Closing device for a vehicle

A technology for equipment and vehicles, applied in vehicle components, leaf shutters, vehicle safety arrangements, etc., to solve problems such as driver inference, foreign objects not providing control, and inability to reliably identify trapped foreign objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0066] Minimum spring rate TB negative Average spring rate TB positive Maximum spring rate SLS 20N / mm -42.86% 35 N / mm +42.86% 50 N / mm KUFE 16 N / mm -20% 20 N / mm +20% 24 N / mm GES 8.9 N / mm -29.19% 12.6 N / mm +29.19% 16.2 N / mm

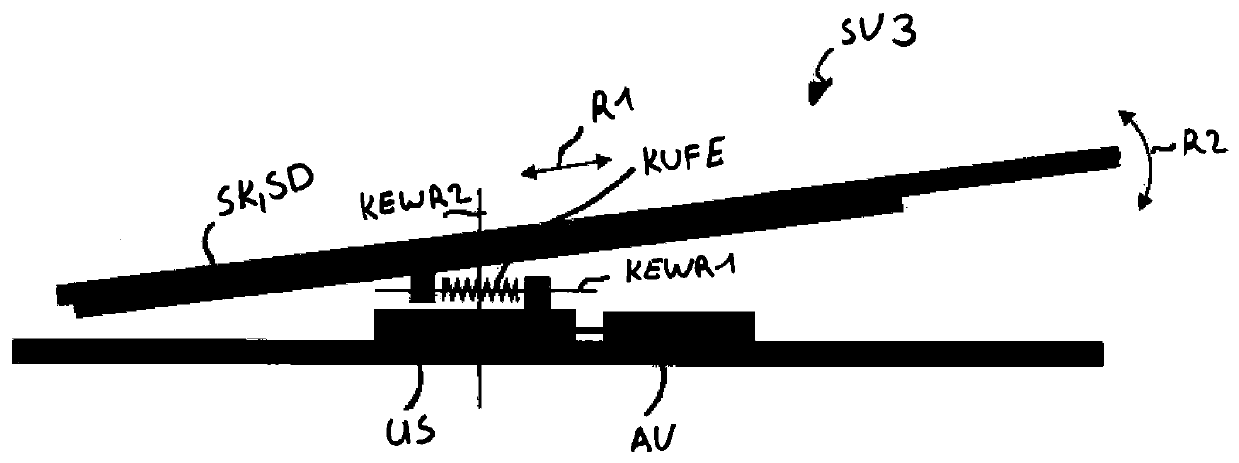

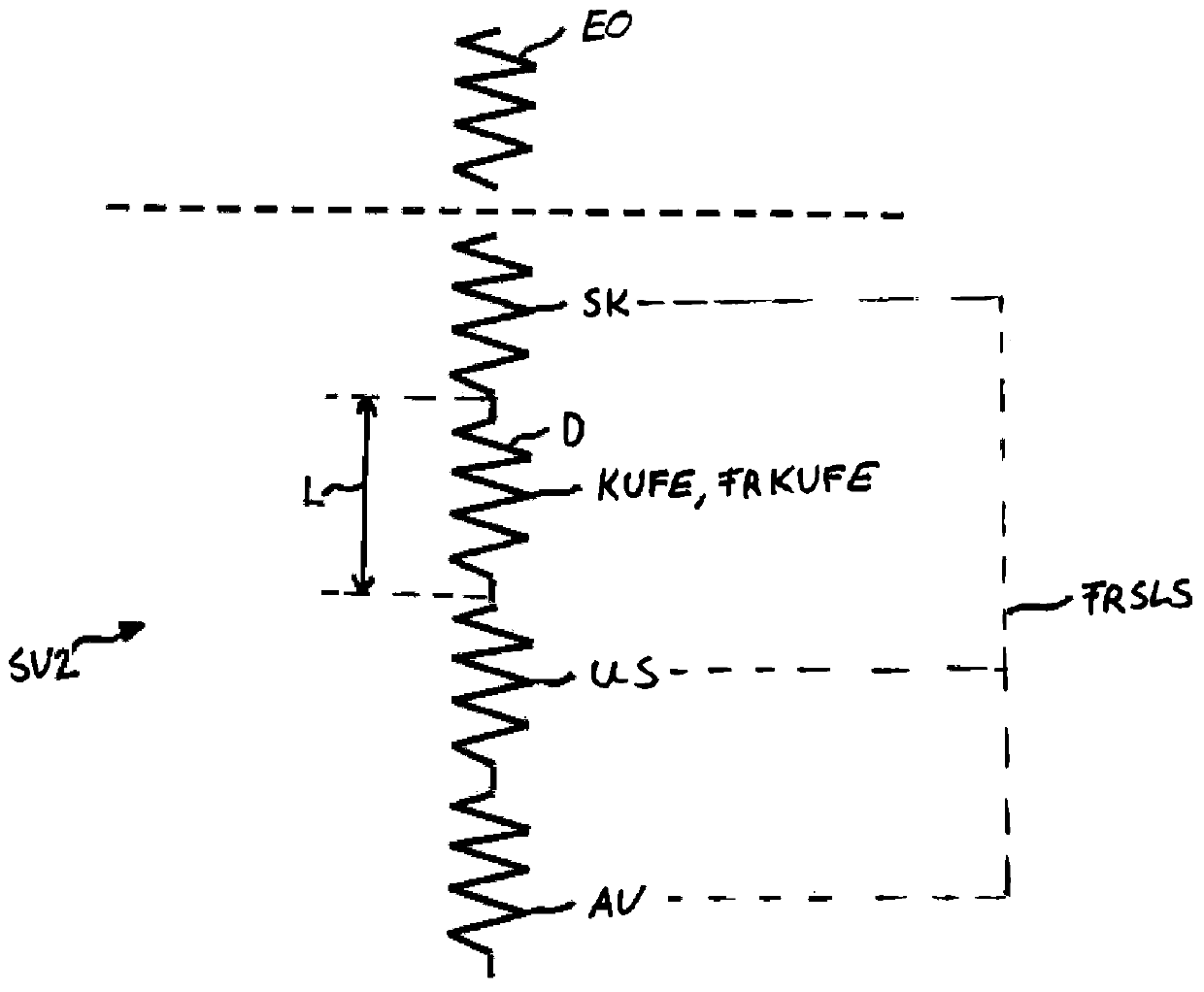

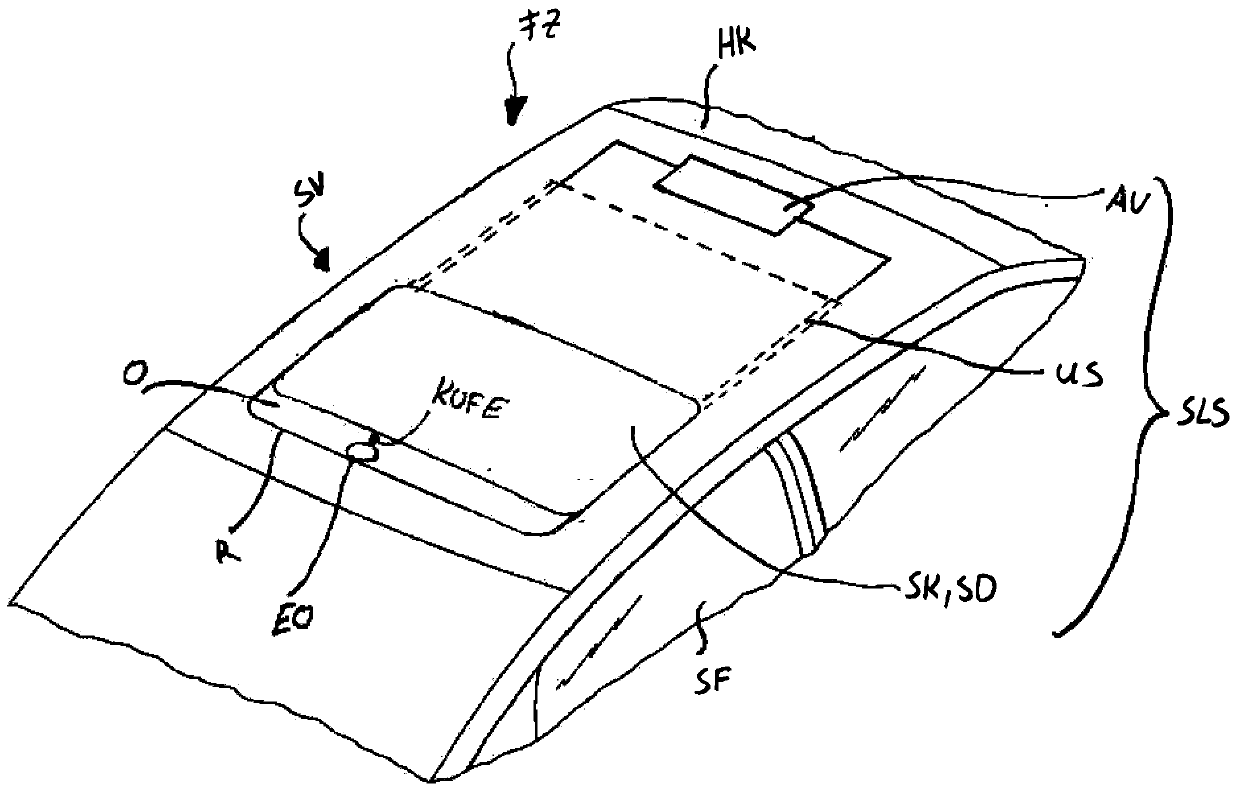

[0067] In Example 1, the closing system SLS has, for example, a closing system spring rate FRSLS of 35 N / mm, which has a closing system spring rate tolerance range TSLS of 42.86%. Consequently, the closing system spring stiffness (eg based on the above-mentioned effects) fluctuates between values of 20 N / mm and 50 N / mm. Furthermore, a force transmission spring unit KUFE having a force transmission spring stiffness FRKUFE of 20 N / mm is arranged in the closing system SLS. When the force transmission spring stiffness FRKUFE has a force transmission spring stiffness tolerance range TKUFE of 20%, the force transmission spring stiffness FRKUFE (for example based on the aforementioned effects) fluctu...

example 2

[0070] Minimum spring rate TB negative Average spring rate TB positive Maximum spring rate SLS 20N / mm -42.86% 35 N / mm +42.86% 50 N / mm KUFE 7.5N / mm -25% 10 N / mm +25% 12.5 N / mm GES 5.5 N / mm -29.41% 7.7N / mm +29.41% 10.0 N / mm

[0071] In Example 2, the closing system SLS has the same closing system spring rate FRSLS of 35 N / mm, which has the same closing system spring rate tolerance range TSLS of 42.86%. In contrast to Example 1, however, a force transmission spring unit KUFE with a force transmission spring stiffness FRKUFE of 10 N / mm was selected. The force transmission spring stiffness tolerance range TKUFE can thus be increased up to 25% without the resulting overall spring stiffness FRGES having a total spring stiffness tolerance range TGES of more than 30%.

[0072] In example 2, a softer force transmission spring unit KUFE was selected than in example 1. At the same time, however, a larger force-transmitting sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com