Magnetic element and iron cores thereof

A technology of magnetic components and iron cores, used in electrical components, magnetic cores/yokes, inductors with magnetic cores, etc. Small tolerance range, improved consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

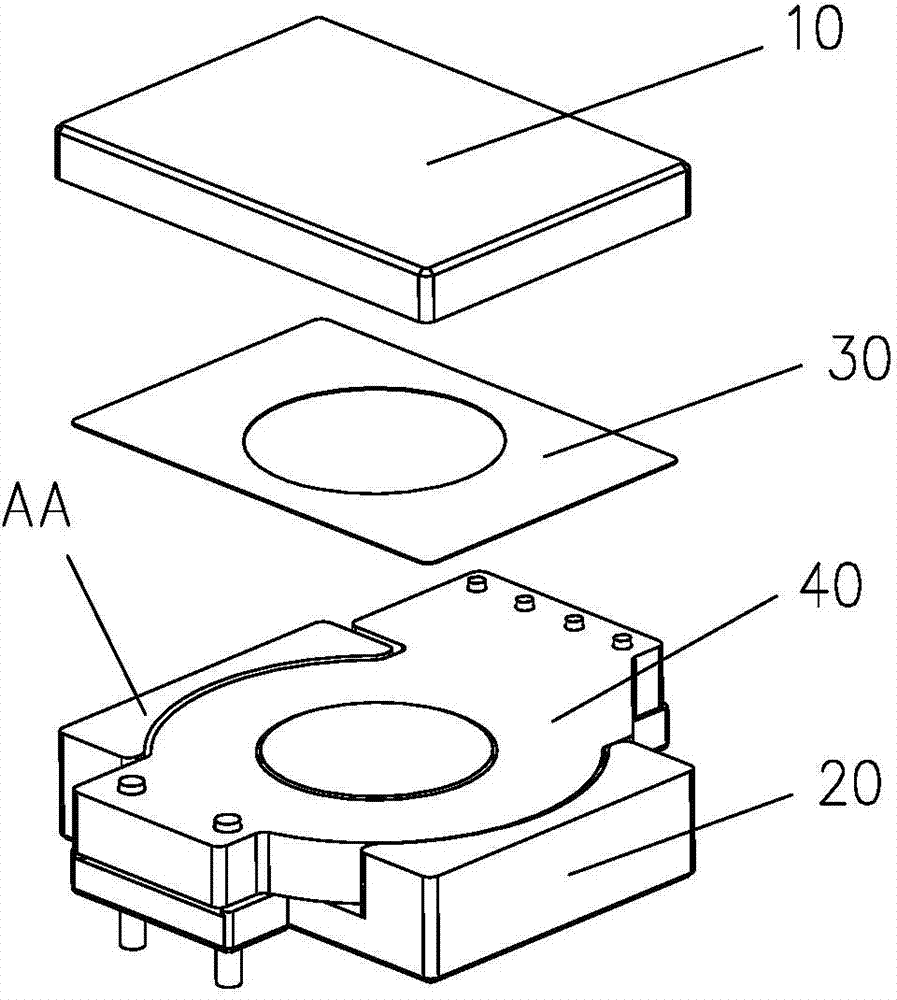

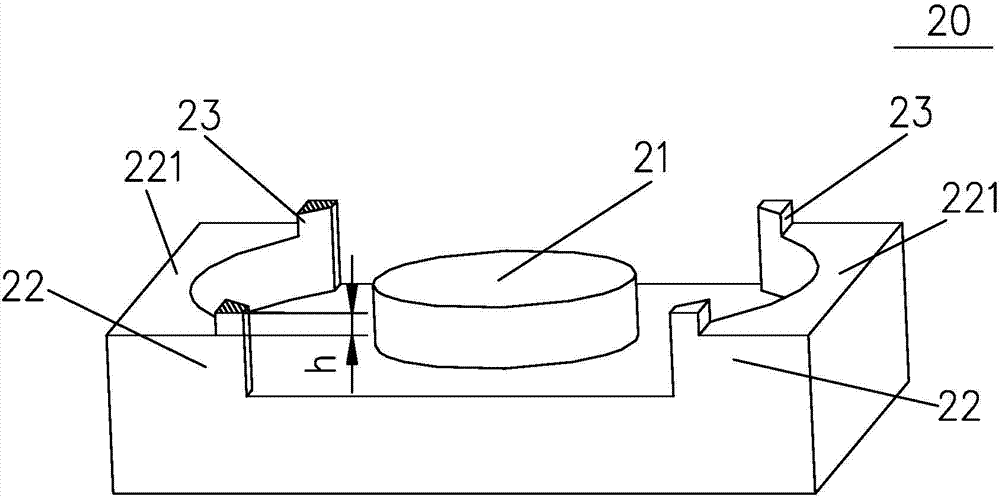

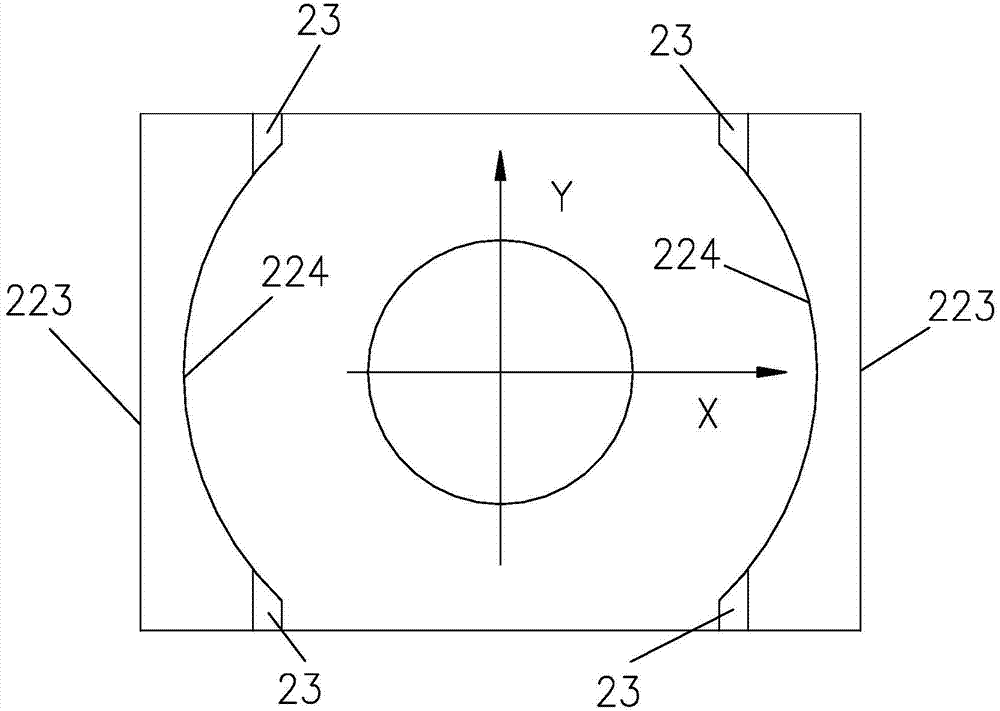

[0050] In order to realize that the air gap can be distributed and set, and effectively reduce the tolerance range of the inductance, the iron core of the first embodiment proposed by the present invention is as follows: Figure 2a with Figure 2b shown. The iron core 20 includes a plurality of joint surfaces 221 and a plurality of protrusions 23 . The joint surface 221 is used for jointing with another iron core; a plurality of bosses 23 are arranged on the joint surface 221 to generate mechanical support for the other iron core, and the bosses 23 have a height dimension, which is used to control the magnetic The air gap size of the component.

[0051] In this embodiment, the EQ iron core is taken as an example. The iron core 20 includes a central column 21 and two side columns 22 , and the two side columns 22 are arranged on the periphery of the central column 21 . The joint surface refers to the surface where the two iron cores are assembled when there is no boss, such a...

no. 2 example

[0060] Such as Figure 3a with 3b Shown is another embodiment of the present invention. The iron core of this embodiment has substantially the same structure as that of the first embodiment, except that the type of the iron core is different. The iron core of this embodiment is an RM iron core, while the iron core of the first embodiment is an EQ iron core. When forming the boss 23, it is only necessary to grind along the X-axis direction, thereby reducing the number of times of grinding.

[0061] In this embodiment, there are two bosses on the left column and the right column of the RM iron core respectively, and the upper surfaces of these four bosses are closely attached to the opposite iron core to form a new combined surface.

[0062] The main difference between the magnetic element of the present invention and the magnetic element of the prior art lies in the structure of the iron core. Specifically, the iron core of the magnetic element of the present invention adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com