Combined automatic constant tension pneumatic twine tensioner

A rope tightener and constant tension technology, applied in the direction of motor vehicles, vehicles used for freight, transport objects, etc., can solve the problem of uneven force on both ends of the rope tightener, unable to tighten the rope in time, and difficult to fasten goods, etc. problem, to achieve the effect of compact structure, large bearing capacity and stable torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

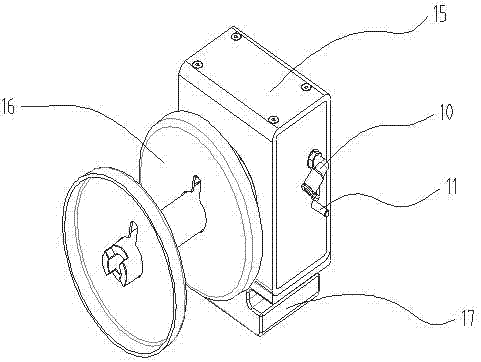

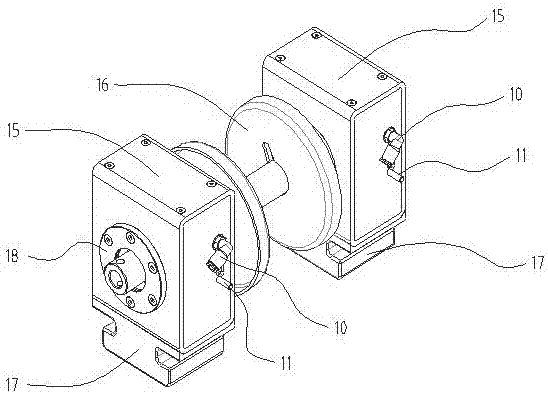

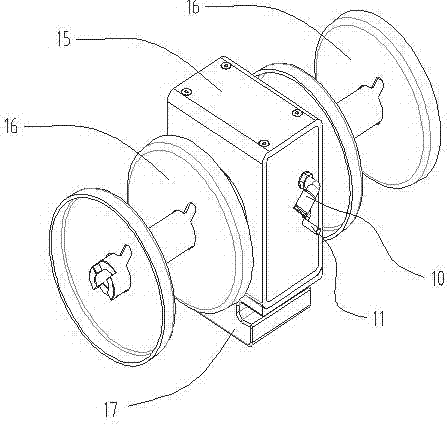

[0040] Such as figure 1 One embodiment shown is a combined automatic constant tension pneumatic rope tensioner, including a rope tensioner body and a reel assembly connected to the rope tensioner body, wherein one of the rope tensioner bodies is connected with a Reel assembly, this connection structure is suitable for occasions with general winding force requirements; such as figure 2 Another embodiment of the automatic constant tension pneumatic rope tensioner is shown, in which two rope tensioner bodies are connected with a reel assembly, which is suitable for occasions requiring higher winding force; image 3 In the automatic constant tension pneumatic rope tightener shown in the third embodiment, one rope tensioner body is connected with two reel assemblies, which is suitable for occasions requiring lower w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com