Rapid restart using traditional starter in after-running of engine

A technology of starter and start signal, which is applied in the direction of engine motor start, engine start, engine components, etc., to achieve the effect of shortening the start delay time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

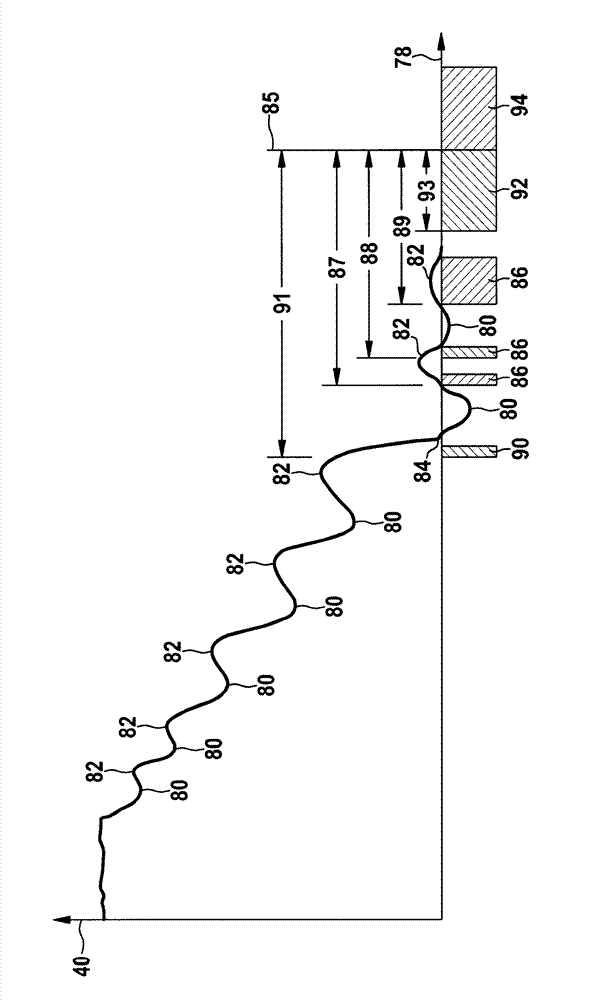

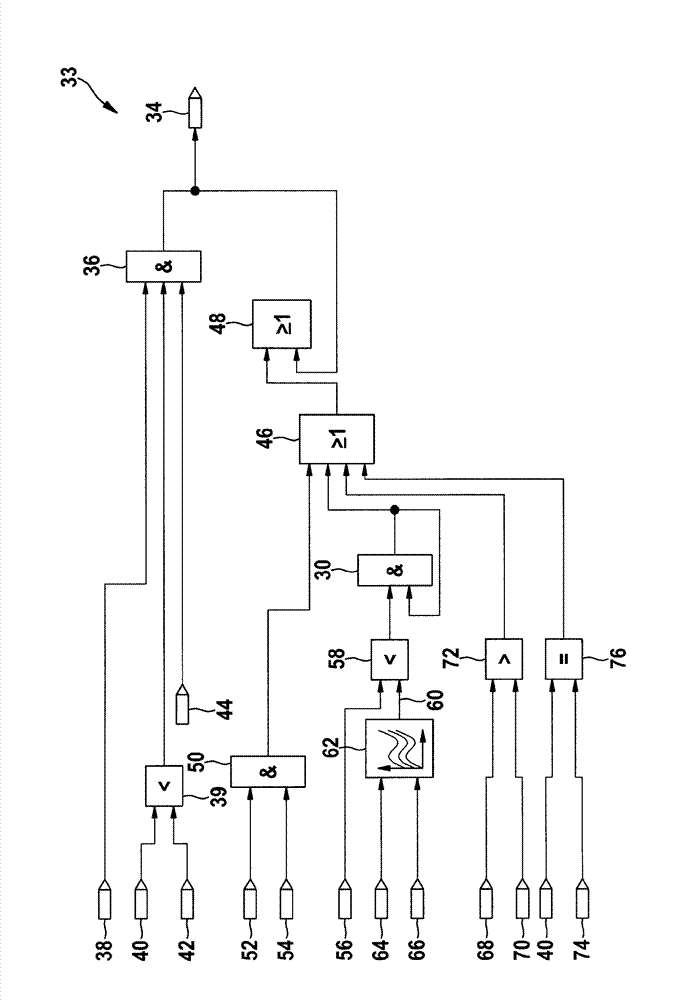

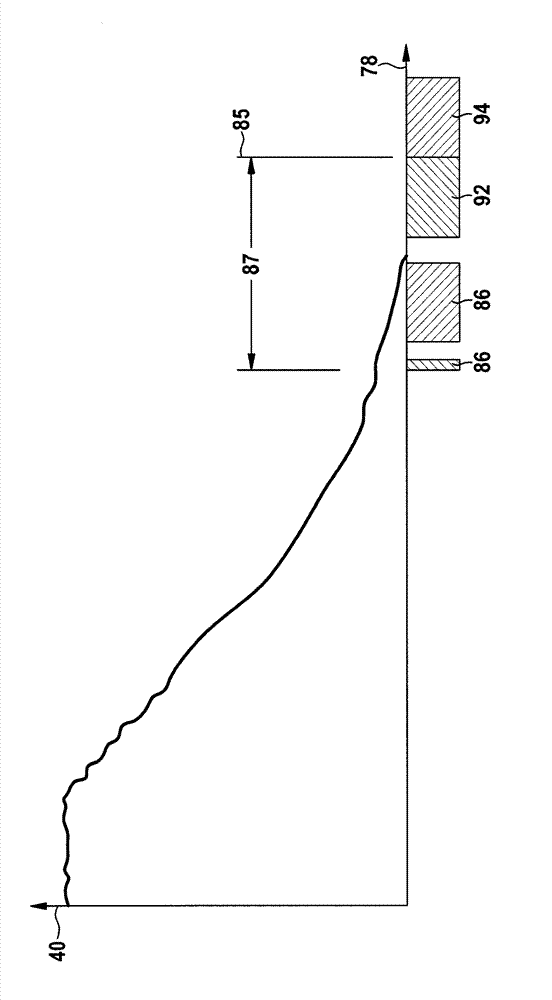

[0032] In the figures, identical elements are provided with the same reference symbols and are described only once.

[0033] involve figure 1 , which shows the internal combustion engine 2 . The internal combustion engine 2 has a schematically indicated combustion chamber 4 in which a reciprocating piston 6 is movably mounted. The reciprocating piston 6 is connected to the crankshaft 8 via a connecting rod 10 . The crankshaft 8 is a general shaft 12 on which a crank 14 is fastened in a non-rotatable manner. The connecting rod 10 transmits a linear movement to the crank 14 and thus rotates the shaft 12 of the crankshaft 8 .

[0034] Furthermore, a gear wheel 15 is fastened to the crankshaft 8 , which extends peripherally around the shaft 12 . Said gear 15 is formed by a plurality of protrusions in the form of teeth 16 and tooth spaces 18 between said teeth 16 . Each tooth 16 and each tooth space 18 of the gear 15 encloses an angle 20 of 6°. A tooth is omitted at one point o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com