Apparatus and method for controlling weight fabric produced by textile machine, in particular by circular knitting machine

A fabric weight, textile machine technology, applied in the field of control by the textile machine, can solve the problems of not being able to eliminate marks, confusion of characteristics, economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

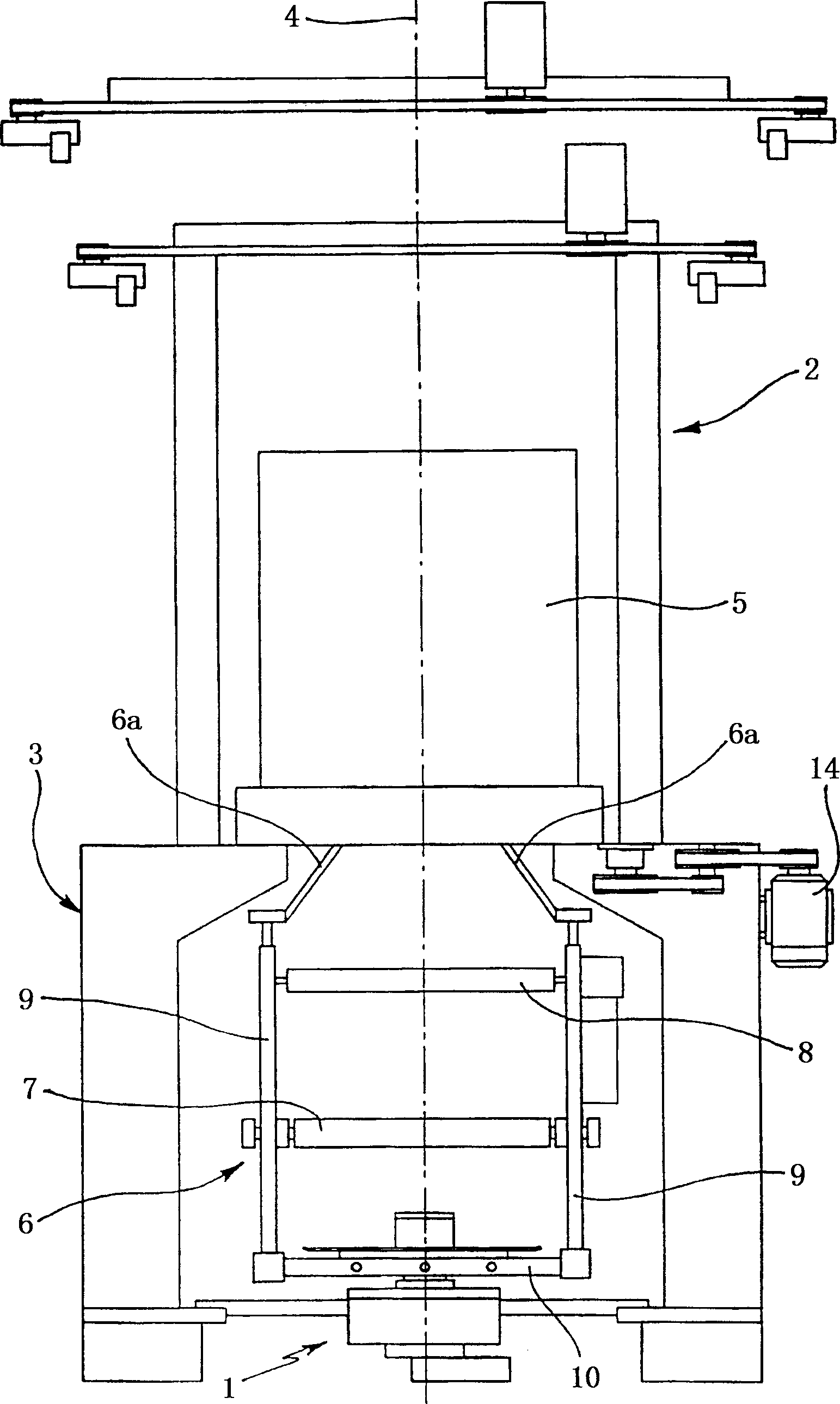

[0031] As shown with reference to the preceding figures, an apparatus for controlling weight according to the invention is generally indicated by the numeral 1 .

[0032] Said device 1 is mounted on a textile machine 2, in particular a circular knitting machine, comprising a fixed structure 3 on which at least one needle bed 5 is rotatable about a vertical axis 4 Install. Said needle bed 5 is constituted, for example, by needle cylinders and / or dials rotating around a fixed cam, or vice versa.

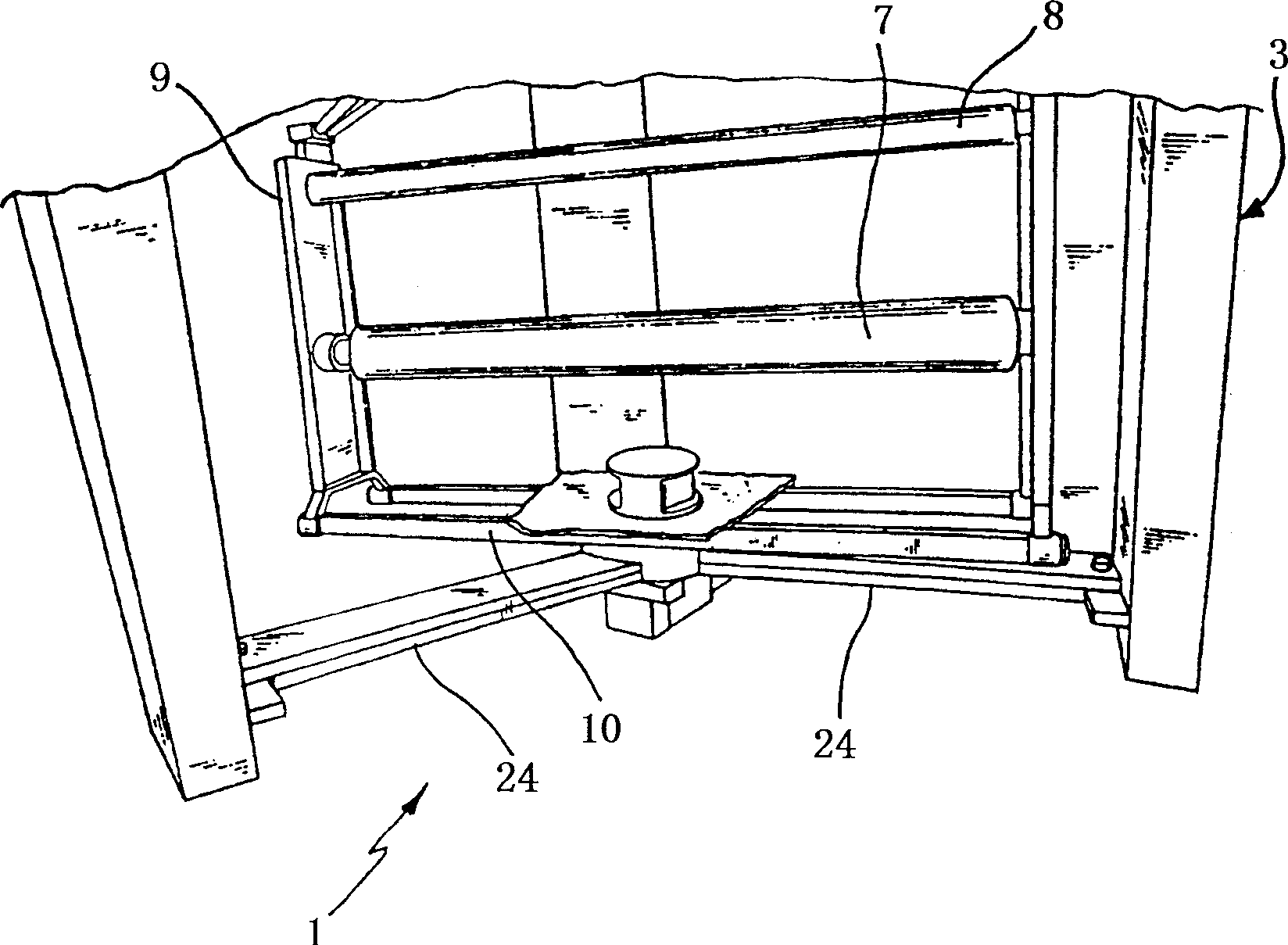

[0033] A take-up mechanism 6 for the fabric sheet is installed below the needle bed 5, in which a winding roller 7 is installed, in this case the fabric sheet is wound into a fabric roll, or equipped with A fabric folder.

[0034] The fabric sheet is drawn onto the winding roll 7 by means of at least one pulling roll 8 .

[0035] The coiling mechanism 6 can rotate around the vertical axis 4, the vertical axis 4 is integrated with the needle bed 5, and the coiling mechanism 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com