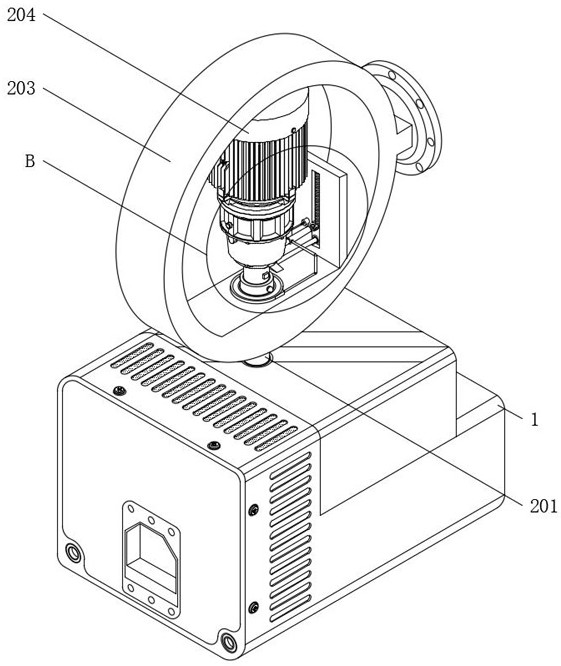

Drive control system and stabilization head with same

ActiveCN107203223ARelieve pressureEliminate the effects of induced electromotive forceElectronic commutation motor controlVector control systemsBrushless motorsControl system

The invention relates to a drive control system for brushless motors. According to the drive control system, a stability digital control system is connected with at least one power digital control system, and communicates with the power digital control systems according to the order of the power digital control systems. The power digital control systems are connected with at least one brushless motor, and are used for getting the duty ratio of output PWM according to the current electrical degree value, the alternating-axis voltage control quantity and the direct-axis voltage control quantity to control the rotation of the brushless motors, and saving the absolute initial value of electrical degree when an acquired control instruction is an end instruction.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

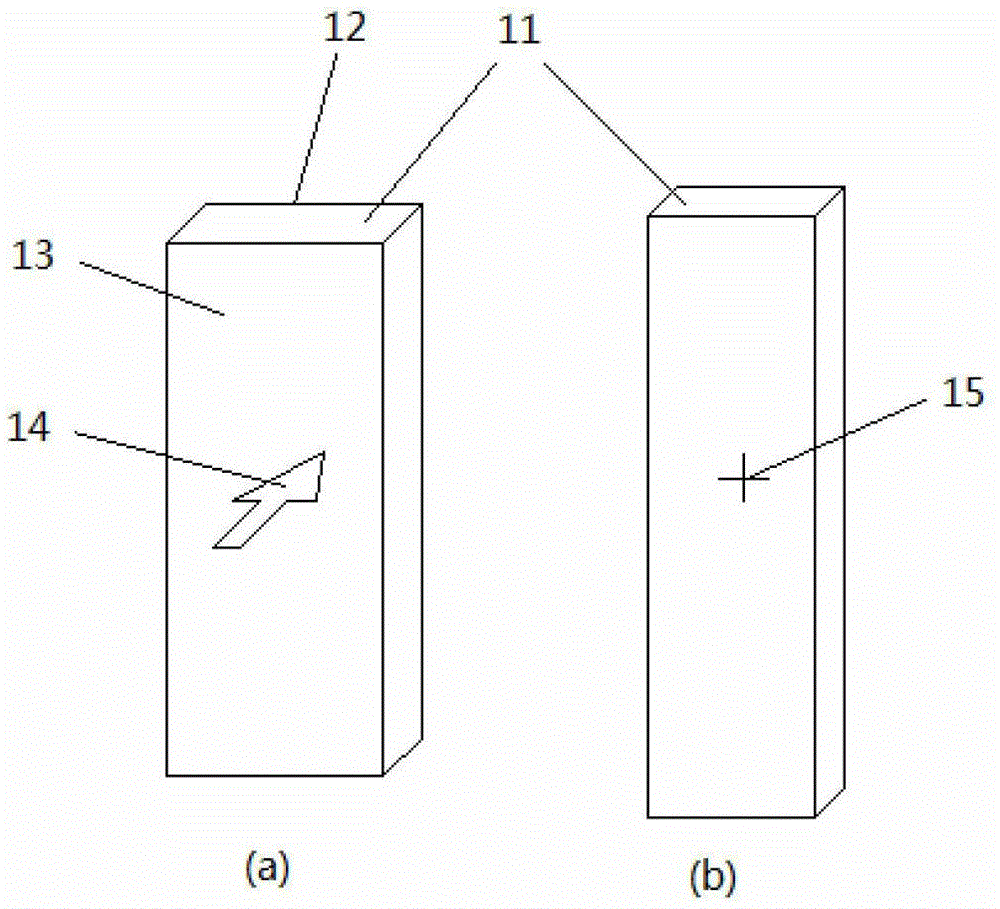

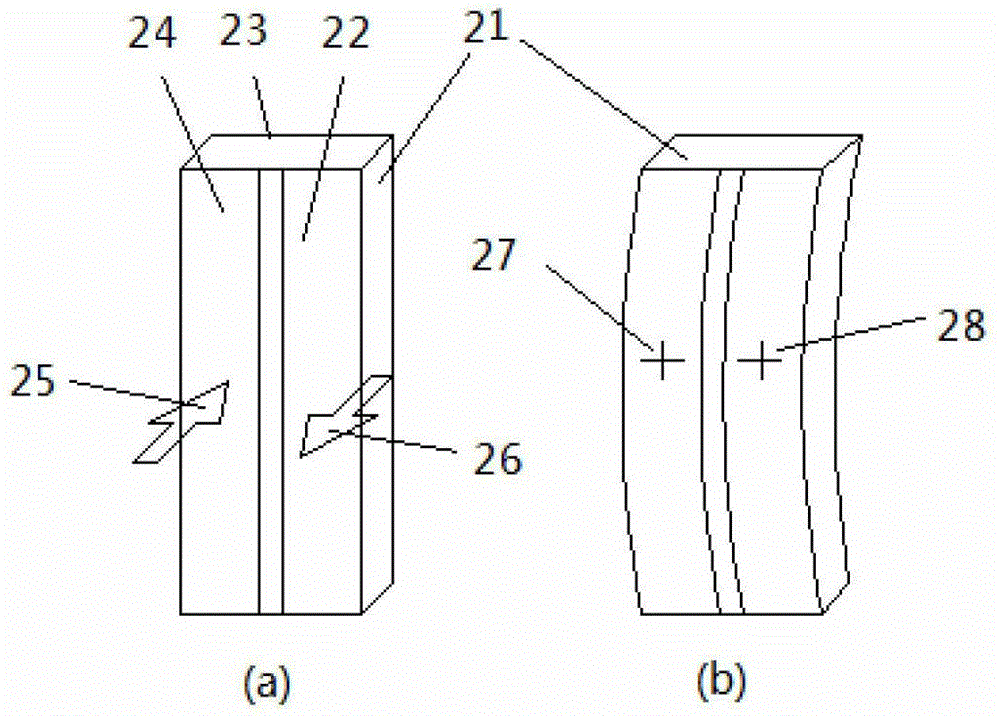

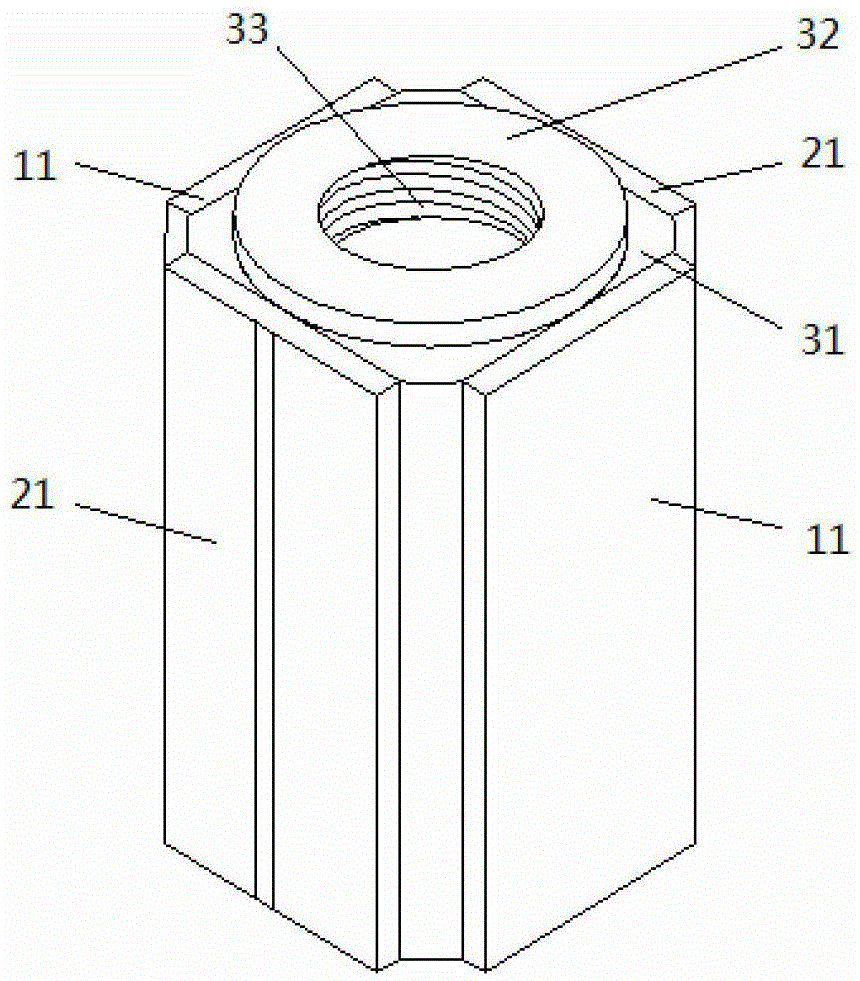

Threaded Linear Ultrasonic Motor

InactiveCN103036472BOvercome Difficulties Difficult to MiniaturizeSimple processPiezoelectric/electrostriction/magnetostriction machinesMiniaturizationLongitudinal vibration

The invention discloses a threaded linear ultrasonic motor. The threaded linear ultrasonic motor comprises a stator and a rotor, wherein the stator comprises stator bases, longitudinal vibration piezoelectric plates and torsional vibration piezoelectric plates. The longitudinal vibration piezoelectric plates and the torsional vibration piezoelectric plates are sticked on the stator. The stator bases are four flat surfaces which are uniformly cut on a hollow cylinder to be used for sticking the longitudinal vibration piezoelectric plates and the torsional vibration piezoelectric plates. The longitudinal vibration piezoelectric plates and the torsional vibration piezoelectric plates are respectively arranged symmetrically and used in pairs. The rotor is penetrated through the stator, and is matched with an inner thread of two thread driving ends of the stator through an outer thread of the rotor. The longitudinal vibration piezoelectric plates and the torsional vibration piezoelectric plates excite compound vibrations of a longitudinal vibration and a torsional vibration in the stator to enable a particle movement locus of the thread driving ends of the stator to be ellipses. The stator drives the rotor to be rotated through rub and transform a rotational motion to a rectilinear motion. The threaded linear ultrasonic motor can achieve speed regulation and dual direction driving. The threaded linear ultrasonic motor has the advantages of being low in cost, high in accuracy, and simple to manufacture. The threaded linear ultrasonic motor contributes to miniaturization and industrialization.

Owner:SHANGHAI JIAOTONG UNIV

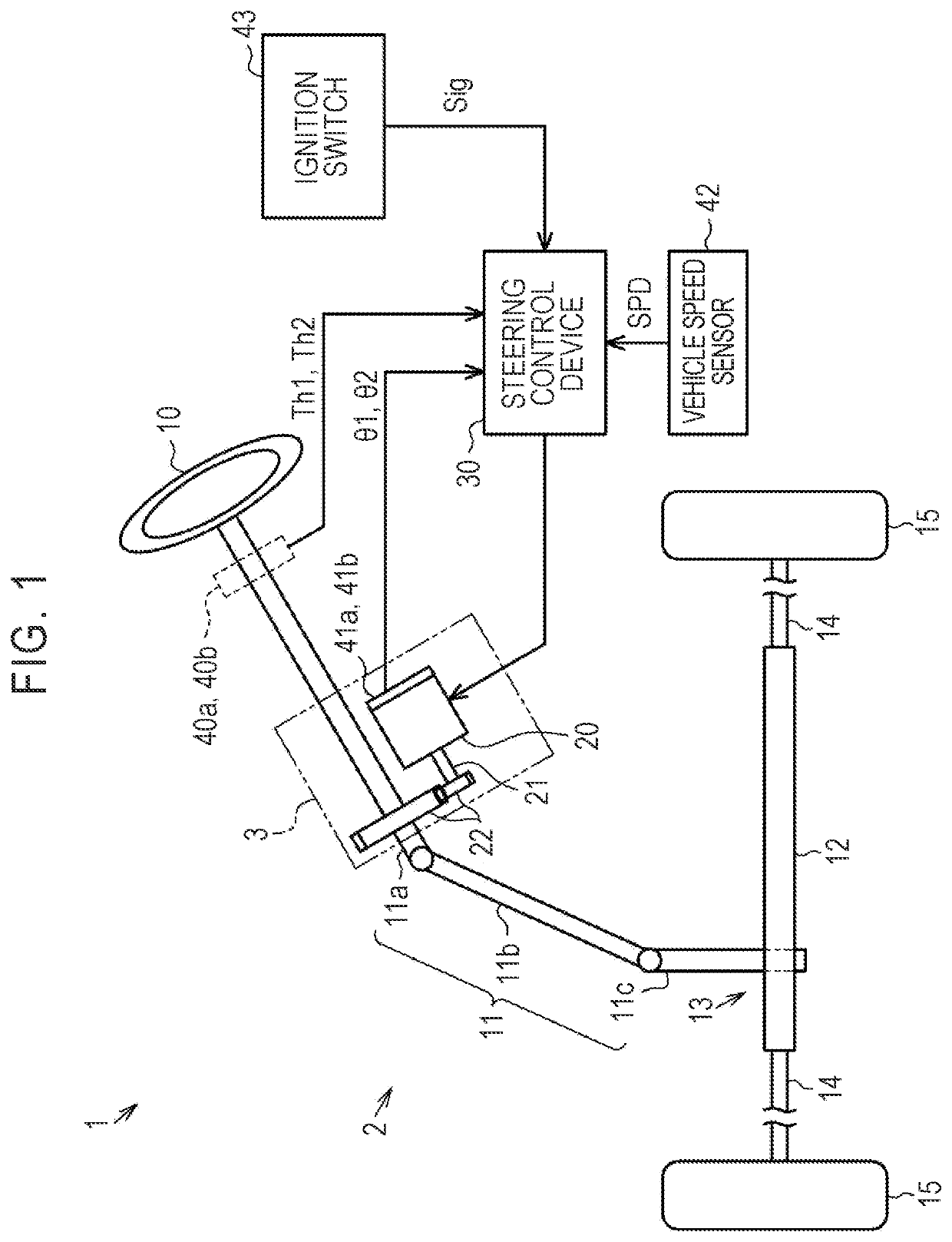

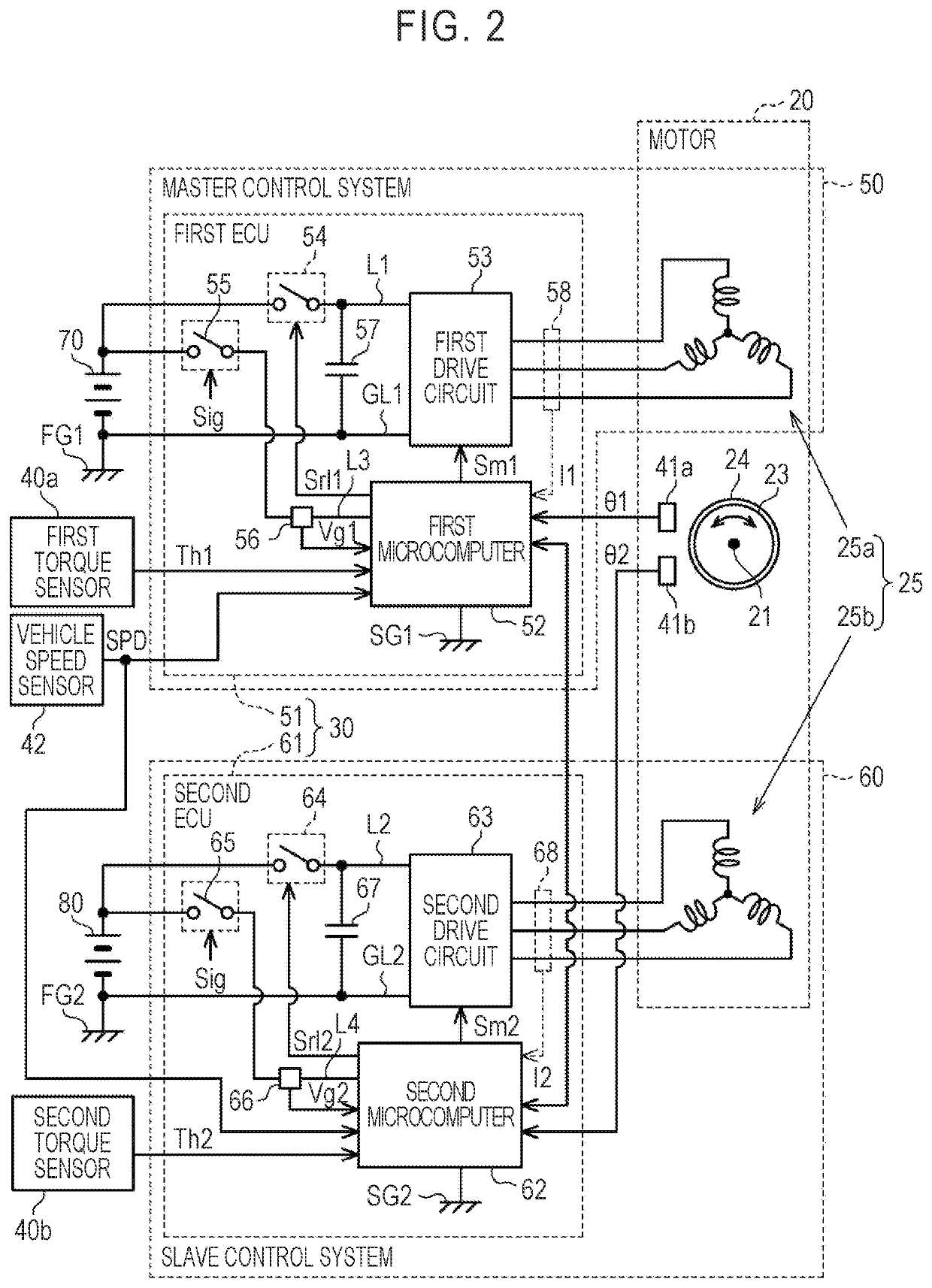

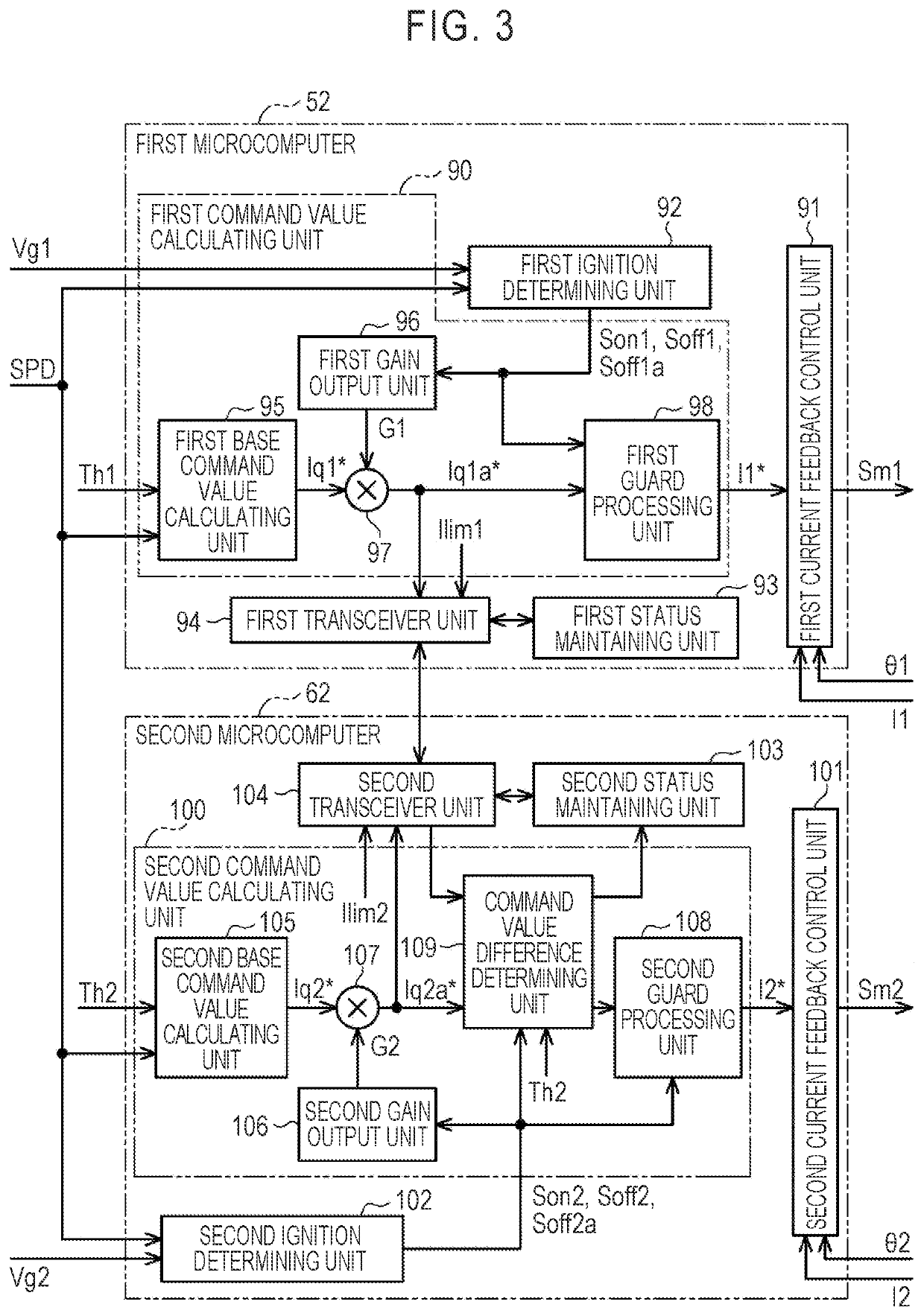

Steering control device

PendingUS20220297743A1Curb fluctuation of torque outputSuppress fluctuationsElectrical steeringControl systemMode control

In a steering control device, a plurality of control systems is configured to switch a drive mode to a cooperative drive mode when command values calculated by control units of the control systems are not different from each other and to switch the drive mode to an independent drive mode when the command values calculated by the control units of the control systems are different from each other. The control systems are configured to gradually limit the command values respectively calculated by the control units of the control systems when a start switch of a vehicle has been turned off. The control systems are configured to switch the drive mode to the independent drive mode regardless of whether the command values calculated by the control units of the control systems are different from each other when the start switch has been turned off while the vehicle is traveling.

Owner:JTEKT CORP +1

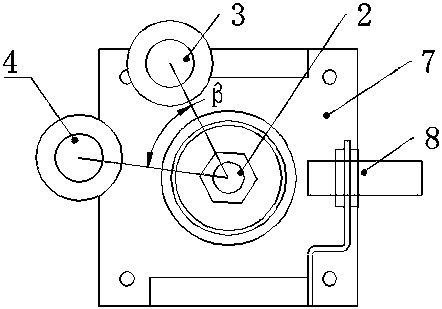

Cable machine steel strand bending device

PendingCN107919194AAvoid breakingNot easy to damageCable/conductor manufactureCable machineClassical mechanics

The invention relates to a machining tool, in particular to a cable machine steel strand bending device. The cable machine steel strand bending device comprises an electric motor and a bending mechanism for connecting the electric motor, wherein the bending mechanism comprises a connecting shaft, a rotating shaft and a fixed shaft, wherein the electric motor is connected with the connecting shaftand synchronously drives the connecting shaft to rotate; the rotating shaft and the fixed shaft are arranged in parallel to the connecting shaft mutually respectively; the rotating shaft can rotate bidirectionally and freely around the axis of the rotating shaft; the connecting shaft, the rotating shaft and the fixed shaft are positioned on different straight lines; and the connecting wires of thecircle centers of the three shafts form a triangle. The device has the characteristics that the structure is simple, the torque output is stable, a cable is unlikely to fracture, the surface of the cable is unlikely to damage and the bending curvature is relatively trim.

Owner:浙江三信智能机械股份有限公司

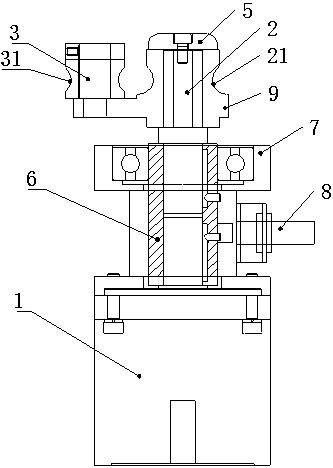

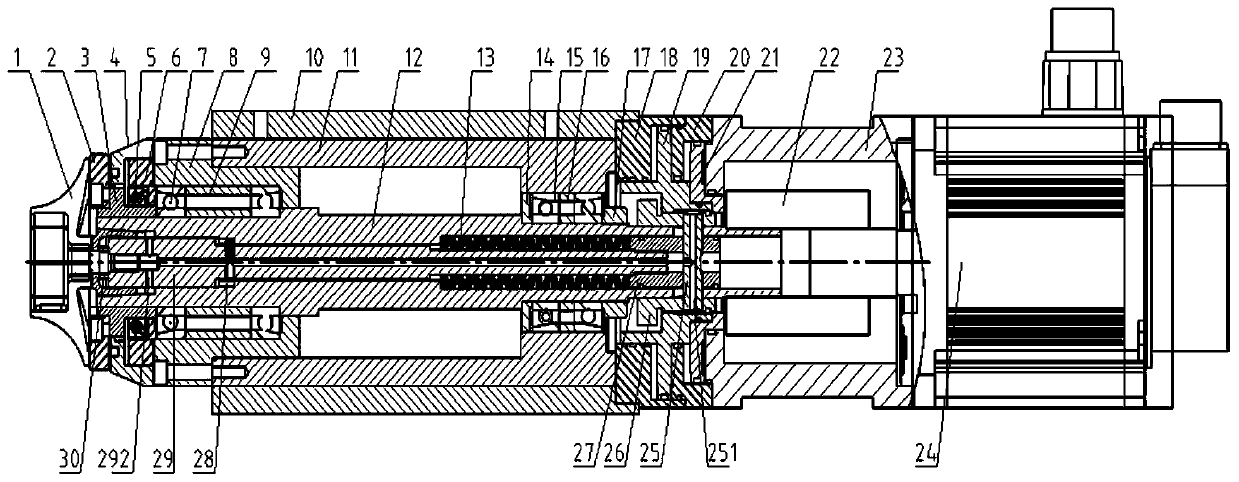

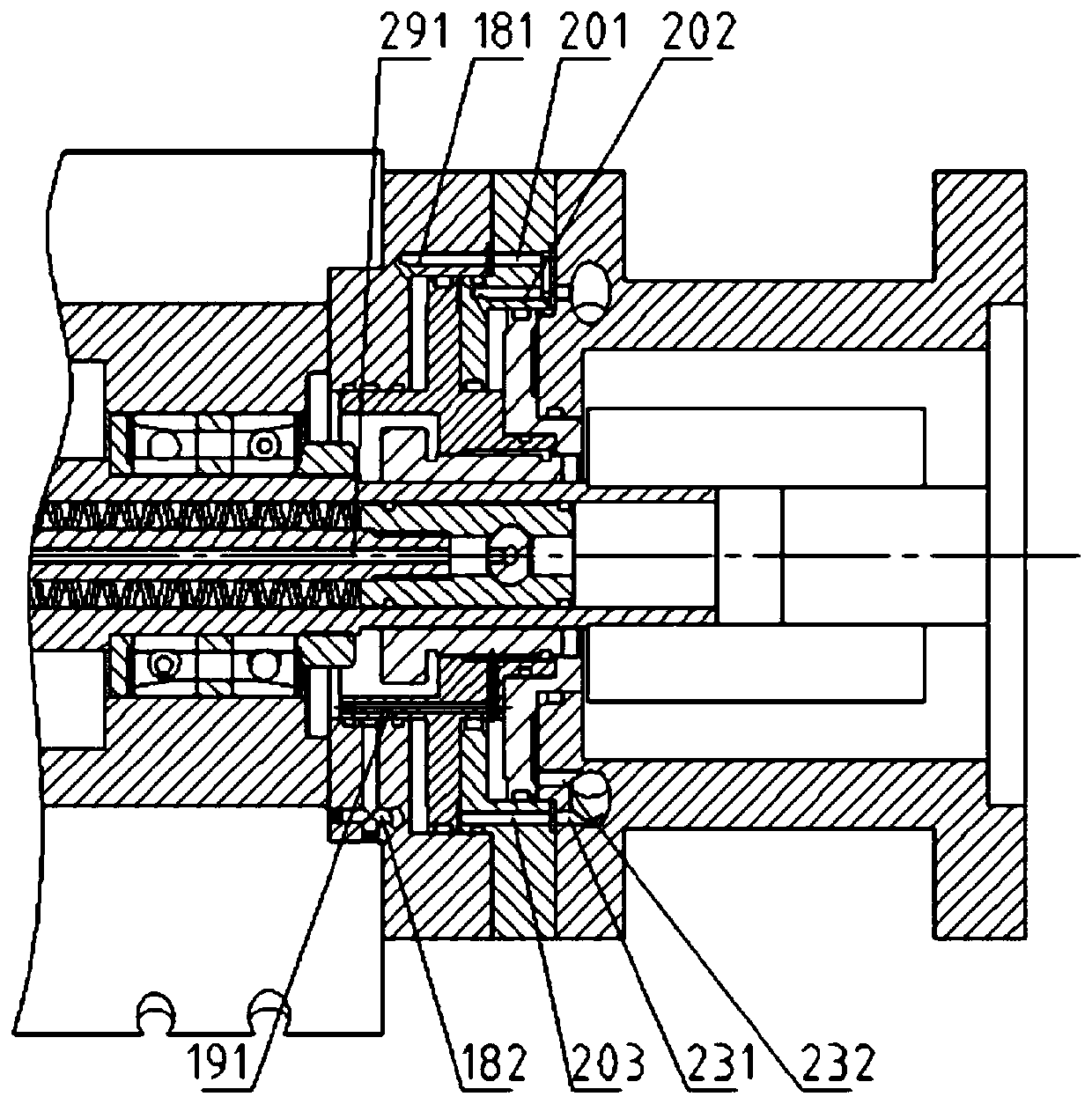

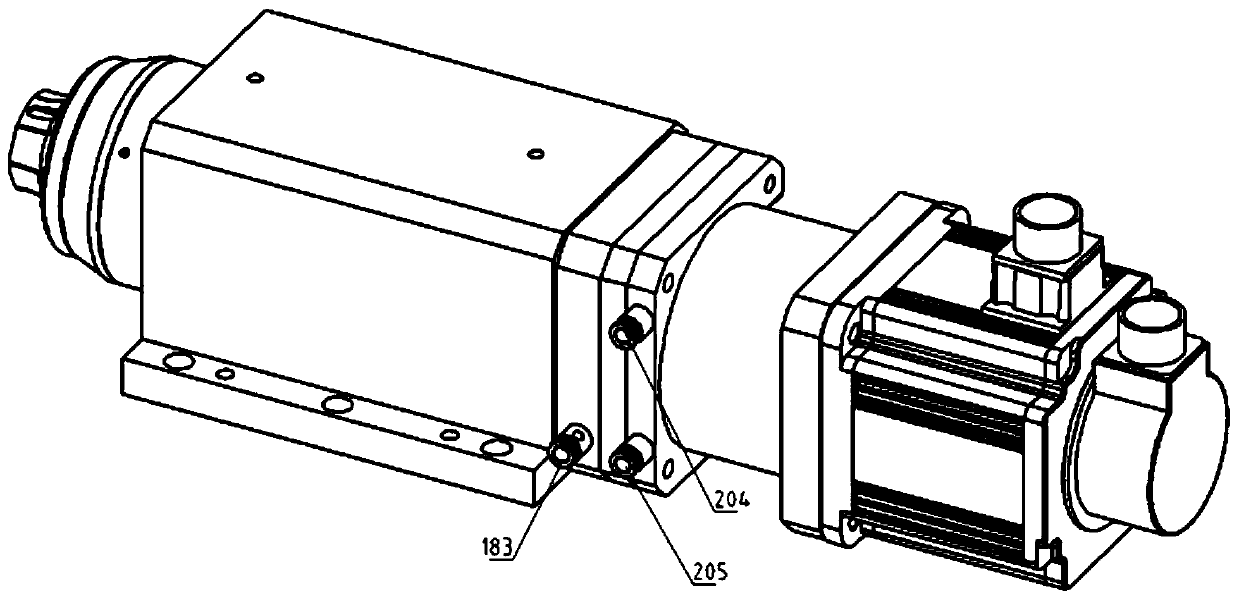

Servo direct connection type spindle device

PendingCN111331511ARealize automatic releaseRealize automatic clampingGrinding drivesGrinding work supportsRotational axisCoupling

The invention discloses a servo direct connection type spindle device which comprises claws, a rotating shaft, a disc spring assembly, a first air cylinder, a second air cylinder, a sliding sleeve, apressing sleeve and a transmission device. A push rod is arranged in the rotating shaft, the claws are arranged at one end of the rotating shaft and connected with one end of the push rod, the slidingsleeve is arranged at the other end of the rotating shaft, the disc spring assembly is arranged on the push rod in a sleeving mode, the pressing sleeve is arranged at the other end of the push rod ina sleeving mode, and the sliding sleeve is connected with a positioning pin; and the first air cylinder pushes the sliding sleeve through a first piston, the second air cylinder makes contact with the positioning pin through a second piston and pushes the pressing sleeve, and the rotating shaft is connected with the transmission device through a coupler. According to the servo direct connection type spindle device, the air cylinder pushes the positioning pin to drive the pressing sleeve to move forwards, meanwhile, the push rod moves forwards, the claws are separated from the rotating shaft to achieve automatic loosening, and automatic clamping is achieved through pre-tightening force of the disc spring.

Owner:江苏华雕机械有限公司

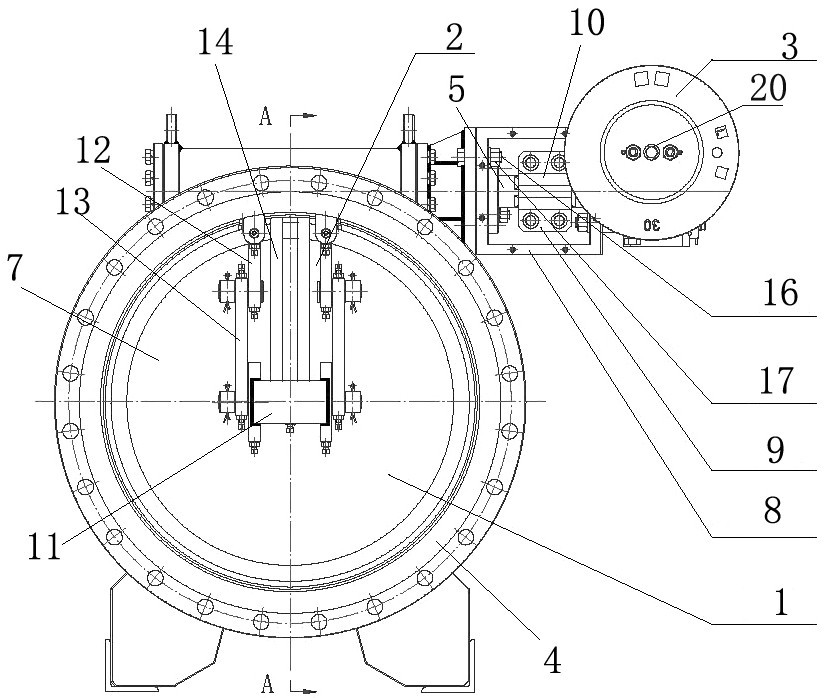

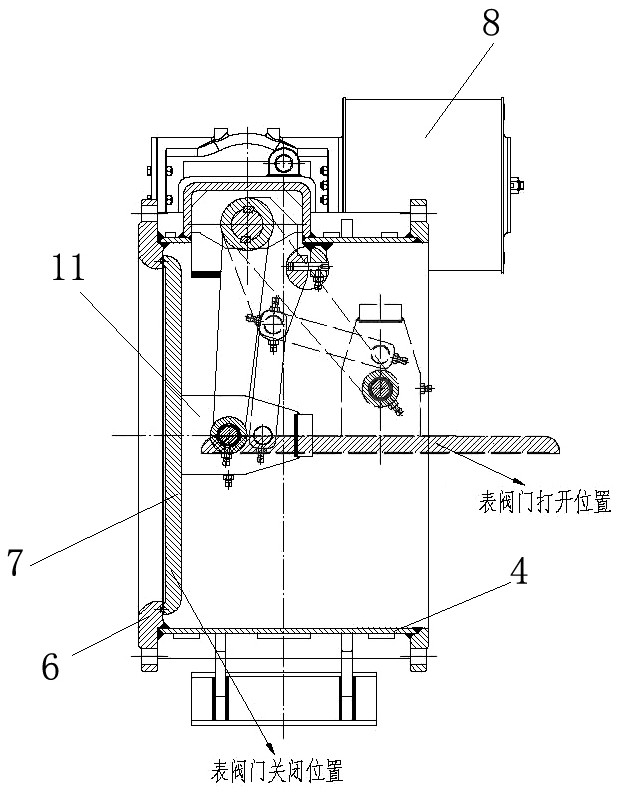

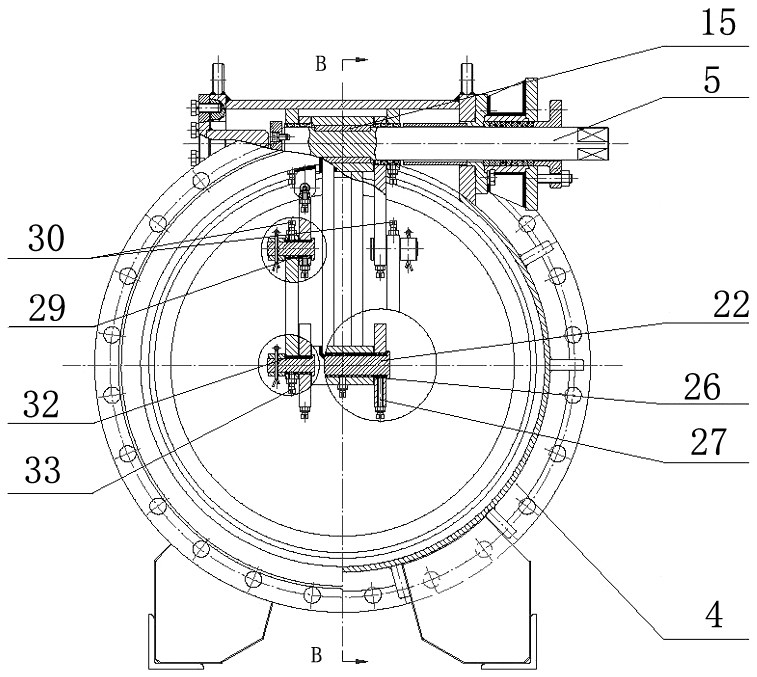

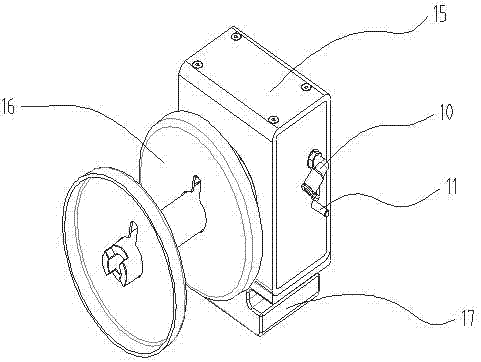

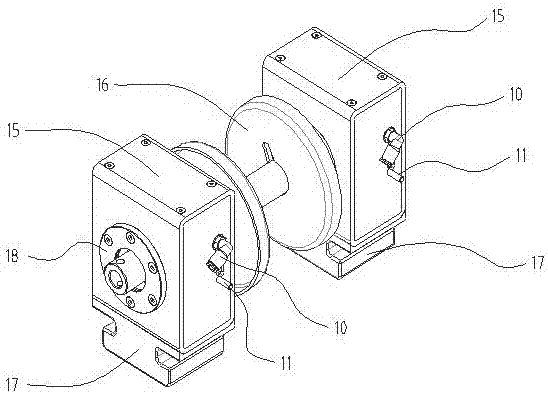

Novel three-rod valve

PendingCN113883281AExtended service lifeLarge circulation capacityOperating means/releasing devices for valvesLift valveEngineeringVALVE PORT

The invention relates to a novel three-rod valve which comprises a three-rod valve body. The three-rod valve body is composed of a main valve part, a transmission mechanism and a driving part; the main valve part comprises a valve body, a valve rod, a valve seat and a valve plate; the valve seat is arranged in the valve body; the valve plate is installed on the valve seat; the valve plate is sequentially connected with the transmission mechanism, the valve rod and the driving part; and the valve rod is driven by the driving part to drive the transmission mechanism to move, so that the valve plate on the main valve part is opened and closed, and the opening and closing actions of the valve are realized. The novel three-rod valve provided by the invention has the advantages of simple structure, convenience in use, long service life and the like.

Owner:HANGZHOU HANGYANG KOSO PUMP & VALVE

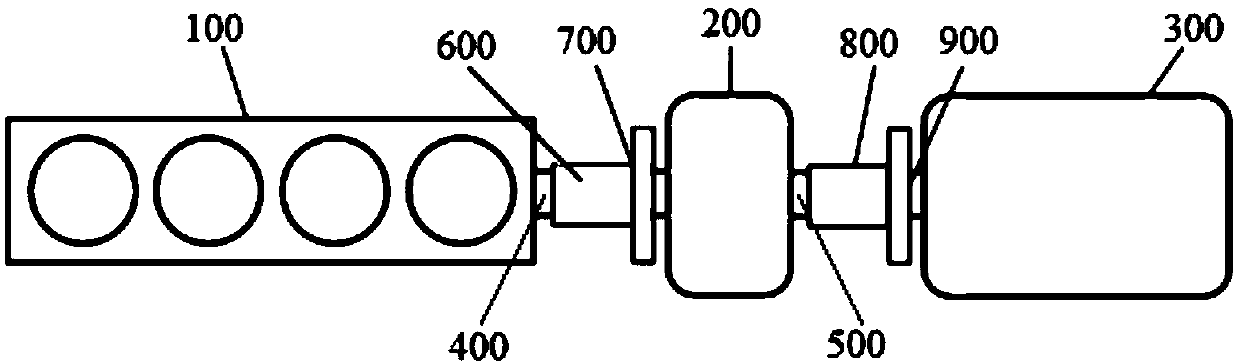

Combined automatic constant tension pneumatic twine tensioner

PendingCN107458297AReduce volumeSmall tolerance rangeLoad securingTransportation itemsSpool valveDrive shaft

The invention discloses a combined automatic constant tension pneumatic twine tensioner. The combined automatic constant tension pneumatic twine tensioner comprises twine tensioner bodies and coiling block assemblies connected to the twine tensioner. One twine tensioner body is connected to one or more coiling block assemblies or one coiling block assembly is connected to the plurality of twine tensioner bodies. Each of the twine tensioner bodies comprises a power driving mechanism, a slide valve guiding mechanism and a stress housing and a clutch mechanism. The slide valve guiding mechanism is arranged on the side portion of the power driving mechanism, and the stress housing and the clutch mechanism are arranged on the outer side of the power driving mechanism and the slide valve guiding mechanism. By changing a conventional piston rod to a piston plate and arranging a transmission shaft and the piston plate in a cross manner, the transmission shaft and the piston plate do not interfere with each other; and two air cylinders which are mutually collaborated are adopted as a power driving source, and the steering structure is compact, small in size and large in bearing capacity.

Owner:帕瓦夫南通电气科技有限公司

Fixing method of stator core fixing structure of water-cooled motor

ActiveCN103956837BStable torque outputAchieve fixationMagnetic circuit stationary partsManufacturing stator/rotor bodiesColloidEngineering

The invention discloses a water-cooled motor stator iron core fixing structure and a fixing method thereof. According to the fixing structure, a stator iron core and a water channel pressing plate are connected rigidly by utilizing steel pins and colloid injected into a shell, the water channel pressing plate and the stator iron core, the water channel pressing plate is also connected with the shell rigidly, and therefore fixation of the stator iron core is achieved. The fixing structure enables air gaps between a stator and a rotor of a water-cooled motor to be more even and motor torque output to be stable, and noise can be lowered effectively. According to the fixing method of the water-cooled motor stator iron core fixing structure, the hot press fitting technology does not need to be adopted, only a common press fitting technology is needed, the technology is simple, and assembling cost can be reduced. When the hot press fitting technology is adopted, the risks of uneven deformation exist in heating and cooling deformation processes, the unevenness can be transmitted to the air gaps between the stator and the rotor, and the performance of the motor is further influenced, but no mentioned risks exist in the fixing method of the water-cooled motor stator iron core fixing structure.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A vehicle start control method, system and vehicle

The present invention provides a vehicle start control method, system and vehicle. The method is that when a vehicle is detected to have a start demand, the vehicle power control unit PCU controls the power source torque and the clutch torque slope, and controls the power source torque and clutch reference. The torque and clutch offset torque work together to fine-tune the clutch target transmission torque in real time according to the actual speed of the power source. The invention controls the power source end and the clutch load end, and through the joint action of the clutch reference torque and the clutch offset torque, the speed fluctuation of the power source end is weakened, the stable torque output is ensured, and the vehicle has good starting smoothness and dynamic performance. Since there is no need to pass complex calculations to determine the torque output of the powertrain and the transmission torque of the clutch, the speed fluctuation caused by the PID closed-loop control is also weakened, and there is no need to refine the different stages of the speed ascent, so it is easier to control and calibrate.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

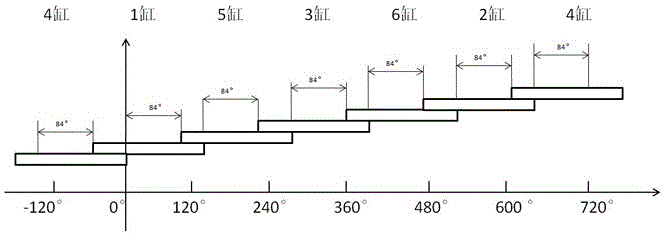

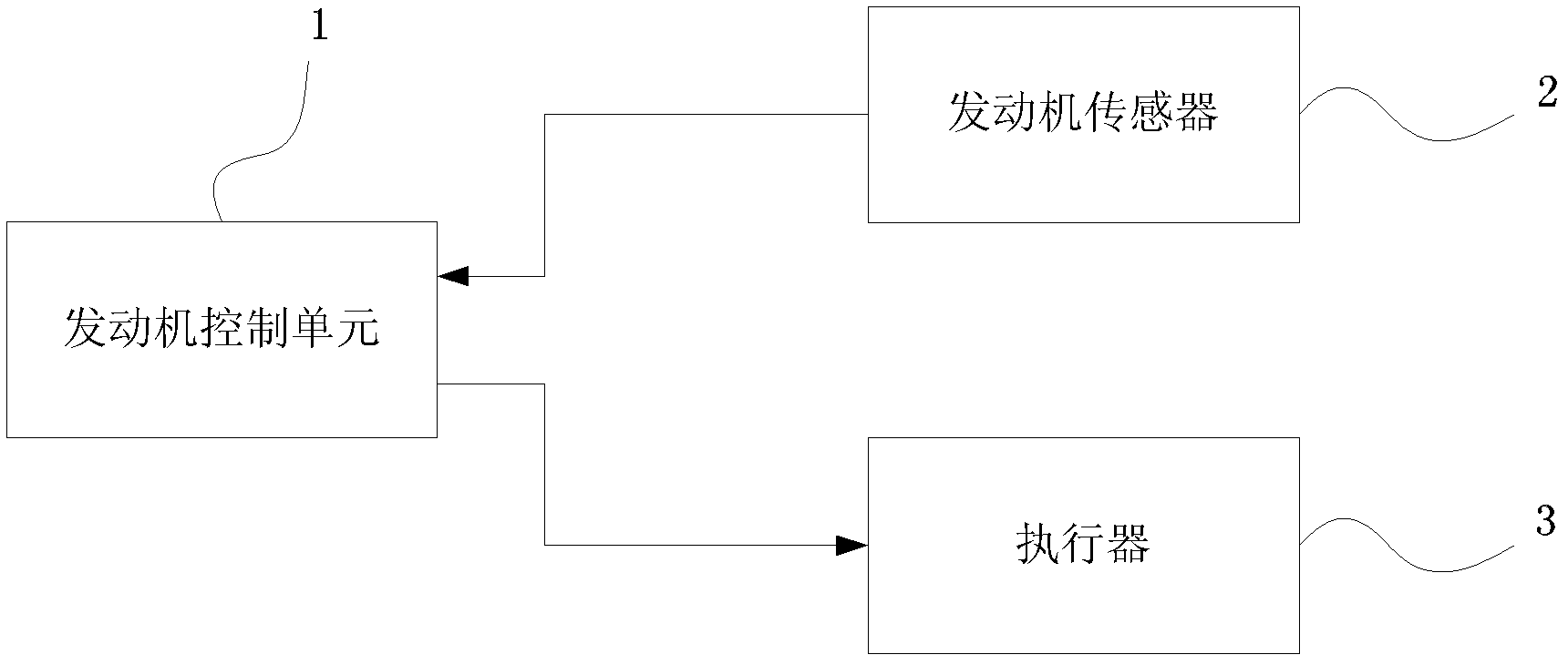

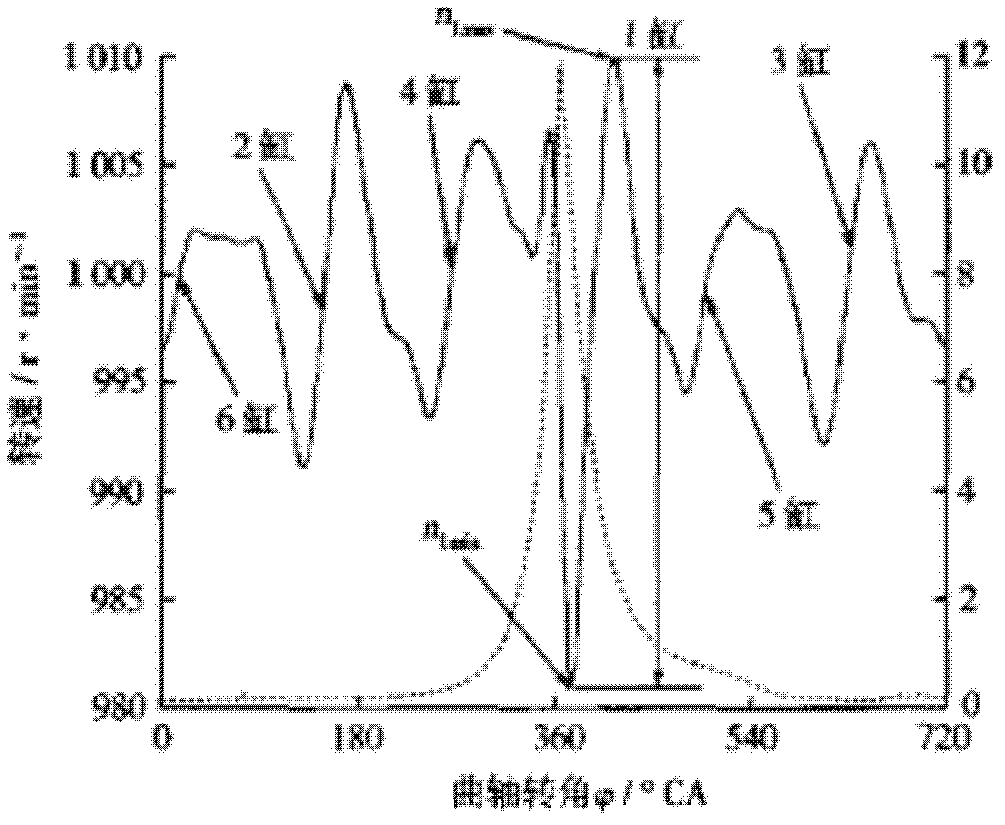

Natural gas engine cylinder self-checking control system and natural gas engine cylinder self-checking control method

InactiveCN103047036AStable torque outputProtectiveElectrical controlMachines/enginesControl systemSpray nozzle

The invention discloses a natural gas engine cylinder self-checking control system and a natural gas engine cylinder self-checking control method. The control system comprises an engine control unit, an engine sensor and an actuator. The engine sensor and the actuator are in communicating connection with the engine control unit. The engine sensor is used for measuring an engine rotating speed signal. The actuator is used for controlling an output drive air injection pulse width signal. The engine control unit is used for calculating angular acceleration of the rotating speed signal through circulating average, accordingly changing drive air injection pulse width of cylinder natural gas spray nozzles in a software adjusting mode and then sending the output drive air injection pulse width signal to the actuator. The actuator controls natural gas injection amount of cylinders according to the received drive air injection pulse width signal. The natural gas engine cylinder self-checking control system and the natural gas engine cylinder self-checking control method can solve the control problem caused by consistency of the spray nozzles of the natural gas engine control system, maintain stable torque outputting of a natural gas engine, have protective effect on the engine and can be applied to control of different natural gas engines.

Owner:上海格令汽车电子有限公司

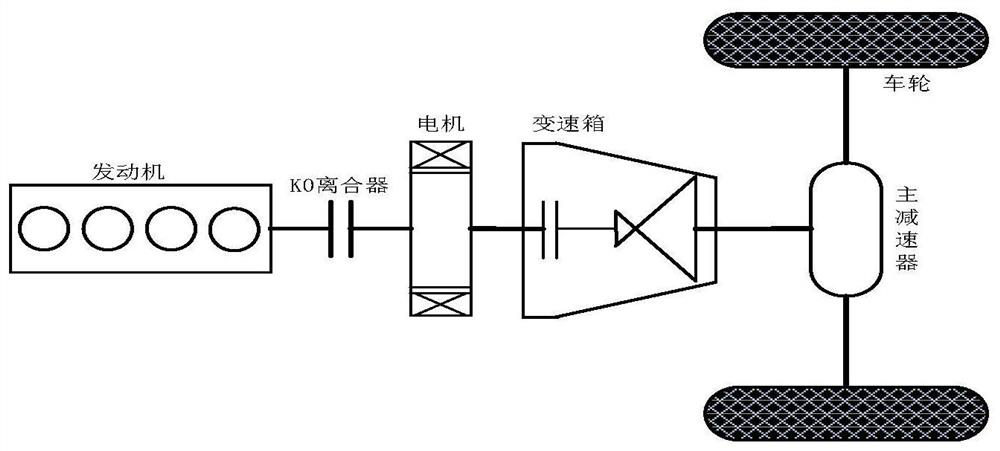

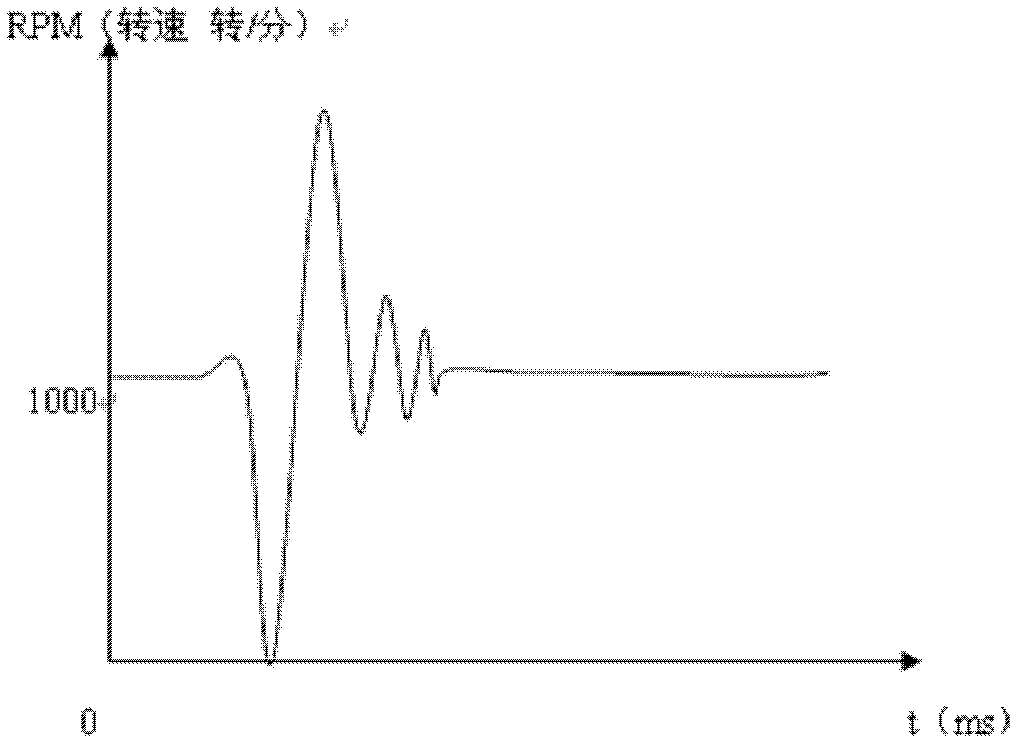

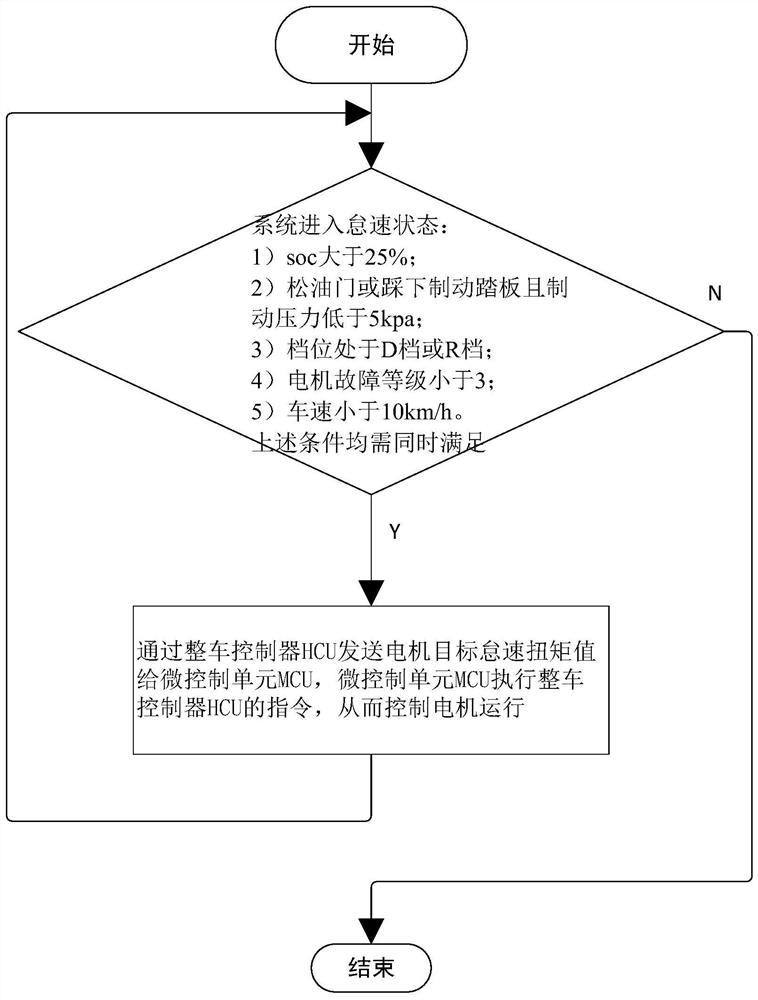

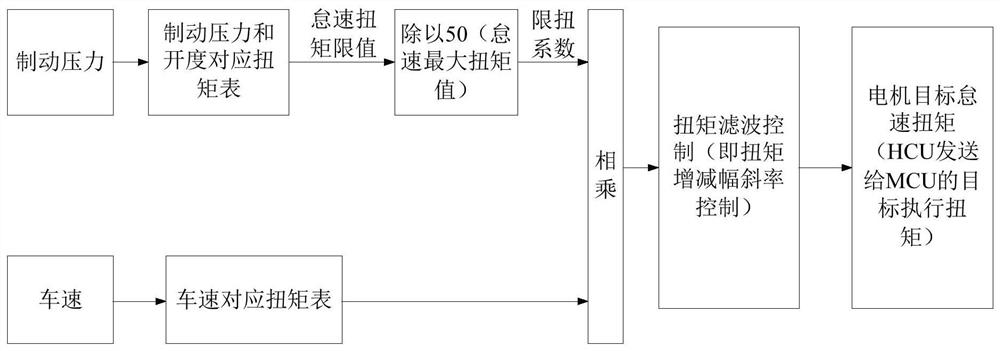

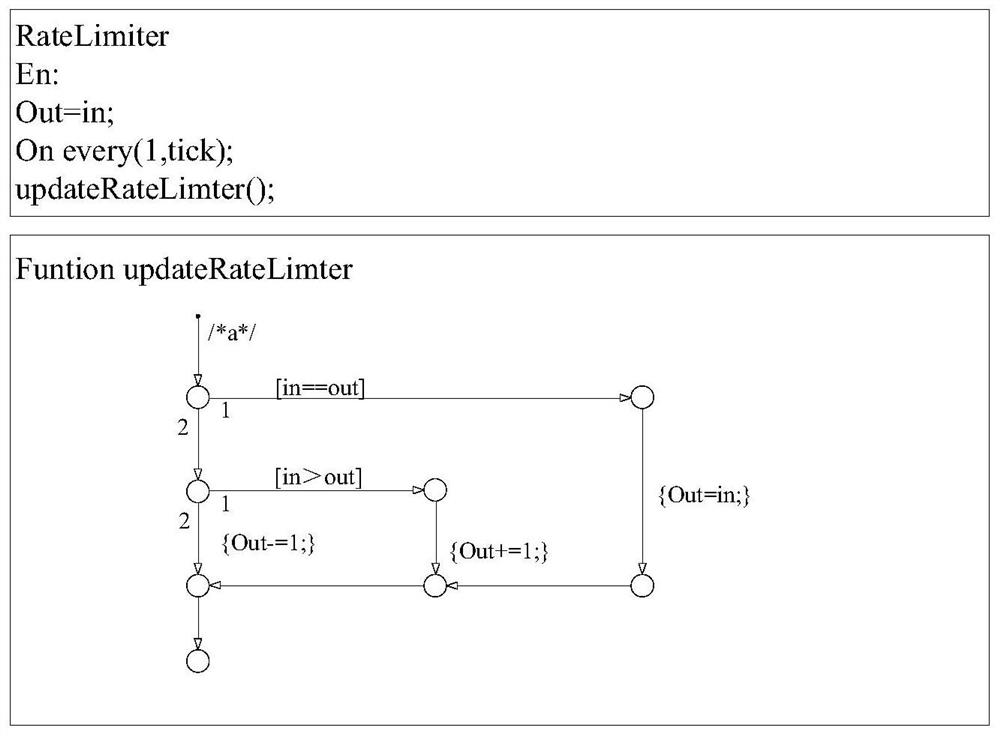

A P2 architecture hybrid idle speed control method

ActiveCN108909528BImprove shortcomingsSmooth torque outputSpeed controllerElectric energy managementIdle speed controlElectric machinery

A P2 architecture hybrid idle speed control method, which belongs to a motor idle speed control method. Aiming at the defects of high fuel consumption, high emission pollution, unsafe and unstable in the existing idling method, the present invention provides a P2 architecture hybrid idling control method with no fuel consumption, no pollution, safety and stability. A P2 architecture hybrid idle speed control method involved in the present invention judges whether the whole machine system enters the idle speed state, if it is satisfied, enters the idle speed state, if not, exits the idle speed state; after entering the idle speed state, through the vehicle control The controller HCU sends the motor target idle torque value to the micro control unit MCU, and the micro control unit MCU executes the instructions of the vehicle controller HCU to control the operation of the motor, and the motor performs torque control according to the target torque to realize driving under idling conditions. The invention is mainly applied to controlling the fuel consumption and emission level of the idling working condition.

Owner:HARBIN DONGAN AUTOMOTIVE ENGINE MFG CO LTD

Drive control system and stable pan/tilt with the control system

ActiveCN107203223BRelieve pressureEliminate the effects of induced electromotive forceElectronic commutation motor controlVector control systemsBrushless motorsControl system

The present invention relates to a drive control system for a brushless motor. The drive control system includes: a stable level digital control system connected to at least one power level digital control system and connected with the power level digital control system in sequence. The power level digital control system communicates; the power level digital control system is connected with at least one brushless motor, and is used to obtain the duty ratio of the output PWM according to the current electrical angle value, the quadrature axis voltage control amount and the direct axis voltage control amount to control the rotation of the brushless motor; and when the obtained control command is an end command, save the absolute initial value of the electrical angle.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Circular Superimposed Magnetic Circuit Switched Reluctance DC Motor

ActiveCN105978275BImprove energy efficiencyImprove power densitySynchronous machine detailsElectrical polarityElectromagnetic field

The invention discloses a loop superposition magnetic circuit switch reluctance direct current motor. The motor comprises a stator unit and a rotor unit arranged in the stator unit. The stator unit comprises a number of split stator iron core laminations arranged in a cabinet, stator windings wound on the salient poles of the stator iron core laminations, stator permanent magnets, and an iron-magnetically permeable wedge assembly used for fixing the stator iron core laminations and the stator permanent magnets. A stator permanent magnet of the same polarity is placed on the ring direction surface of both ends of each independent stator iron core lamination. A stator iron core lamination and a stator permanent magnet form a unipolar stator iron core lamination single body. After a stator winding on the salient pole of a stator iron core lamination is energized, an electromagnetic field generated by the winding of the phase and a permanent magnetic field are superimposed, strengthened and applied on the rotor. The rotor is in a non-winding non-magnet salient pole type structure. The loop superposition magnetic circuit switch reluctance direct current motor provided by the invention uses the structure, and has the advantages of high work efficiency, low power consumption, high power density, smooth operation and excellent comprehensive performance.

Owner:冯西川

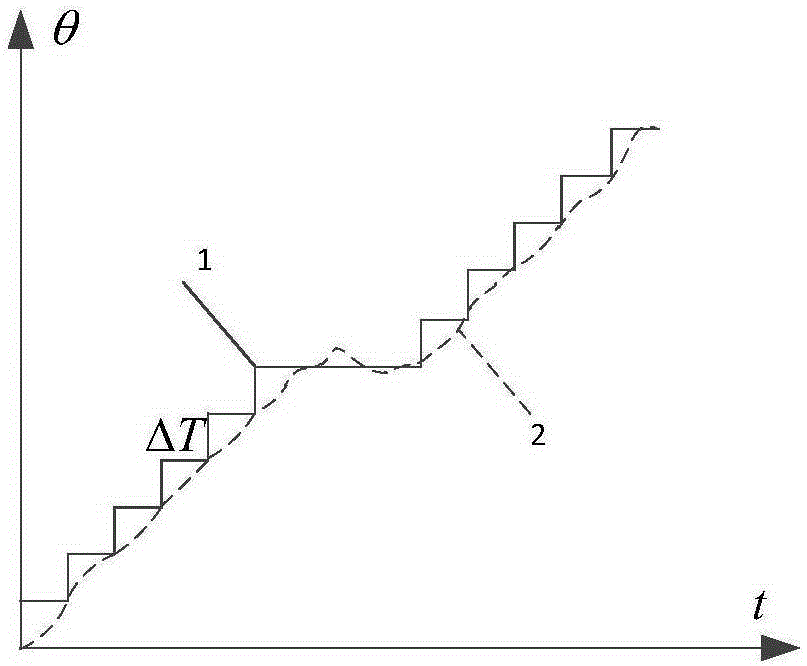

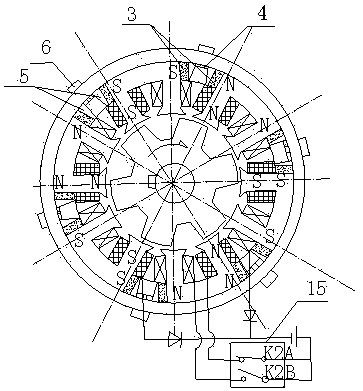

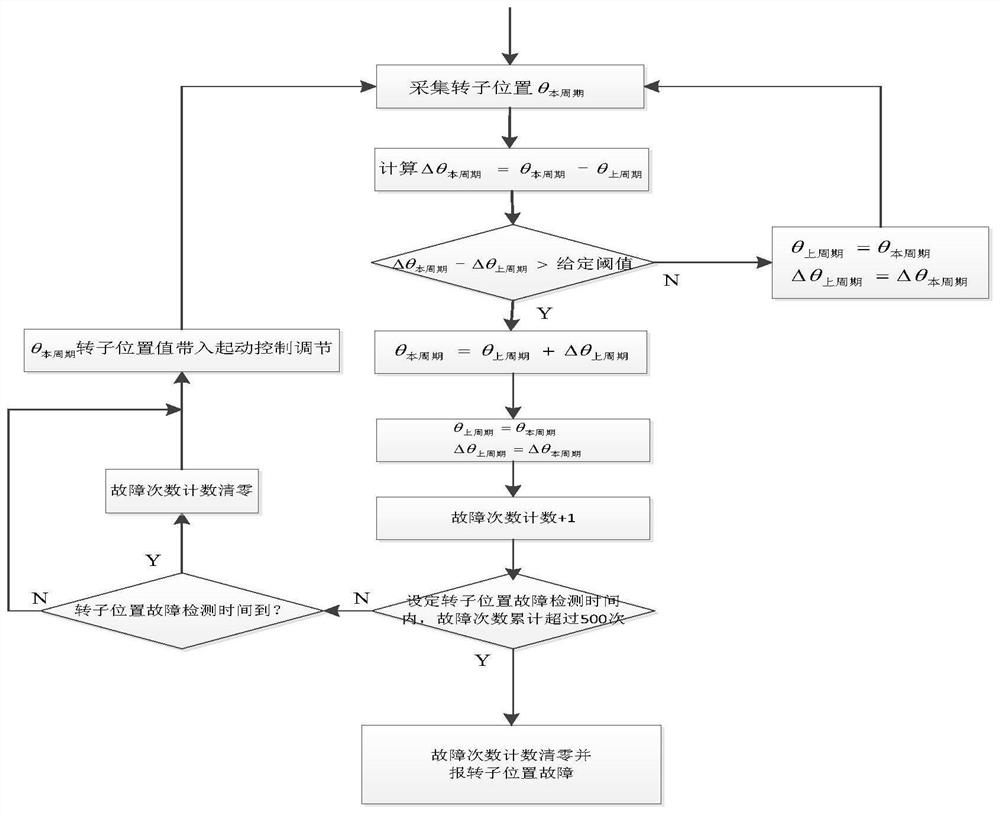

Rotor position fault identification and compensation method based on aviation three-level motor starting/power generation control system

PendingCN113824382AStable torque outputSmooth acceleration startMotor parameters estimation/adaptationPolyphase induction motor starterAviationElectric machine

The invention provides a rotor position fault identification and compensation method based on an aviation three-level motor starting / power generation control system. The method comprises the steps of: firstly calculating a rotor position variable quantity in each sampling interval through using a collected rotor position; using a difference value between the rotor position variable quantity of the current period and the rotor position variable quantity of the previous period, namely delta theta<current period>-delta theta<previous period>, as a rotor position sampling fault judgment condition; when the delta theta<current period>-delta theta<previous period> is greater than a set threshold value, performing rotor position compensation and performing fault counting; and when the fault count exceeds a set number of times within the given time, reporting rotor position sampling faults, and stopping startup. According to the rotor position fault identification and compensation method, the rotor position can be continuously compensated under the condition that a rotor position sampling error occurs in a continuous period of time under the condition that a rotary transformer is disturbed, so that stable torque output and acceleration starting of the motor are ensured, and the tracking control stability and timeliness of a servo control system are met.

Owner:SHAANXI AVIATION ELECTRICAL

Duty cycle design method, system, medium and equipment for eliminating current sampling interference

ActiveCN110798050BThe sampling value is accurateImprove efficiencyEfficient power electronics conversionPower conversion systemsFrequency changerControl engineering

The present invention provides a duty cycle design method, system, medium and equipment for eliminating current sampling interference. The duty cycle design method for eliminating current sampling interference includes: synchronously setting the power factor corrector and the clock signal of the frequency converter , so that the clock signal used by the power factor corrector and the frequency converter is the same; under the same clock signal, the switching frequency of the power factor corrector is set to the fixed frequency of the switching frequency of the frequency converter multiple; set the sampling time of the frequency converter according to the parity of the fixed multiple; compare the relationship between the duty cycle time and the sampling time of the frequency converter, and phase-shift the duty cycle of the power factor corrector according to the comparison result ; the duty cycle time and the power factor corrector duty cycle are determined according to the switching period of the power factor corrector. The invention solves the problem of current sampling interference generated when the PFC and the frequency converter are used simultaneously by providing a control method of the PFC duty cycle.

Owner:RUKING EMERSON CLIMATE TECH SHANGHAI CO LTD

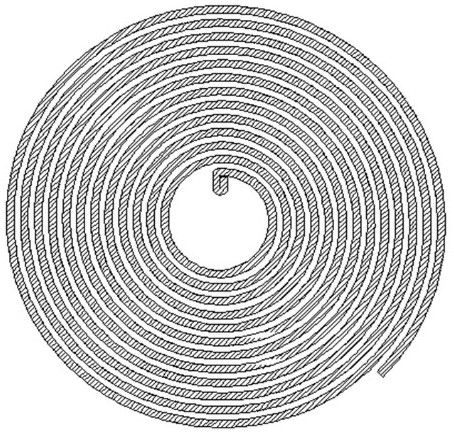

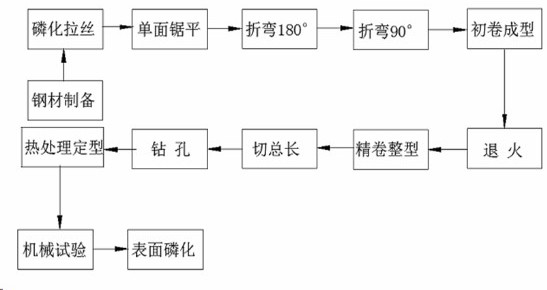

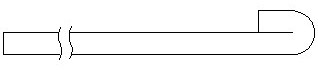

A kind of preparation method of planar scroll spring

The invention discloses a method for preparing a flat scroll spring, including steel preparation, phosphating and wire drawing, single-sided sawing, bending, initial coil forming, annealing, finishing coil shaping, overall length cutting, drilling, heat treatment and shaping, mechanical Experiment, surface phosphating, etc., the preparation process is simple and easy to realize, the steel strip is not easily deformed or damaged during preparation, the process adopts a vacuum double-chamber quenching furnace, the degree of automation is high, the human intervention is less, the industrial quenching time is short, and the prepared product has no delamination. Carbon, no deformation, balanced temperature, stable metallographic structure, and stable torque output of the flat scroll spring after production.

Owner:青海金泽恩新材料科技有限公司

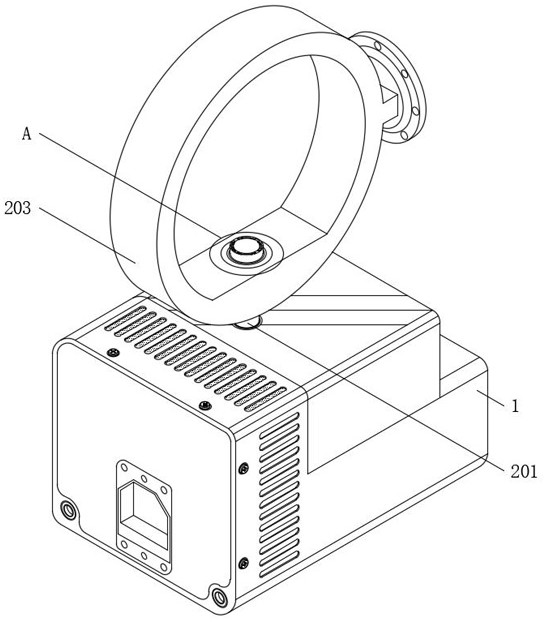

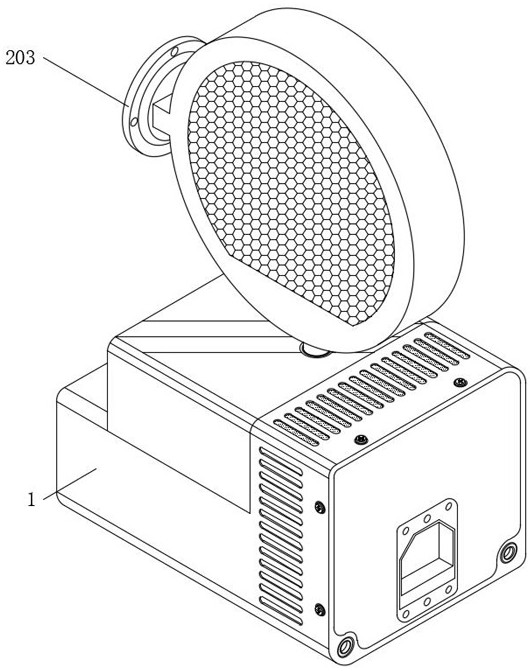

Protective monitoring equipment for smart park management based on big data

ActiveCN114811331AEfficient removalStable torque outputStands/trestlesCleaning using gasesPark managementControl engineering

The invention discloses a protective monitoring device for smart park management based on big data, and belongs to the technical field of monitoring devices, the protective monitoring device comprises a camera, and the top of the camera is fixedly connected with a steering mechanism. In the invention, the pressure on one side of the piston disc is gradually increased in the piston movement process of the piston disc in the first piston cylinder, the one-way valve on the first one-way valve pipe is automatically opened when the pressure is increased to a certain strength, and high-pressure air flow in the first piston cylinder enters the fixing sleeve through the first one-way valve pipe; due to the fact that the high-pressure air flow enters the fixing sleeve in the tangential direction, the high-pressure air flow can drive the driving fan and the reducing sleeve on the driving fan to rapidly rotate on the end face of the steering bearing, and the high-pressure air flow in the reducing sleeve can be jetted to the steering bearing through the jet holes in the rapid rotation process of the reducing sleeve. The interior of the steering bearing is purged through high-pressure airflow, and then dust, rust and other harmful impurities in the steering bearing can be effectively removed.

Owner:杭州智科飞创信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com