Patents

Literature

41results about How to "Small tolerance range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

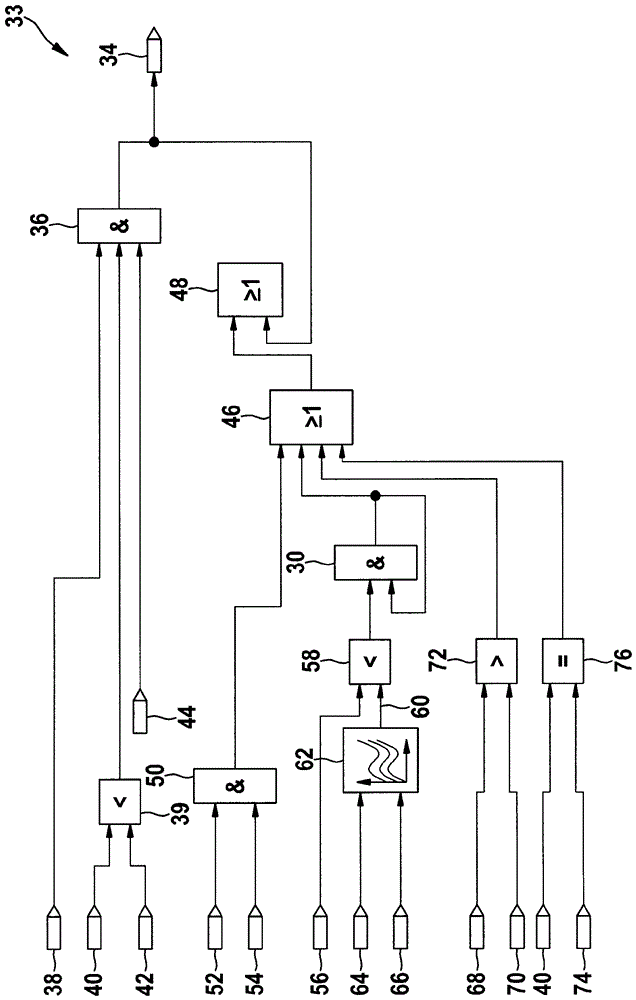

Speed stabilizer for automatically turning conventional cruise controls on/off in dense low speed traffic to save fuel

InactiveUS7706953B1Filter out instabilityMaximizing periodControlling membersVehicle fittingsDriver/operatorLED display

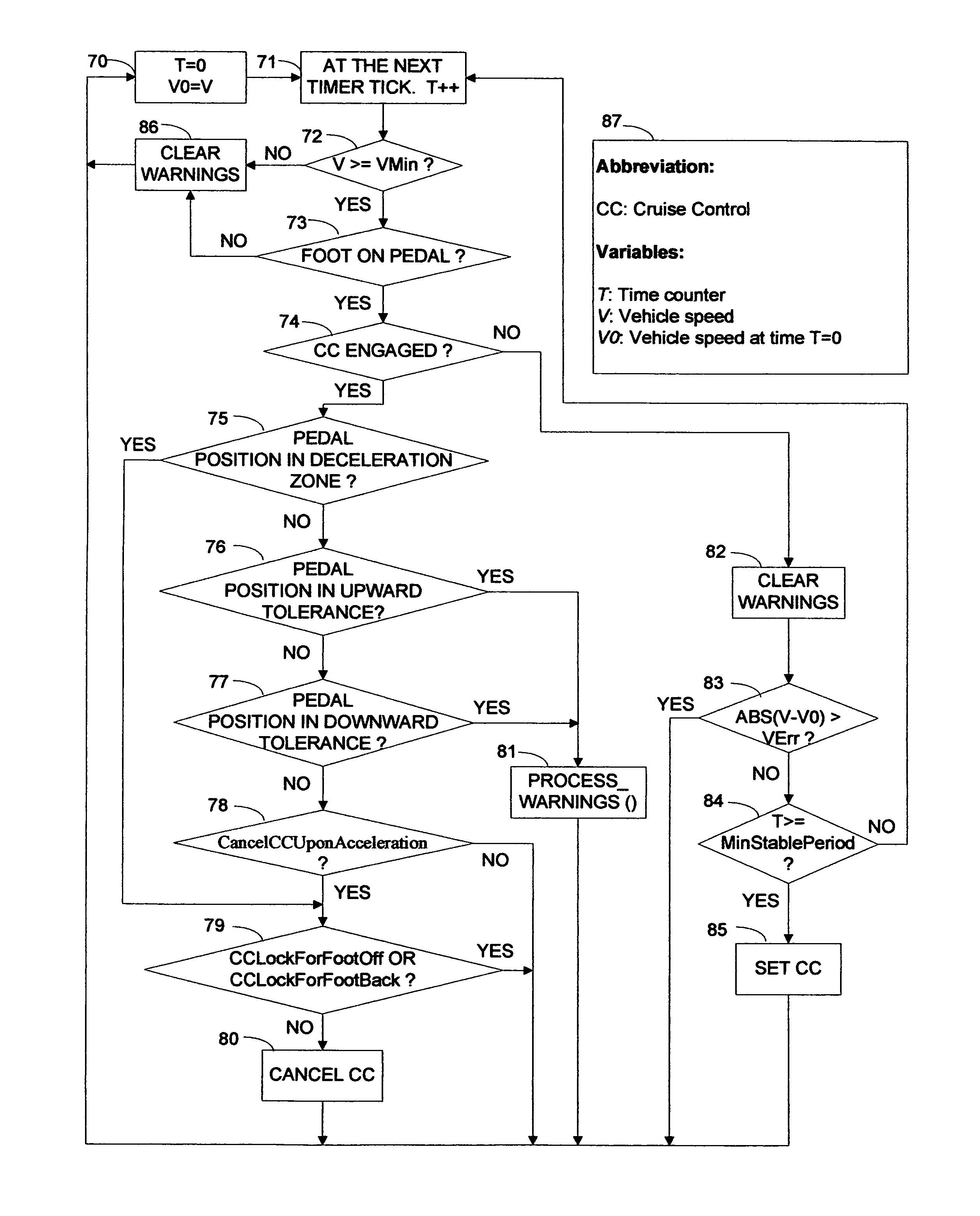

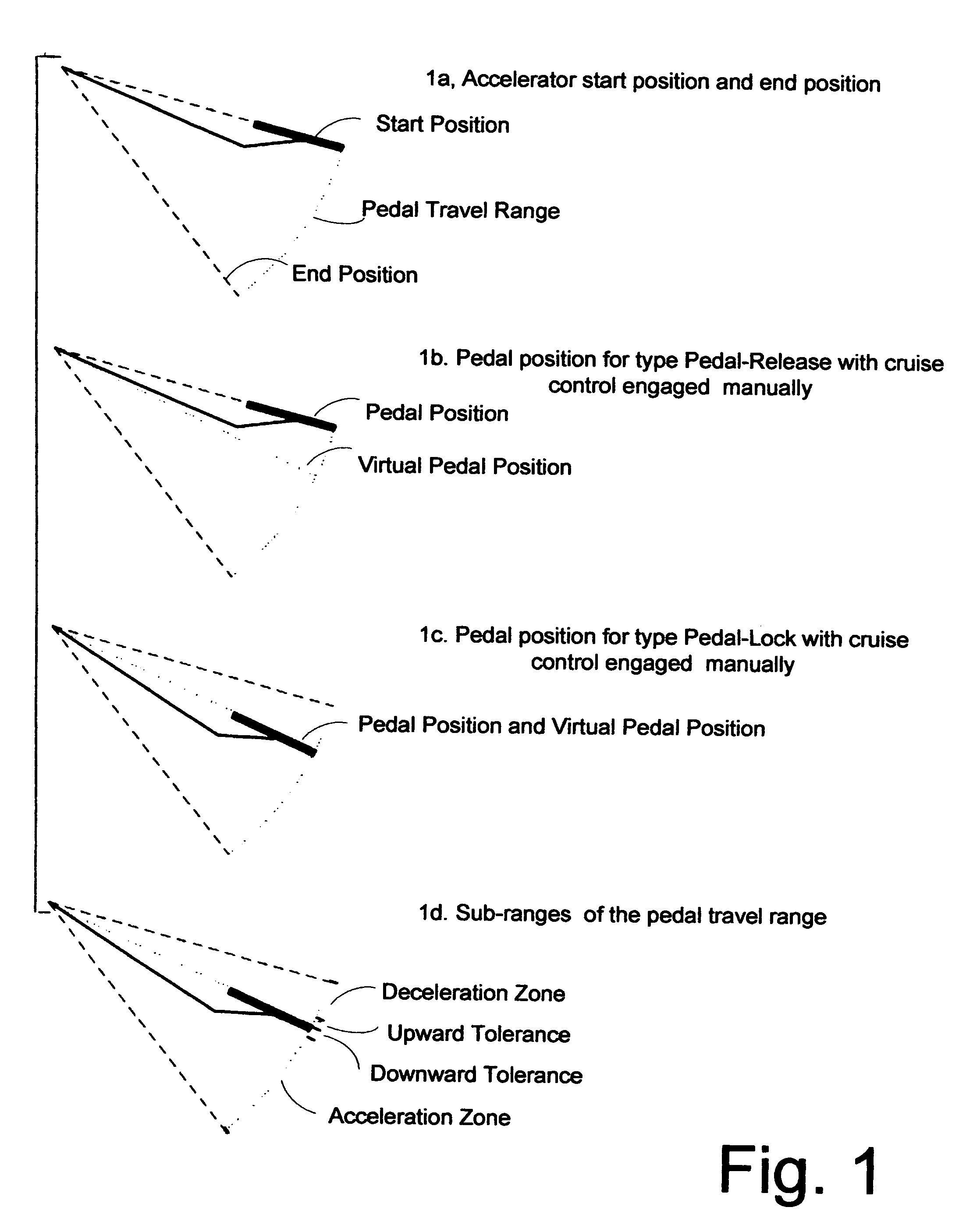

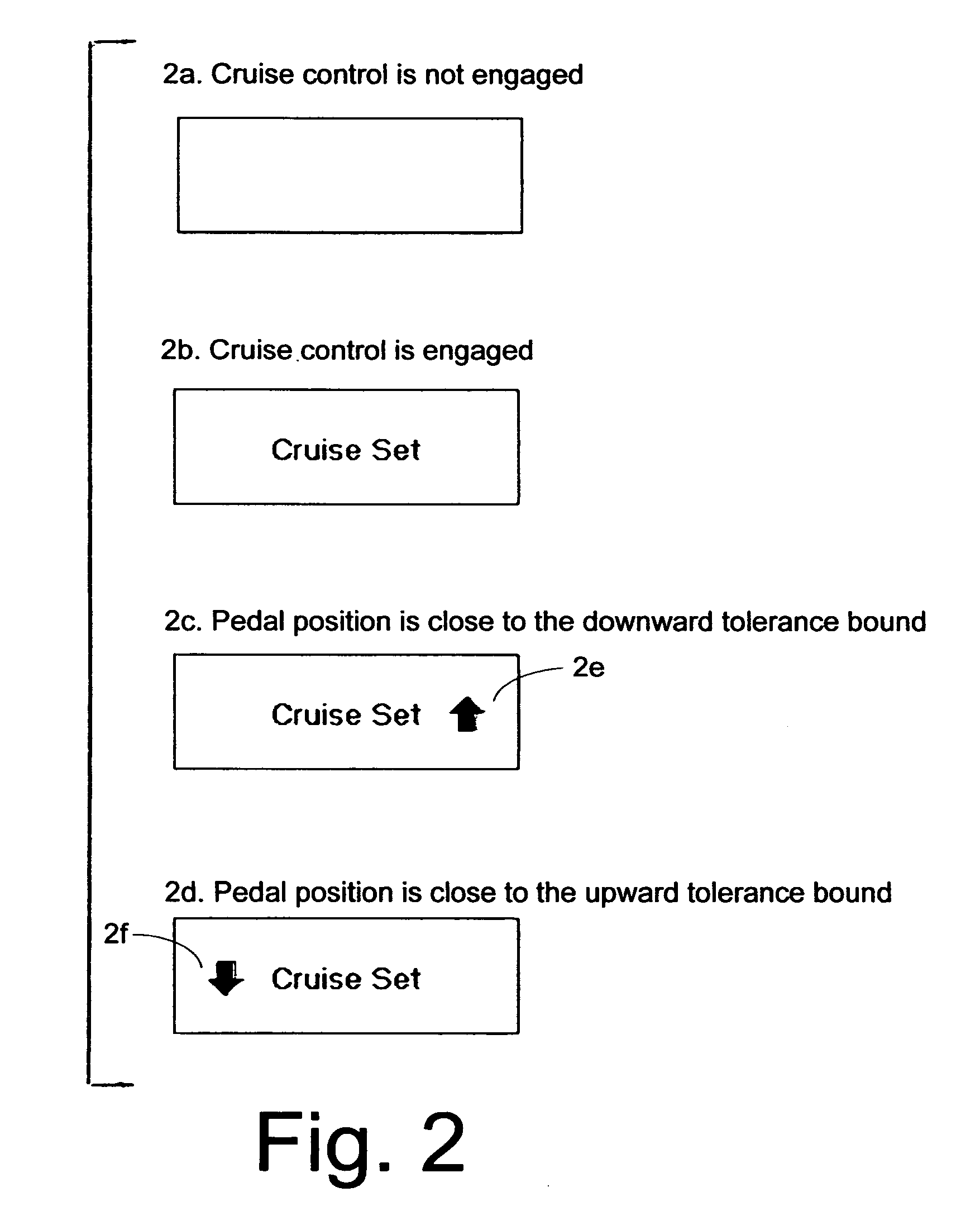

The stabilizer works with any conventional cruise control (CC) and permits automatic CC in slower heavy traffic as it eliminates laborious frequent manual actuation of CC control buttons otherwise needed in such heavy traffic. More frequent automatic CC operation at slower speeds increases fuel efficiency. When the vehicle maintains a speed above a minimum speed and exceeds a brief preset period, the speed stabilizer sets the cruise control at that speed. When the cruise control is thus engaged, the driver's foot can move the accelerator pedal within a small tolerance range without canceling the cruise control. When the pedal is close to the bounds of the tolerance range, a warning signal such as a flashing LED display, is generated by the speed stabilizer to inform the driver that further movement of the pedal will cause acceleration / deceleration, automatically canceling cruise control. Actuation of conventional CC control buttons restores conventional CC.

Owner:SUN JUN SHI

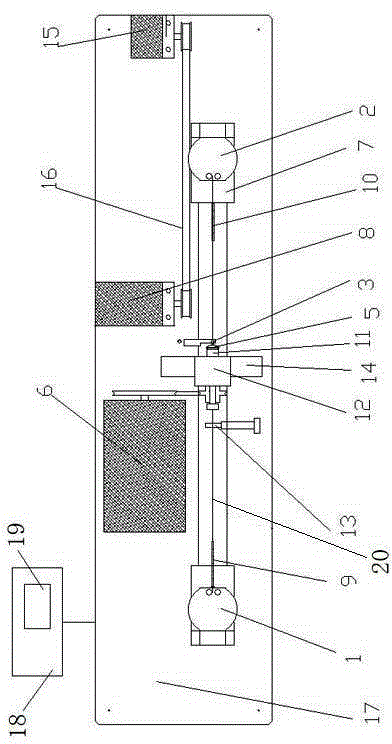

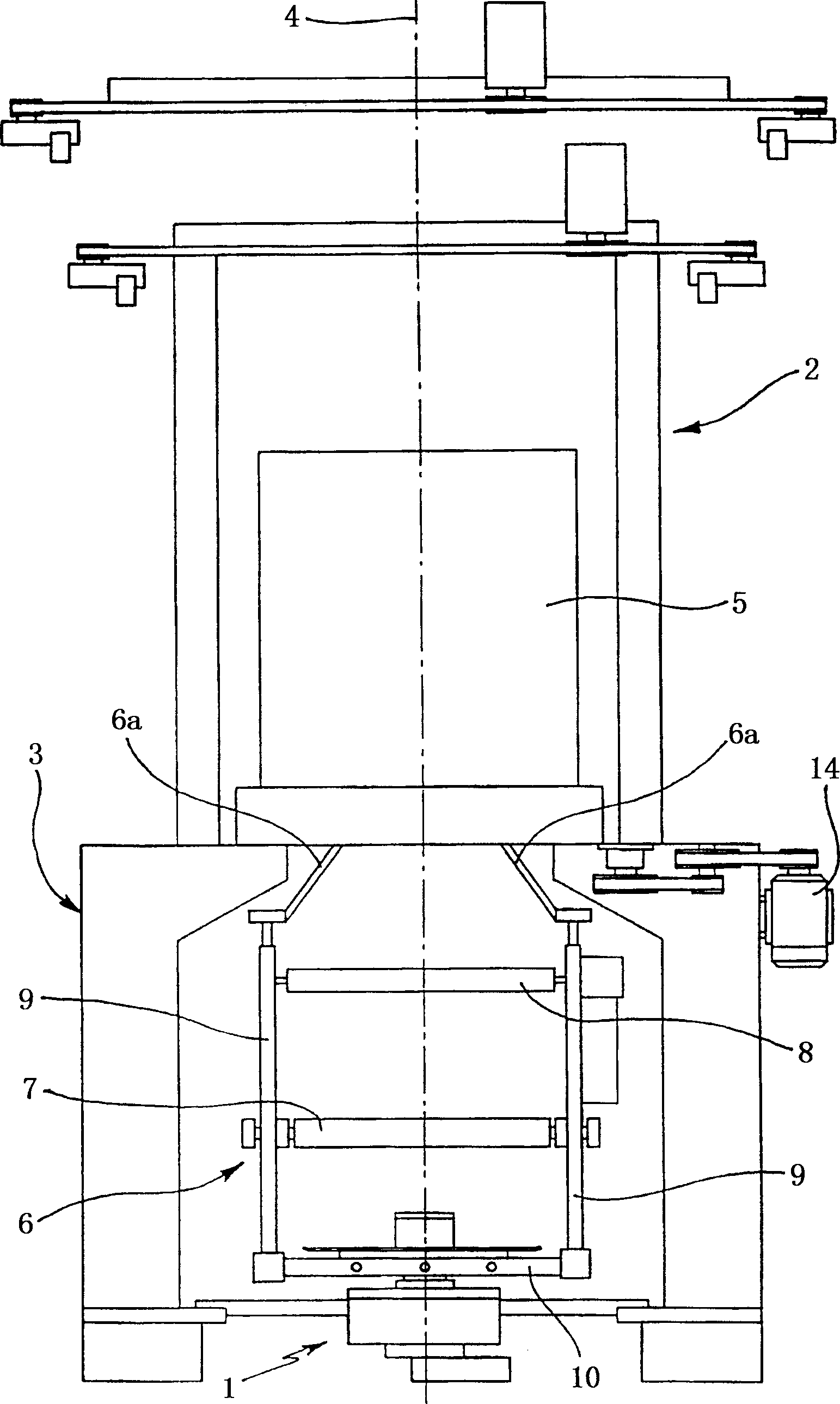

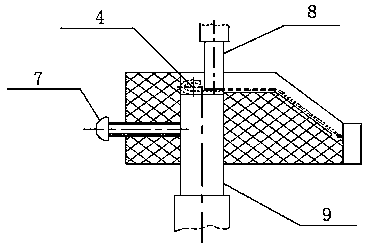

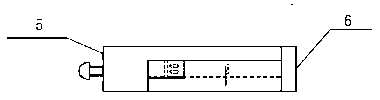

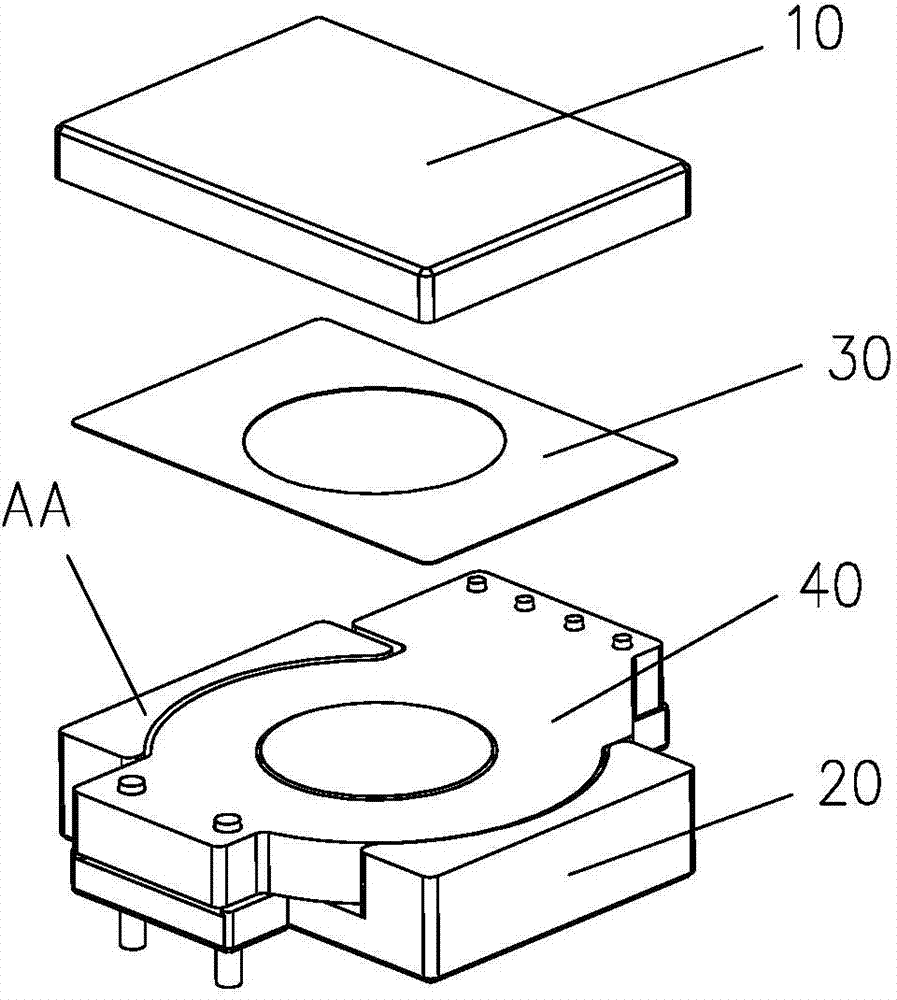

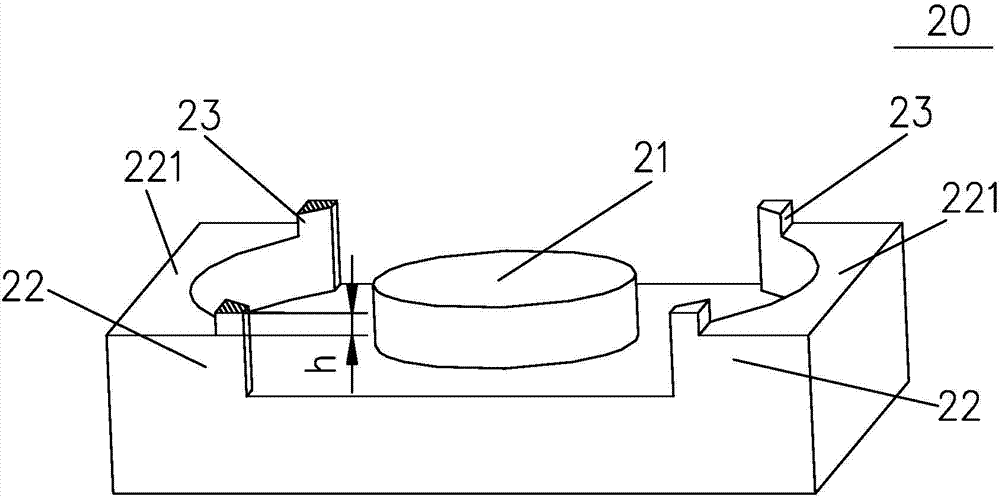

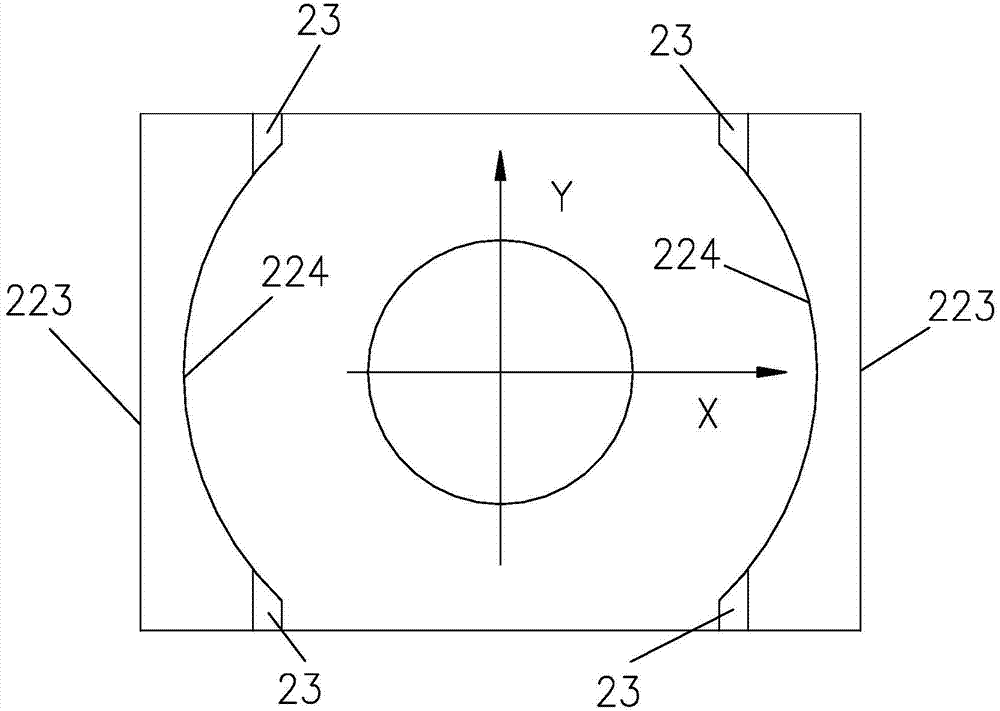

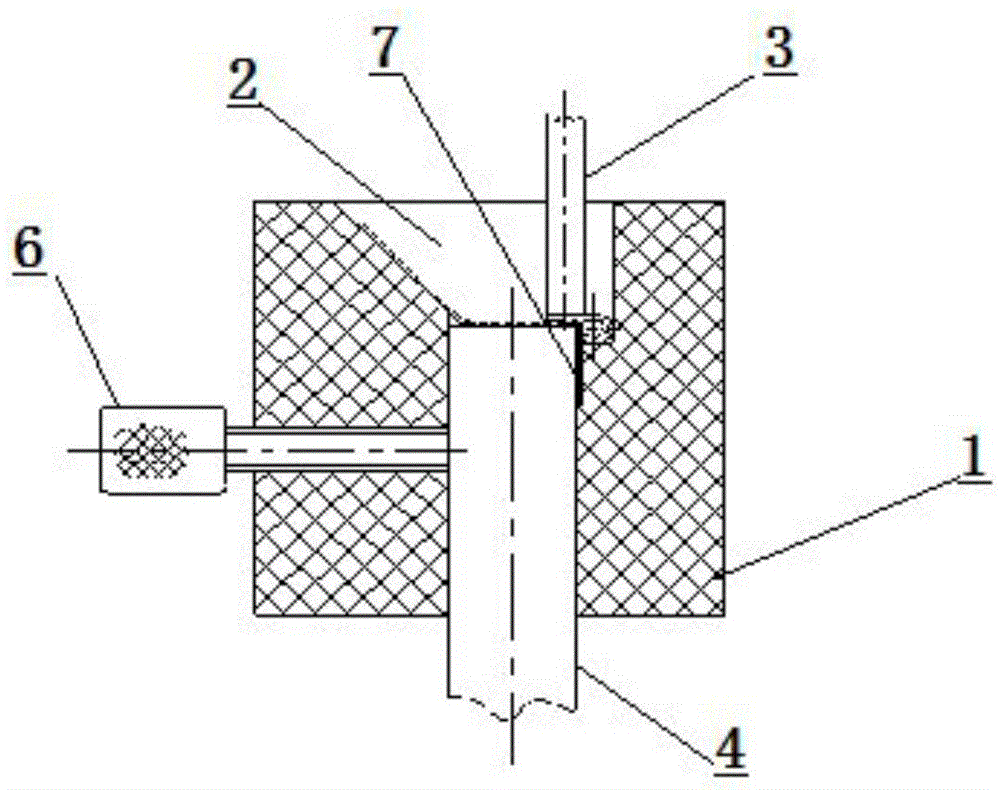

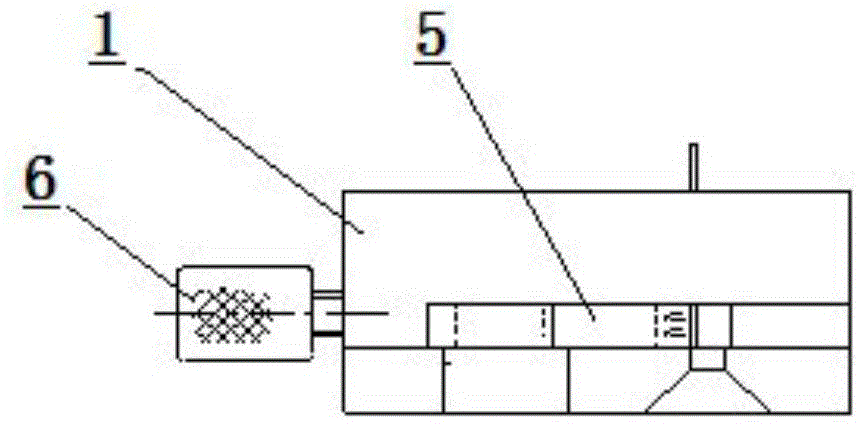

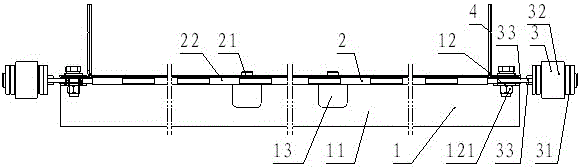

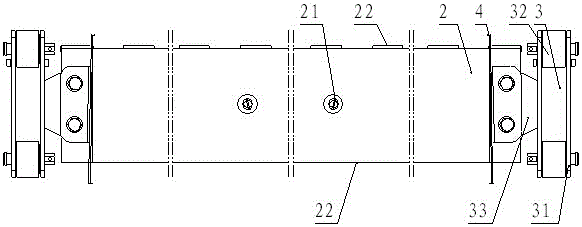

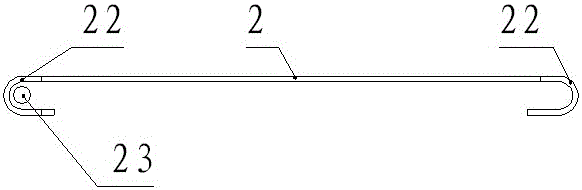

Grinding miller for inner holes of ceramic inserting core

InactiveCN104690640AWon't breakImprove consistencyLapping machinesLapping toolsReciprocating motionControl system

The invention discloses a grinding miller for inner holes of a ceramic inserting core, and relates to the technical field of optical equipment. The grinding miller comprises a miller table, a ceramic inserting core fixture is rotatably arranged on the miller table and is connected with a rotary driving device, a reciprocating motion support is arranged on the miller table, the reciprocating motion support is connected to a reciprocating motion driving device directly or indirectly, two ends of the reciprocating motion support are provided with tension sensors, and two ends of a grinding steel wire are fixedly connected to the tension sensors arranged at the two ends of the reciprocating motion support respectively. The grinding miller is internally provided with a control system, the rotary driving device, the reciprocating motion driving device and the tension sensors are all connected to the control system. The grinding miller is better than domestic and overseas grinding millers with same equipment in manufacture quality at present. In correct use, a steel wire cannot rupture in the grinding process, the production efficiency is high, and the labor cost is saved.

Owner:佛山森洋自动化包装设备有限公司

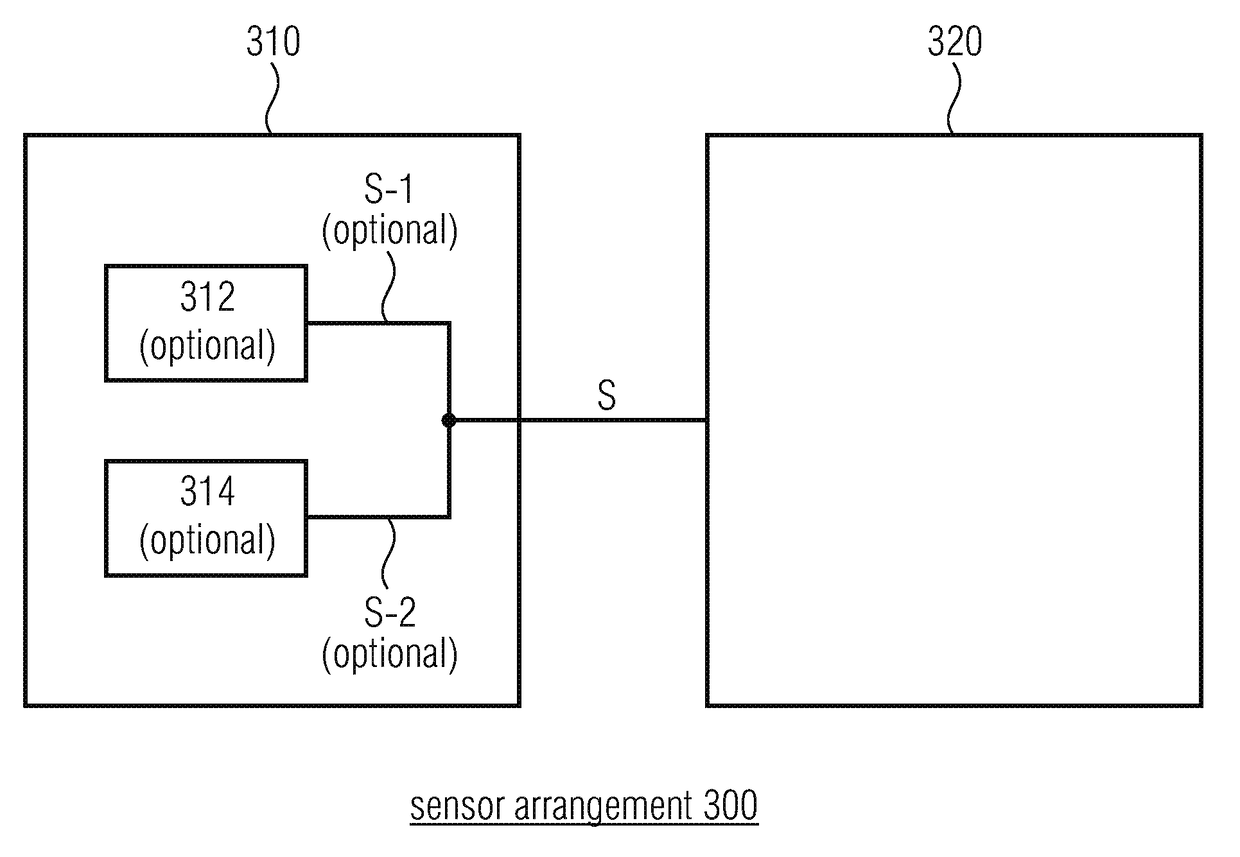

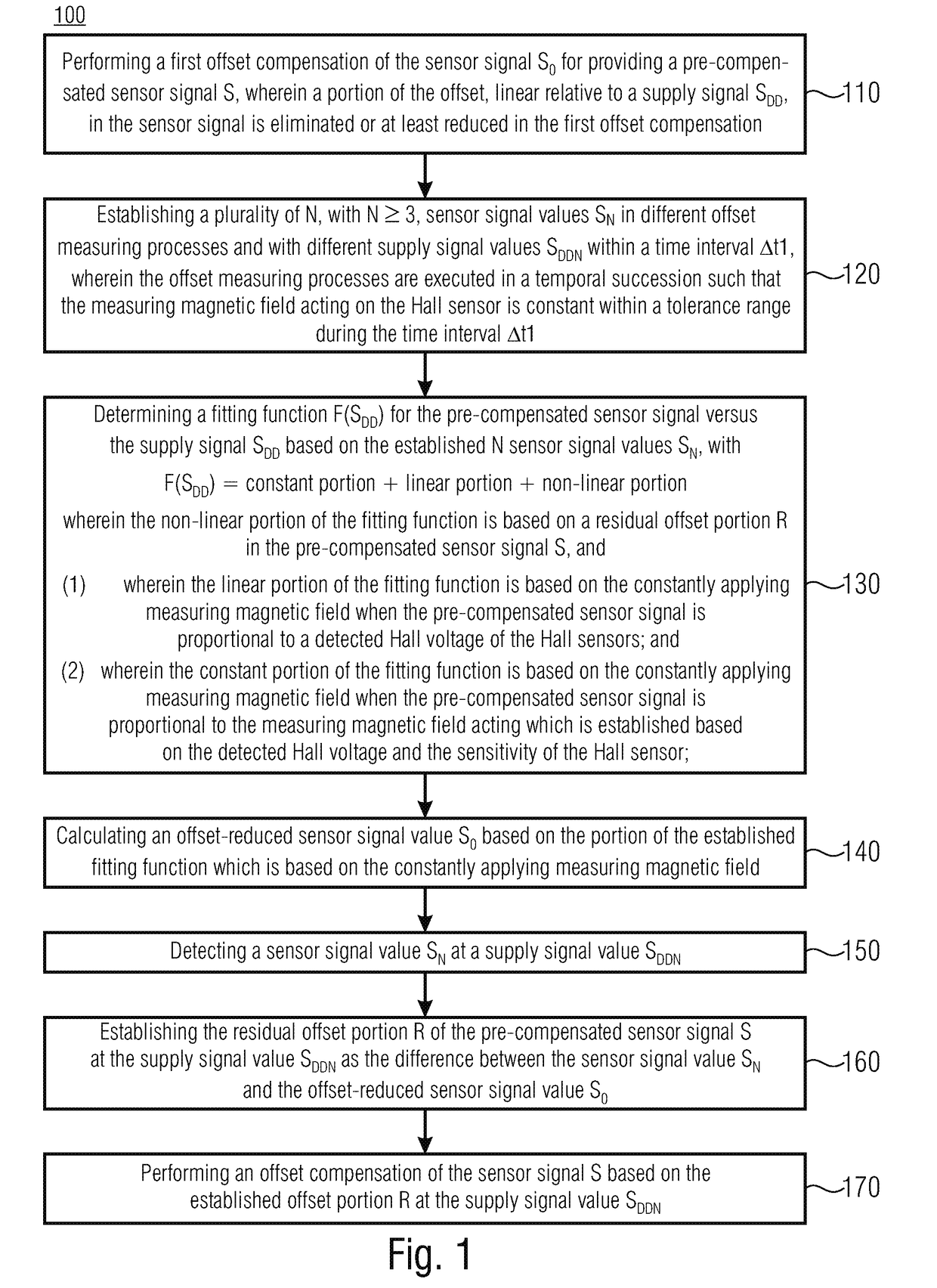

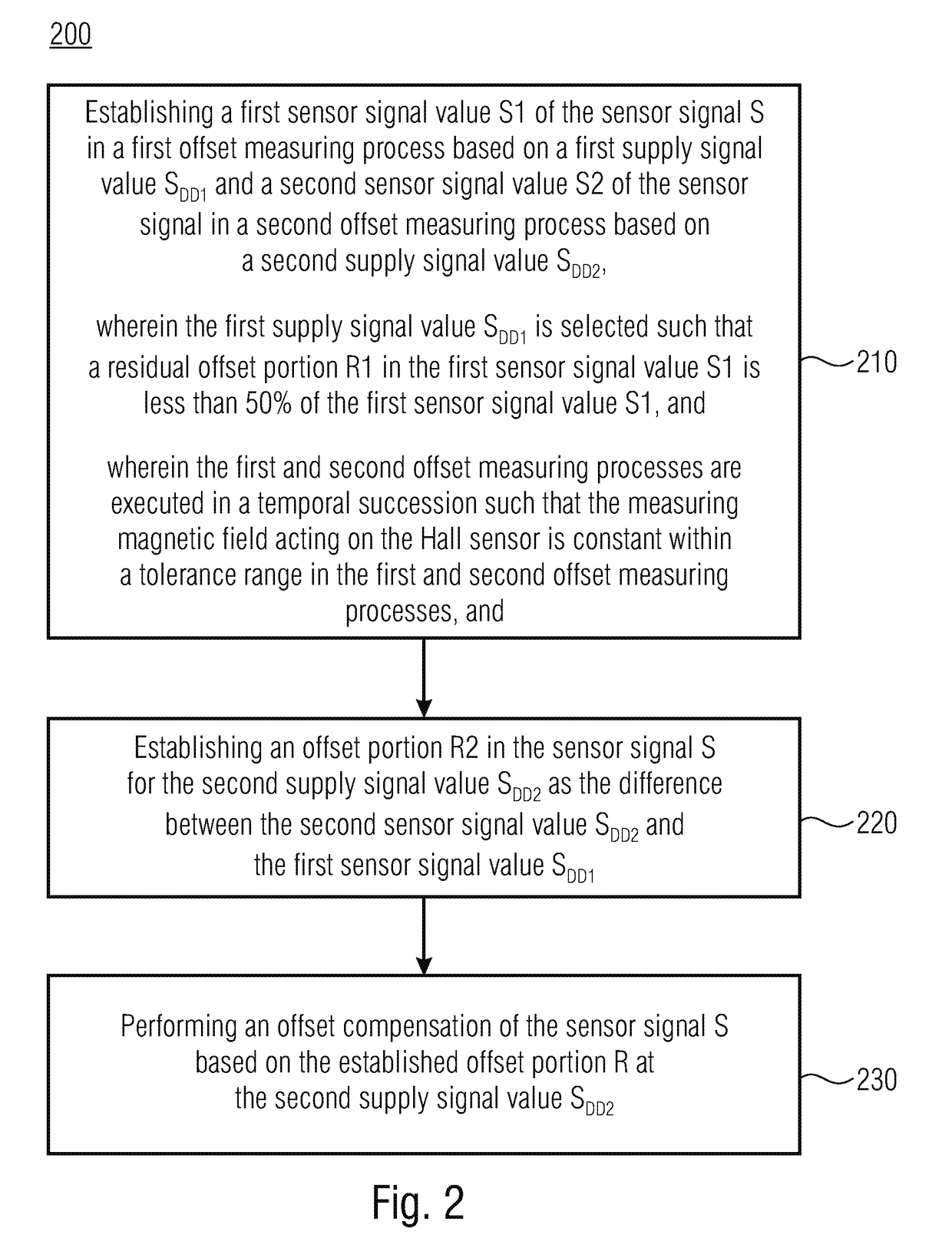

Method for Offset Compensation of a Sensor Signal of a Hall Sensor and Sensor Arrangement

ActiveUS20180172779A1Sufficient compensation resultSmall tolerance rangeMagnetic field offset compensationEngineeringMagnetic field

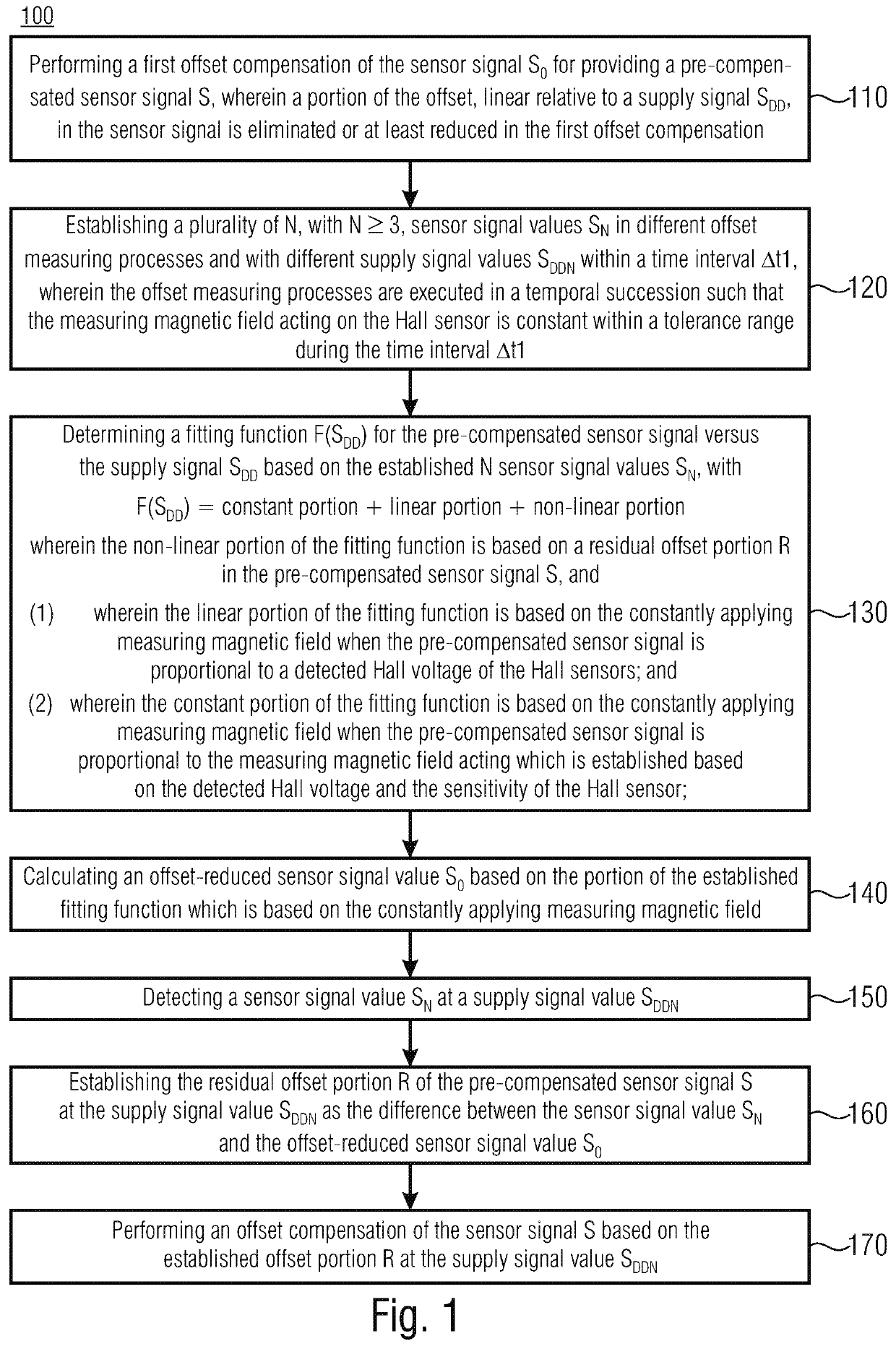

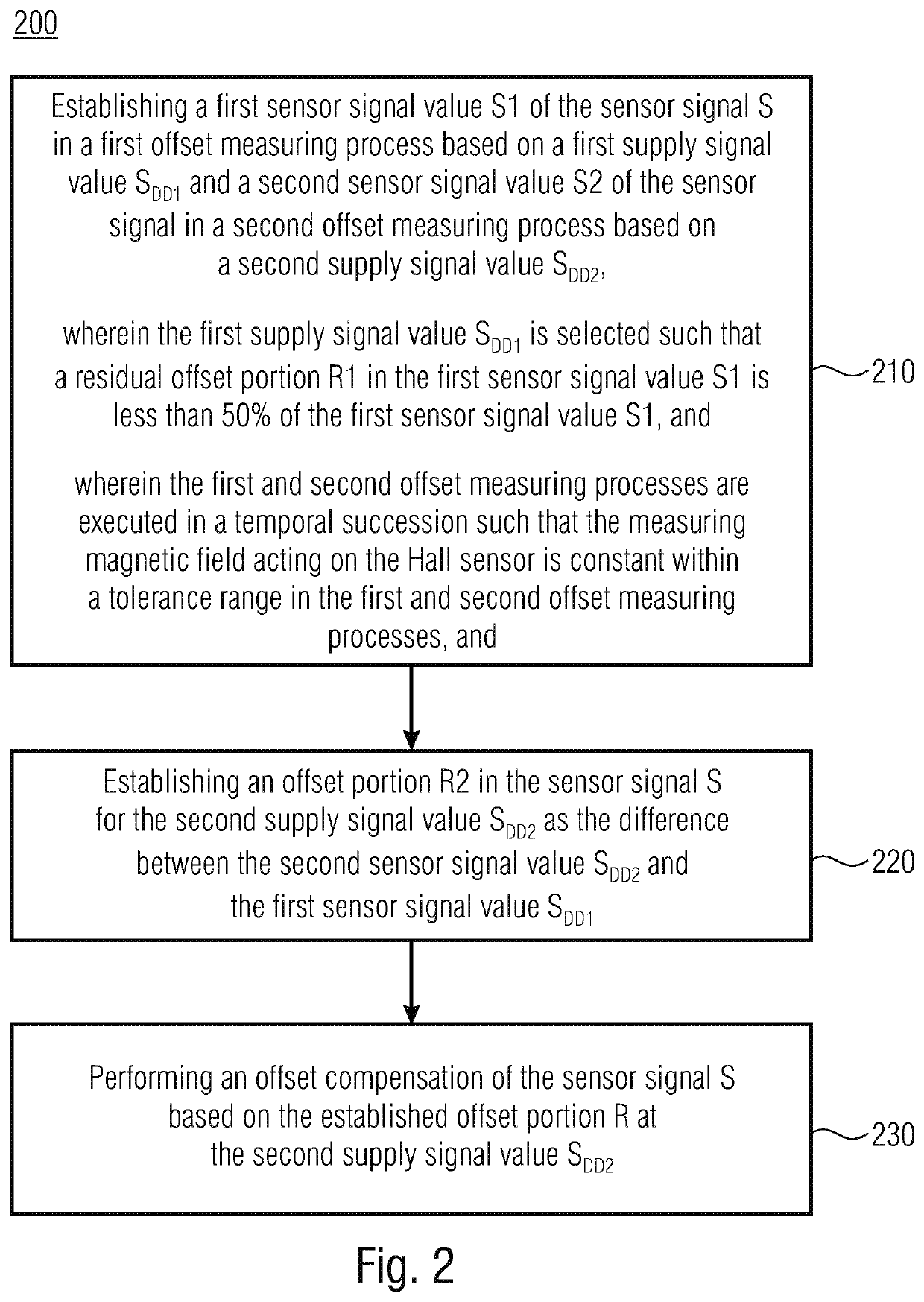

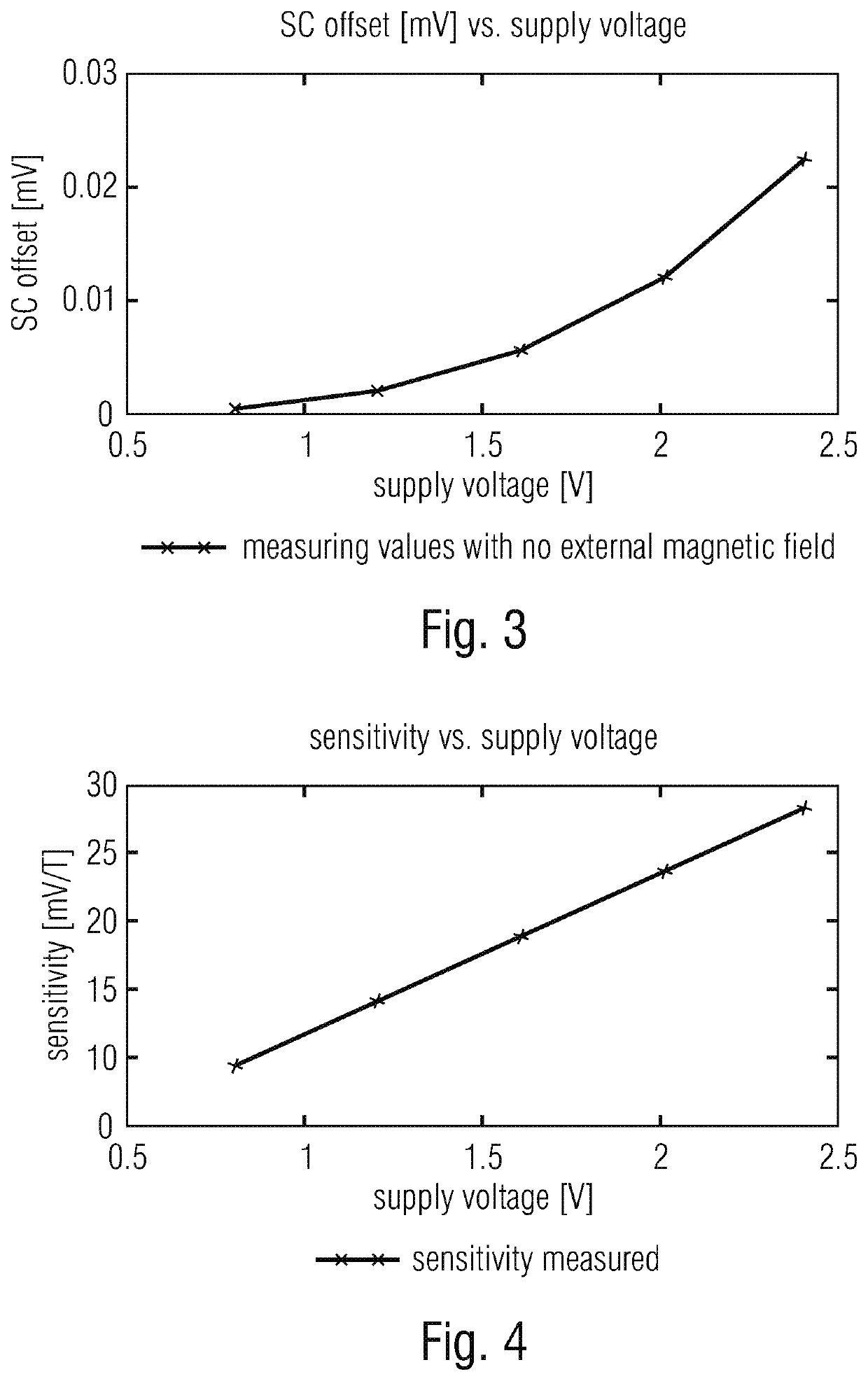

A central idea of techniques herein is that by means of modulation or variation of the supply signal of a Hall sensor, the useful signal portion in the resulting sensor output signal can be separated from the offset portion during operation of the Hall sensor, with no previous calibration or previous serial tests. That course of the sensor output signal resulting from the modulation or variation of the supply signal can then be evaluated or decomposed relative to the components which can be attributed to the offset portion and the useful signal portion. Thus, the offset portion in the sensor output signal can be determined with no (or a negligibly small) external magnetic field applied or with an external magnetic field applied, in case the external magnetic field is constant within a tolerance range while determining the offset portion.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

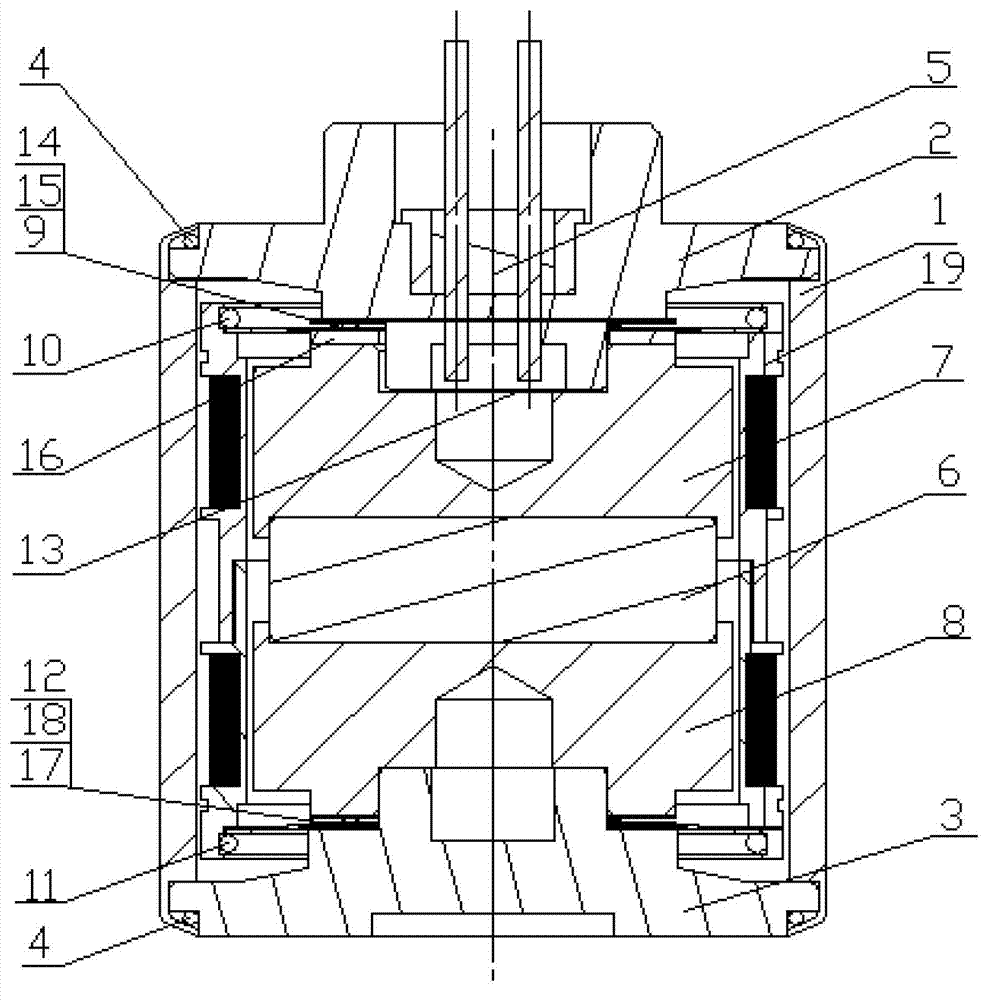

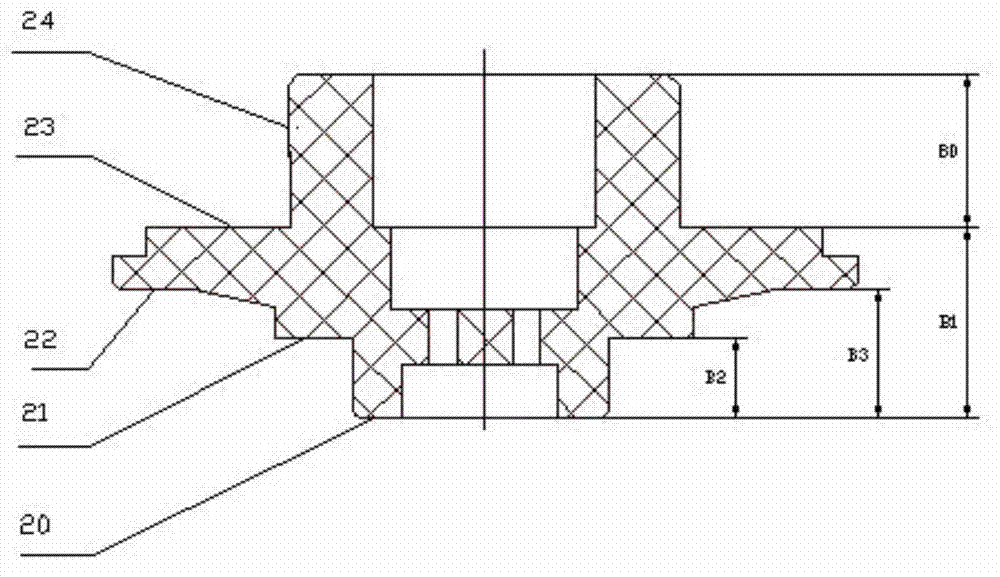

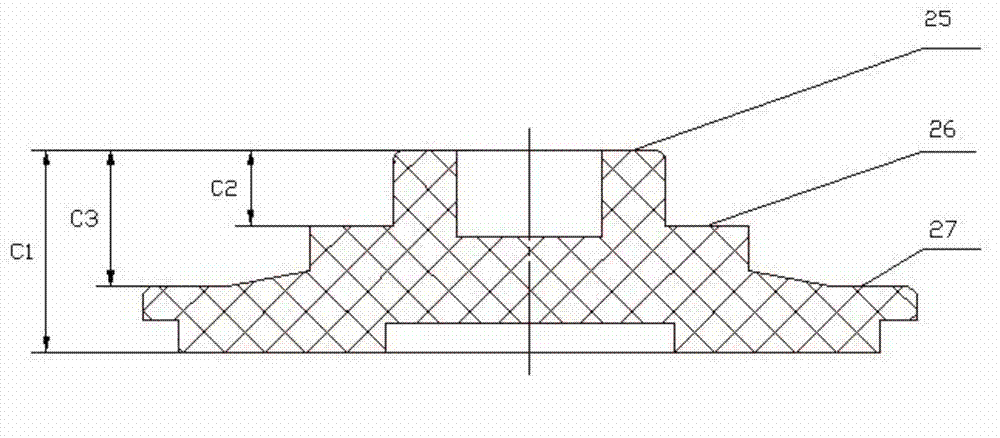

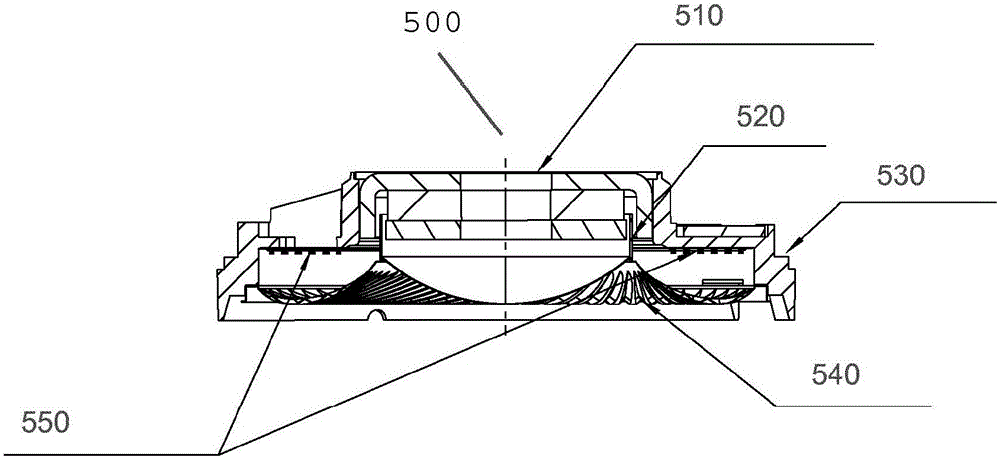

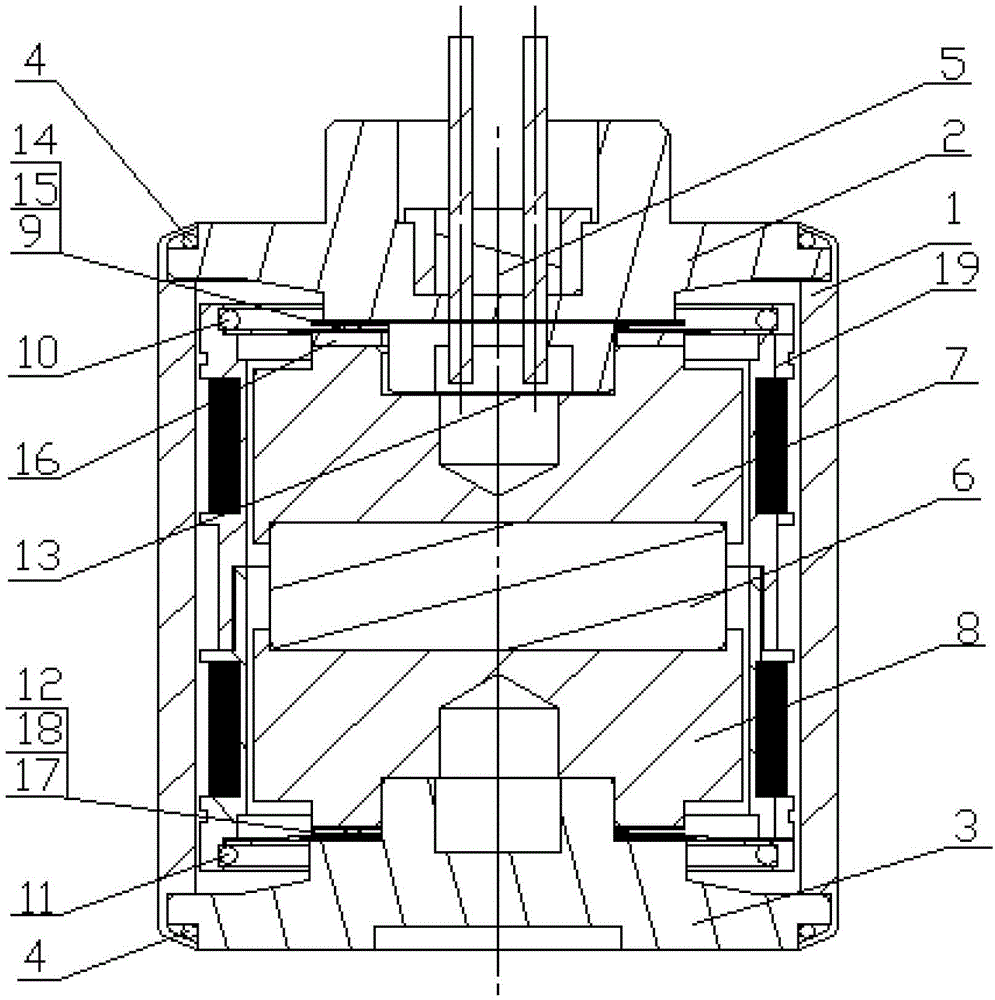

High-resolution earthquake detector and manufacturing method thereof

ActiveCN102901980ASmall distortionReduce consistencySeismic signal receiversLow distortionImage resolution

The invention relates to a high-resolution earthquake detector and a manufacturing method thereof. With the adoption of a detector structure, an upper cover with a guide positioning part, a magnetic system consisting of upper and lower magnetic boots and magnetic steel, a spring-mass system consisting of a coil frame with a winding and a spring, a lower cover, and a shell are coaxial in an assembling process, so that the detector distortion can be effectively reduced. The matching condition ensures that inner and outer rings of upper and lower spring sheets are at a horizontal position after being assembled; the upper and the lower spring sheets are not additionally stressed by external force; and each part inside the detector with a sealed opening is compactly matched without release, so that the distortion of the detector can be reduced. The natural frequency of single spring can be directly detected, and the two springs with equal frequencies can be selected to be matched in pair, so as to ensure the consistency of the spring, and reduce the allowance range and the distortion. With the adoption of a method for directly testing the frequency, the natural frequency of the earthquake detector can be tested before the opening of the detector is sealed, so that the allowance range of the detector can be further reduced.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

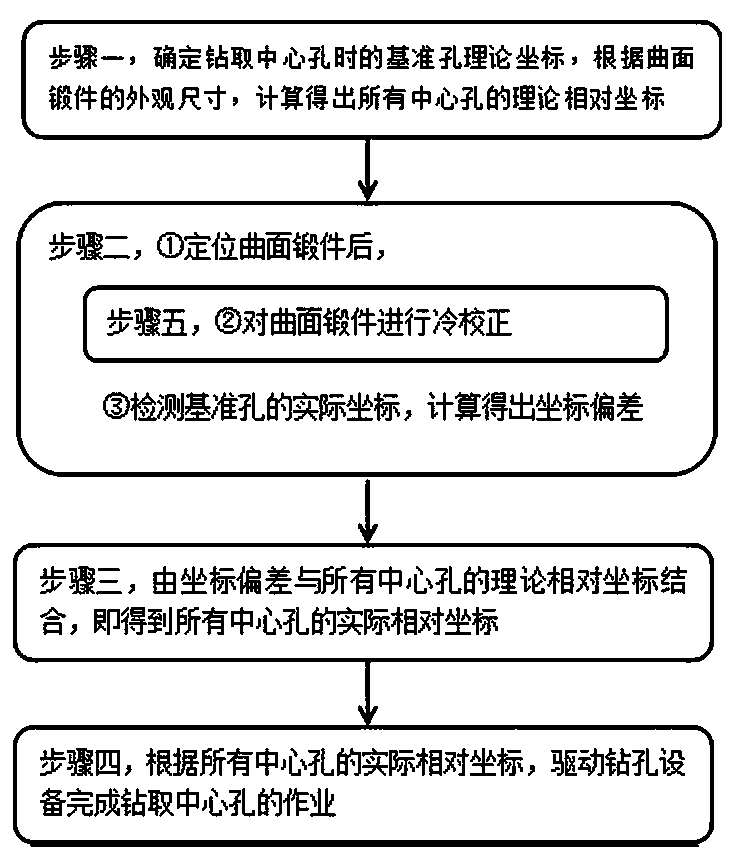

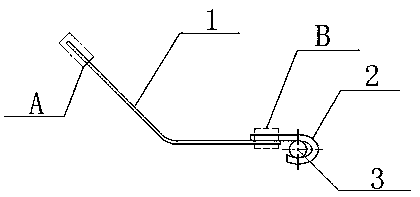

Method for drilling central hole of cambered forging

ActiveCN110281017AHigh precisionMaintain Position AccuracyOther manufacturing equipments/toolsPositioning apparatusMachiningDrill hole

The invention belongs to the technical field of machining, and particularly relates to a method for drilling a central hole of a cambered forging. The main technical scheme is characterized by comprising the following steps of, determining theoretical coordinates of a reference hole during drilling of a central hole, and calculating theoretical relative coordinates of all central holes according to the external dimension of the cambered forging to be machined; after positioning the cambered forging, detecting actual coordinates of the reference hole, and obtaining coordinate deviations through calculation; obtaining the actual relative coordinates of all the central holes by combining the coordinate deviations with the theoretical relative coordinates of all the central holes; and driving drilling equipment to complete the operation of drilling the central hole according to the actual relative coordinates of all the central holes. The method for drilling central hole of cambered forging has the characteristics that the shape of the cambered forging is not limited, the position precision of the central hole is high, and the central hole distance tolerance is small.

Owner:HENGSHUI ZHONGTIEJIAN CASTING & FORGING

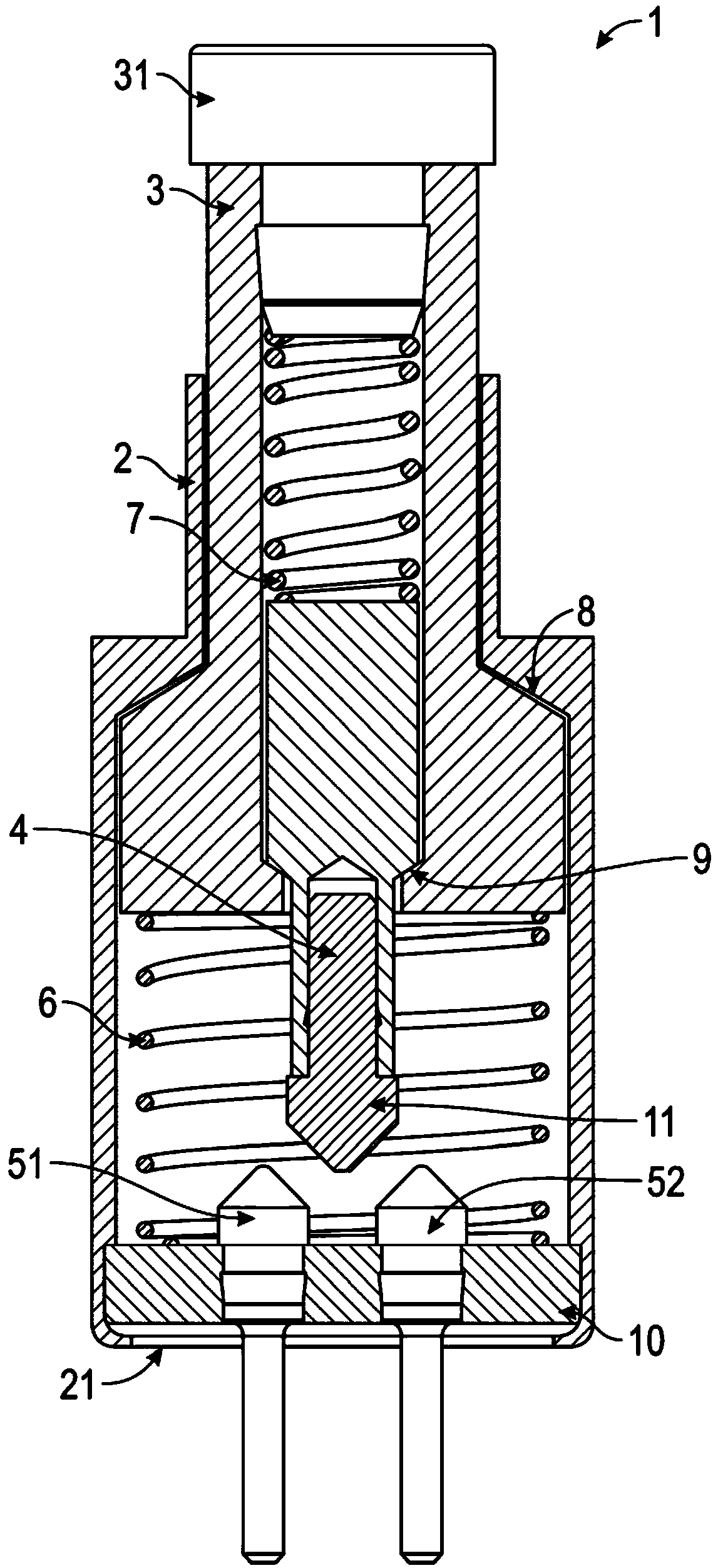

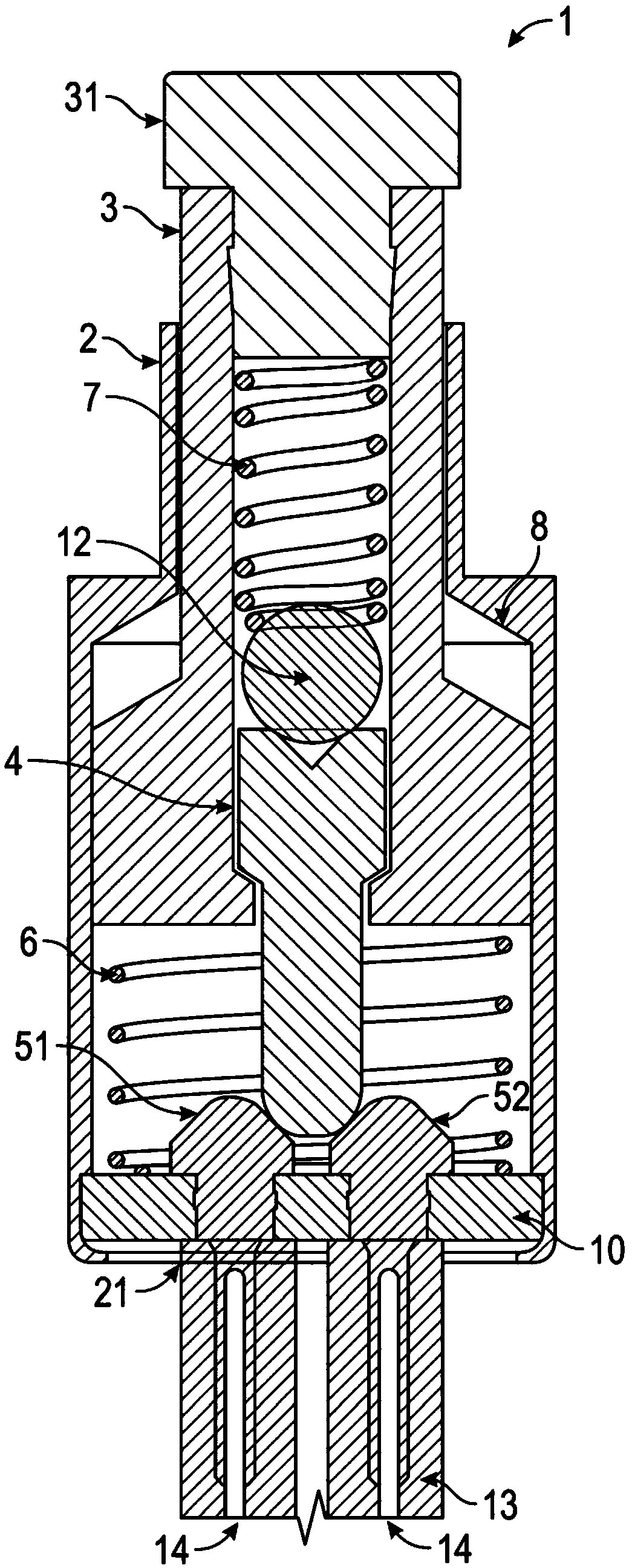

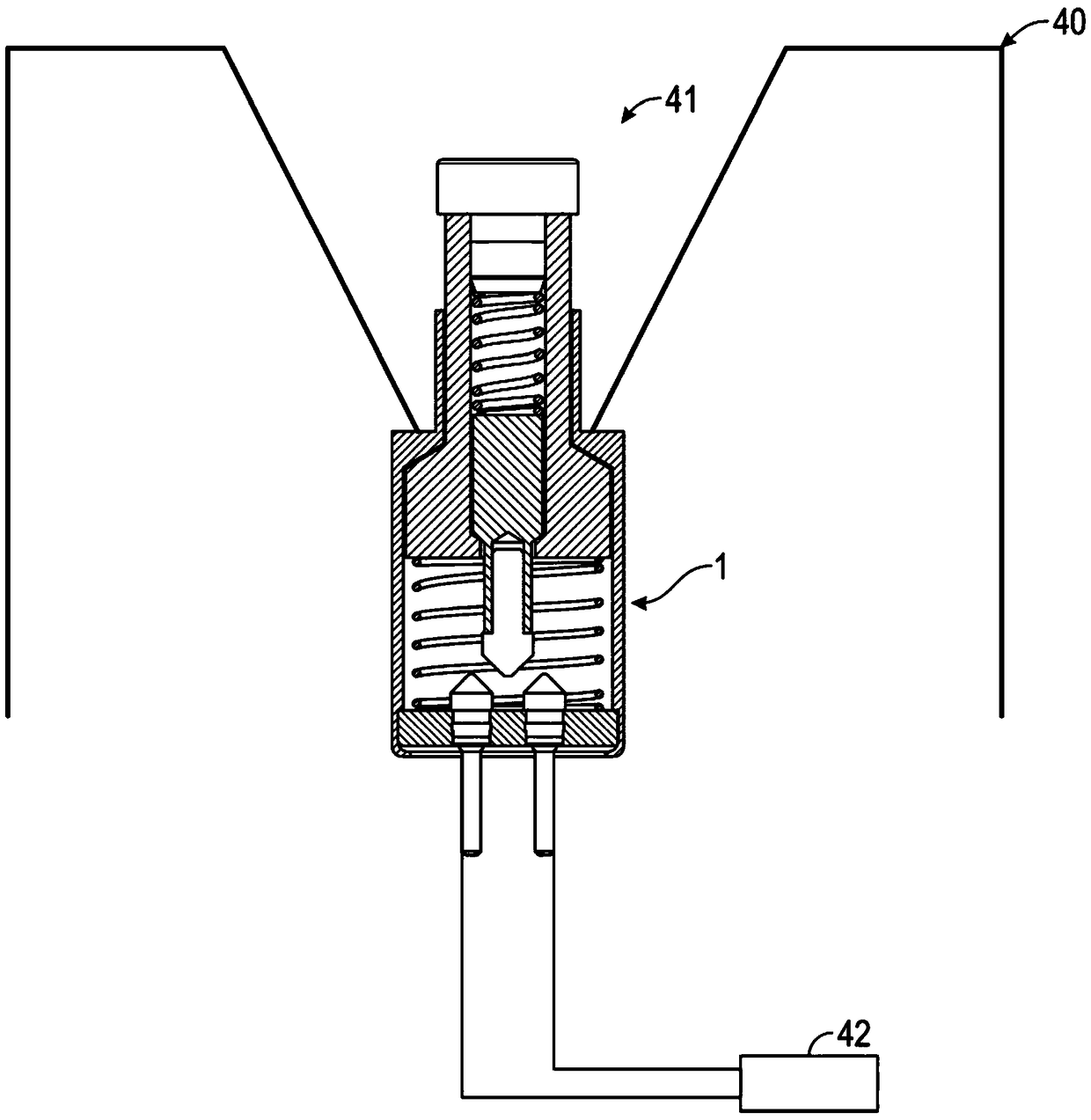

Microswitch and test system

PendingCN109148193ASmall tolerance rangeSave construction spaceContact operating partsContact engagementsSpring forcePiston

The present invention relates to a microswitch that includes a cylindrical sleeve in which a piston is axially movably disposed. A contact pin is axially movably disposed within the piston. The contact pin interacts with two mating contacts that are fixed in the bottom of the sleeve spaced apart from one another. The movement of the contact pins is supported by two springs. A return spring is disposed between the bottom of the sleeve and the piston and moves the piston to an initial position when the microswitch is not actuated. A buffer spring is disposed between the contact pin and a pistonactuating cap and is responsible for gently placing the contact pin onto the mating contacts. In order to buffer the movement of the contact pin only shortly before being placed on the mating contacts, the buffer spring has a larger spring force than the return spring. The microswitch can be constructed with a stable metal sleeve and works despite the lack of insulation between the piston and thesleeve. The two mating contacts also result in a larger contact area and improved guiding of the contact pins.

Owner:LISA DRAXLMAIER GMBH +1

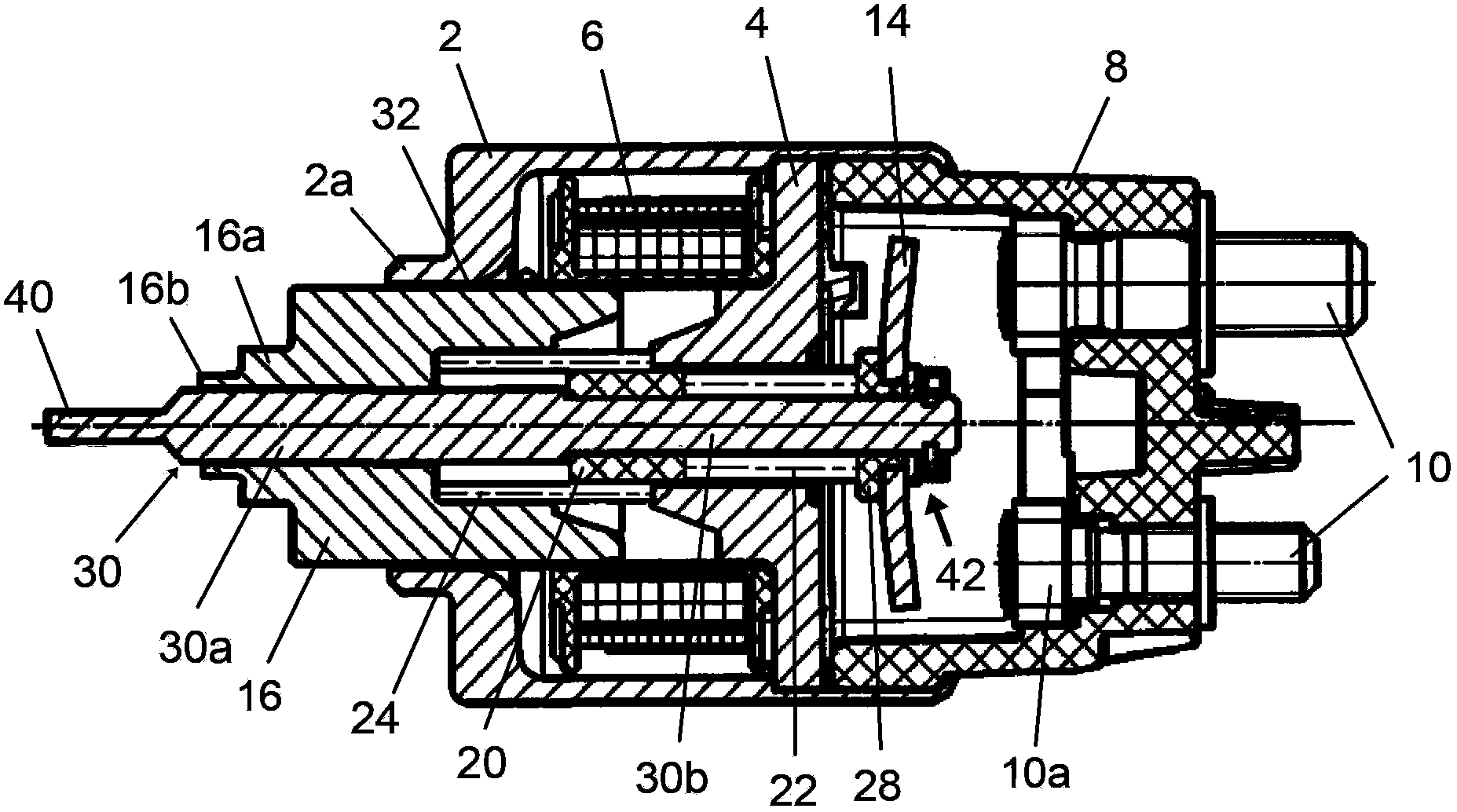

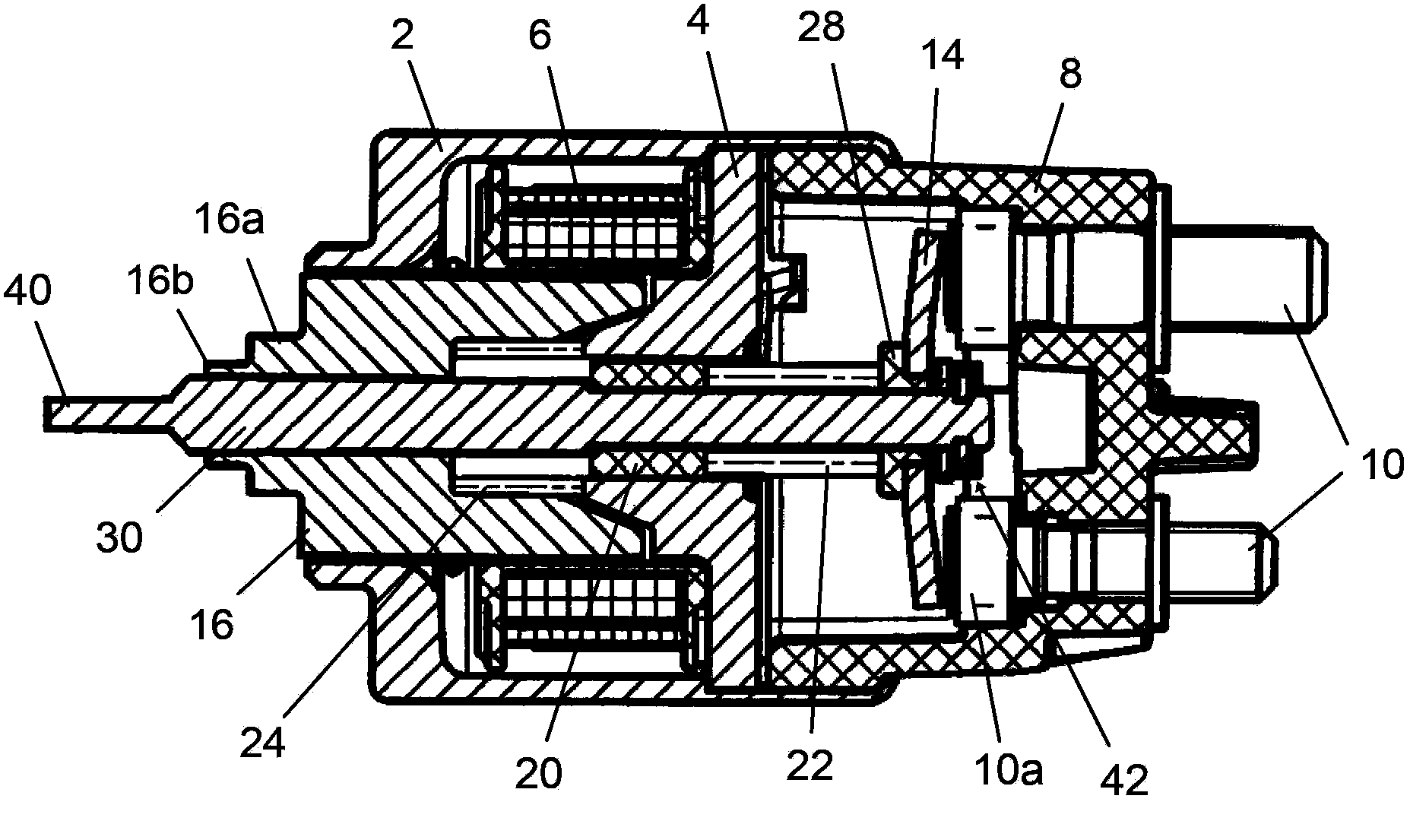

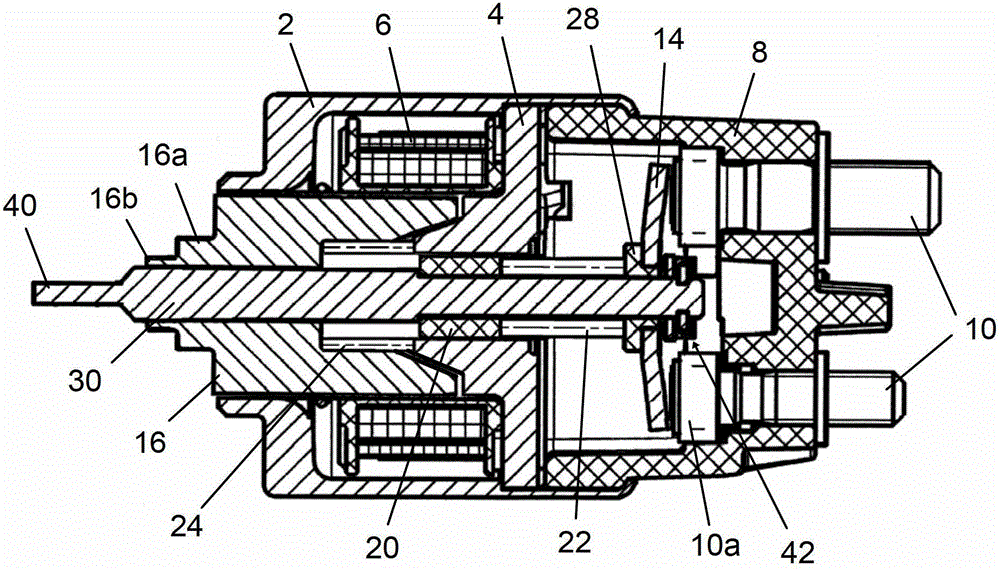

Electromagnetic switch, manufacturing method of electromagnetic switch and vehicle starter

ActiveCN103426684ASmall toleranceSmall tolerance rangePower operated startersElectric motor startersElectricityEngineering

The invention discloses a manufacturing method of an electromagnetic switch of a vehicle starter. A single push rod is moved backwards until an initial electric connection state which is set up between two binding posts through a contact bridge on the push rod is detected. The push rod is further moved backwards for a reserved distance, under the condition that the state that a movable iron core is pushed to abut against a fixed iron core is kept, the movable iron core is fixed on the push rod and a splicing window used into which the upper end of a shift fork to can be inserted is machined in the front end of the push rod. The invention further discloses the electromagnetic switch manufactured with the manufacturing method and the vehicle starter comprising the electromagnetic switch. The manufacturing method of the electromagnetic switch, the electromagnetic switch and the vehicle starter can improve the positioning precision of a drive gear.

Owner:ROBERT BOSCH STARTER MOTORS GENERATORS (CHINA) CO

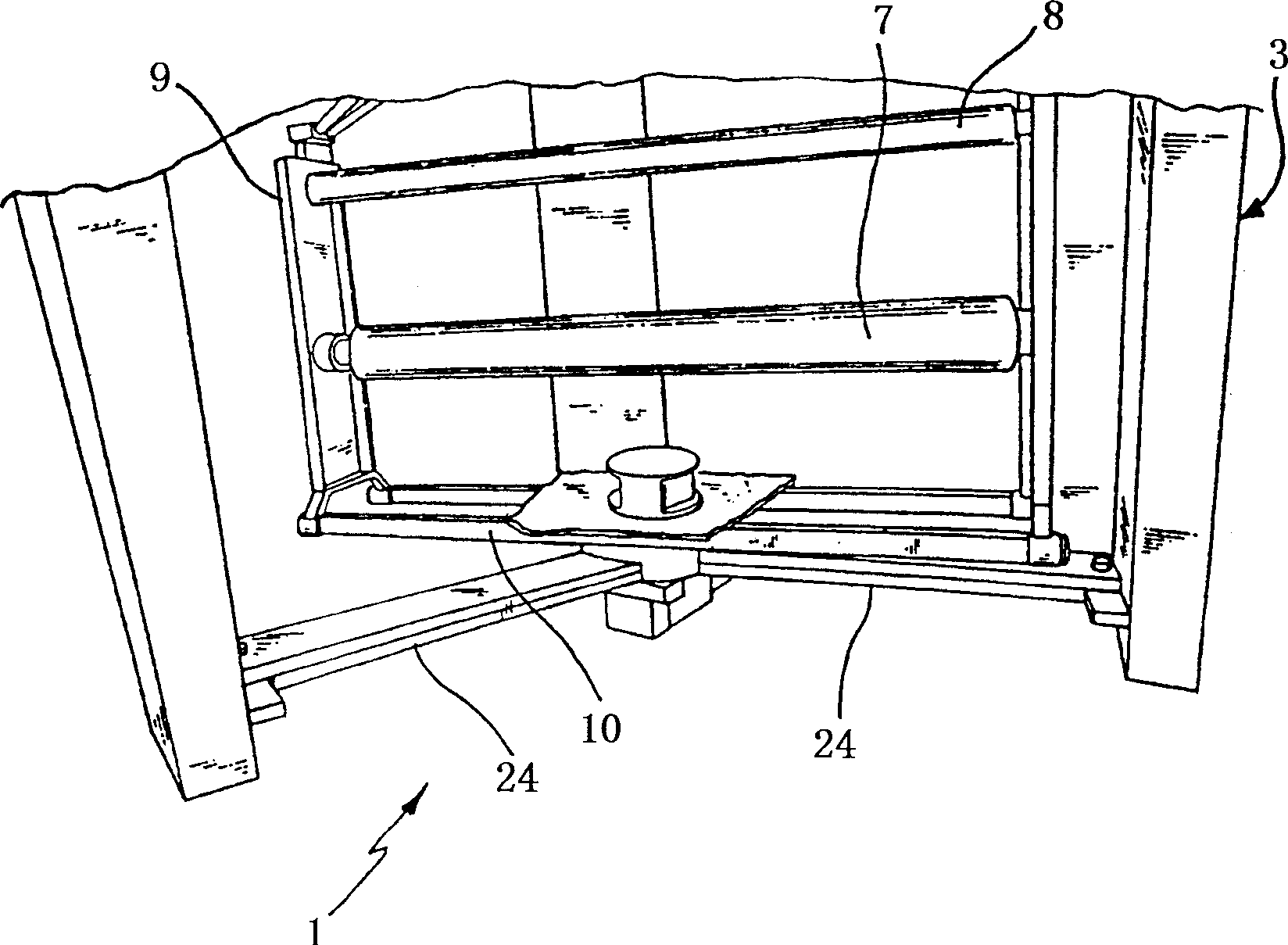

Apparatus and method for controlling weight fabric produced by textile machine, in particular by circular knitting machine

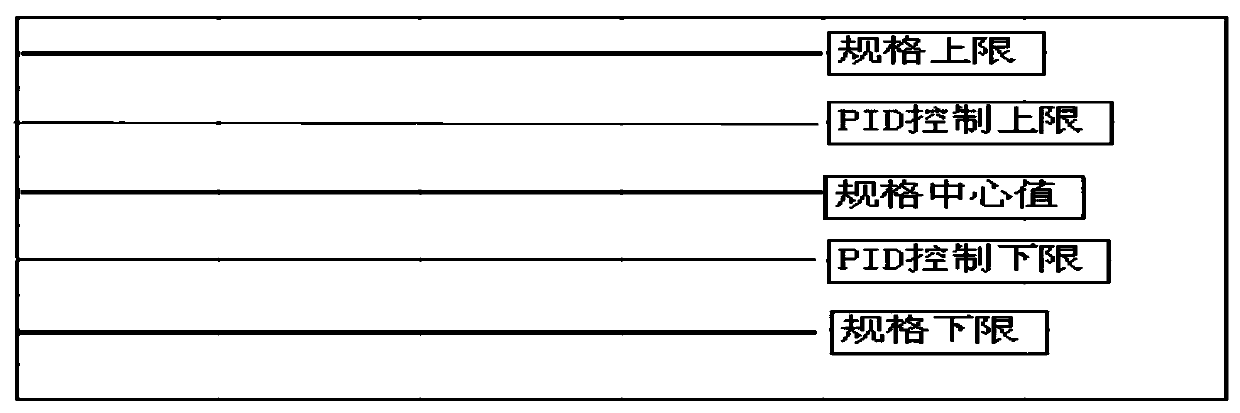

InactiveCN1425088ASmall tolerance rangeImprove uniformityWeft knittingLoomsProcess engineeringIndustrial engineering

An apparatus is provided to control the weight of fabric produced by a textile machine (2), comprising weighting means of every single fabric piece directly associated to the textile machine dedicated to the manufacture of the same. A procedure is also provided to control the weight of the fabric produced by a textile machine, comprising a weighting stage of every single fabric wounded or folded, near the textile machine dedicated to the manufacture of said piece, and to apply to every manufactured piece a printed label suitable to provide at least specific data concerning the piece weight.

Owner:SANTONI SPA

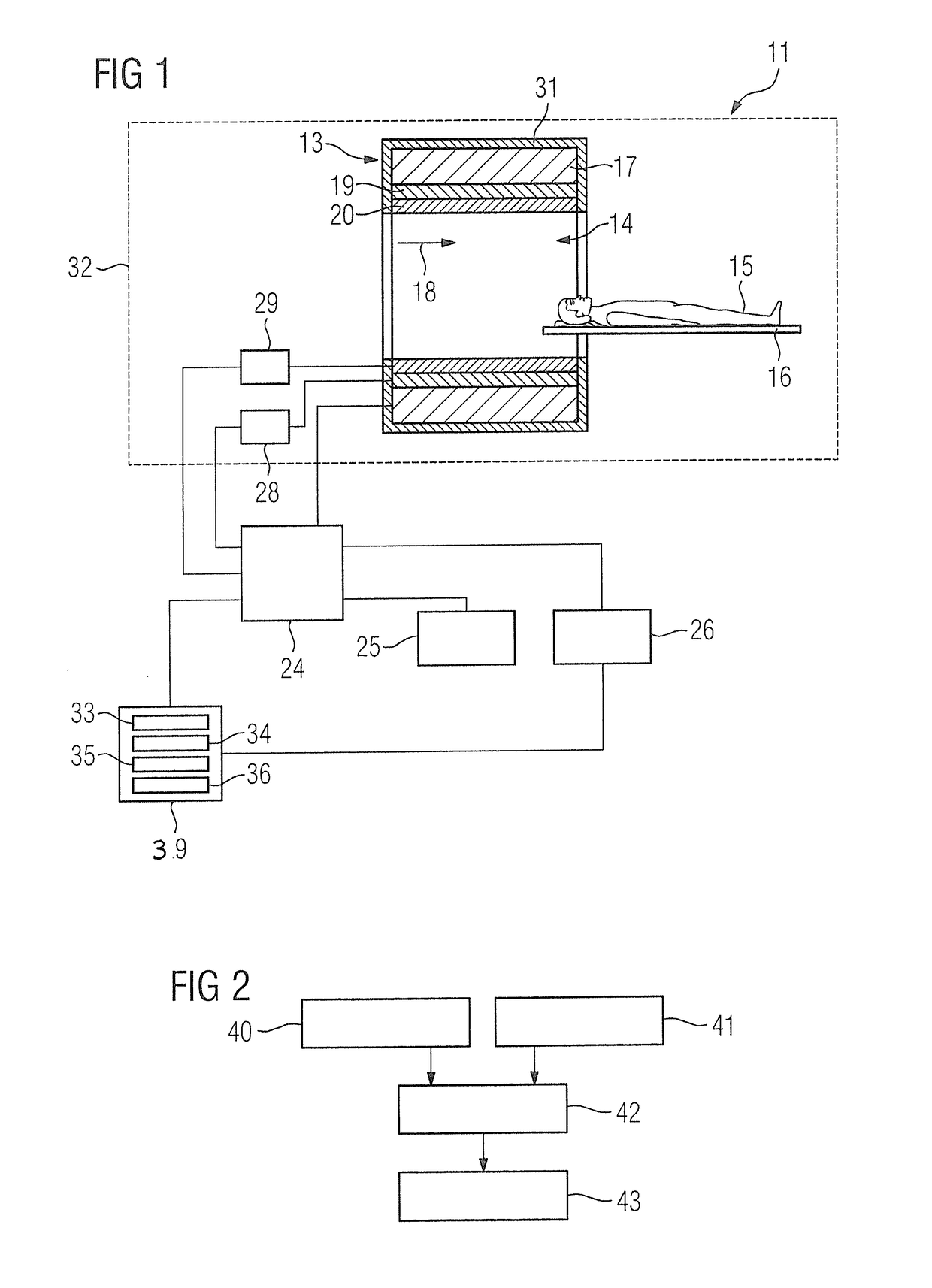

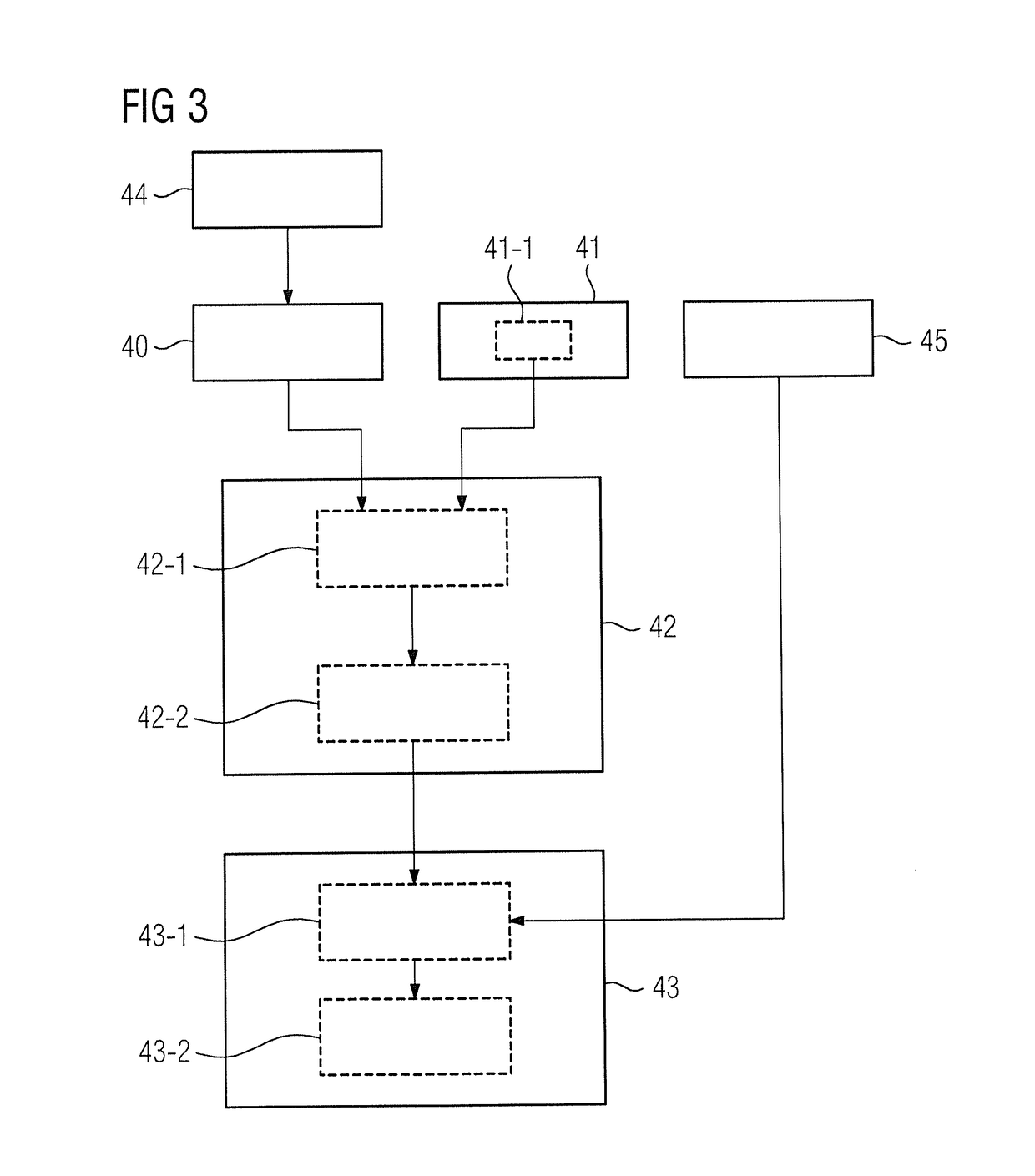

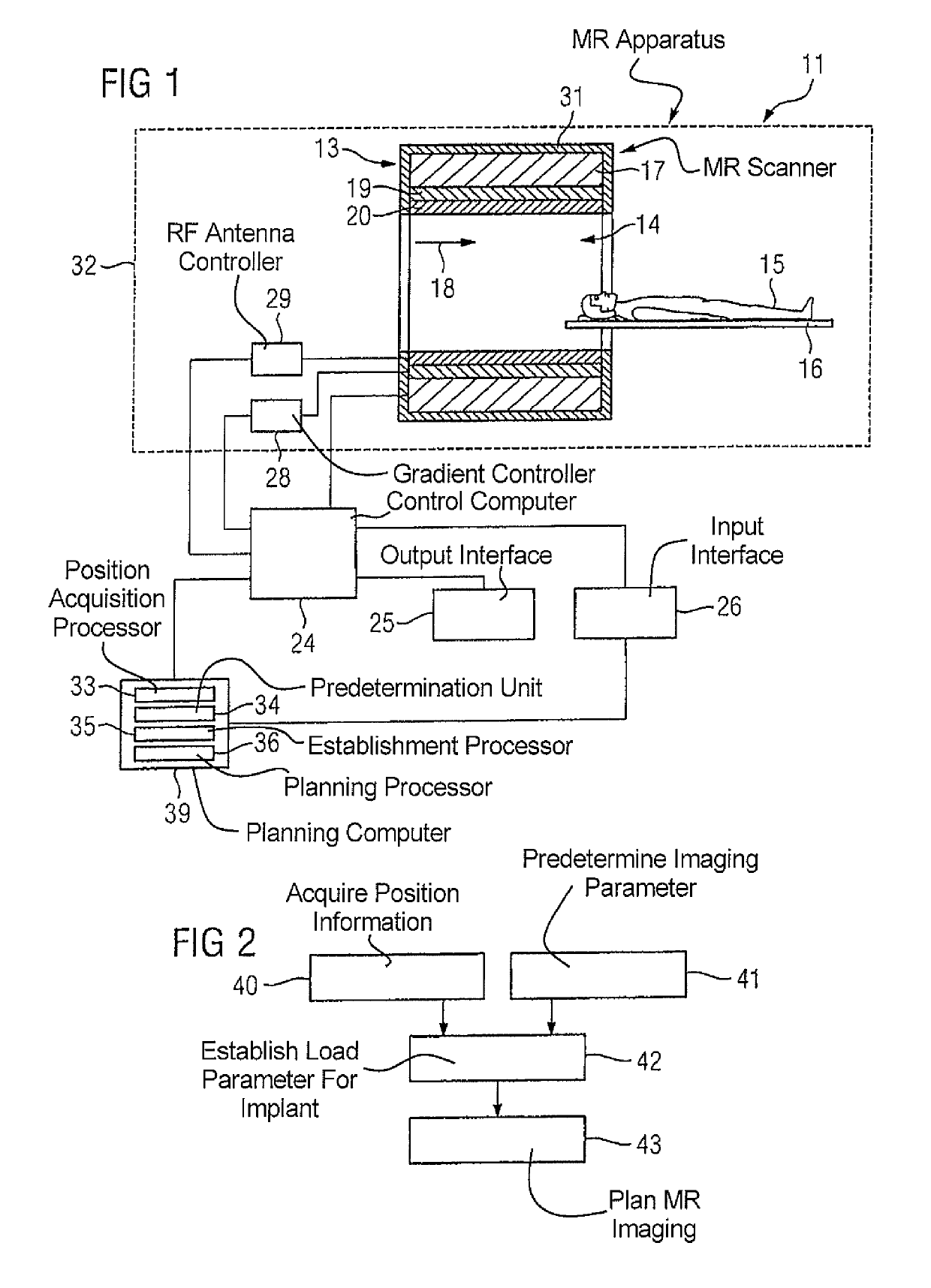

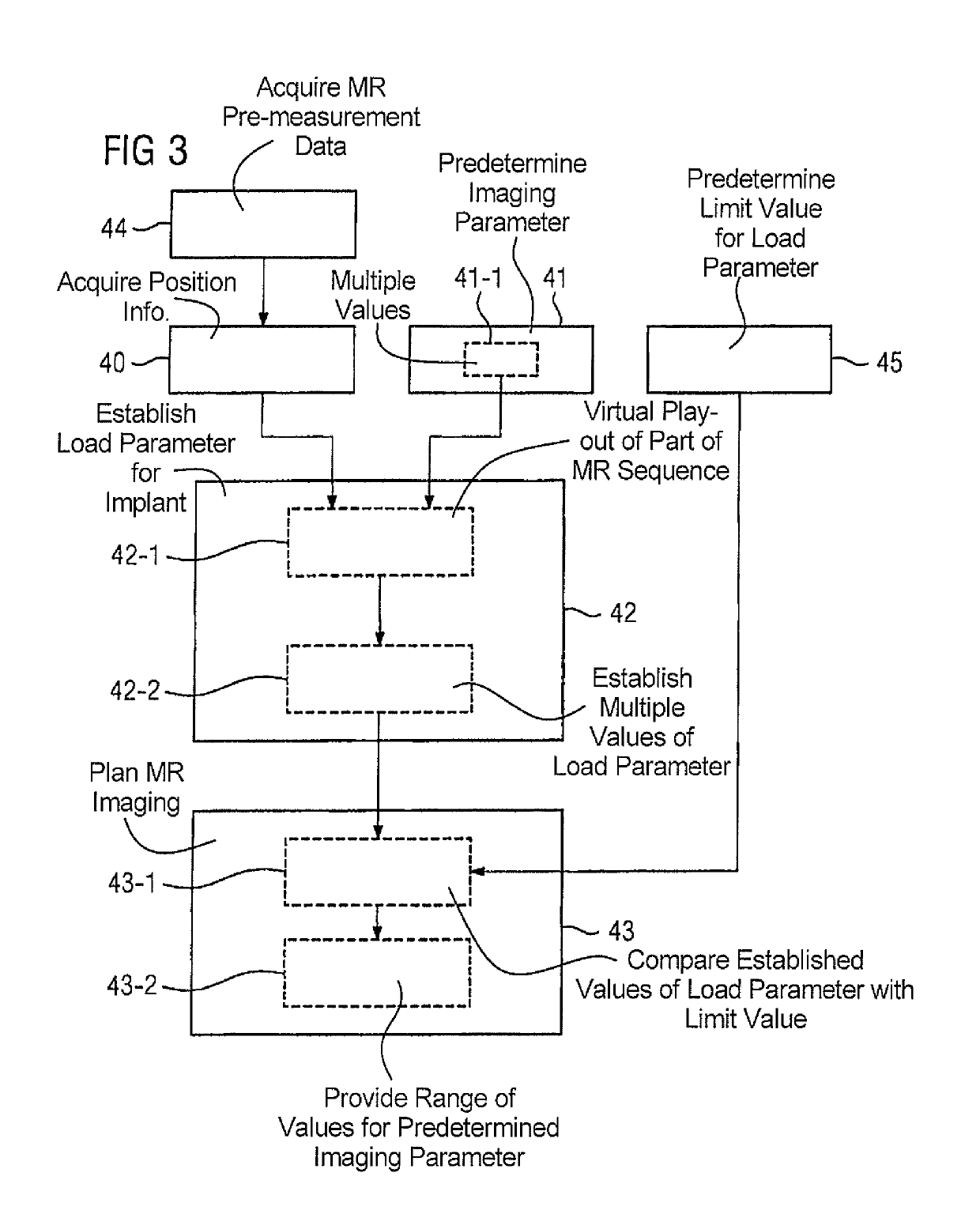

Method, computer and magnetic resonance apparatus for planning imaging of a subject that contains an implant

ActiveUS20170205477A1Improve planningEasy to planMeasurements using NMR imaging systemsMagnetic variable regulationResonanceMagnetic resonance imaging

In a method and computer for planning magnetic resonance imaging of a body of an examination object that contains an implant, to be implemented by a magnetic resonance apparatus, position information of the implant is provided to the computer, the position information characterizing a position of the implant in the body of the examination object, and at least one imaging parameter for the magnetic resonance imaging is predetermined before the imaging. At least one load parameter of the implant is established in the computer on the basis of the acquired position information and the at least one predetermined imaging parameter. The magnetic resonance imaging is planned in the computer on the basis of the established load parameter of the implant.

Owner:SIEMENS HEALTHCARE GMBH

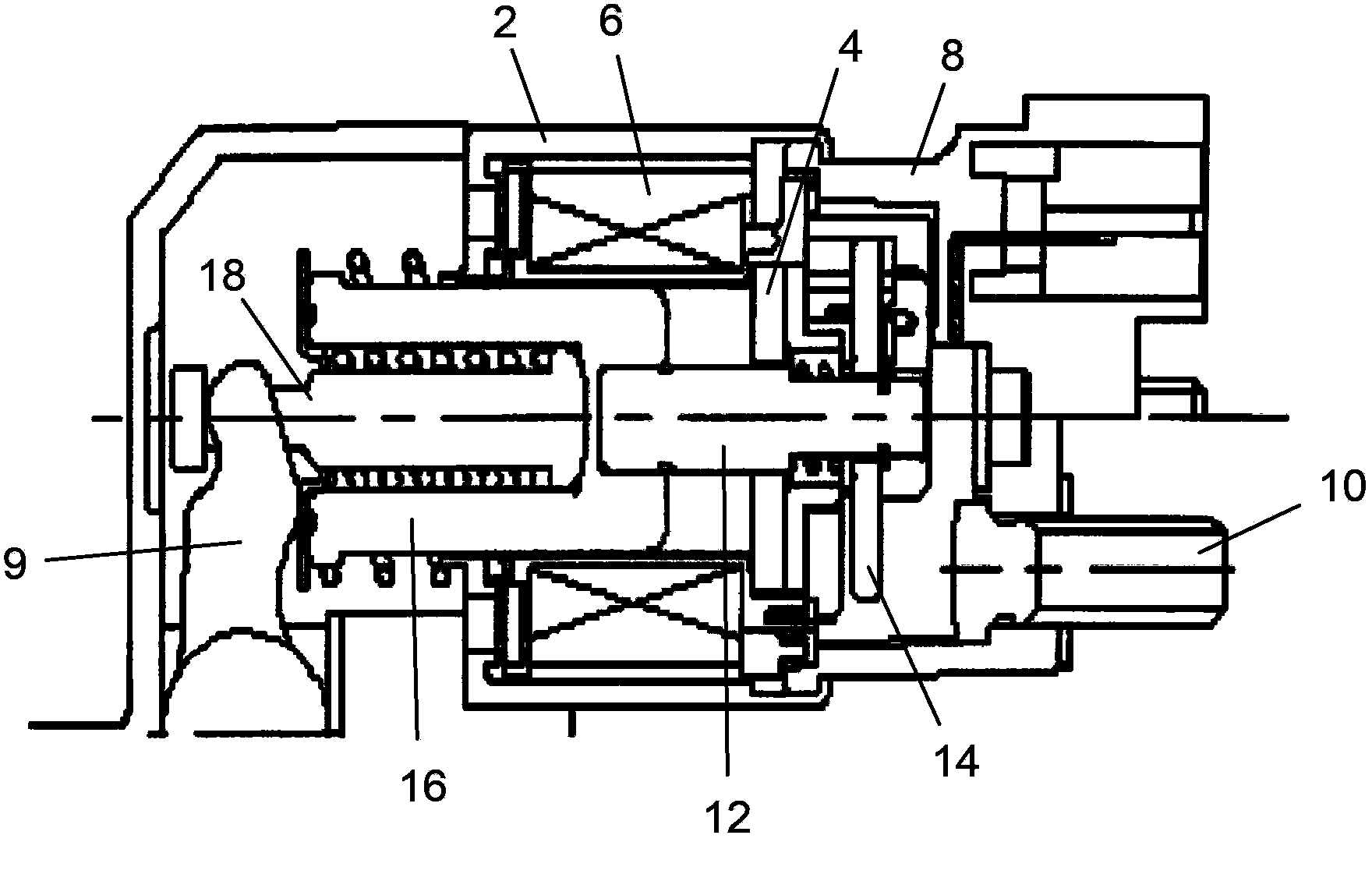

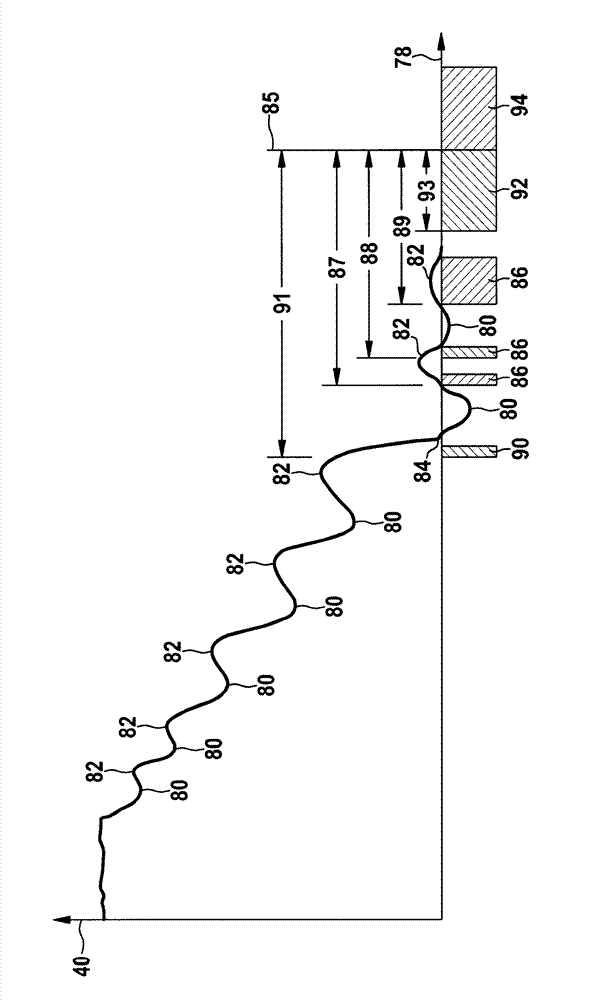

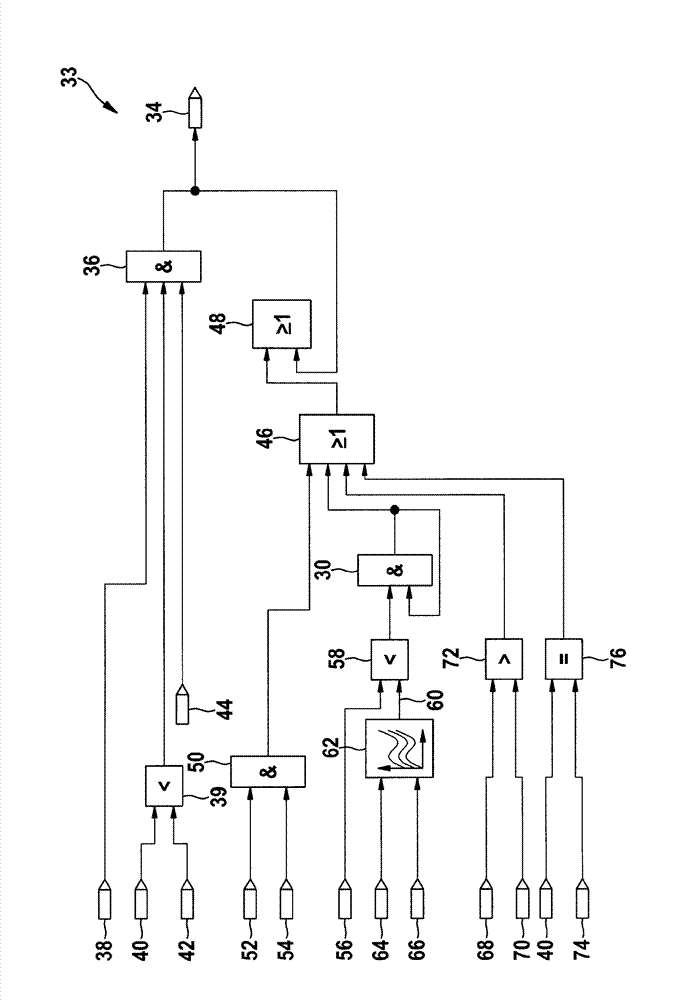

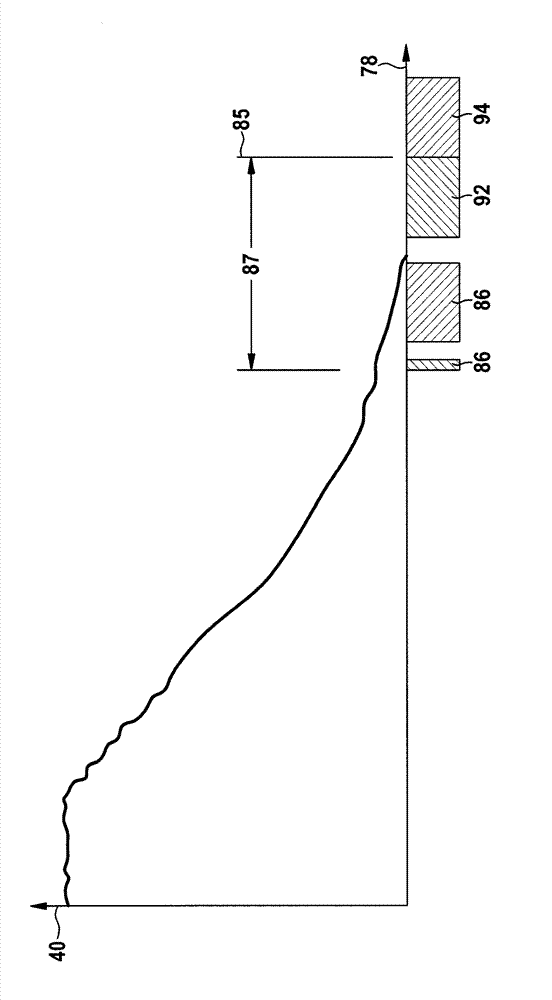

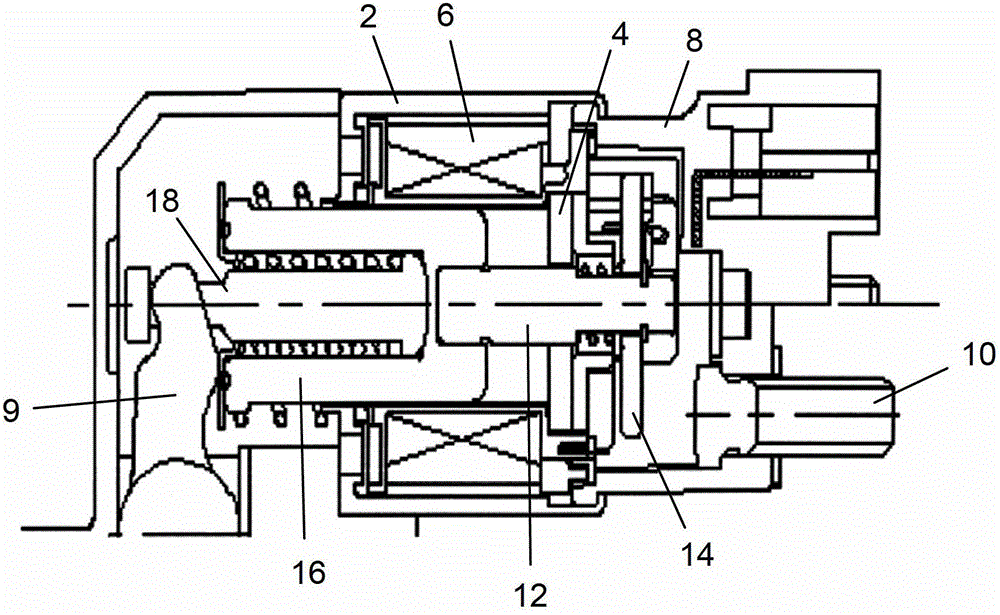

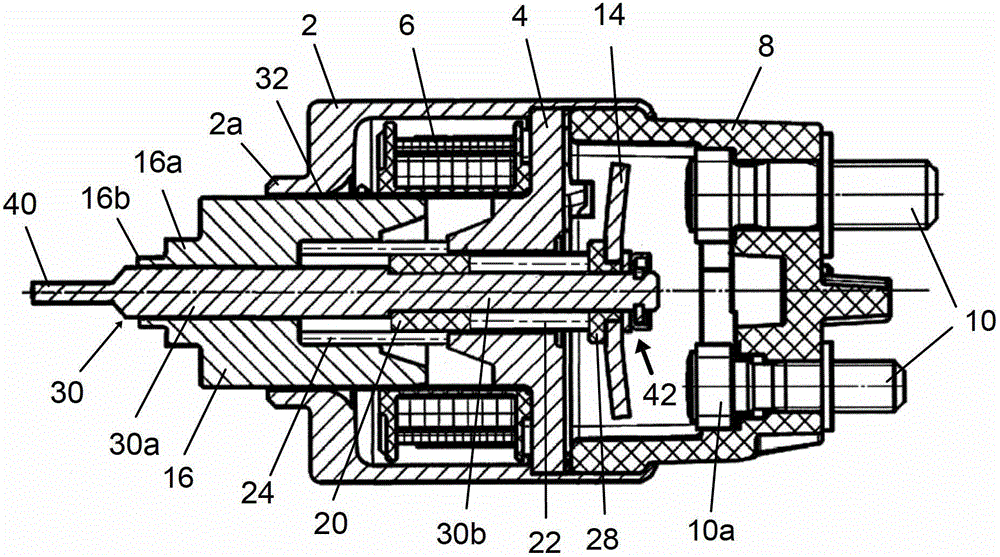

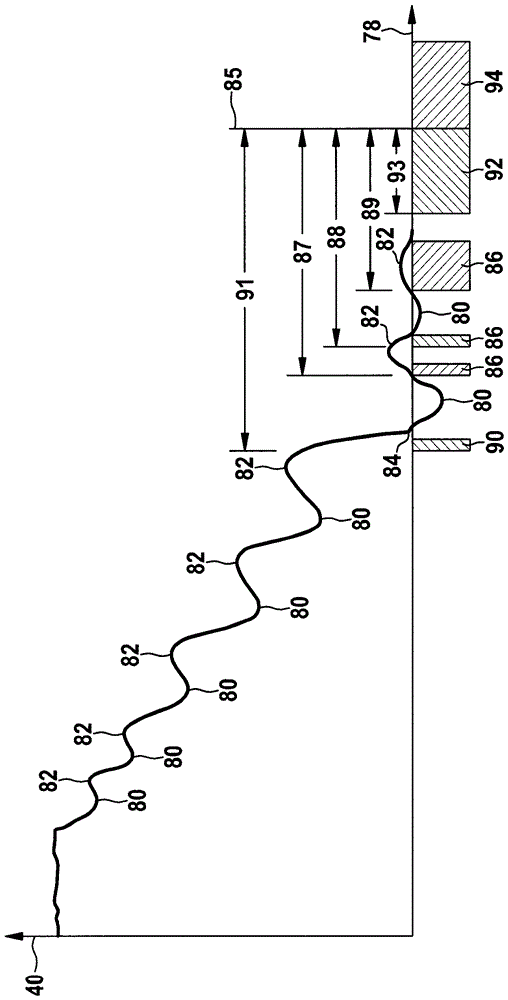

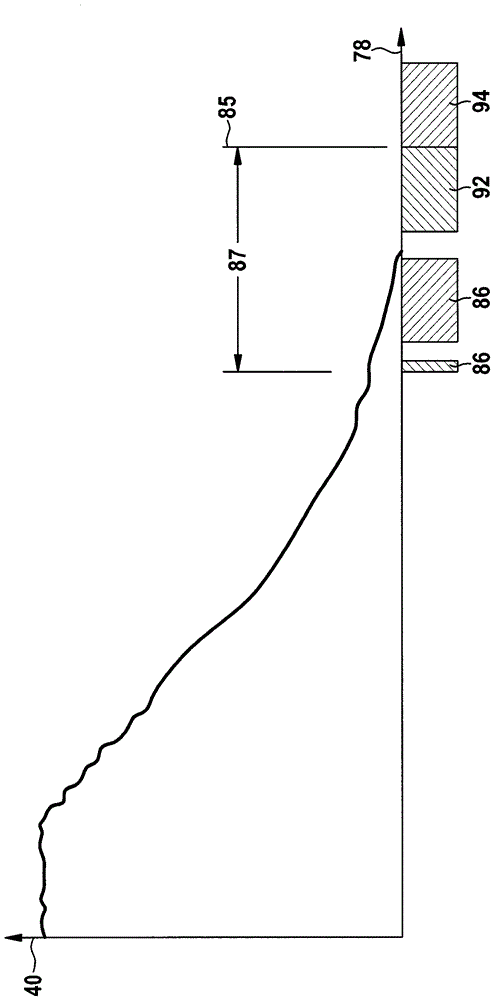

Rapid restart using traditional starter in after-running of engine

ActiveCN103161639AClose to restStart delay time shortenedPower operated startersElectric motor startersEngineeringInternal combustion engine

* The invention relates to a method for determining engaging time (86, 90, 92) of a starter in an internal combustion engine (2), comprising: determining a revolution number (40) of a crankshaft (8) of the internal combustion engine (2), particularly depending on an oscillation stroke of a piston (6) of the internal combustion engine (2), and qualifying the engaging time (86, 90, 92) before or at state time of the crankshaft (8), wherein the revolution number (40) has a symbol which shows that a rotating direction of the crankshaft (8) is identical to a working direction of the internal combustion engine (2).

Owner:ROBERT BOSCH GMBH

A welding structure of a relay contact reed assembly

InactiveCN109192607ASmall tolerance rangeOvercome the defect of poor parallelismRelay terminal arrangementsEngineeringDestructive testing

The invention relates to a welding structure of a relay contact reed assembly, comprising a reed assembly, a positioning fixture, an adjusting screw, an insulating sheet, an upper electrode assembly and a lower electrode assembly. A limit groove of the spring assembly is arranged in the positioning fixture. The reed assembly adopts the structure the the reed is below and the wrapping angle is above in the positioning fixture. After welding, each position dimension requirement of the product reed assembly meets the requirements of the process technology, and the welding wrapping angle is good in parallelism with the contact reed. The adhesion between the welding piece and the electrode head is greatly improved. After the welded reed assembly is loaded into the product, the technical parameters of the product meet the requirements of the process technology, and the mechanical aging, vibration, impact and other destructive tests are carried out on the product, and there is no product failure or reed fracture; accurate positioning, changing the main welding surface, increasing the contact area between the electrode and the reed, enhancing the thermal conductivity and electrical conductivity of the electrode welding positioning system, to meet the needs of mass production of products, while reducing the labor intensity of workers, improve labor efficiency.

Owner:GUIZHOU TIANYI ELECTRICAL

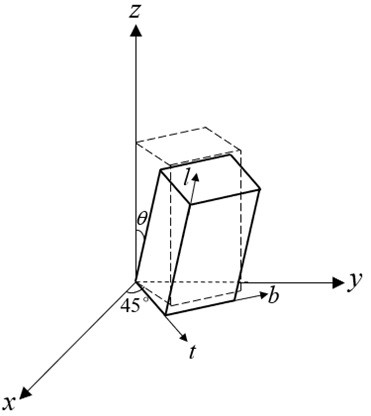

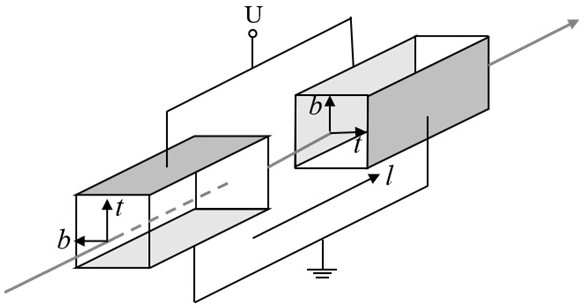

Transverse modulation KDP type electro-optic Q switch

ActiveCN112421372AAdjustable half wave voltageEasy to manufactureLaser detailsLight extinctionHalf wave

The invention provides a transverse modulation KDP type electro-optic Q switch which is characterized in that two identical KDP type crystals are combined, the KDP type crystals are cut into differenttypes, x and z represent crystal axes of the KDP type crystals, l and b represent the length direction and the width direction of the cut crystals respectively, the value range of the angle theta isshown in the specification, and the value range of the angle theta is shown in the specification; the length direction of the KDP type crystal is a light transmission direction, and the thickness direction of the KDP type crystal is an electric field applying direction. The switch is advantaged in that the half-wave voltage of the electro-optic Q switch is adjustable, the switch shape and the electrodes are easy to prepare, and the electric field is more uniform, so the extinction ratio is higher, the influence of natural birefringence and temperature on the electro-optic Q switch is smaller,requirements on length deviation, temperature deviation and the like of two crystals for matching are lower, the allowable range is larger, and the electro-optic Q switch is more practical.

Owner:HENAN INST OF ENG

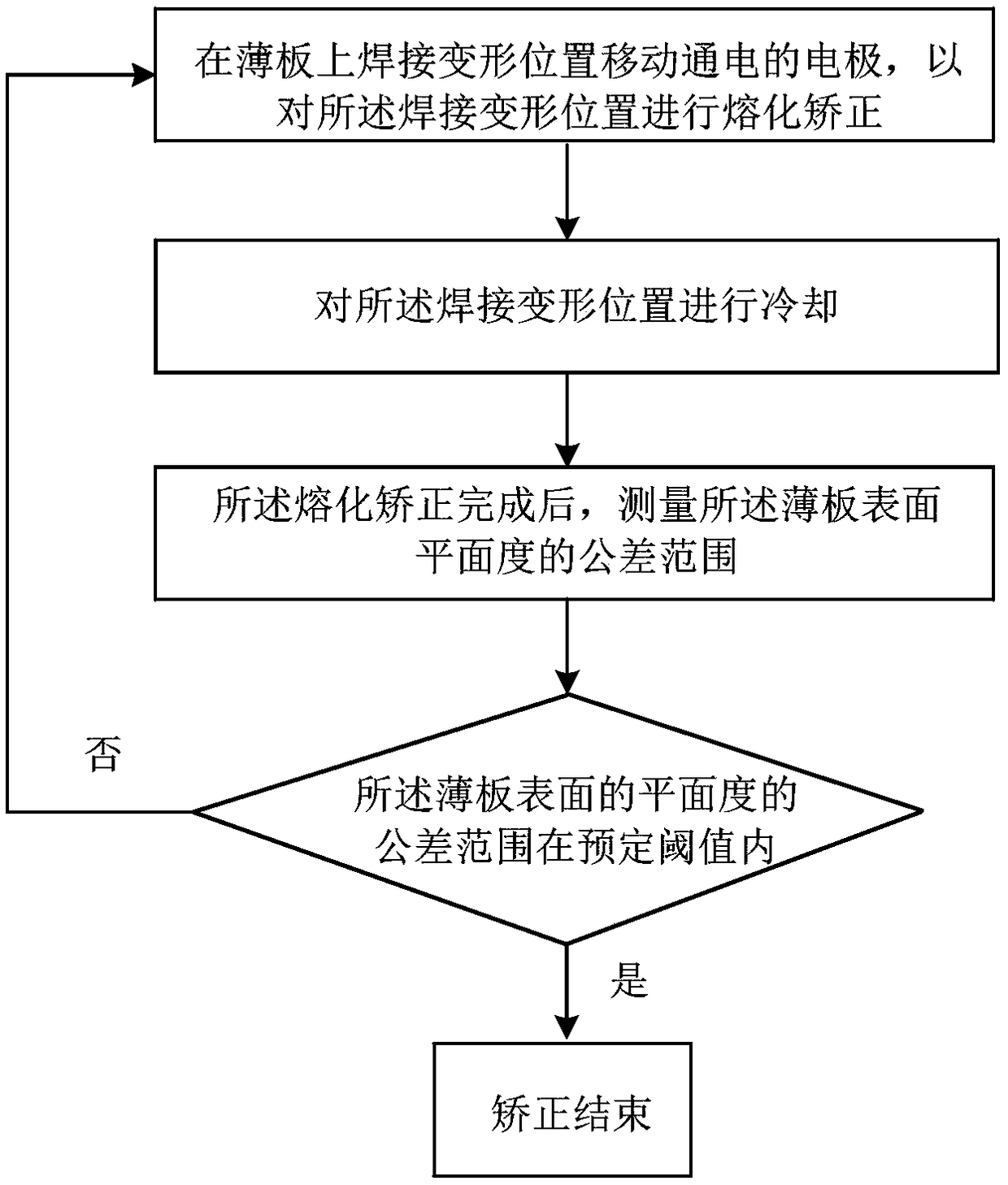

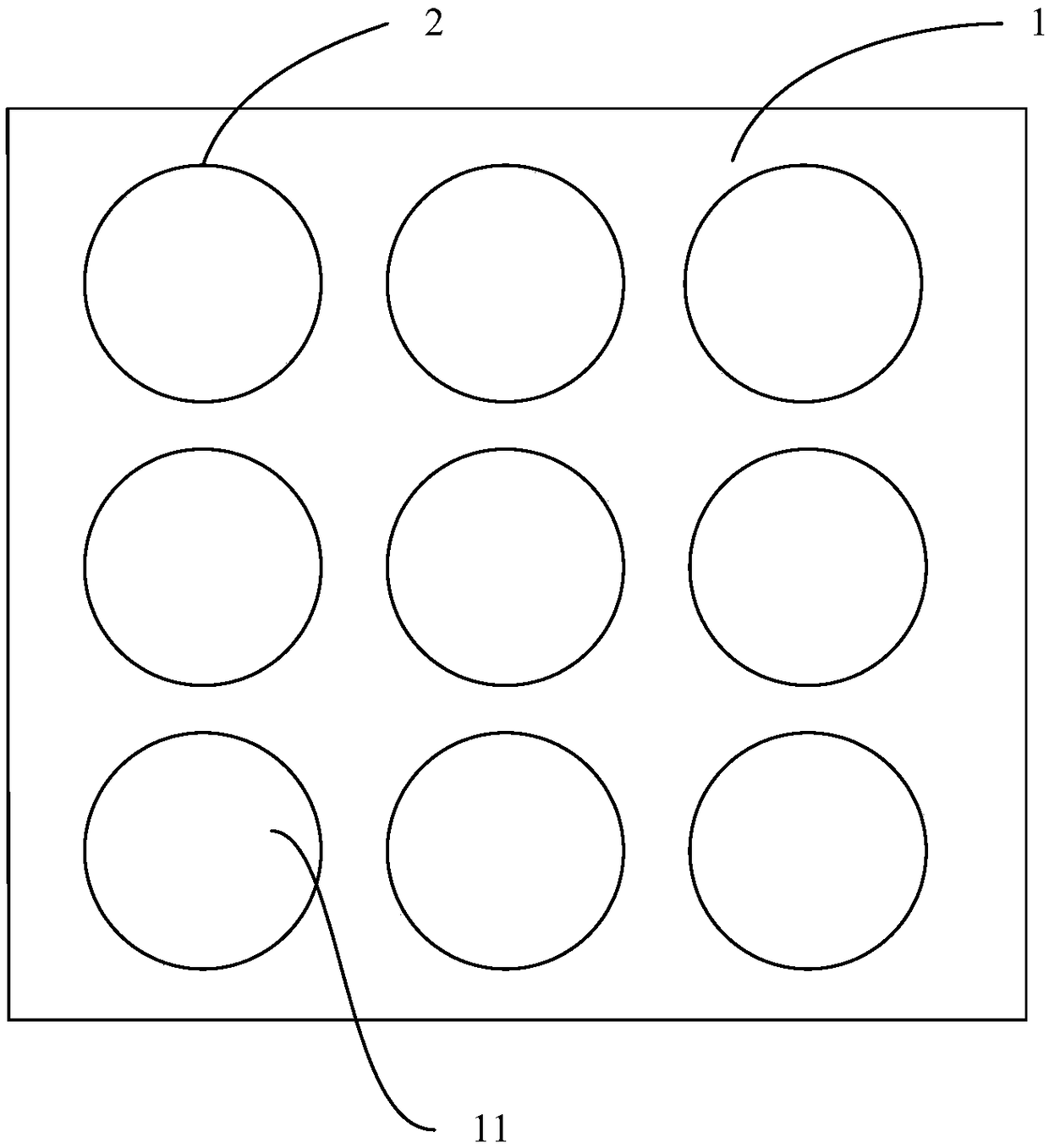

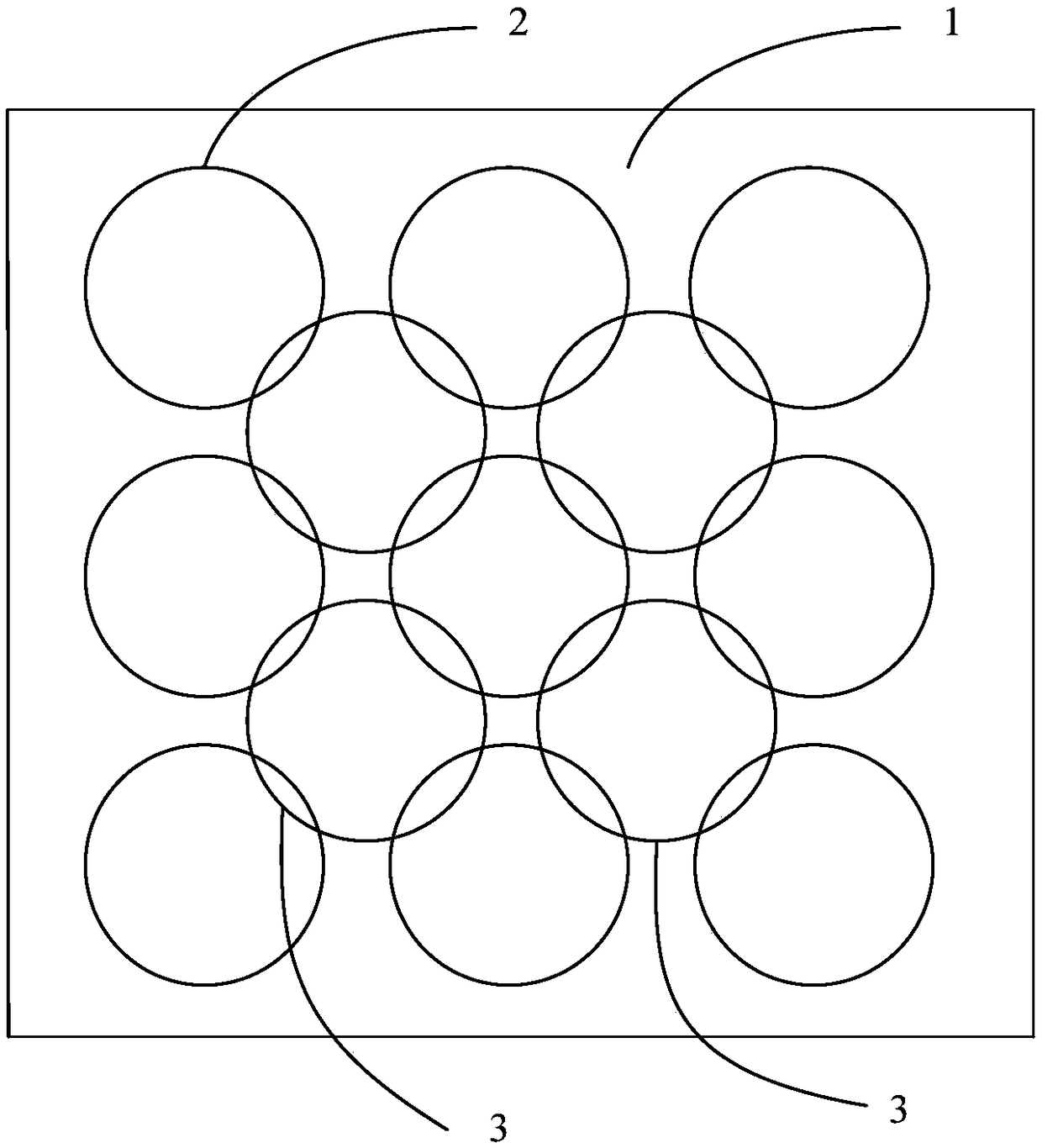

Deformation correcting method

ActiveCN109332425AAvoid correcting spot bumpsSmall tolerance rangeWelding deformationMaterials science

The invention provides a deformation correcting method. The deformation correcting method comprises the steps that S1, an electrode which is energized is moved at a welding deformation position on a thin plate to perform melting correction on the welding deformation position, and a movement trajectory of the electrode when performing the melting correction is at least one circle; and S2, after themelting correction is completed, the tolerance range of the flatness of the surface of the thin plate is measured, and the steps S1 and S2 are repeated until the tolerance range of the flatness of the surface of the thin plate is within a predetermined threshold value. The occurrence of irregular spots at the correction position is effectively avoided, and the tolerance range of the flatness of the correction position is further reduced, so that the surface of the thin plate is smoother and more attractive.

Owner:CRRC DALIAN CO LTD

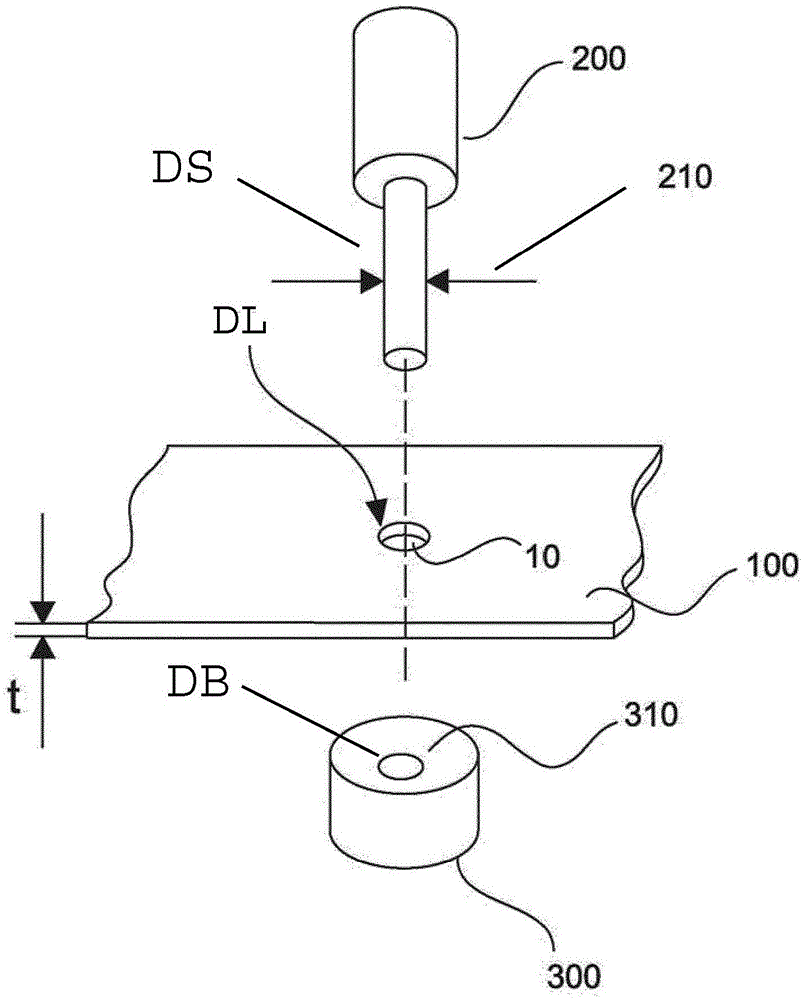

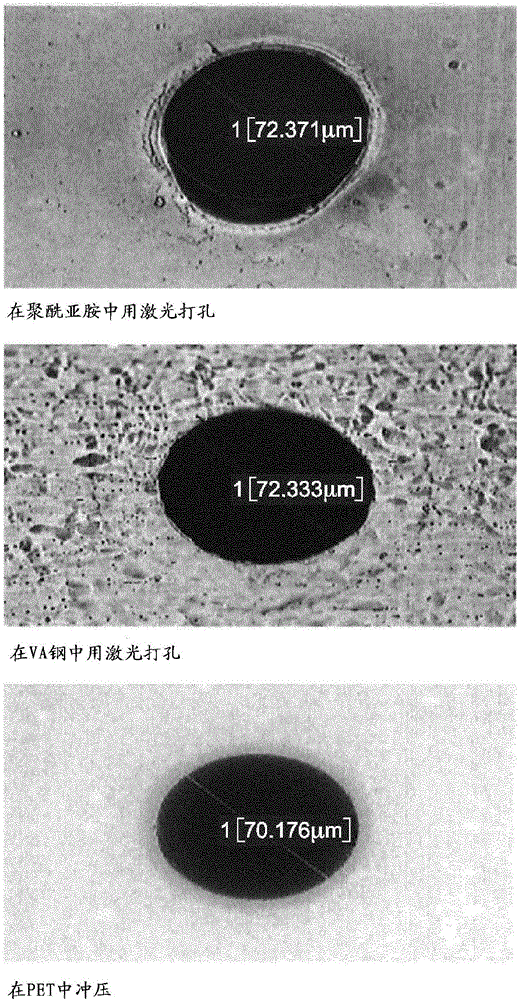

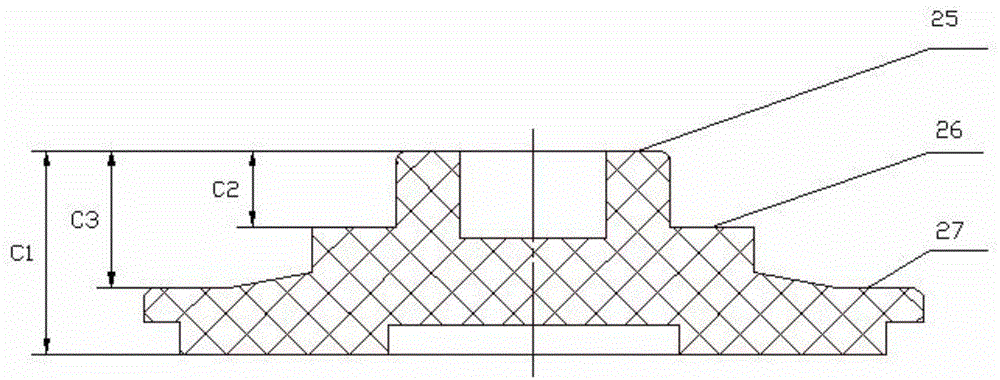

Method for producing acoustic damping elements

InactiveCN106660102AFast preparationSmall tolerance rangeTransducer detailsSound producing devicesPunchingEngineering

The invention relates to a method for producing acoustic damping elements having an acoustic resistance. For this purpose, at least one bushing (300) with a hole (310) having a diameter (DB) is placed below a base material (100). At least one hole (10) is punched into the base material (100) by means of at least one punch (200) having a punch diameter (DS). The punching process is repeated in different locations of the base material (100).

Owner:SENNHEISER ELECTRONICS GMBH & CO KG

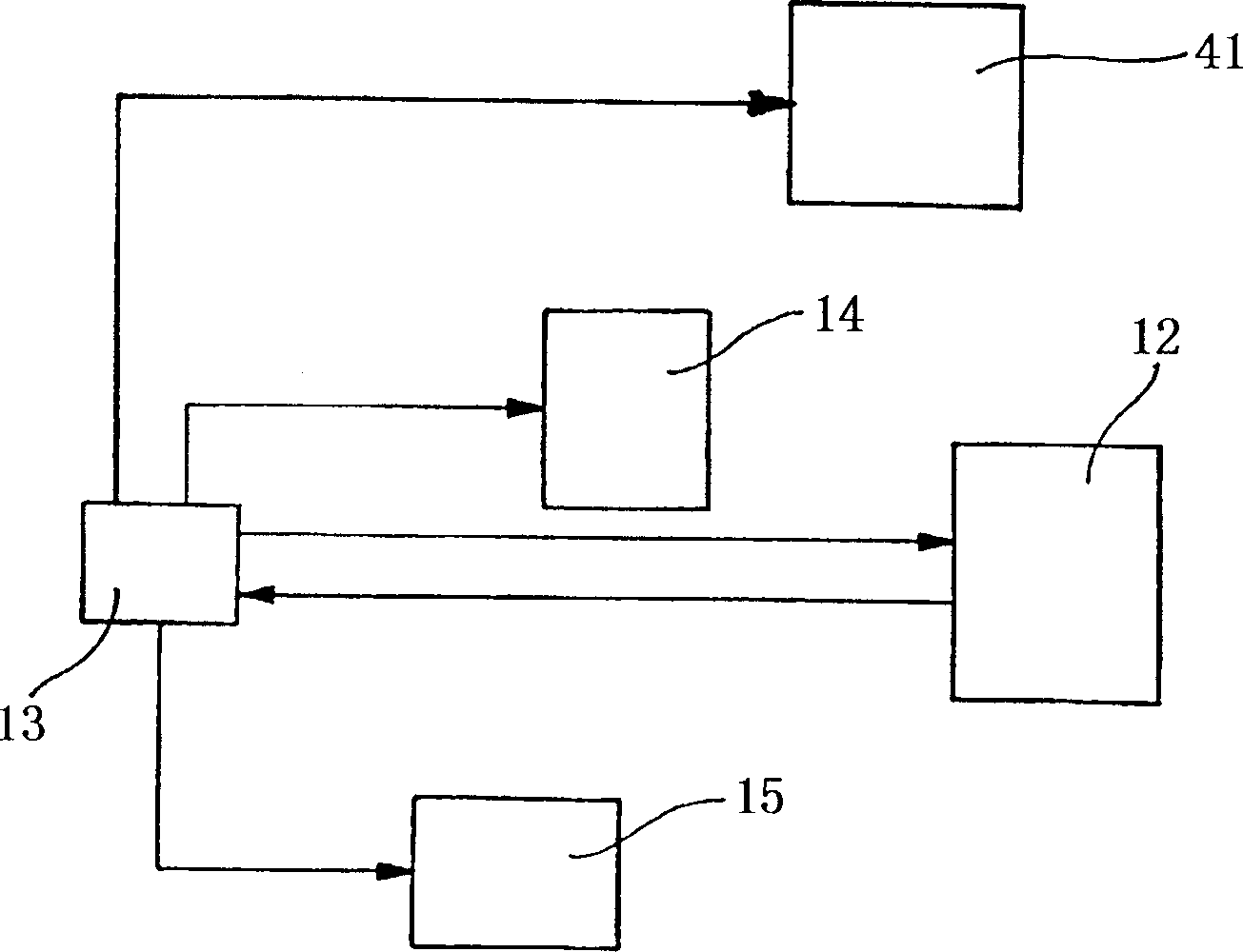

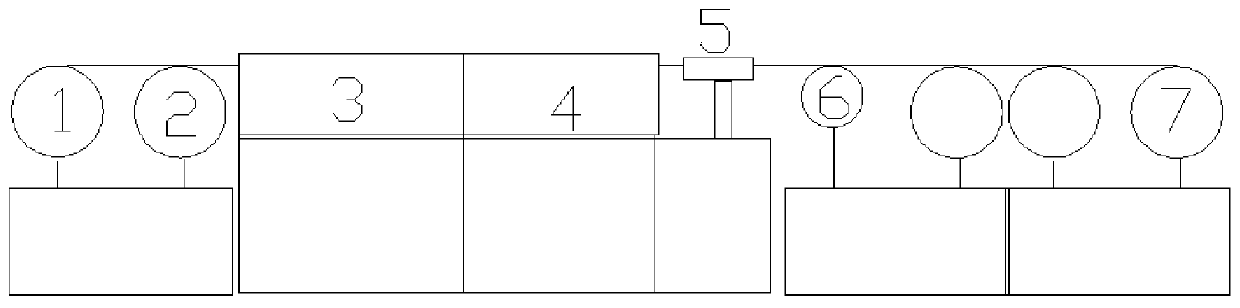

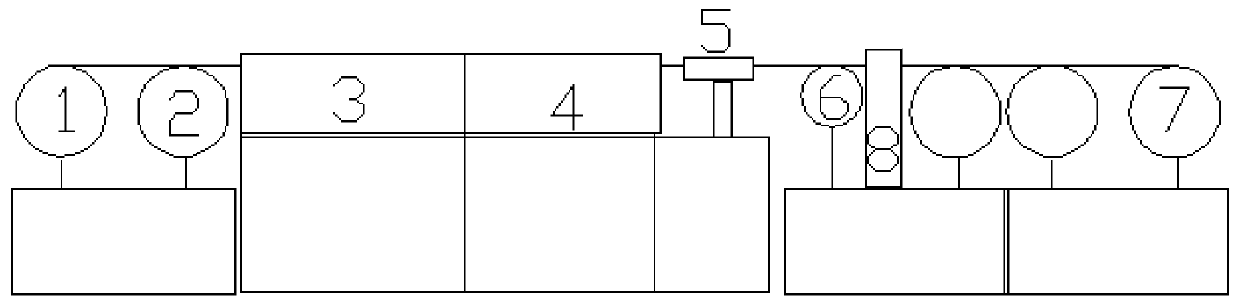

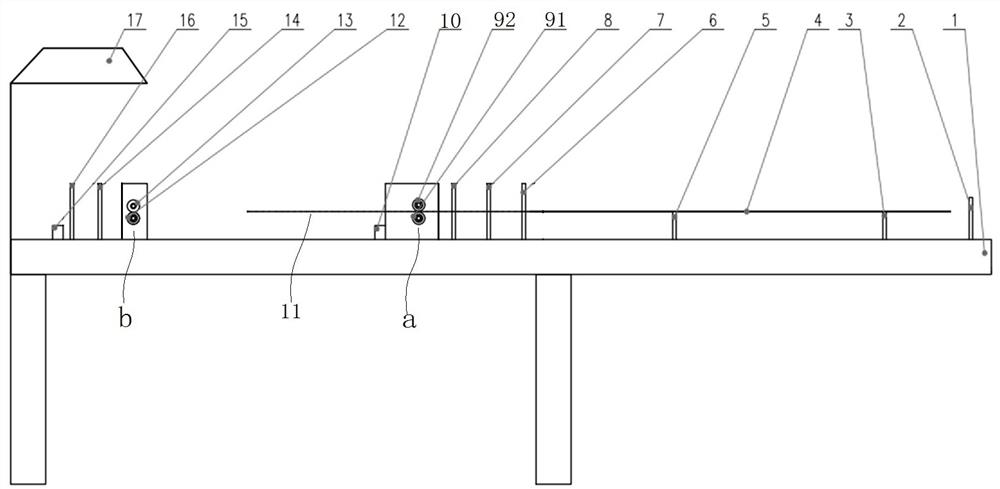

Machining device and method for controlling size of tungsten molybdenum wire

InactiveCN111218713AA reduction in failure rateHigh input and outputElectrolysis componentsControl signalMeasuring instrument

The invention provides a machining device for controlling the size of a tungsten molybdenum wire. The machining device sequentially comprises the following components of a pay-off wheel, a tension adjusting component, an electrolytic cell, a cleaning tank, a drying component, a wire guide wheel, a size measuring instrument and a wire collecting wheel, and further comprises an electrolysis power supply, a controller and a current tester, wherein the input end of the current tester is connected between an electrode cathode of the electrolytic cell and the electrolysis power supply, and the output end of the current tester is electrically connected with the input end of the controller; the output end of the size measuring instrument is electrically connected with the input end of the controller; and the output end of the controller is connected with the current adjusting component of the electrolytic cell. By adopting the machining device, the measuring instrument sends the measured sizeto the controller, when the size fluctuates, the controller outputs a control signal to adjust the electrolysis current, and the size tolerance range of the wire is extremely small ((0.1mm) through accurate control over the electrolysis current, so that the requirements of customers are met, the primary unqualified rate of the wire is greatly reduced, the production efficiency and the input-outputof the wire are improved, and the production cost is reduced.

Owner:ZIGONG CEMENTED CARBIDE CORP

Method for offset compensation of a sensor signal of a hall sensor and sensor arrangement

ActiveUS10809313B2Sufficient compensation resultSmall tolerance rangeMagnetic field offset compensationComputational physicsElectric signal

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

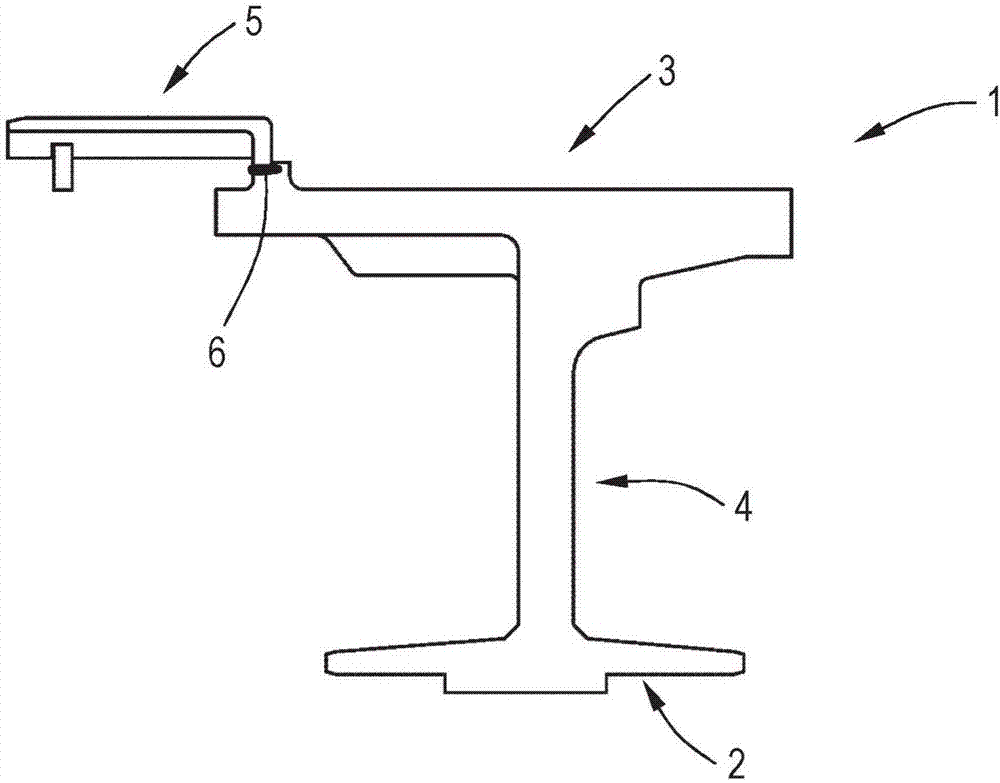

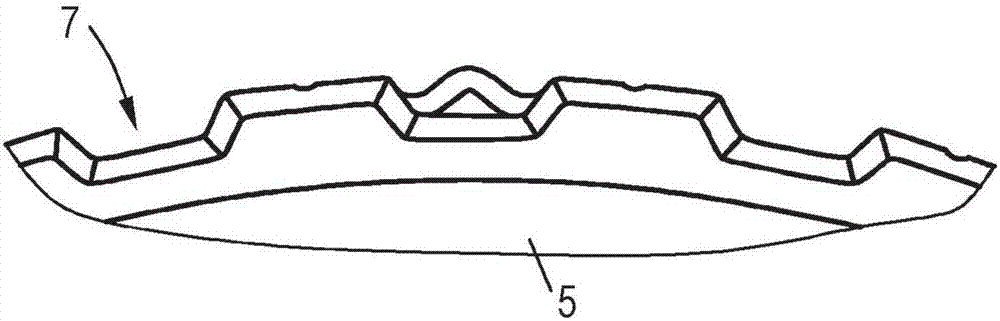

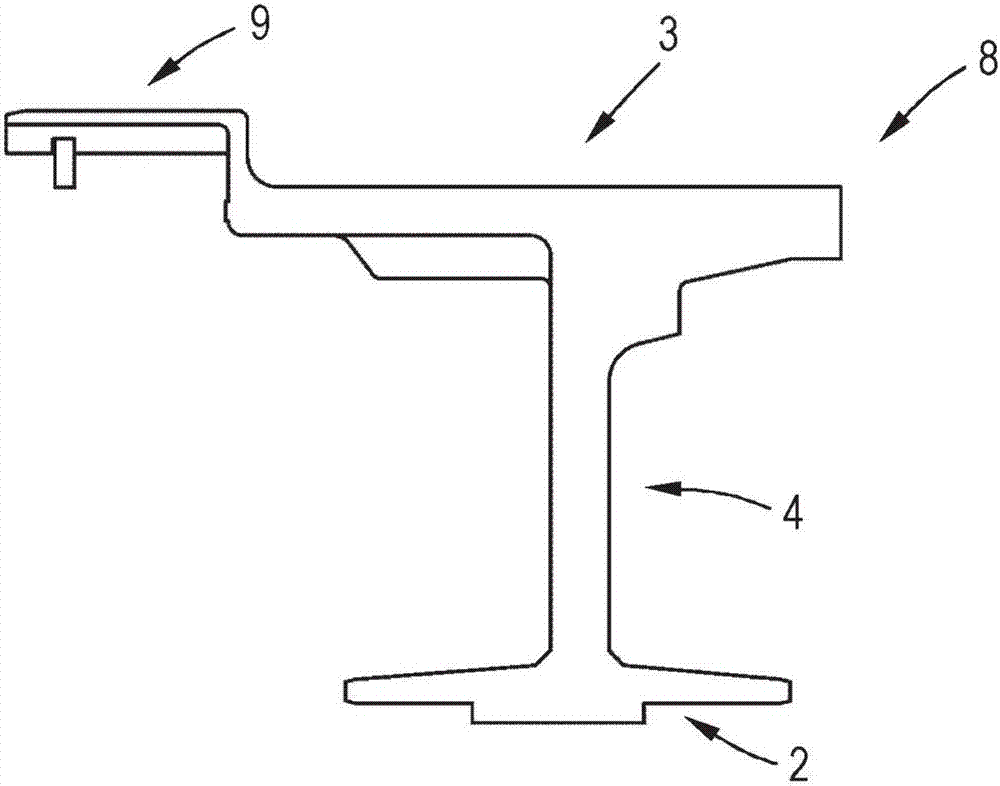

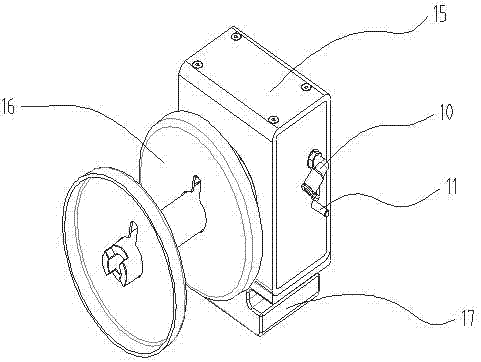

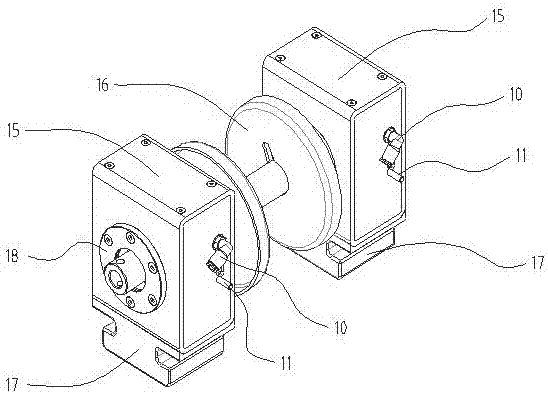

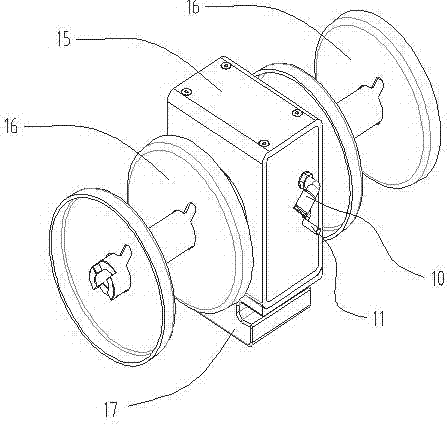

A clutch device and a method for manufacturing the same

ActiveCN107120360ADimensionally stableAvoid welding deformationFriction clutchesEngine componentsEngineeringClutch

Owner:SCHAEFFLER TECH AG & CO KG

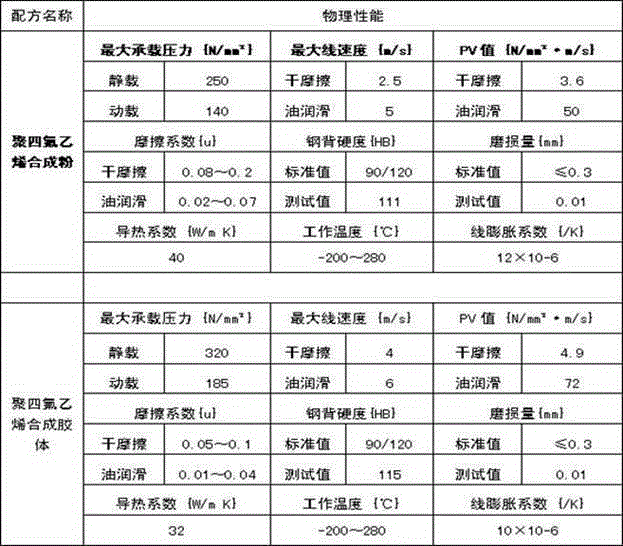

Polytetrafluoroethylene synthesis material

The invention discloses a polytetrafluoroethylene synthesis material. The polytetrafluoroethylene synthesis material contains polytetrafluoroethylene powder, crystallized glass fibers, lead powder, a polytetrafluoroethylene synthesis emulsion and a liquid wear-resistant material according to a weight ratio of 2.7:1.5:2:1.25:4.5; and the polytetrafluoroethylene synthesis emulsion is prepared by mixing 70% of a polytetrafluoroethylene emulsion with 30% of graphite powder. The polytetrafluoroethylene synthesis material has the advantages of improvement of the substance uniformity, reduction of the wall thickness tolerance range, and improvement of the quality and stability of products.

Owner:CHUZHOU DASHI AUTO PARTS

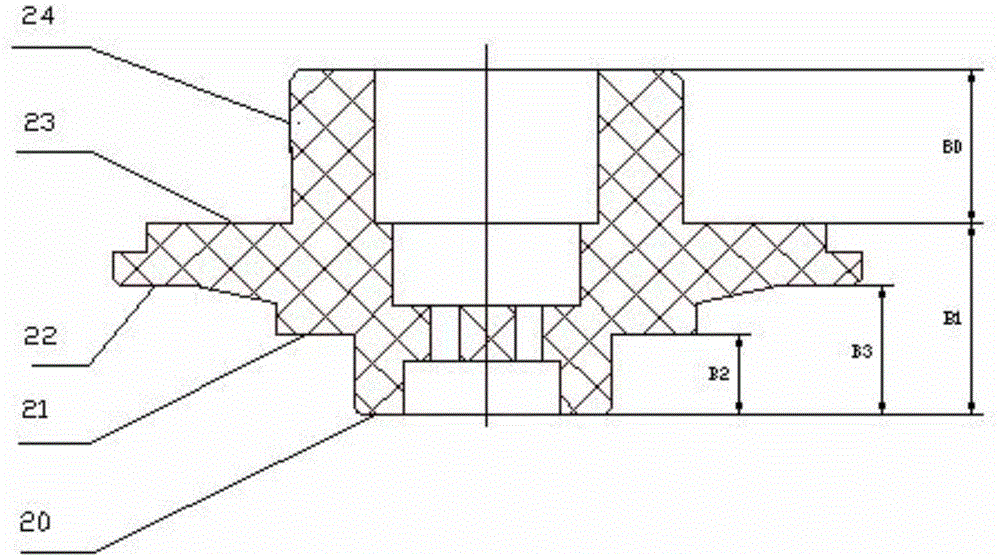

Magnetic element and iron cores thereof

InactiveCN103903836AImprove consistencyGuaranteed decentralizationTransformers/inductances magnetic coresInductance with magnetic coreEngineeringConductor Coil

The invention discloses a magnetic element. The magnetic element comprises two opposite iron cores and an electric conduction winding arranged between the two iron cores. An air gap is reserved between the two iron cores. At least one of the two iron cores comprises a plurality of adjoining planes and a plurality of bosses, the adjoining planes are used for being connected with the iron cores opposite to the adjoining planes, and the bosses are arranged on the adjoining planes to mechanically support the iron cores opposite to the bosses. The bosses have a certain height used for controlling the size of the air gap. According to the magnetic element and the iron cores, the bosses are arranged on the adjoining planes of the iron cores, the air gap is dispersed to all magnetic columns of the iron cores, the tolerance range of the inductance value is effectively reduced, and the consistency of the magnetic element is improved.

Owner:DELTA ELECTRONICS (SHANGHAI) CO LTD

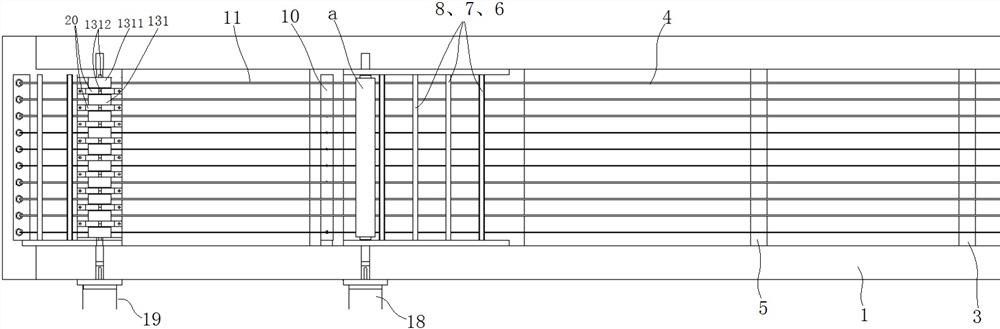

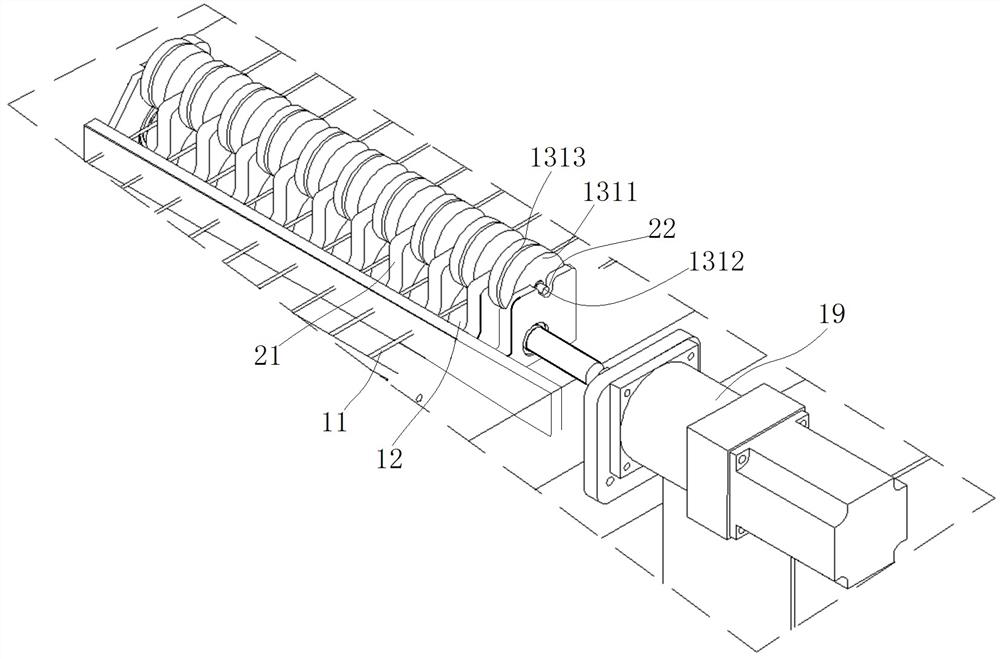

Horizontal quartz wool processing equipment

PendingCN112759251AConsistent intervalGuaranteed diameterGlass making apparatusElectric machineryEngineering

The invention provides horizontal quartz wool processing equipment. The horizontal quartz wool processing equipment comprises a machine frame, wherein the machine frame is provided with a melting burner and a double-roller rod feeder; the melting burner is provided with flame ports corresponding to quartz rods in a one-to-one correspondence mode; the double-roller rod feeder comprises a driving roller and a driven roller which are vertically arranged in parallel at an interval, and the driving roller is driven by a first motor; a double-roller thread guide and a blowing burner are further arranged on the downstream portion of the melting burner; the double-roller thread guide comprises a driving roller located on the lower portion and a pressing roller pressed on the driving roller, the driving roller is driven by a second motor, the pressing roller comprises pressing roller units arranged in one-to-one correspondence with the quartz rods, and the pressing roller units are coaxially arranged; and the blowing burner is provided with flame jet orifices which are arranged in one-to-one correspondence with the beams of quartz wire, and each beam of quartz wire at least comprises one quartz wire. The horizontal quartz wool processing equipment can overcome the technical problems of non-uniform cotton spraying and wire breakage caused by the fact that the structure of existing equipment cannot eliminate diameter errors and the technical problem of dislocation of a quartz rod and quartz fiber.

Owner:河南神玖天航新材料股份有限公司

Method, computer and magnetic resonance apparatus for planning imaging of a subject that contains an implant

ActiveUS10371768B2Easy to planIncrease loadMeasurements using NMR imaging systemsElectric/magnetic detectionResonanceMR - Magnetic resonance

In a method and computer for planning magnetic resonance imaging of a body of an examination object that contains an implant, to be implemented by a magnetic resonance apparatus, position information of the implant is provided to the computer, the position information characterizing a position of the implant in the body of the examination object, and at least one imaging parameter for the magnetic resonance imaging is predetermined before the imaging. At least one load parameter of the implant is established in the computer on the basis of the acquired position information and the at least one predetermined imaging parameter. The magnetic resonance imaging is planned in the computer on the basis of the established load parameter of the implant.

Owner:SIEMENS HEALTHCARE GMBH

Electromagnetic switch, manufacturing method thereof, and vehicle starter

ActiveCN103426684BSmall toleranceHigh positioning accuracyPower operated startersElectric motor startersElectricityPosition tolerance

A method of manufacturing an electromagnetic switch for a vehicle starter is disclosed, wherein a single push rod is moved backward until an initial electrical connection state is detected between two terminals via a contact bridge on the push rod; then, the push rod Further move backward for a reserved stroke; then, fix the movable iron core on the push rod while keeping the movable iron core pushed against the fixed iron core and process an engaging window for inserting the upper end of the shift fork into the front end of the push rod. An electromagnetic switch manufactured by the above method and a vehicle starter including the electromagnetic switch are also disclosed. The invention can improve the positioning accuracy of the driving gear.

Owner:ROBERT BOSCH STARTER MOTORS GENERATORS (CHINA) CO

Rapid restart with conventional starter during engine coasting

ActiveCN103161639BClose to restStart delay time shortenedPower operated startersElectric motor startersExternal combustion engineEngineering

The invention relates to a method for determining the moment of engagement (86, 90, 92) of a starter motor into an internal combustion engine (2), comprising determining the crankshaft (8) of said internal combustion engine (2), in particular dependent on the internal combustion engine (2 ), the number of revolutions (40) of the swing stroke of the piston (6), and the meshing moment (86, 90, 92) is specified before the state moment of the crankshaft (8) or at the moment of the crankshaft (8) At the time of the state, the number of revolutions (40) has a sign, and the sign indicates that the rotation direction of the crankshaft (8) is the same as the working direction of the internal combustion engine (2).

Owner:ROBERT BOSCH GMBH

A high-resolution geophone and its manufacturing method

The invention relates to a high-resolution earthquake detector and a manufacturing method thereof. With the adoption of a detector structure, an upper cover with a guide positioning part, a magnetic system consisting of upper and lower magnetic boots and magnetic steel, a spring-mass system consisting of a coil frame with a winding and a spring, a lower cover, and a shell are coaxial in an assembling process, so that the detector distortion can be effectively reduced. The matching condition ensures that inner and outer rings of upper and lower spring sheets are at a horizontal position after being assembled; the upper and the lower spring sheets are not additionally stressed by external force; and each part inside the detector with a sealed opening is compactly matched without release, so that the distortion of the detector can be reduced. The natural frequency of single spring can be directly detected, and the two springs with equal frequencies can be selected to be matched in pair, so as to ensure the consistency of the spring, and reduce the allowance range and the distortion. With the adoption of a method for directly testing the frequency, the natural frequency of the earthquake detector can be tested before the opening of the detector is sealed, so that the allowance range of the detector can be further reduced.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

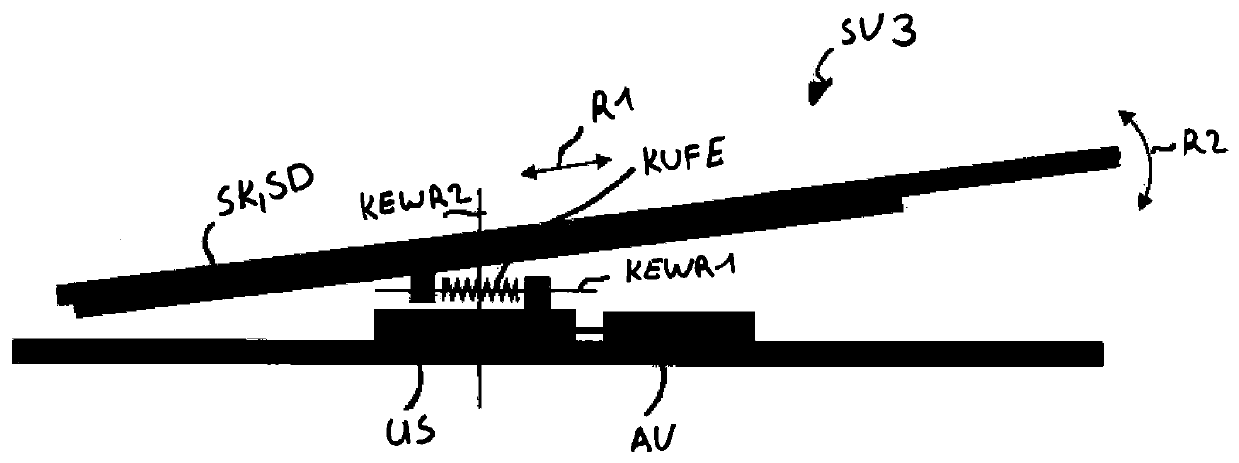

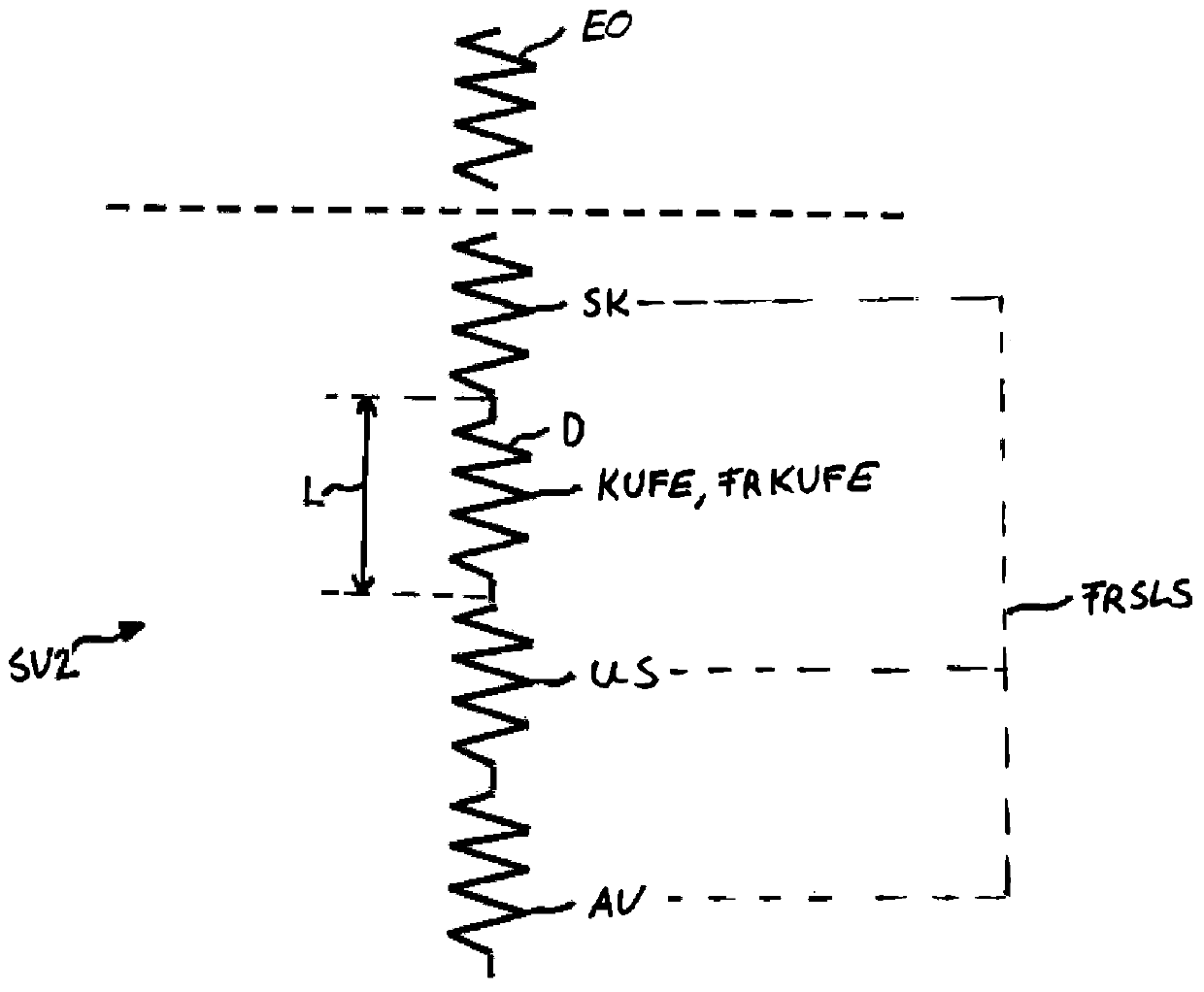

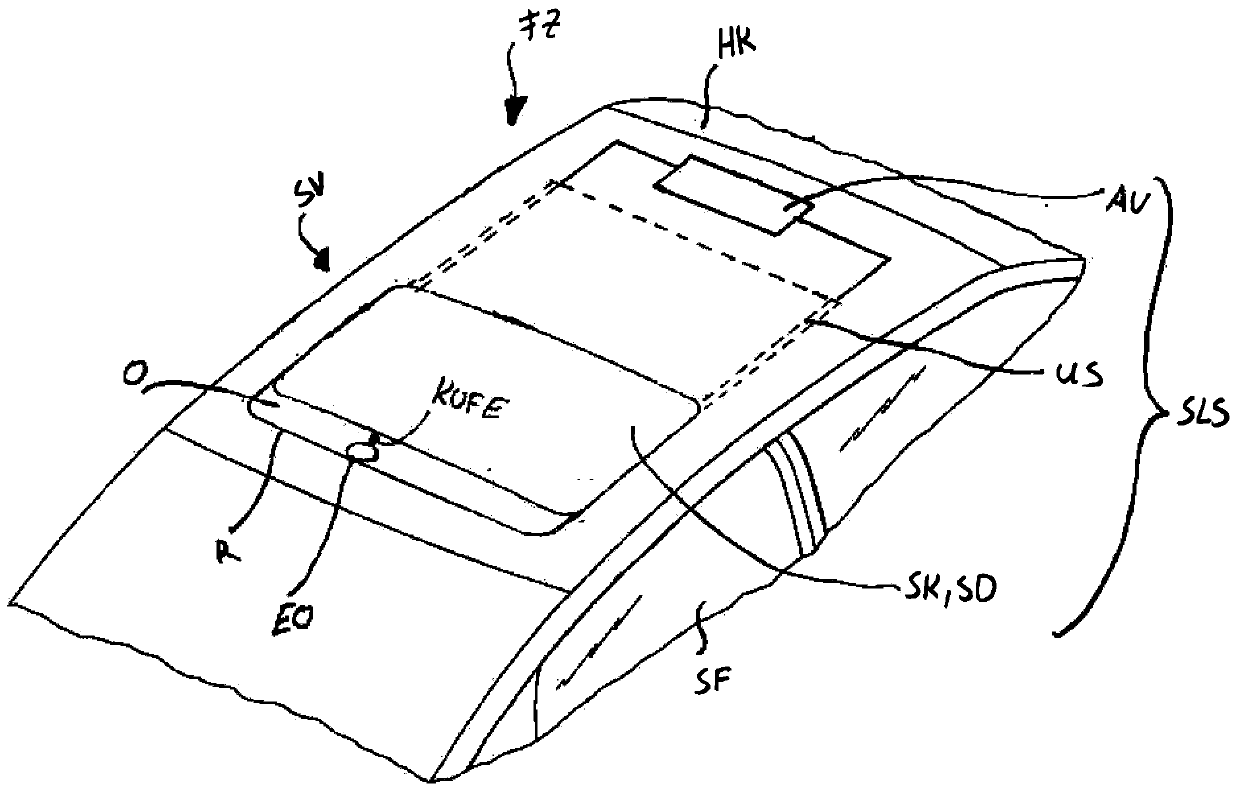

Closing device for a vehicle

ActiveCN110894768ALarge tolerance rangeSmall tolerance rangePedestrian/occupant safety arrangementPower-operated mechanismControl theoryMechanical engineering

A closing device for opening and closing an opening in a vehicle is disclosed. The closing device comprises a closing system, having a closing body (SK) that is fitted on the vehicle (FZ) in a movablemanner and is configured to open and close the opening (O), a drive device (AV) that is operatively connected to the closing body (SK) and is configured to move the closing body (SK), and a transmission system (US) that is arranged between the closing body (SK) and the drive device (AV) and is configured to transmit a drive force generated by the drive device (AV) to the closing body (SK). The closing system (SLS) has a closing system spring rate (FRSLS) that characterizes an overall elasticity of the closing body (SLS), of the drive device (AV) and of the transmission system (US). The closing device (SV) also comprises a force transmission spring unit (KUFE) that is configured to pick up the drive force transmitted from the drive device (AV) to the closing body (SK). The force transmission spring unit (KUFE) has a force transmission spring rate (FRKUFE) that is lower than the closing system spring rate (FRSLS).

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

Combined automatic constant tension pneumatic twine tensioner

PendingCN107458297AReduce volumeSmall tolerance rangeLoad securingTransportation itemsSpool valveDrive shaft

The invention discloses a combined automatic constant tension pneumatic twine tensioner. The combined automatic constant tension pneumatic twine tensioner comprises twine tensioner bodies and coiling block assemblies connected to the twine tensioner. One twine tensioner body is connected to one or more coiling block assemblies or one coiling block assembly is connected to the plurality of twine tensioner bodies. Each of the twine tensioner bodies comprises a power driving mechanism, a slide valve guiding mechanism and a stress housing and a clutch mechanism. The slide valve guiding mechanism is arranged on the side portion of the power driving mechanism, and the stress housing and the clutch mechanism are arranged on the outer side of the power driving mechanism and the slide valve guiding mechanism. By changing a conventional piston rod to a piston plate and arranging a transmission shaft and the piston plate in a cross manner, the transmission shaft and the piston plate do not interfere with each other; and two air cylinders which are mutually collaborated are adopted as a power driving source, and the steering structure is compact, small in size and large in bearing capacity.

Owner:帕瓦夫南通电气科技有限公司

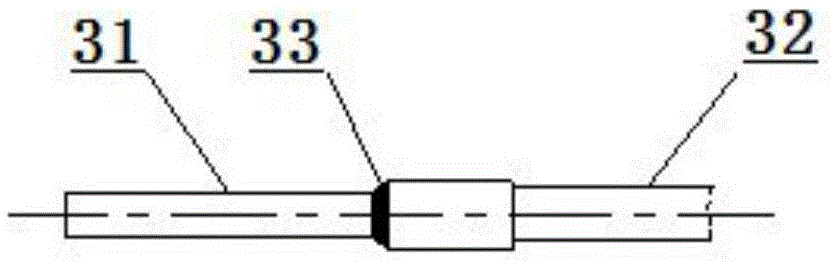

A welding method for a relay contact reed assembly

ActiveCN104485261BSmall tolerance rangeOvercome the defect of poor parallelismElectromagnetic relay detailsCupronickelCobalt

The invention discloses a welding method for a relay contact reed assembly. According to the welding method, a clamping method of an original clamp is changed, and dimension requirements for each position of the contact reed assembly are guaranteed; a traditional welding method of a thin piece and a thick piece is changed, and the thick piece is taken as a main welding face; a traditional welding method employing tungsten copper alloy, chromium zirconium copper alloy and beryllium cobalt copper alloy as electrode materials to weld nickel silver and a silver magnesium nickel assembly is changed, and silver copper alloy and silver chromium alloy are taken as electrode tips to weld the nickel silver and the silver magnesium nickel reed assembly; problems of overhigh temperature of bonding and welding areas of the reed assembly and an electrode in a long term are solved, and burn damage to the reed assembly caused by the electrode in a welding process and crystal boundary organization change are greatly reduced.

Owner:GUIZHOU TIANYI ELECTRICAL

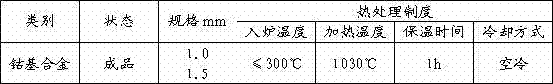

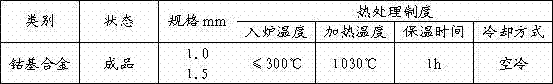

High-performance elastic alloy material for aerial hyperbaric cabin and production method thereof

The invention provides a high-performance elastic alloy material for an aerial hyperbaric cabin. The production method of the high-performance elastic alloy material comprises the following steps: (1) vacuum melting; (2) electroslag refining; (3) forging an ingot billet; (4) hot-rolling molding; (5) cold drawing; and (6) performing heat treatment. The high-performance elastic alloy material obtained by the method has high tensile strength up to 160 / 250(MPa); a wrapping test proves that the alloy material is not ruptured after being wound around not less than 15 circles, which is obviously superior to the national standard; and in the eventthat the alloy material is bent for 90 degrees forwardly and reversely on the same phase plane, the outer side of the bent position is not cracked and ruptured.

Owner:丹阳市龙鑫合金有限公司

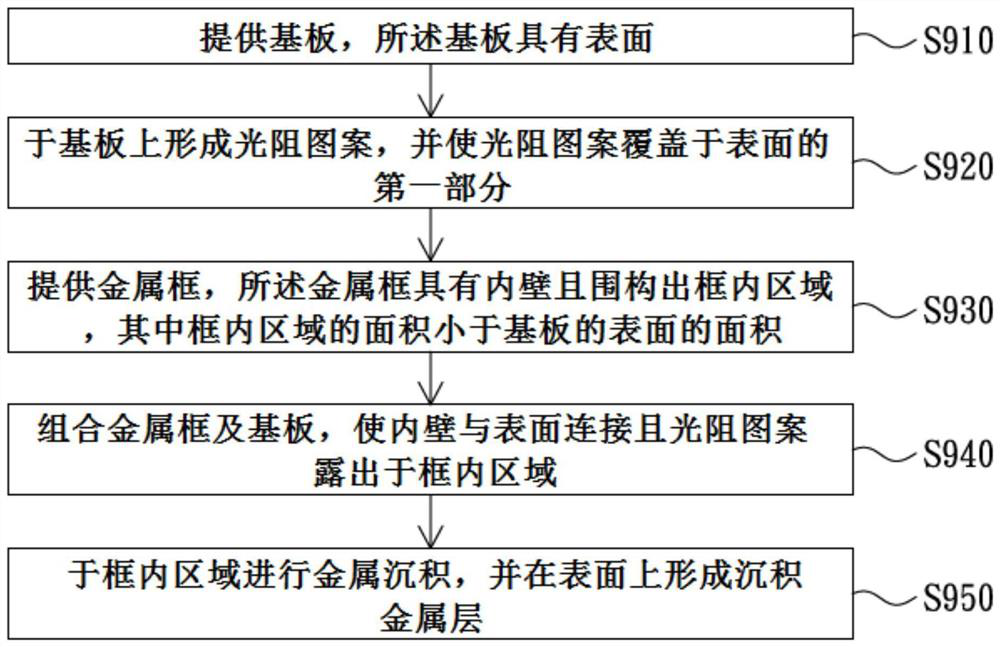

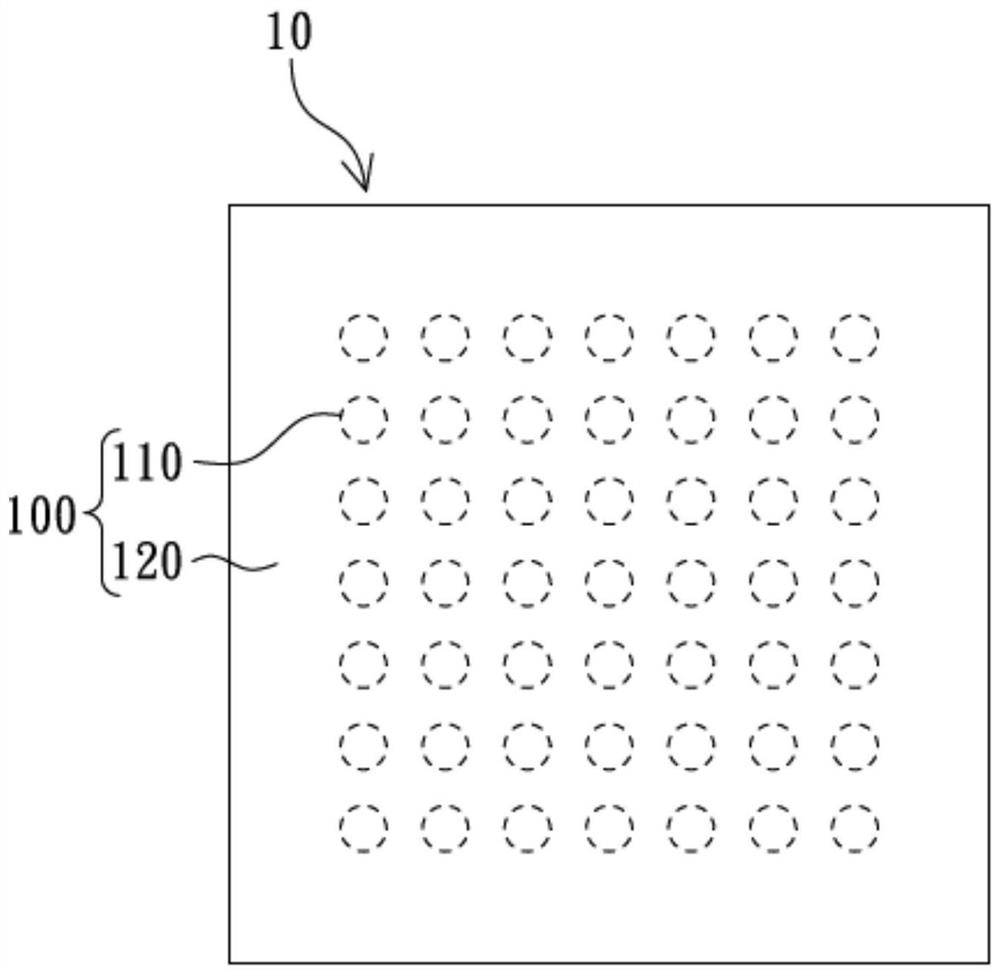

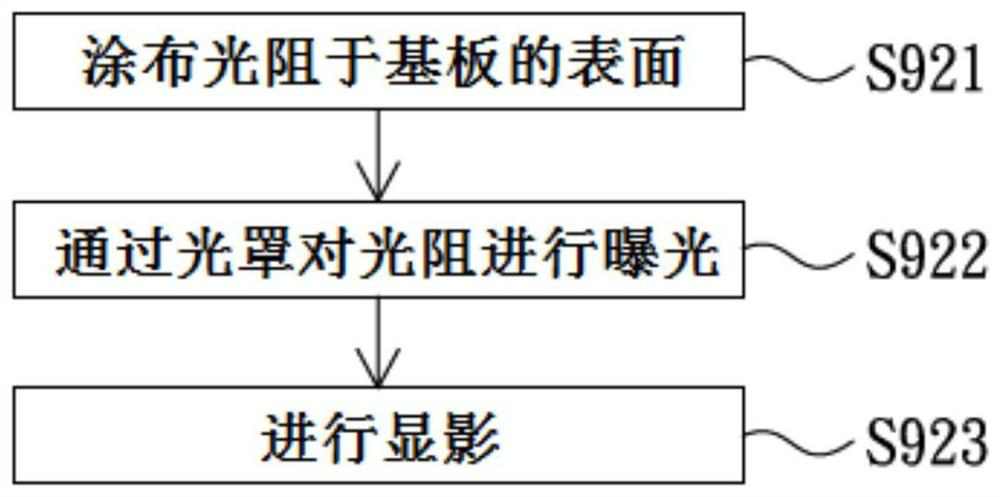

Mask and mask manufacturing method

PendingCN114107894AAvoid stackingAvoid deformationVacuum evaporation coatingSputtering coatingEngineering physicsMaterials science

A method for manufacturing a mask includes the steps of: providing a substrate having a surface; forming a photoresist pattern on the substrate, and enabling the photoresist pattern to cover the first part of the surface; a metal frame is provided, the metal frame is provided with an inner wall and defines an in-frame area, and the area of the in-frame area is smaller than that of the surface of the substrate; combining the metal frame and the substrate so that the inner wall is connected with the surface and the photoresist pattern is exposed out of the in-frame region; and performing metal deposition in the in-frame region, and forming a deposited metal layer on the surface. The invention also provides a mask.

Owner:DARWIN PRECISIONS CORP

A combined conveyor belt plate for a dryer

The invention discloses a combined-type conveyor belt plate for a dryer. The combined-type conveyor belt plate for the dryer comprises belt plates and a supporting frame arranged on the bottom sides of the belt plates. The supporting plate is connected at the bottoms of the belt plates in the length direction of the belt plates in a bolted mode. The ends of the belt plates and the supporting frame are connected with fixed plates arranged on chains in a bolted mode. The two sides of each belt plate are provided with hinged structures. The adjacent belt plates are hinged through the hinged structures. By adopting the conveyor belt plate which is supported by the belt plates and the supporting frame, a more unitized solution scheme is provided, the multiple technology requirements can be met by replacing the belt plates, only the belt plates are customized components, most components are universal standard components, changing is not needed to be carried out according to changing of the application requirement, and the basis is provided for standard producing of the conveyor belt plate.

Owner:FAMSUN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com