Patents

Literature

95 results about "Visual contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

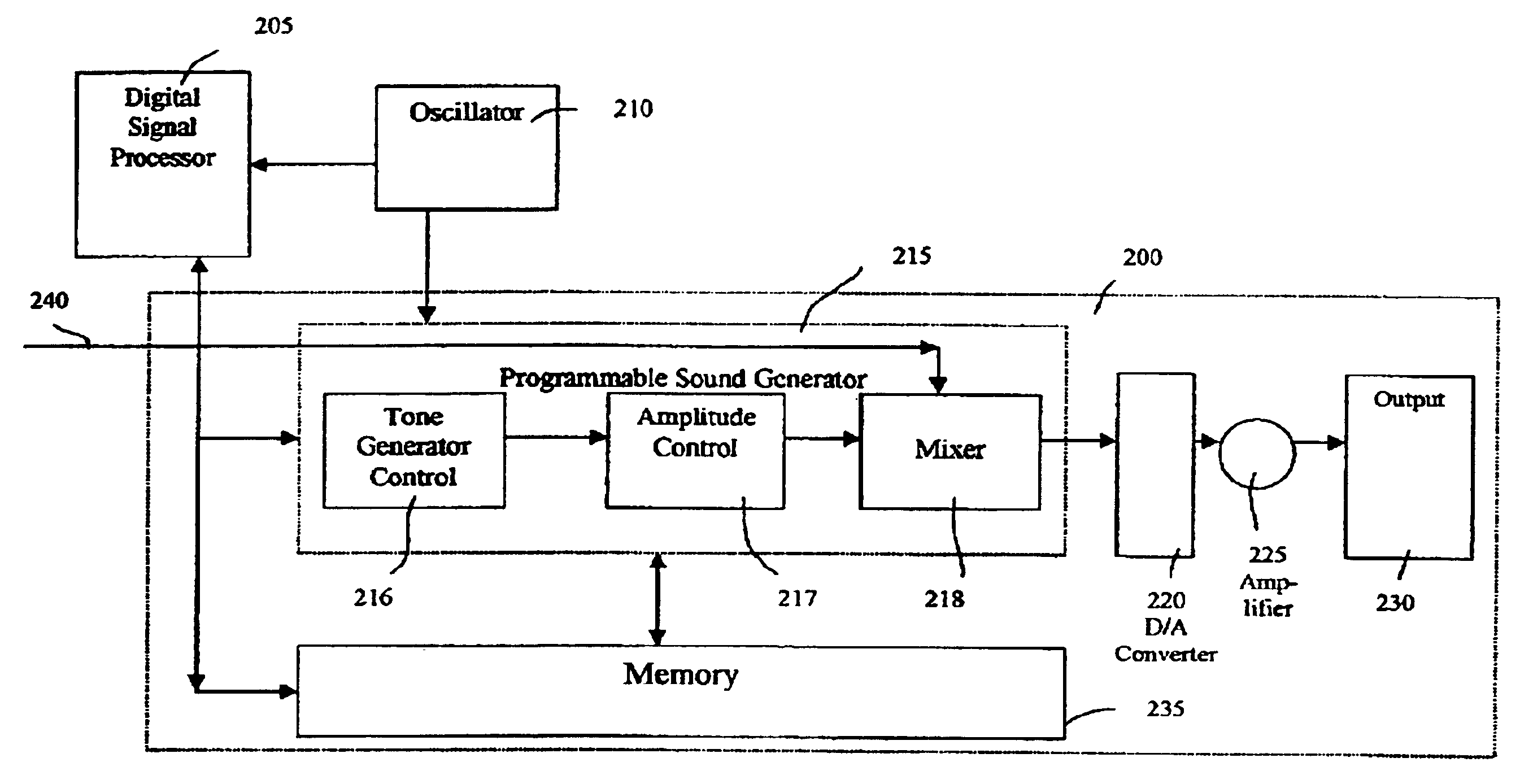

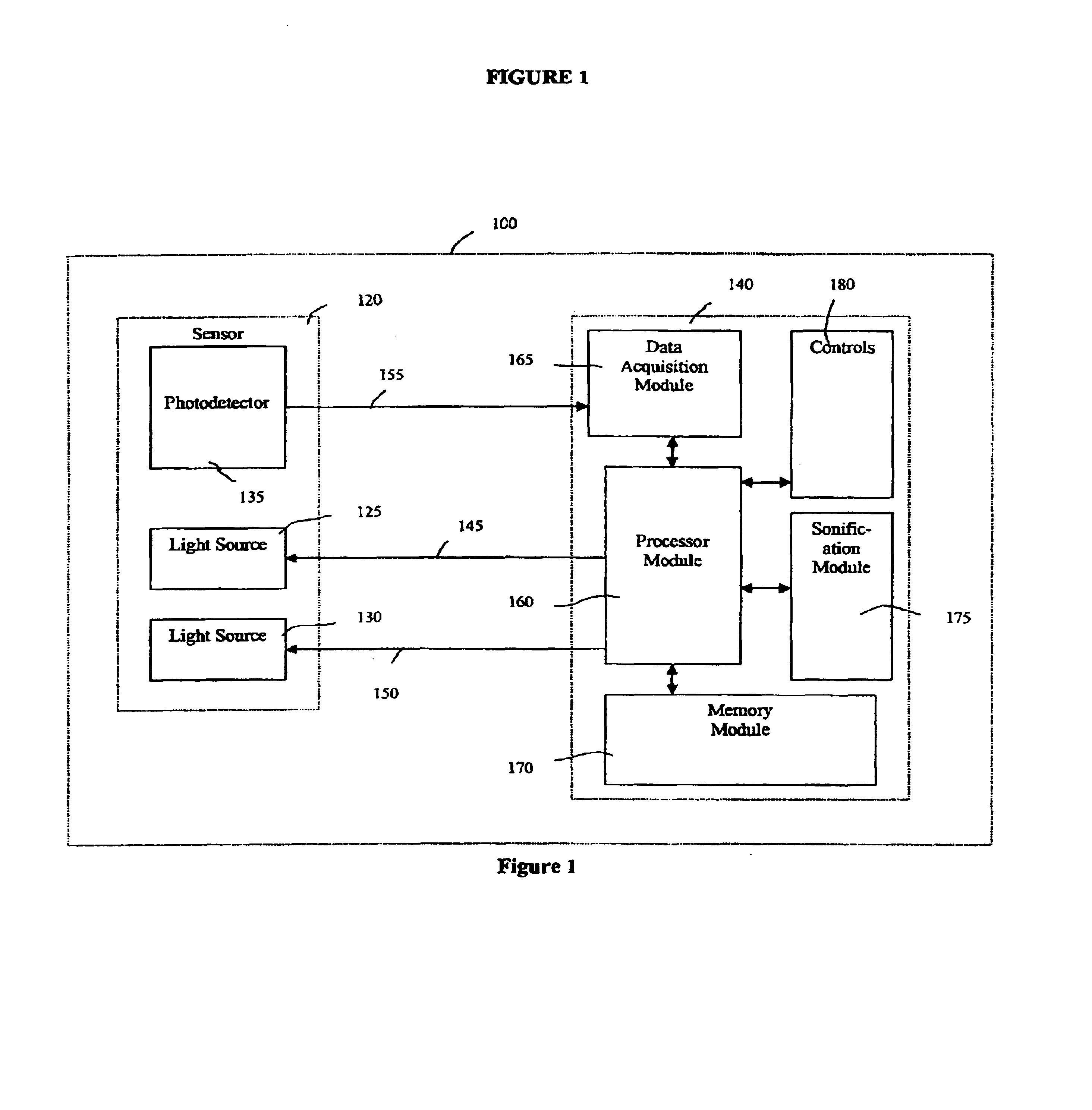

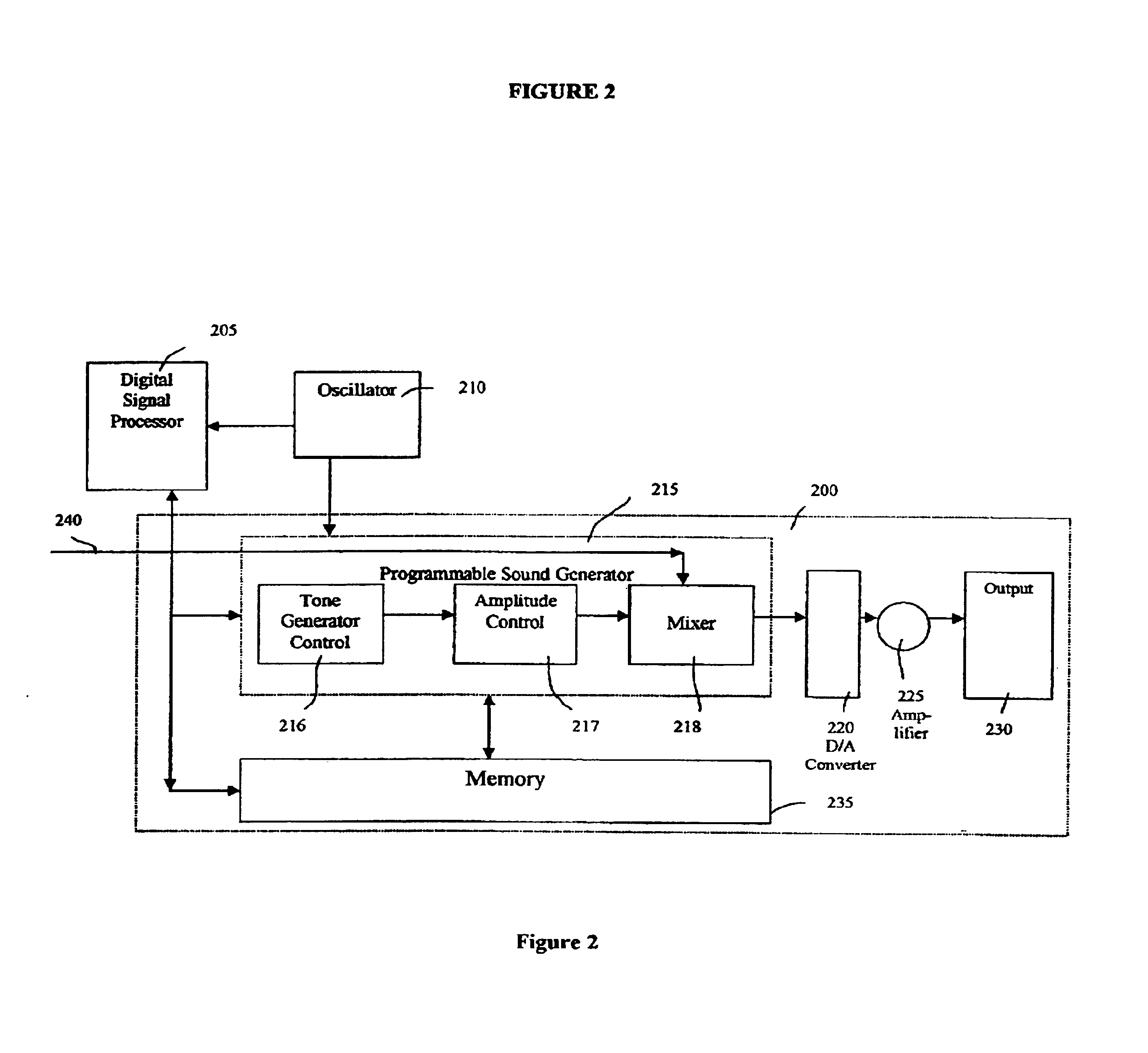

Auditory alarms for physiological data monitoring

ActiveUS6947780B2Strengthen associationCatheterDiagnostic recording/measuringSonificationVisual perception

The present invention provides methods and devices for monitoring physiological data such that a health care provider is able to effectively monitor a patient's health status, including, for example, blood flow characteristics, without having to maintain constant visual contact. In one embodiment of the present invention, a physiological data monitoring system measures at least one physiological characteristic wherein the physiological data monitoring system comprises a sensor unit and a monitoring unit in data communication with the sensor unit. The monitoring unit has a sonification module that comprises one programmable sound generator module to produce a plurality of signals indicative of a physiological parameter and a memory module for storing a plurality of control parameters for managing the programmable sound generator module, wherein the plurality of signals produced have a plurality of frequencies modified in accordance with at least one physiological data value. More specifically, the present invention provides a pulse oximetry sonification system that generates fixed frequency singular and / or combined amplitude-adjusted dual audio tones corresponding to predetermined transition and / or intermediate points over a range of SpO2 measurements.

Owner:SPACELABS HEALTHCARE LLC

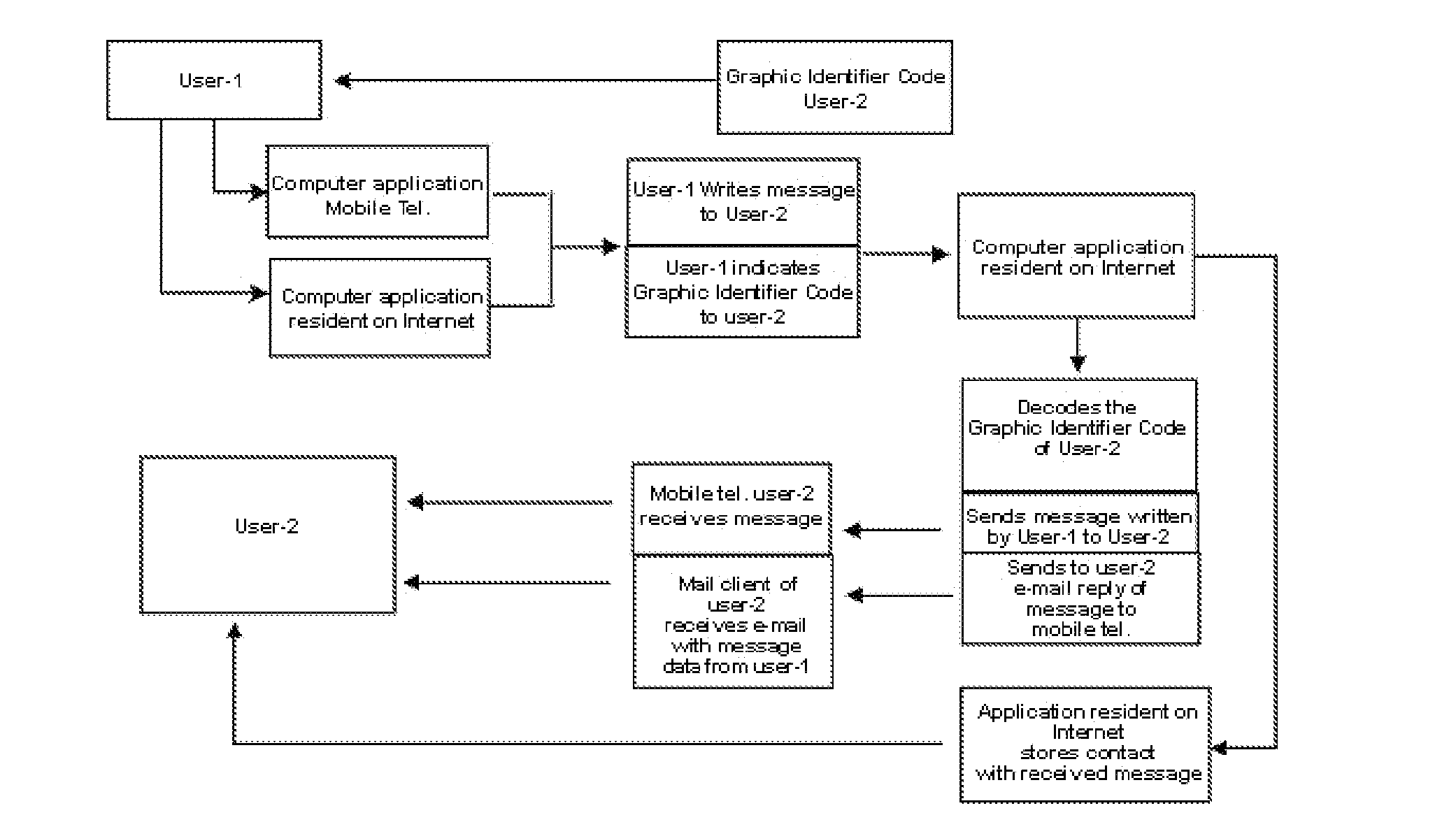

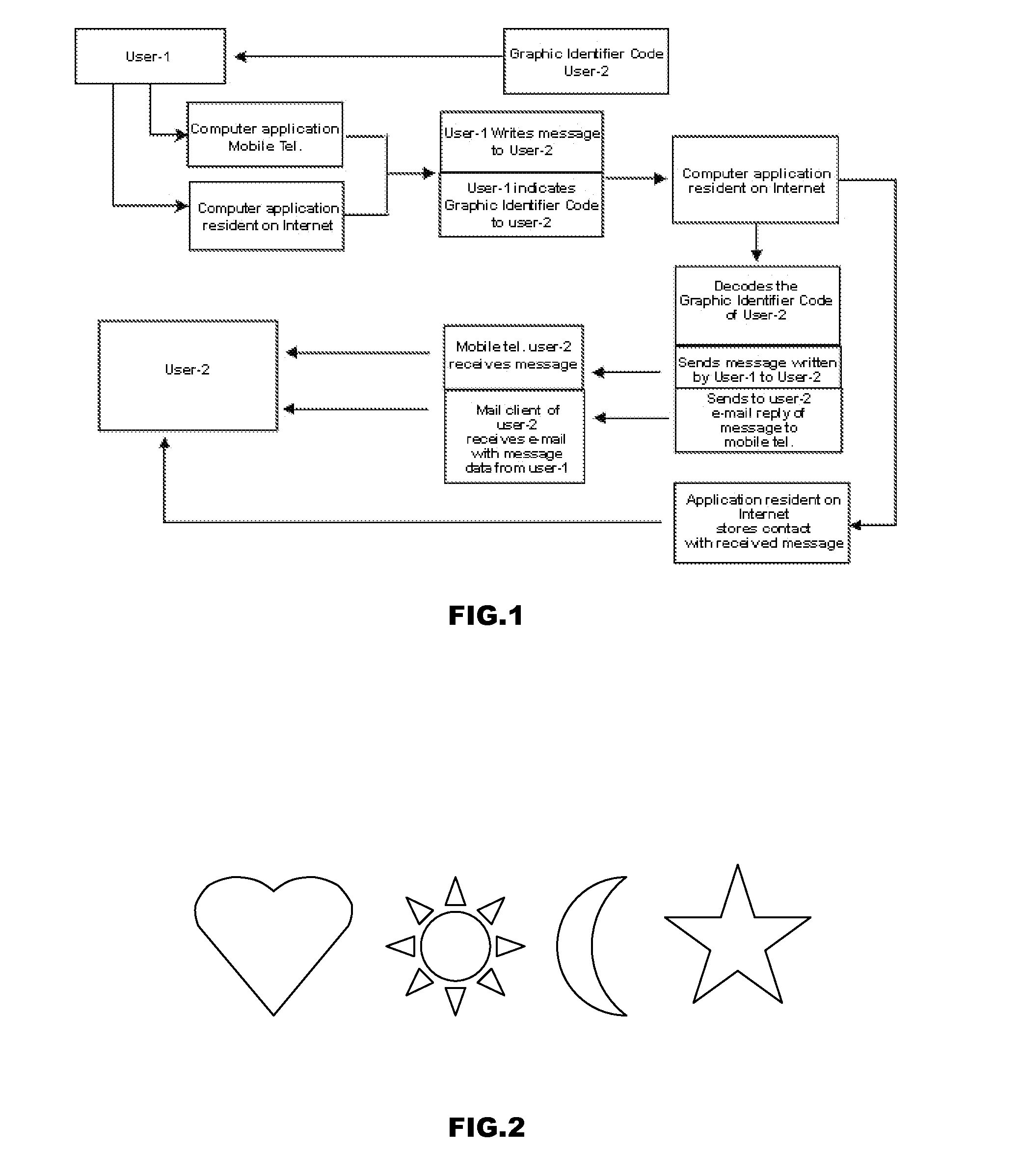

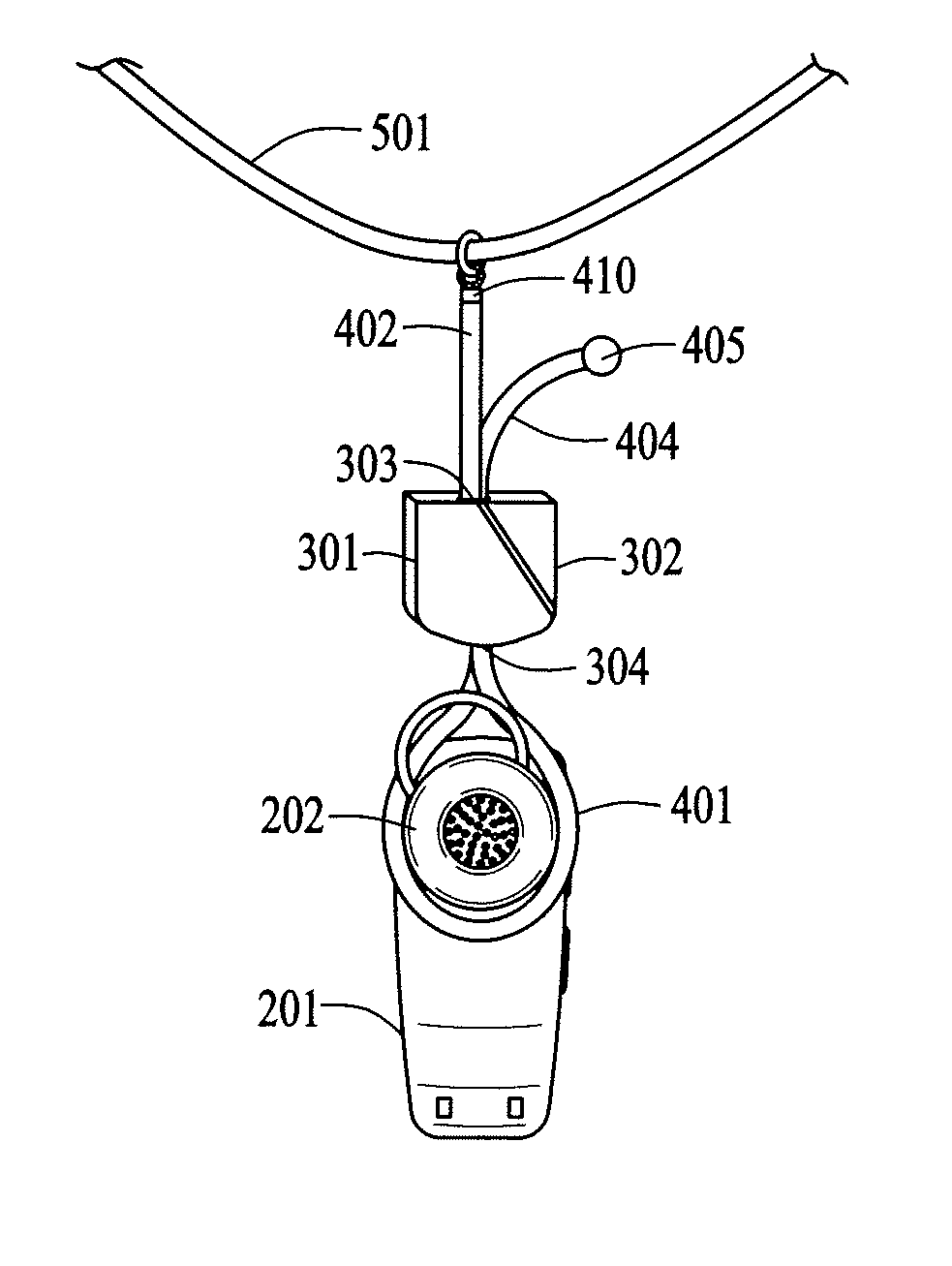

Method and System of Communication That Allow People Unknown to Each Other Who Have Visual Contact to Communicate by SMS or E-mail

InactiveUS20120108274A1Simple and effective and economicalObstacle to communicationWireless commuication servicesCommerceGraphicsPattern perception

Method and system of communication that allow people unknown to each other who have visual contact, to communicate by sms or e-mail based on the identification of system users through the perception of codes of registered users, formed from the combination of graphic symbols that follow uniquely identifying coding rules for each user within the system, by use of a computer application that decodes said user codes and allows the delivery of messages between said users, ensuring maximum discretion during communication, both towards the rest of the environment and towards the user with whom one wishes to establish contact.

Owner:ACEBO RUIZ AGUSTIN +1

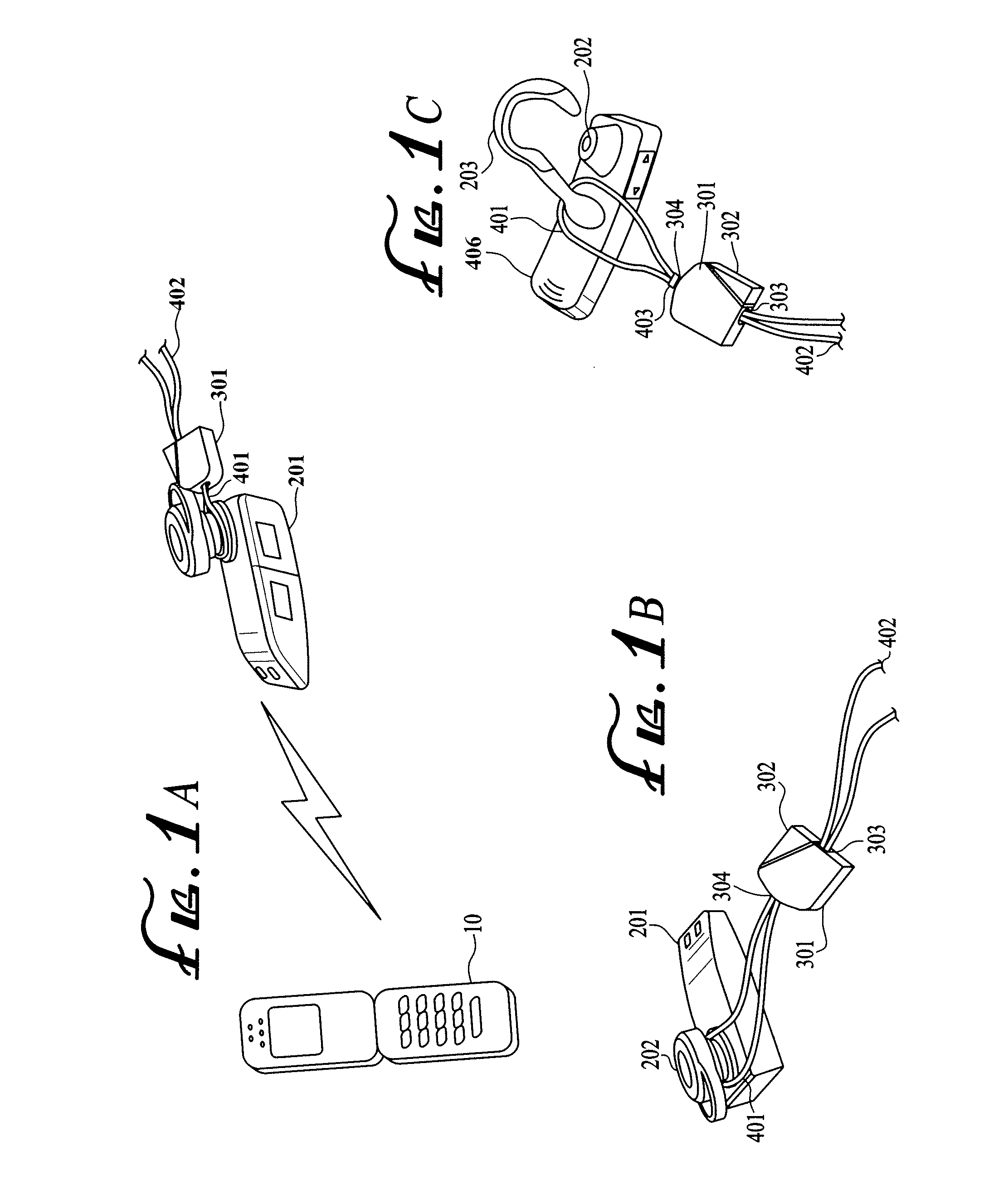

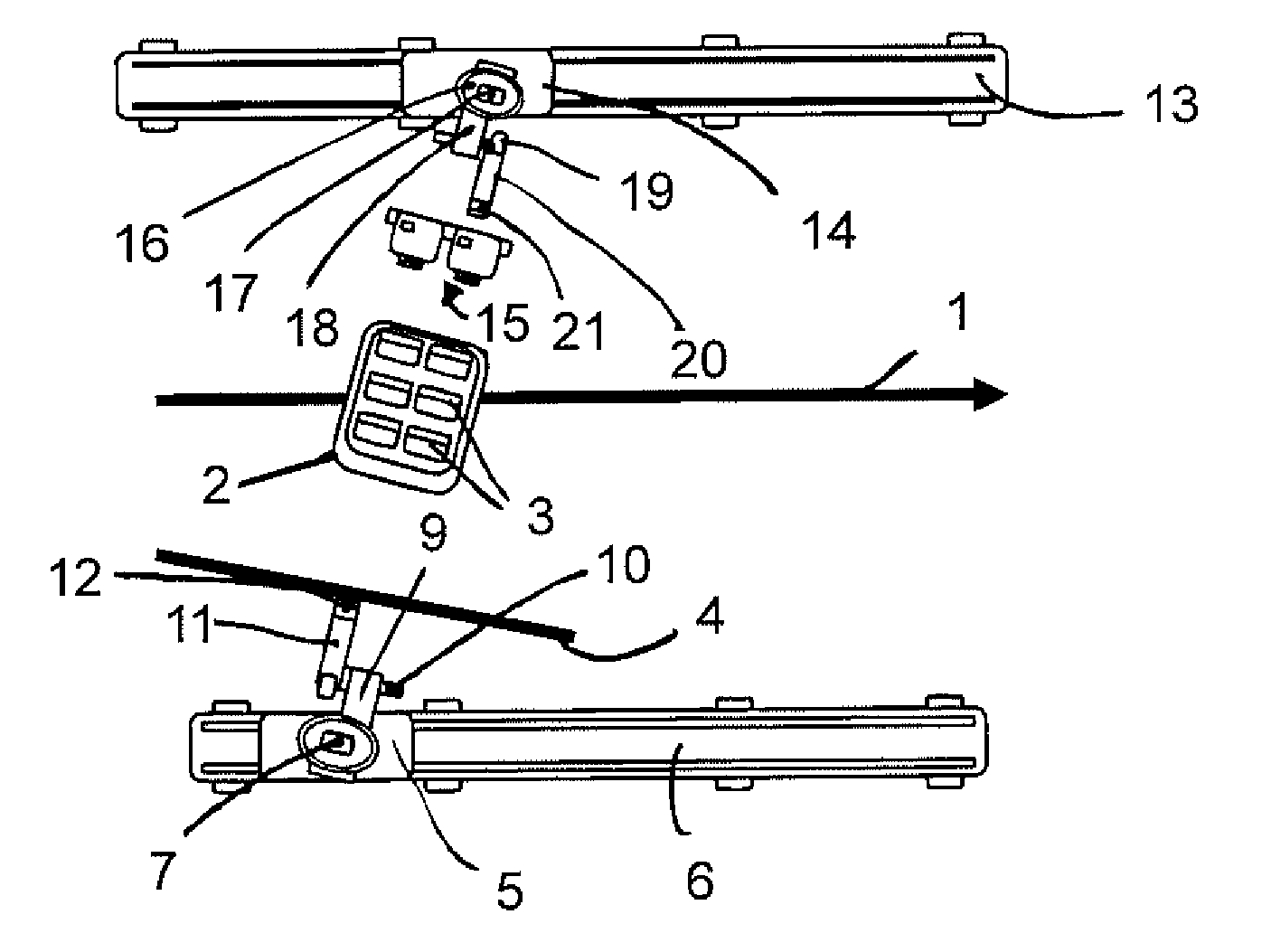

Telecommunication and electronic devices holding apparatus and methods

InactiveUS20090016559A1Ensure accessibilitySecure retentionTravelling carriersHoldersHands freeEngineering

Wearable holding apparatus and methods for securing and storing wireless or wired telecommunication and electronic devices. The apparatus includes a holding unit attached on a user's body or the clothing or accessories of a user or otherwise proximate to the user and having one or more cords attached to the device during both use and non-use. The device is not only convenient to use but is secured from loss. The cord can be dispensed from a cord retracting mechanism for use and the cord retracted back into the mechanism following use. The user can transition from storage of the devices to use of the devices using only one hand and without visual contact with the device or storage unit. The apparatus is small in size and light in weight to allow the user to wear a wireless hands-free device on the ear while attached to the holding unit during use of the apparatus.

Owner:CLEARY RENEE MICHELLE

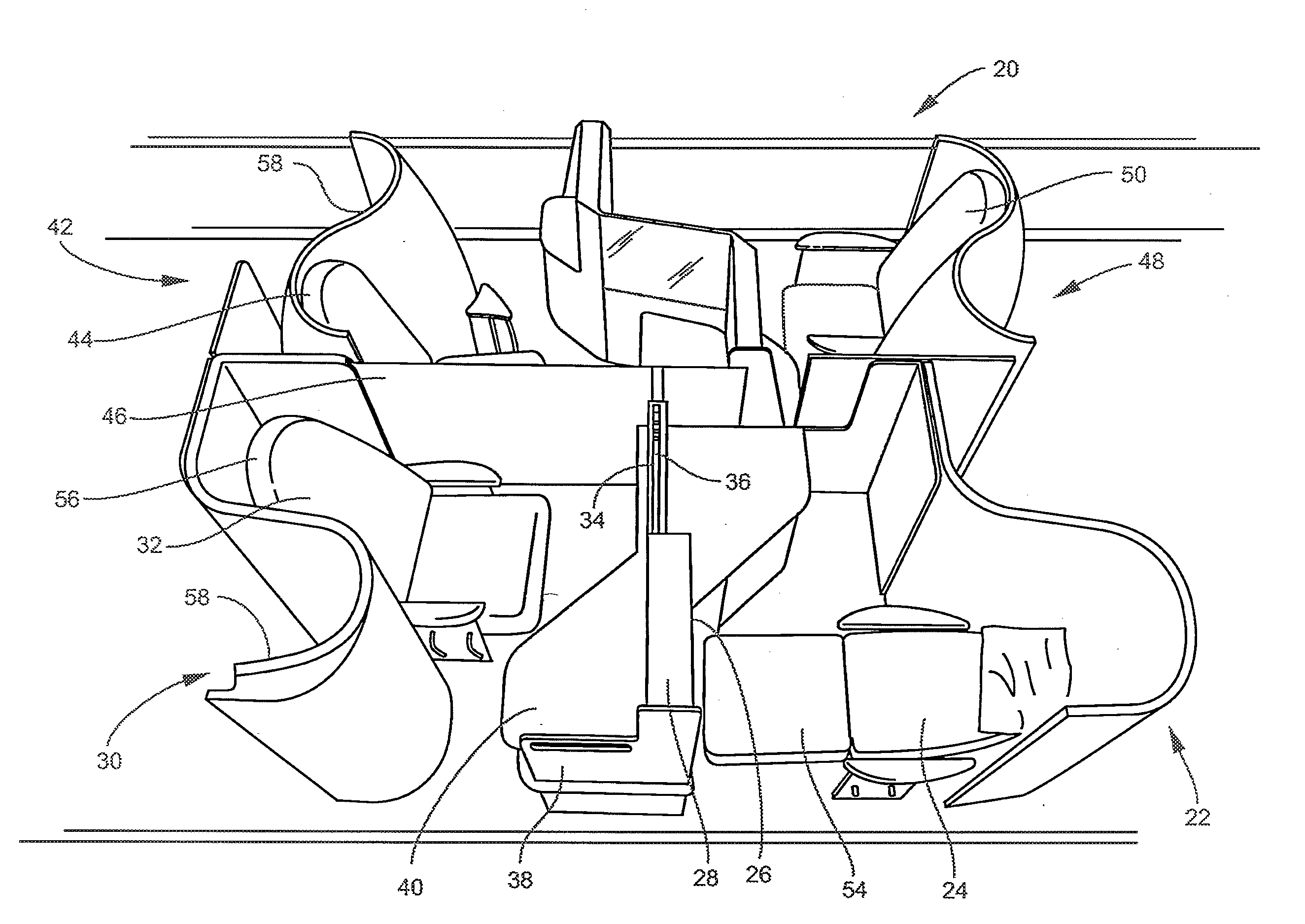

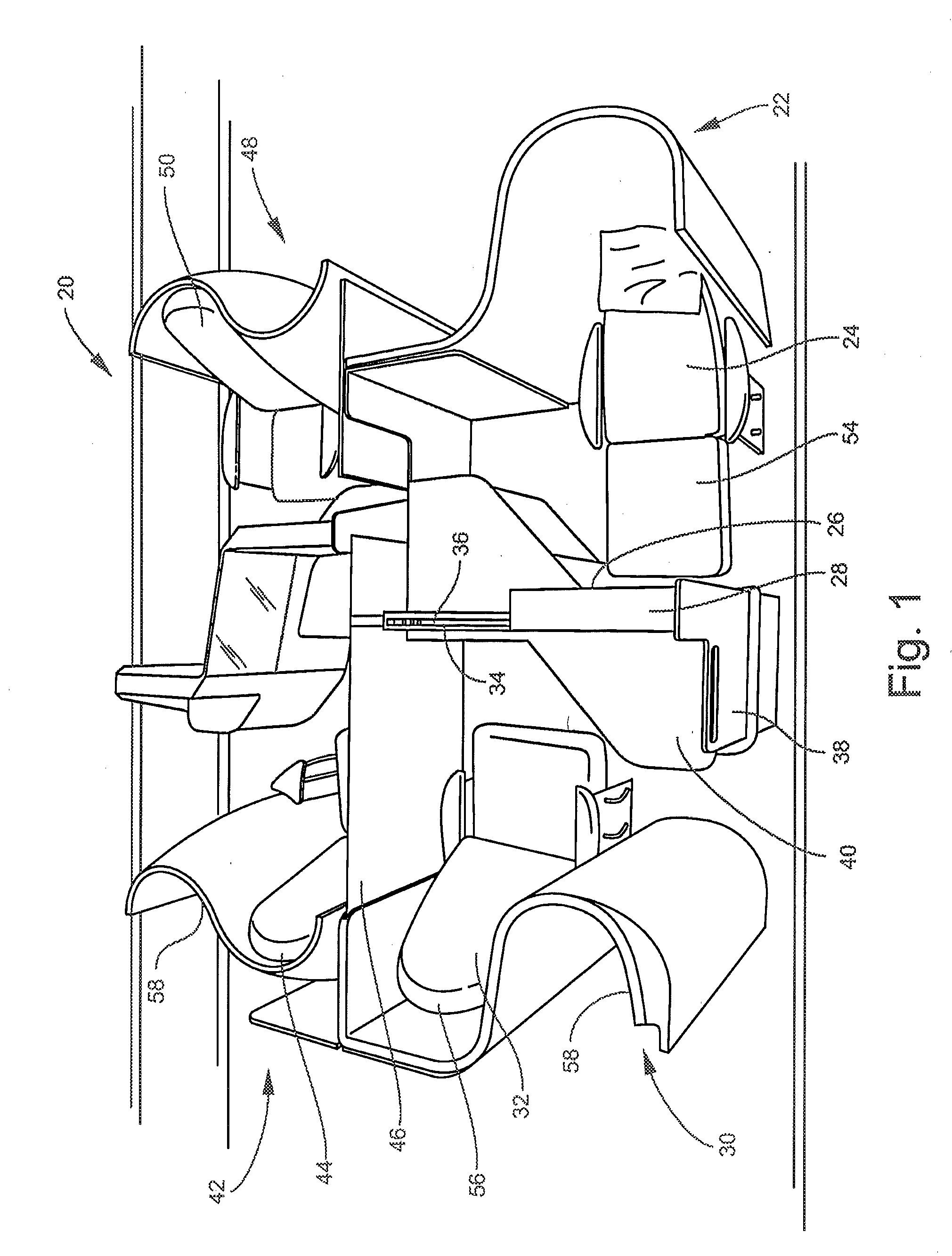

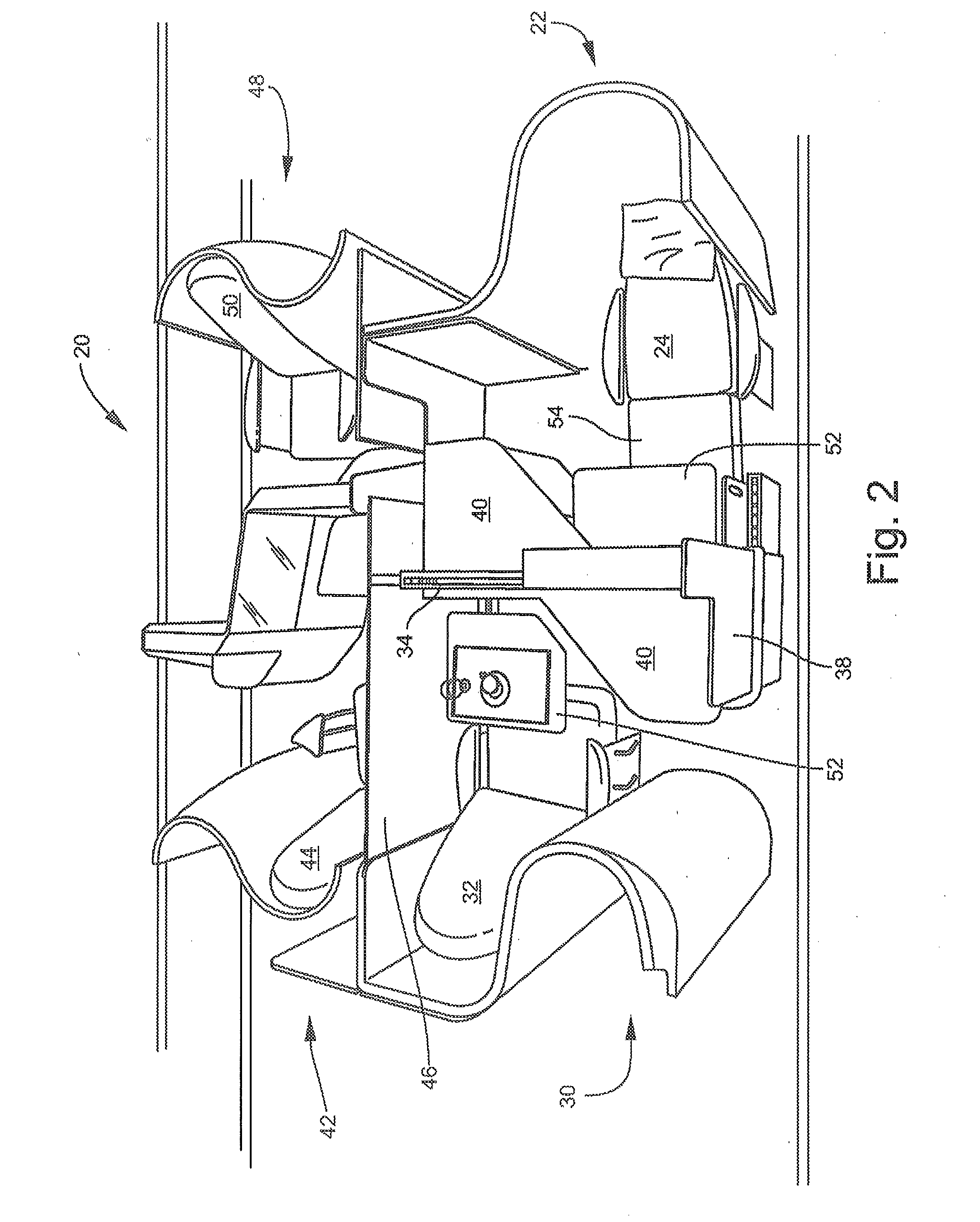

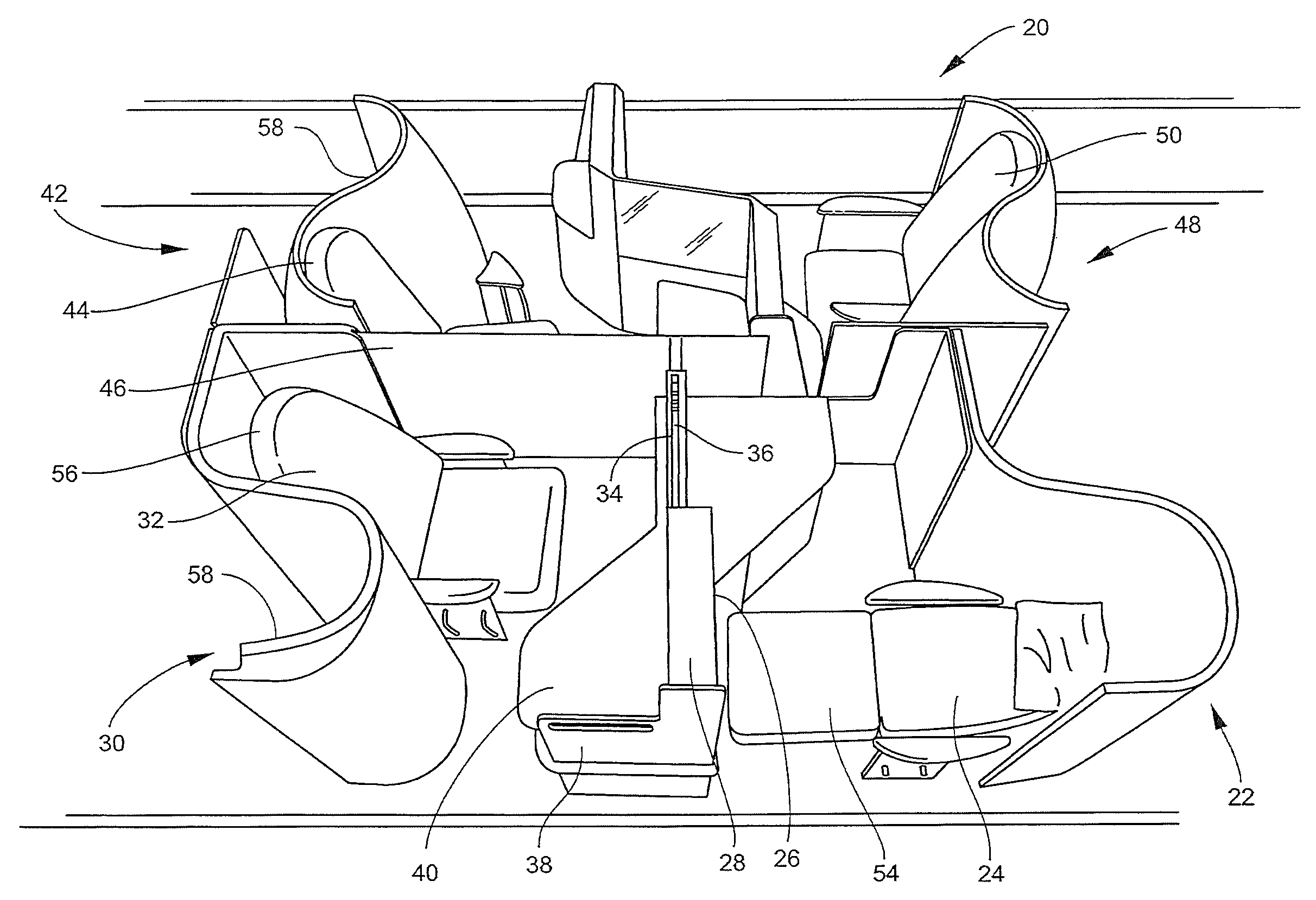

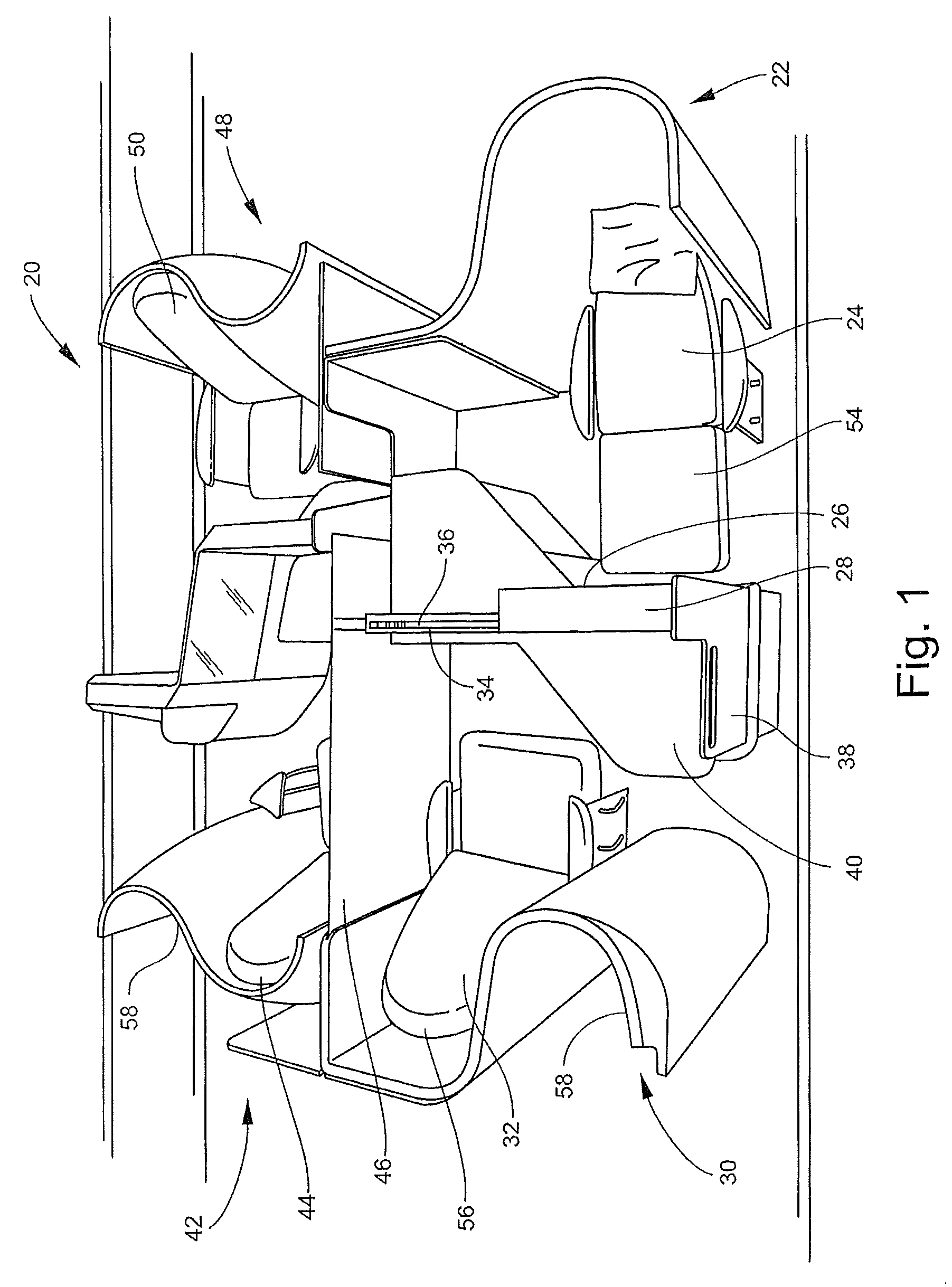

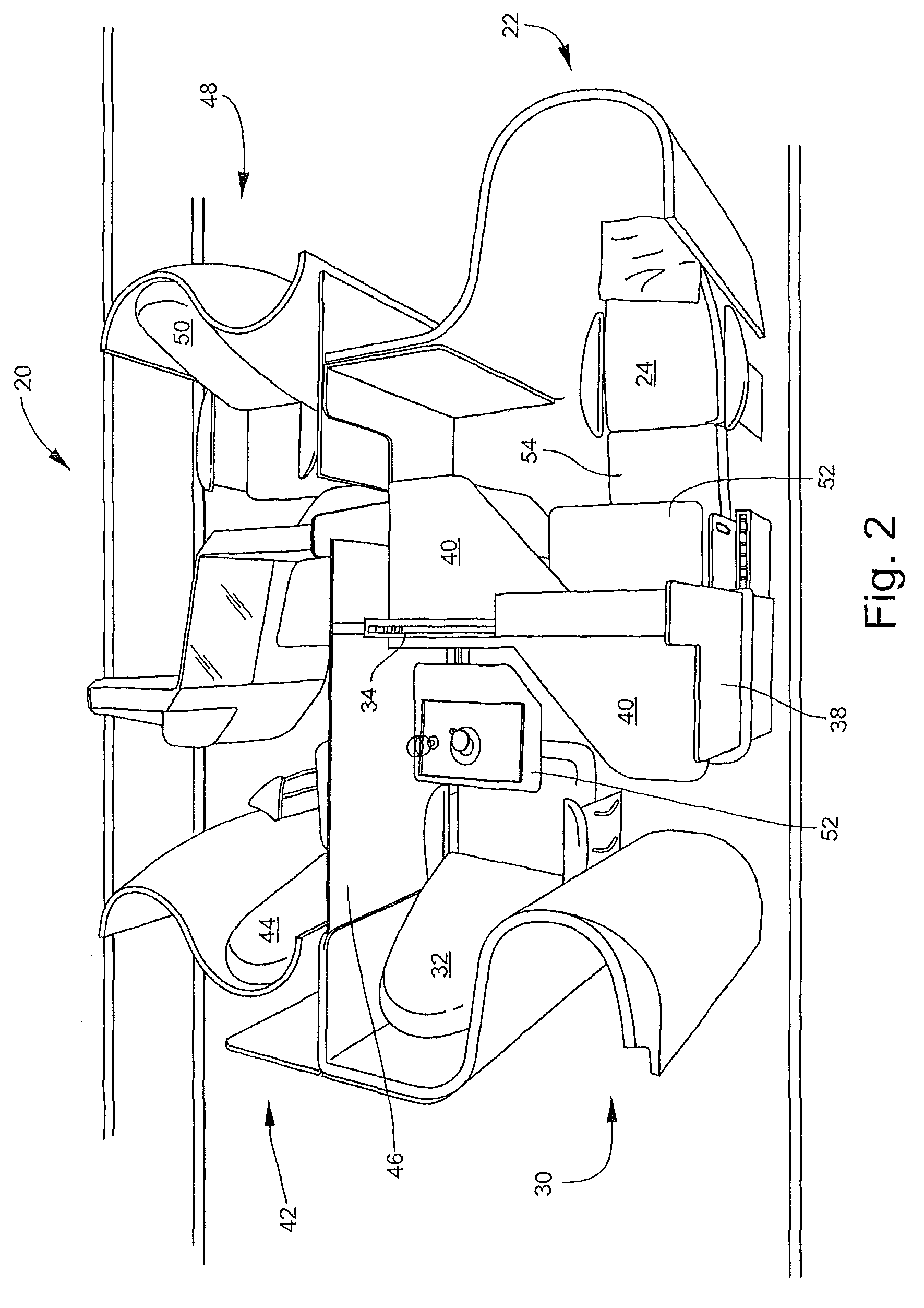

Passenger suite seating arrangement with moveable video monitor

ActiveUS20140361585A1Maximizes densityMaximize the use of spaceVehicle seatsSeating arrangementsEngineeringVisual perception

A passenger suite seating arrangement that includes first and second passenger suites positioned side-by-side and including respective first and second seats and first and second video monitors respectively positioned in a viewing position directly forward of the first seat and second seats. Third and fourth passenger suites are positioned side-by-side and facing the first and second passenger suites, and include respective third and fourth video monitors positioned and adapted to move between a stowed position laterally offset from a viewing position and a deployed viewing position forward of the third and fourth seats. In the deployed viewing position the third and fourth video monitors block visual contact between occupants of the first and second seats and the occupants of the third and fourth seats.

Owner:BE AEROSPACE INCORPORATED

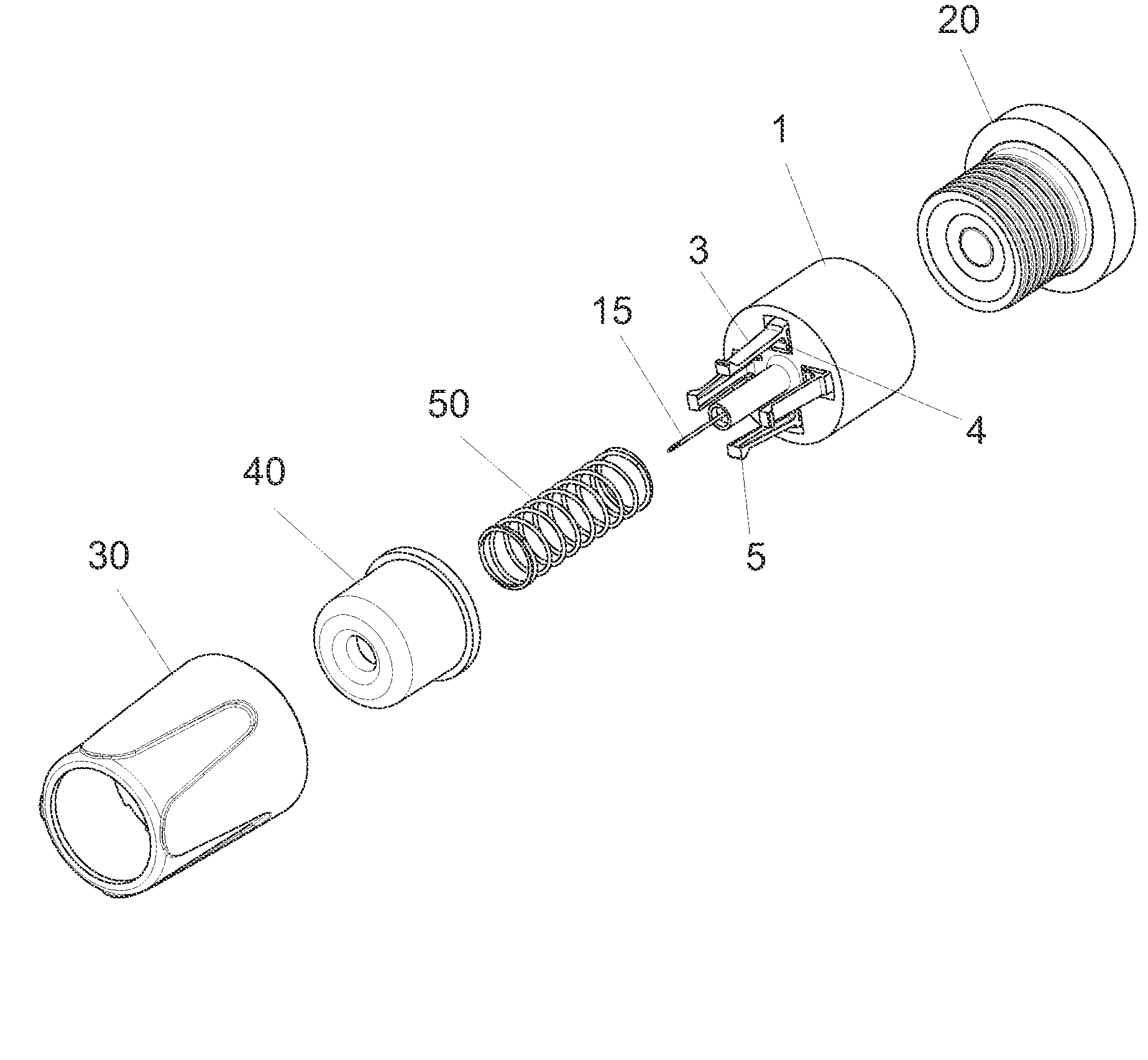

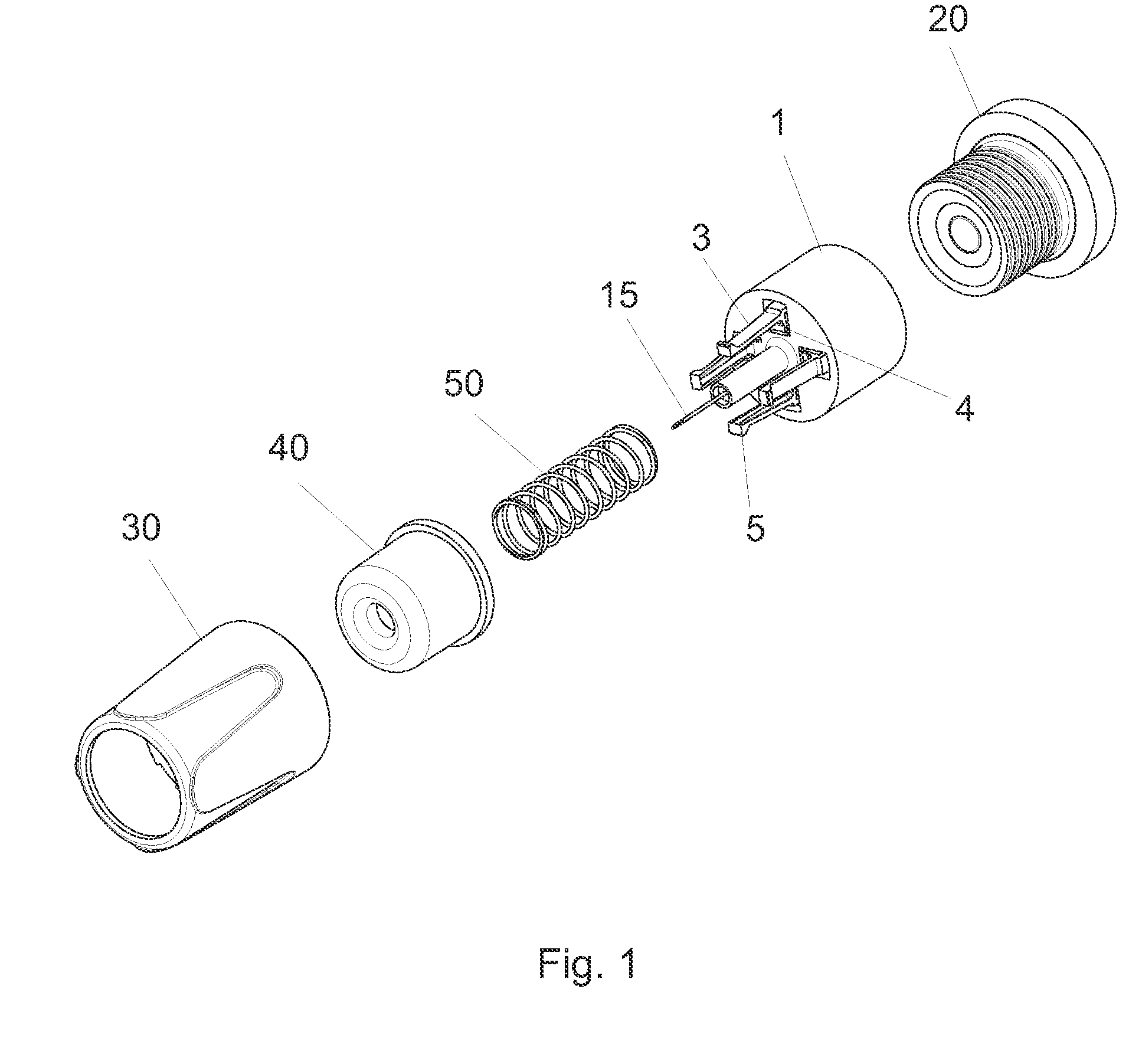

Shieldable needle assembly with biased safety shield

A needle assembly for an injection device comprising a needle cannula which is mounted in a hub connectable to an injection device, and a biasing shield which is telescopically guided relative to the hub between a position in which the needle cannula is covered and a position in which at least the sharp end of the needle cannula is exposed, such that an injection can be performed without visual contact with the needle cannula. Further releasable locking means is provided such that the user can lock or unlock the shield to perform the telescopically movement. In order to release the shield, the injection device itself can be utilized as the key for unlocking.

Owner:NOVO NORDISK AS

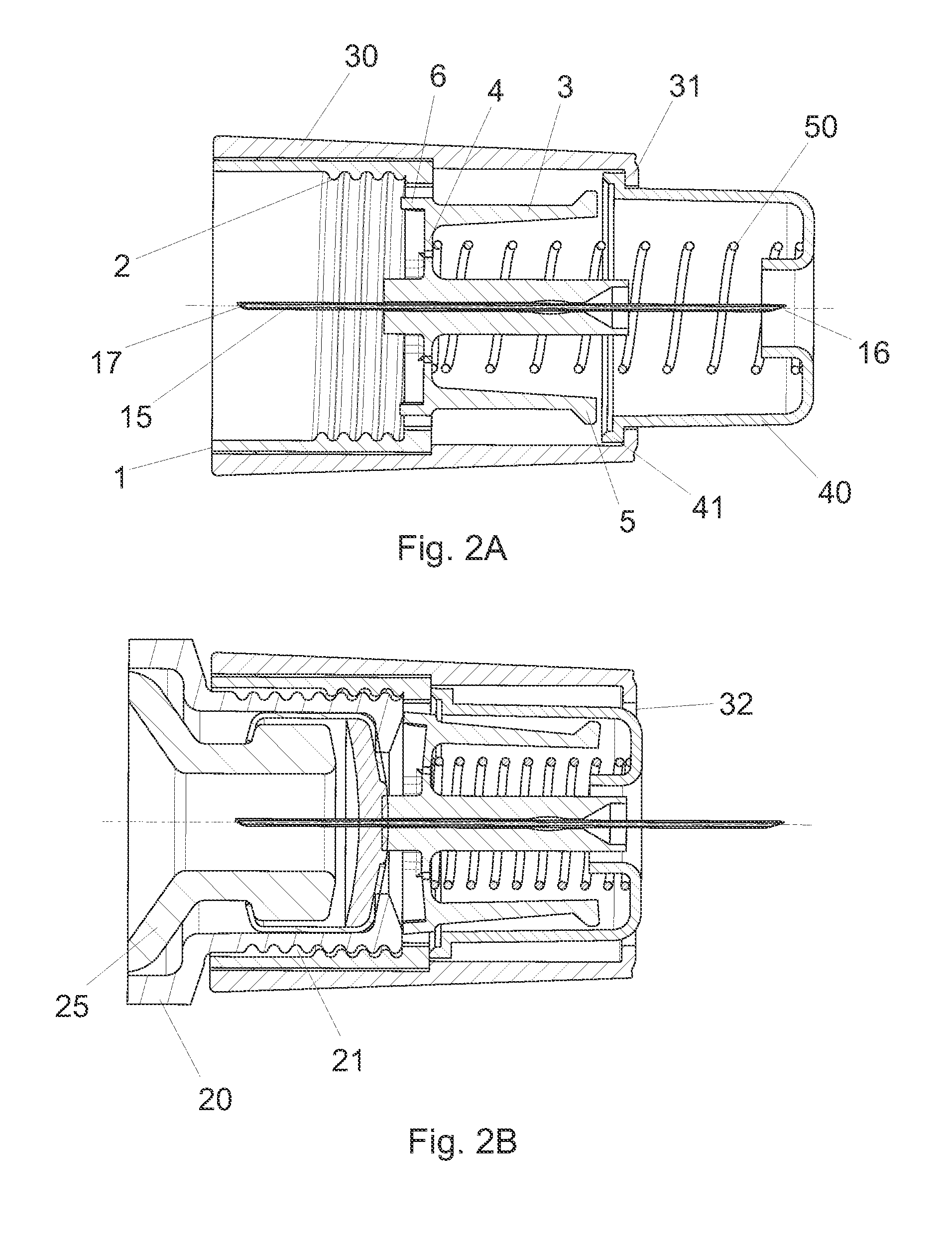

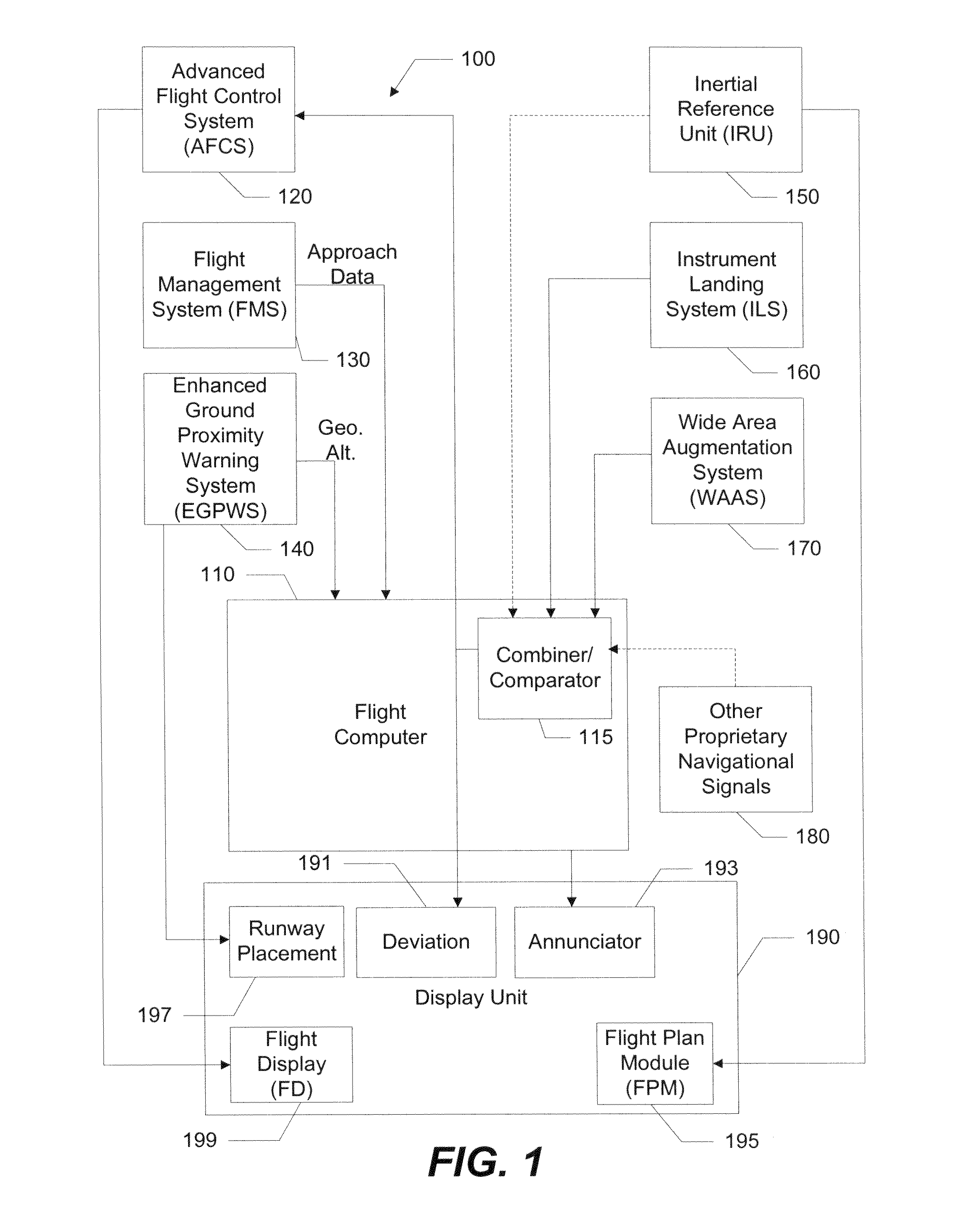

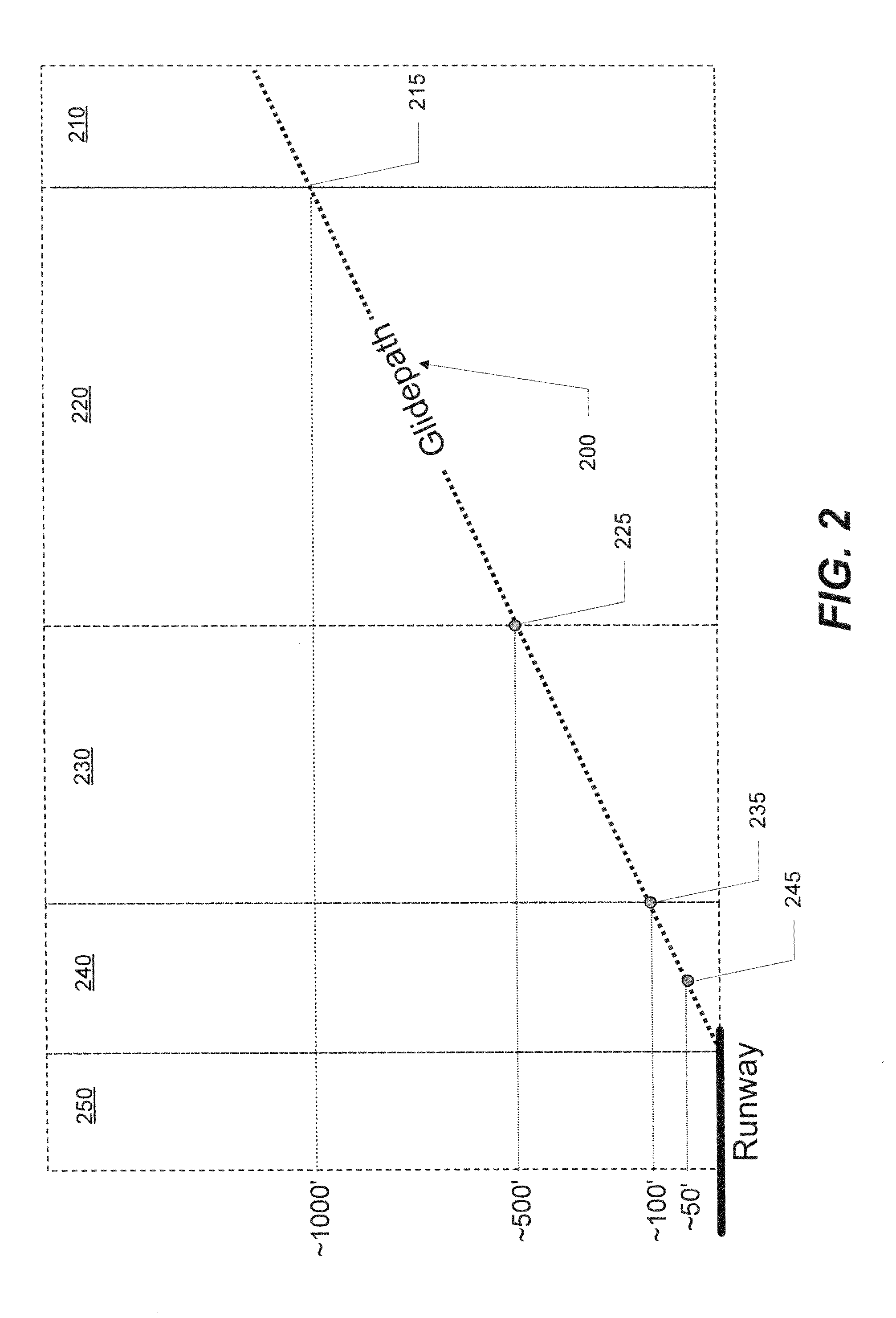

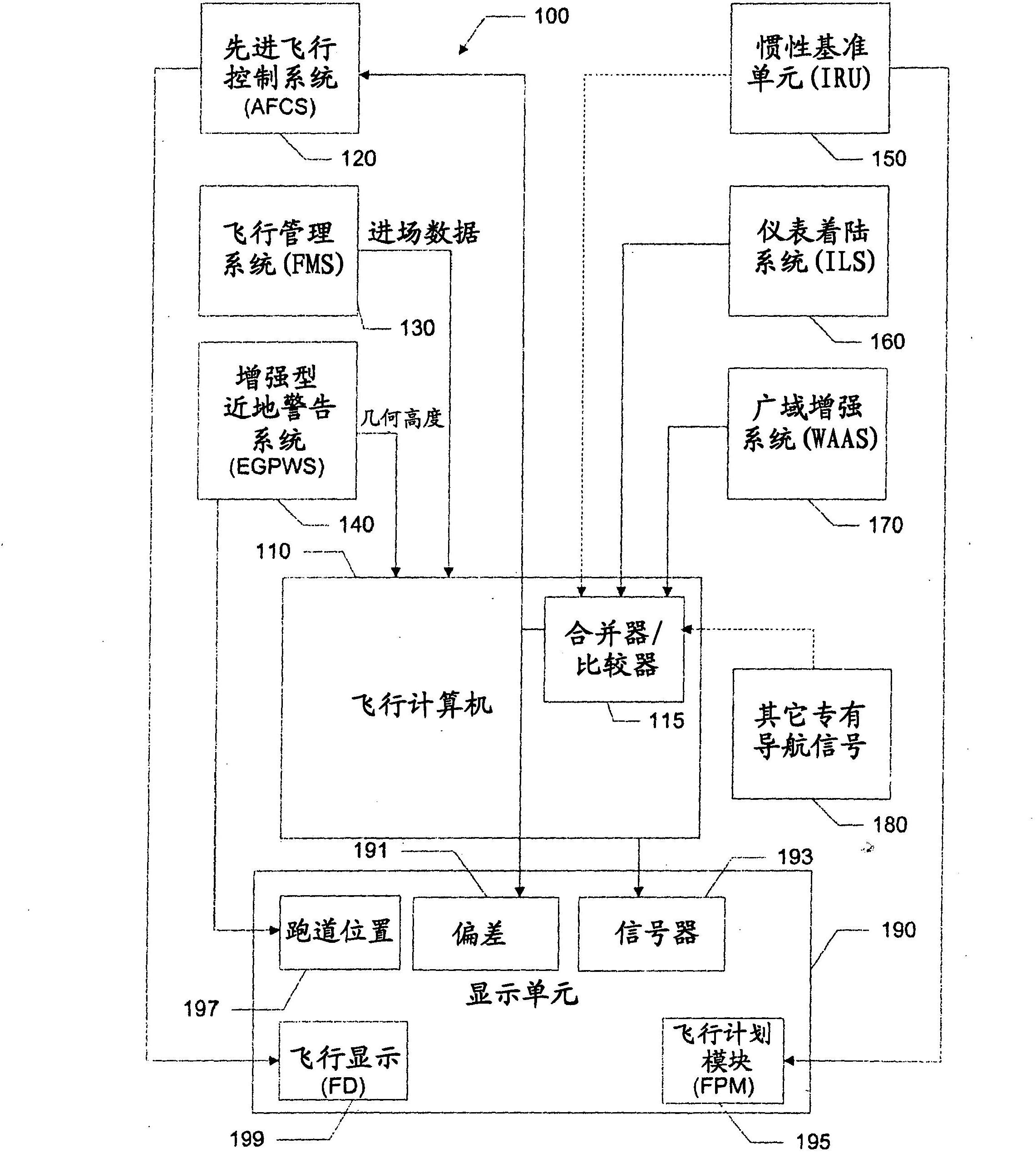

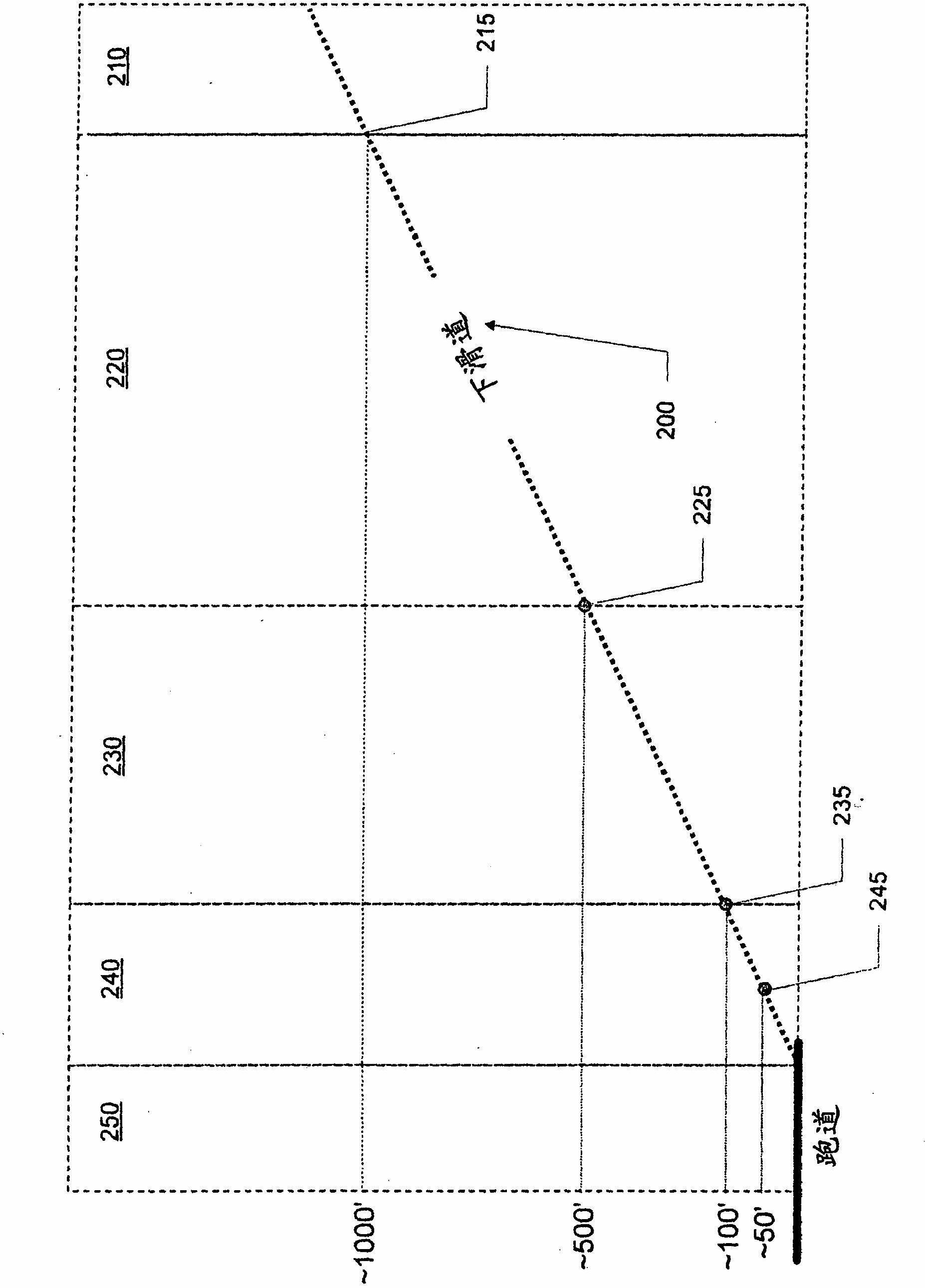

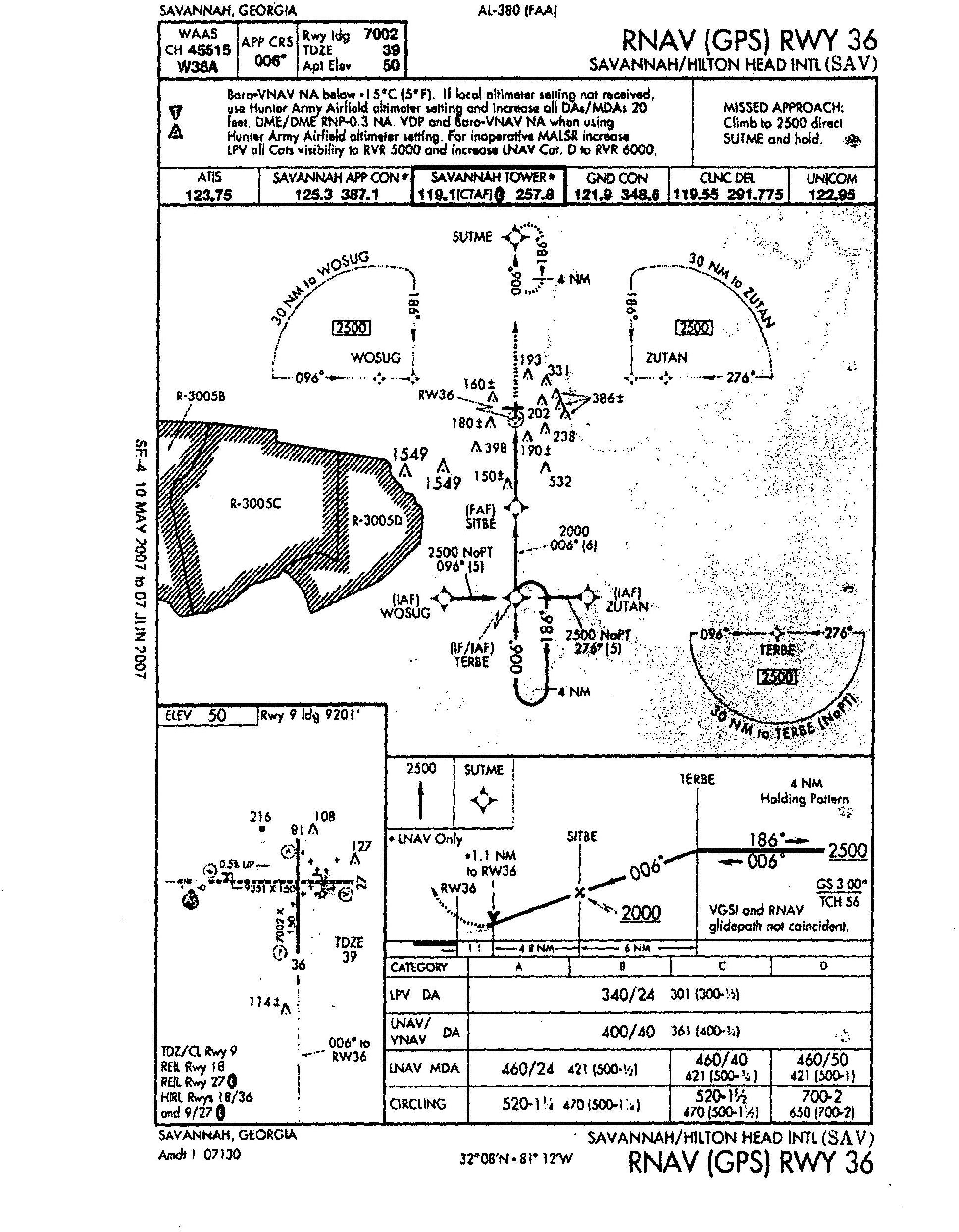

Low visibility landing system

InactiveUS20110106345A1Improve accuracyPrecise positioningAnalogue computers for vehiclesSpecial data processing applicationsVisibilityFlight vehicle

Examples of the present invention may include a low visibility landing system for guiding aircraft on landing approaches. The low visibility landing system may aid a pilot during landing in low visibility conditions such that an aircraft may descend to lower altitudes without visual contact with the runway than is possible with other landing systems. The system may use various navigational systems to produce a hybrid signal that may be more stable than individual signals of those navigational systems. The hybrid signal is compared to a predetermined landing approach plan to determine the deviation of the aircraft from the landing approach plan and to provide guidance to the pilot to get the aircraft back onto the landing approach plan. The system may also use multiple navigational systems to perform checks on an operation of a primary navigational system to ensure that the primary navigational system is operating accurately.

Owner:GULFSTREAM AEROSPACE CORP

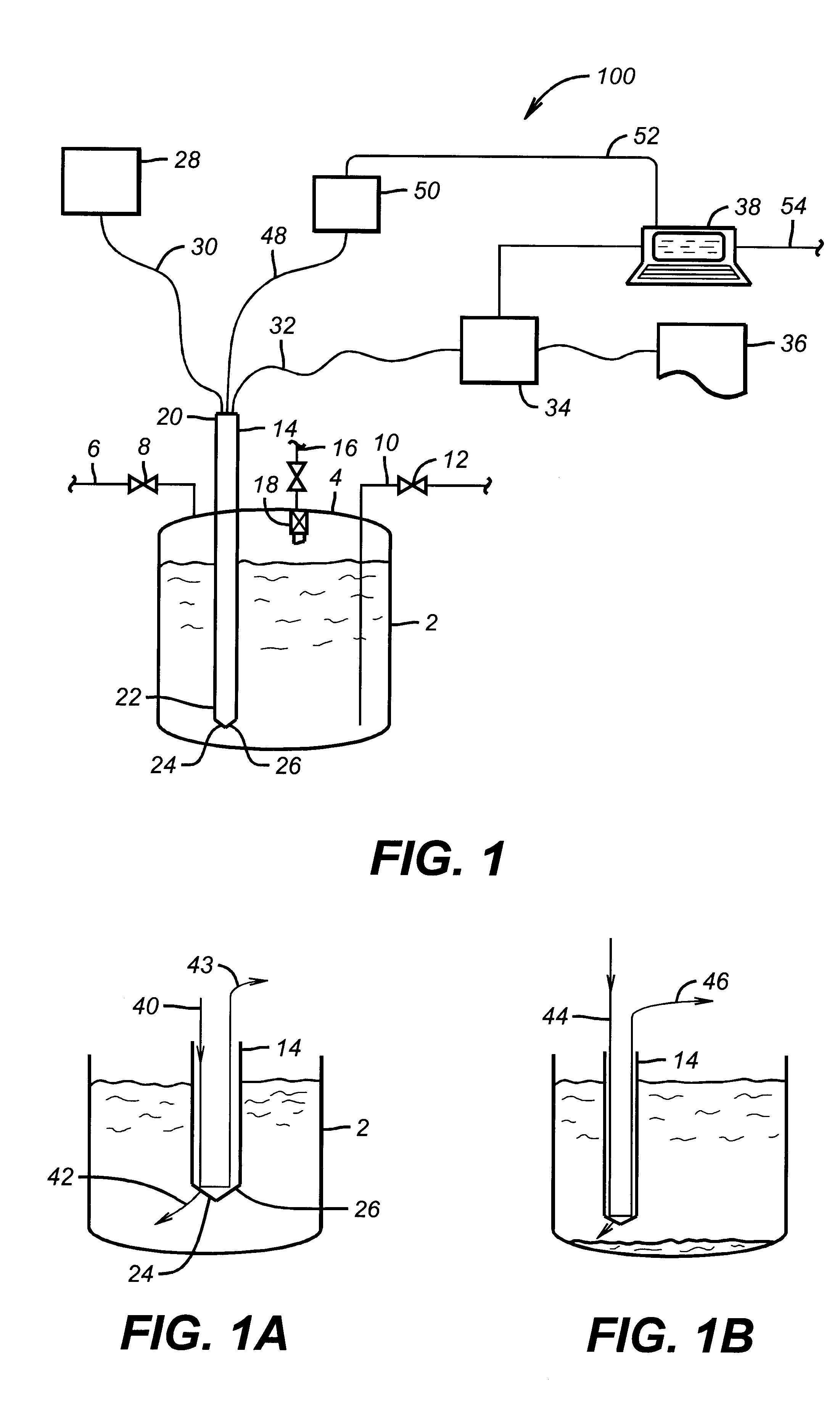

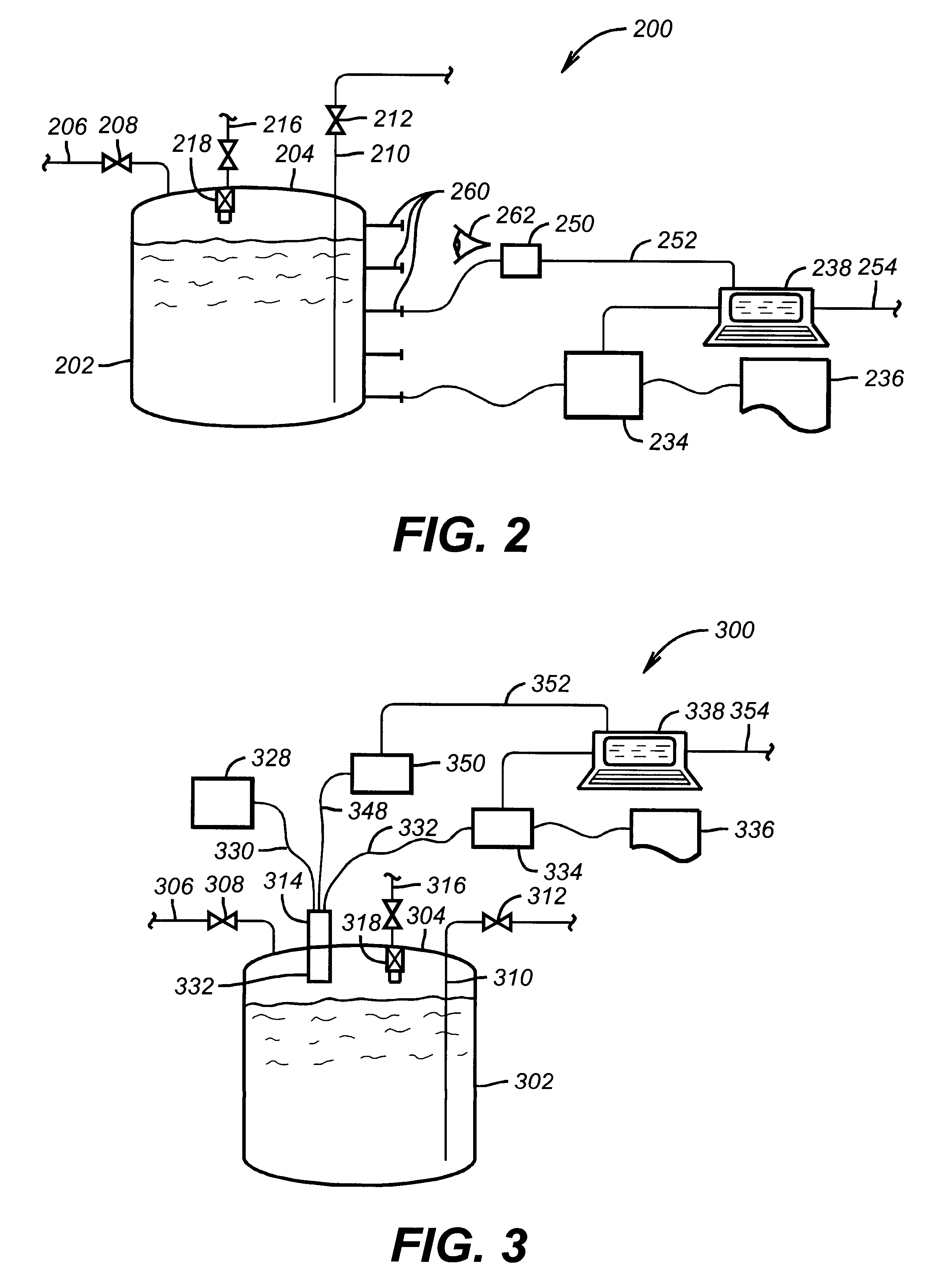

System and method for monitoring the delivery of gas to a person's airway

InactiveUS7159533B1Easy to observeEasily retrofit into exiting gas delivery systemRespiratorsCombination devicesCatheterIntensive care medicine

A gas delivery system and method are disclosed in which a flow indicator is interposed between the distal end of a conduit connected to a gas source and a device for introducing the gas in the airway of an individual so that the individual, or some other person in visual contact with the individual, can easily determine whether or not gas is flowing through the system.

Owner:REDD IRIS GAIL +1

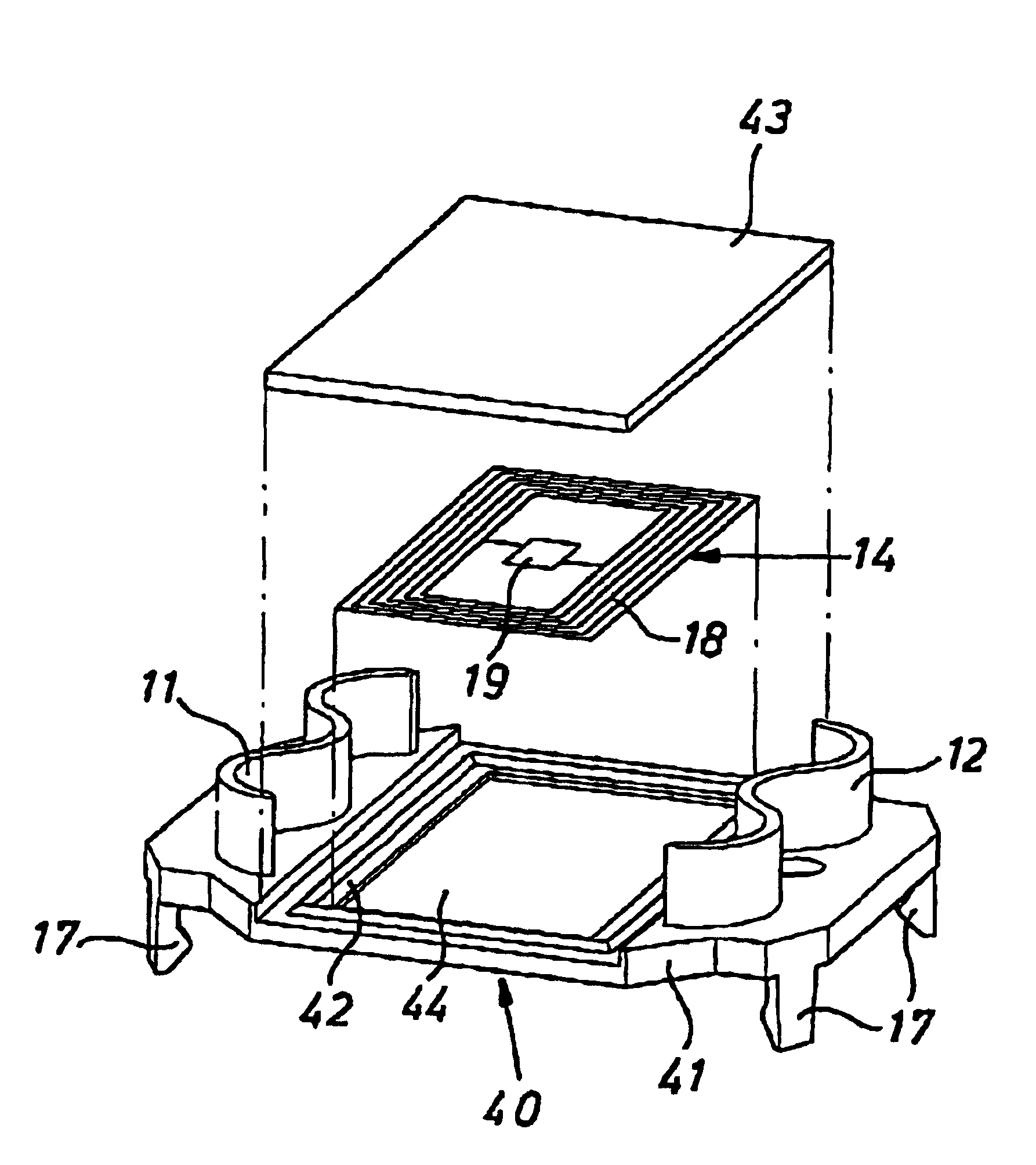

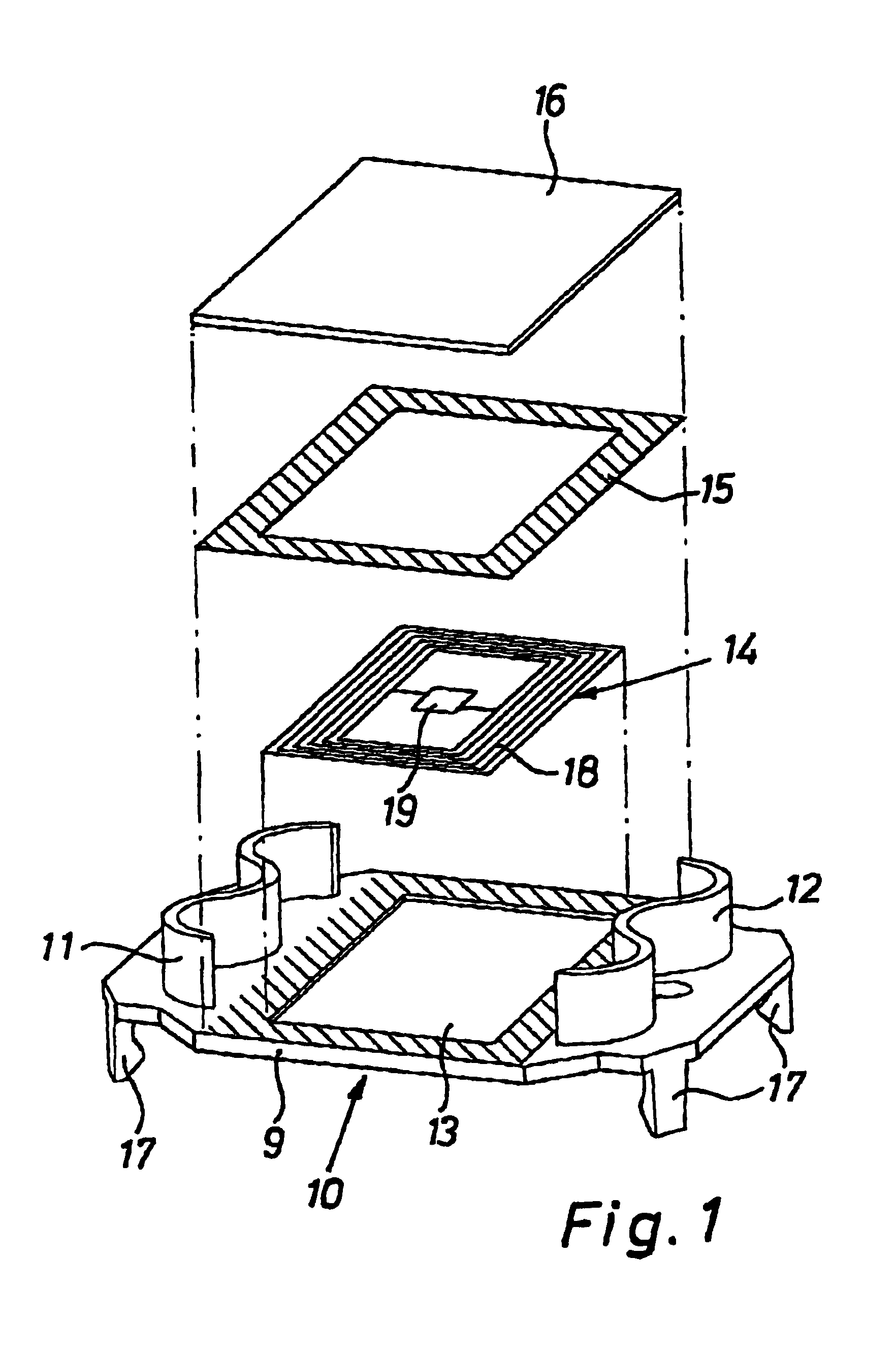

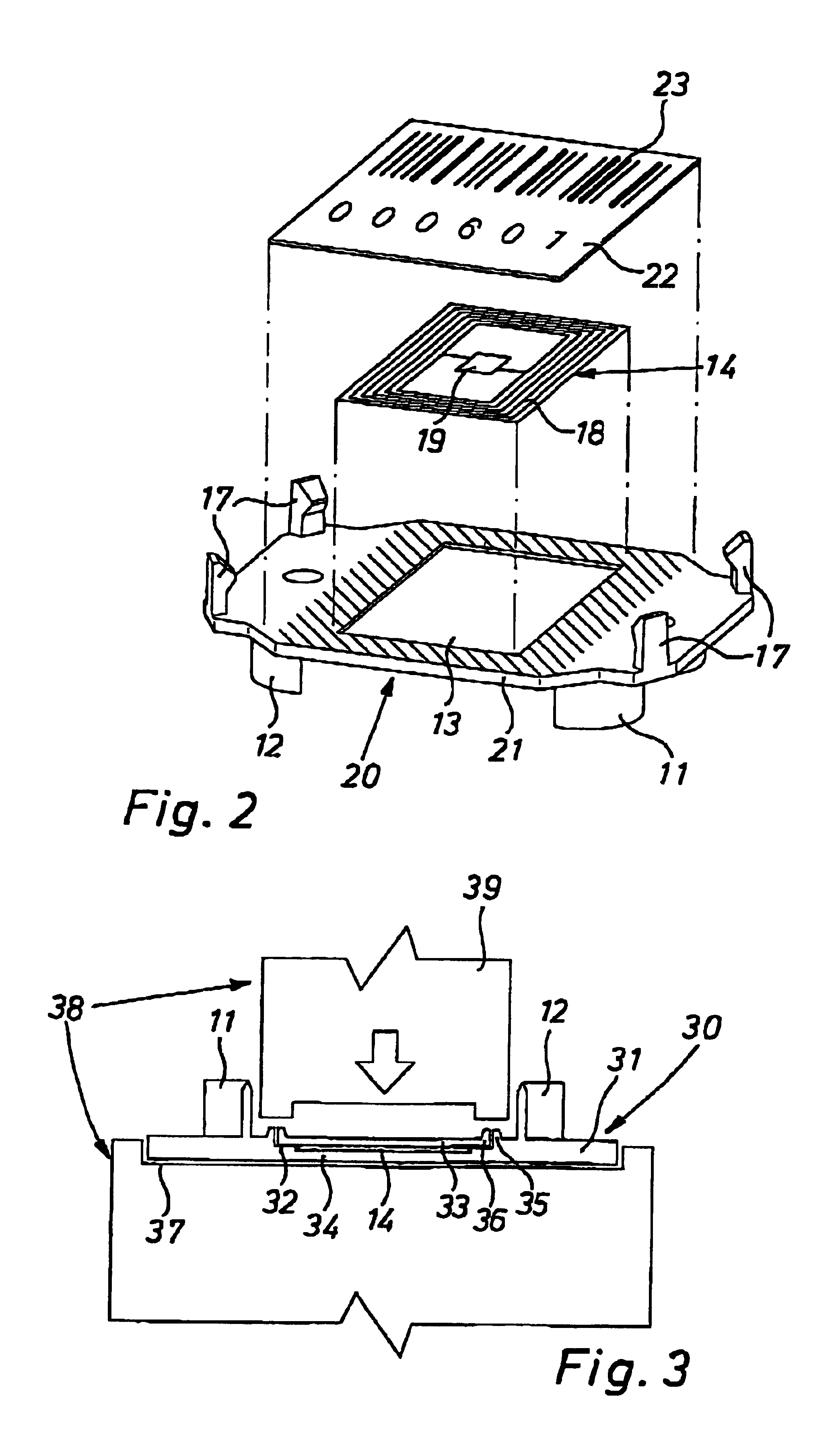

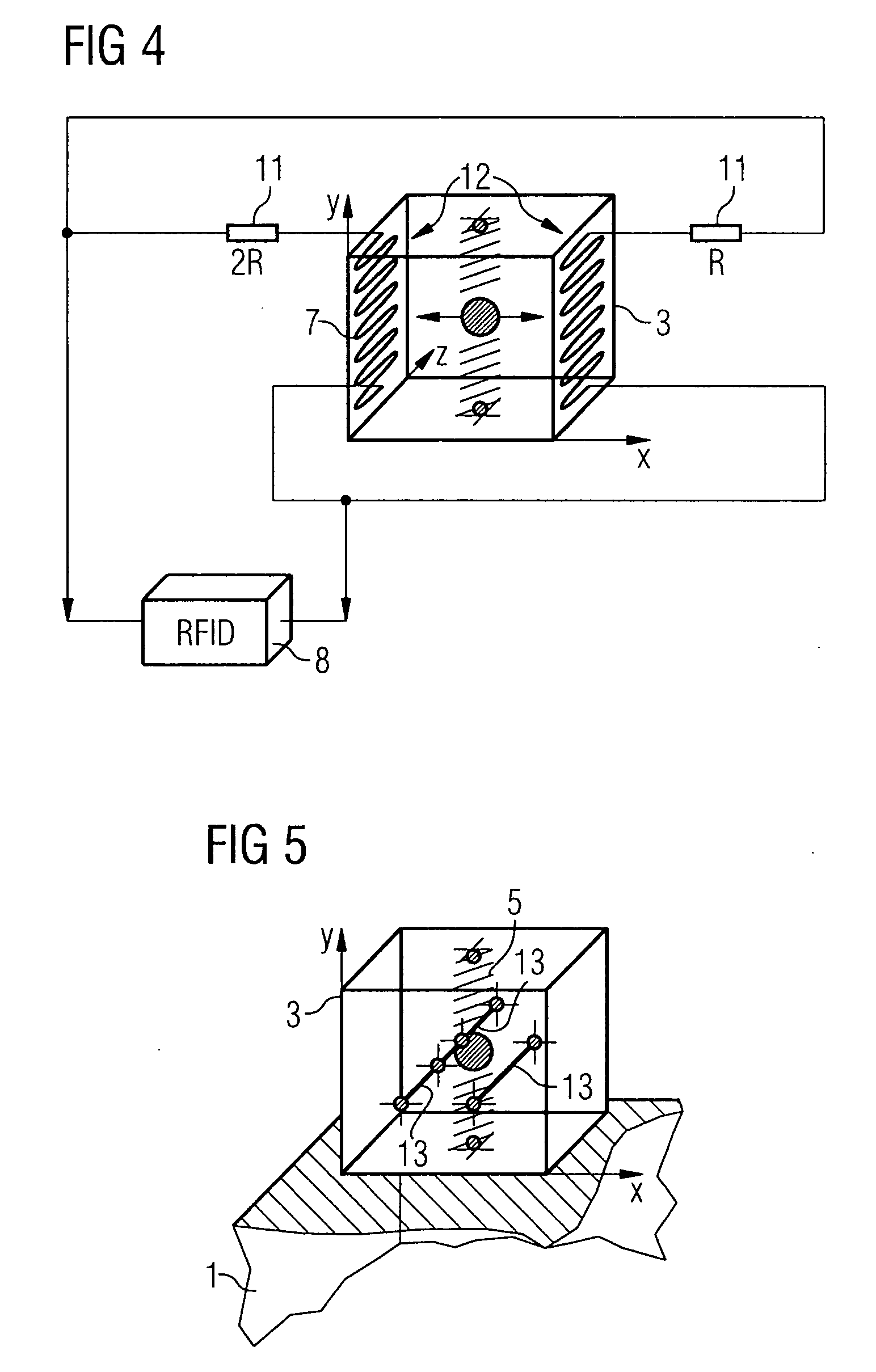

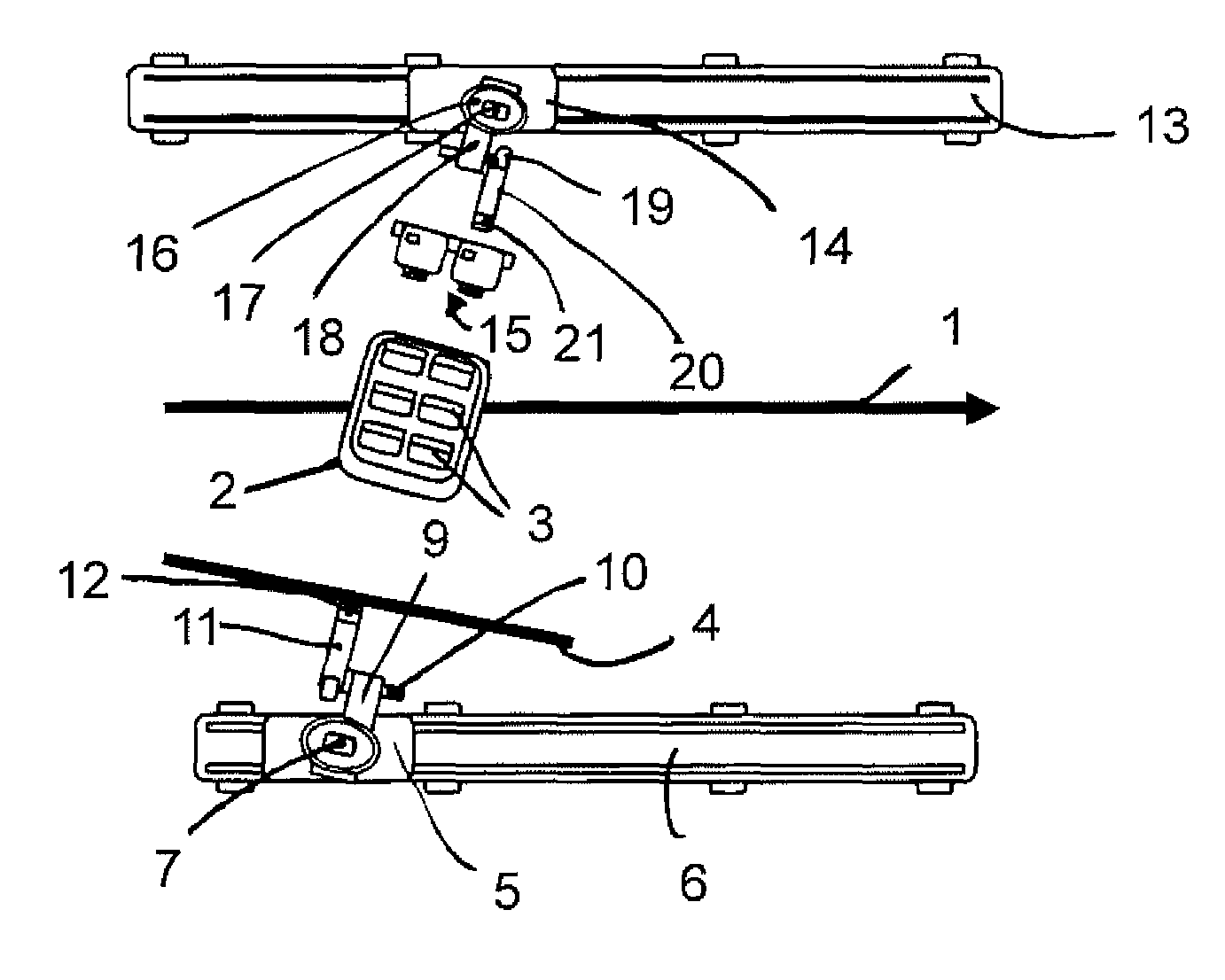

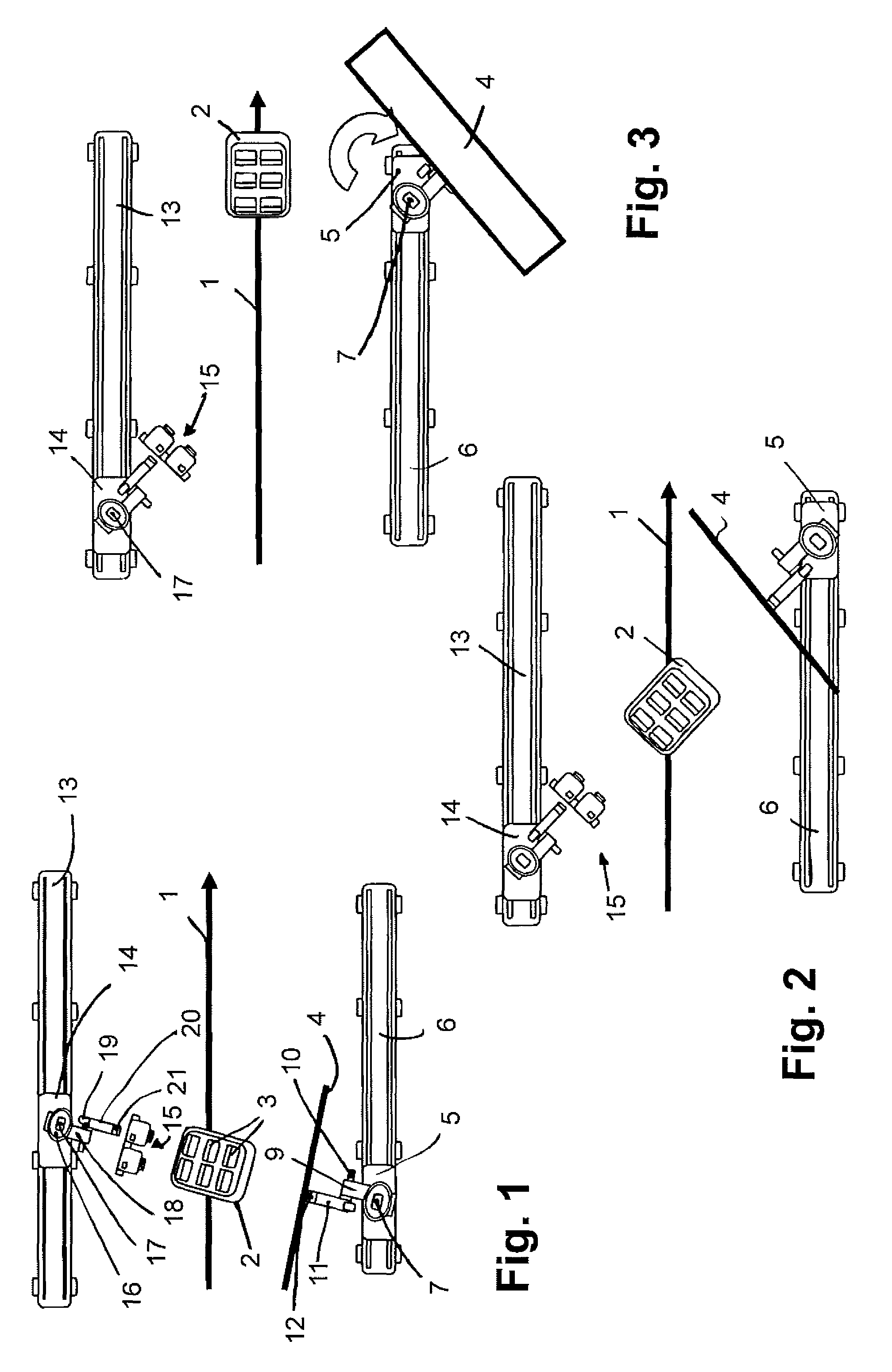

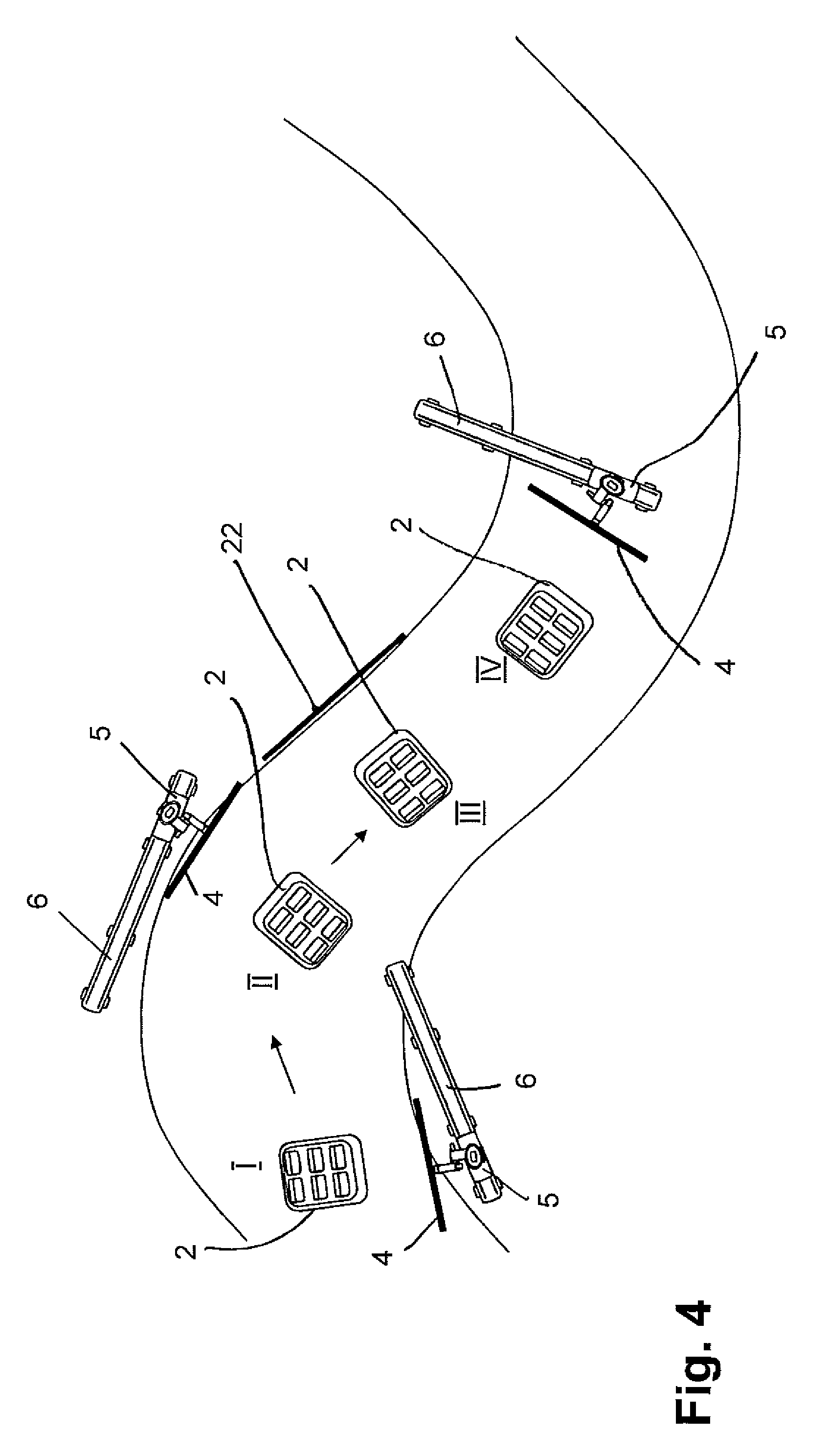

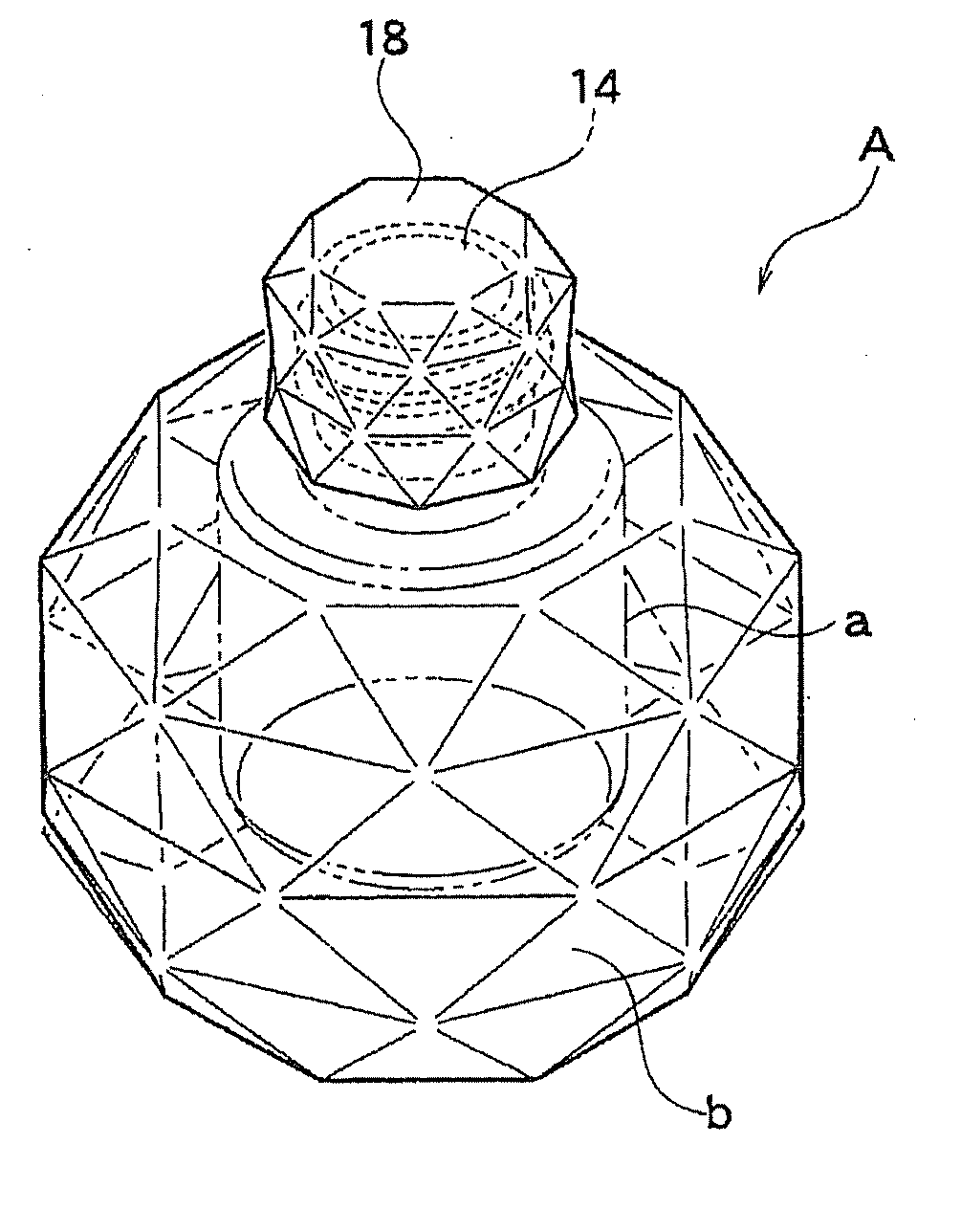

Marking element for marking timber, especially tree trunks

A marking element is proposed for marking timber, especially tree trunks, having a tag-like marking element (9) with at least one fastening element (11, 12) disposed on it for fastening the marking element (10) to the timber to be marked. To provide the marking, the marking element furthermore has a transponder (14) incorporating a data storage for the wireless transmission of data. This permits the wireless storing and reading of a multitude of data without requiring visual contact.

Owner:LATSCHBACHER

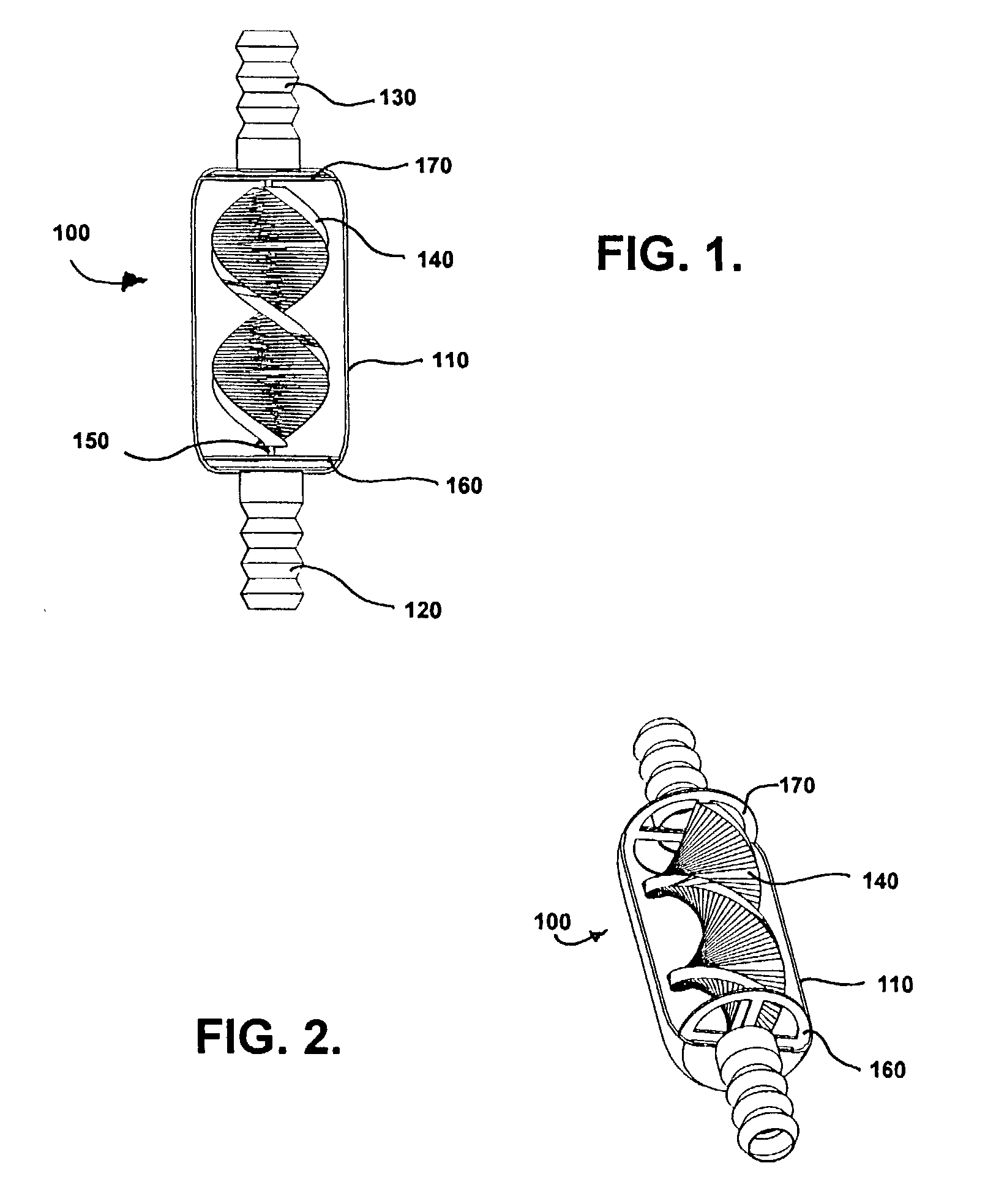

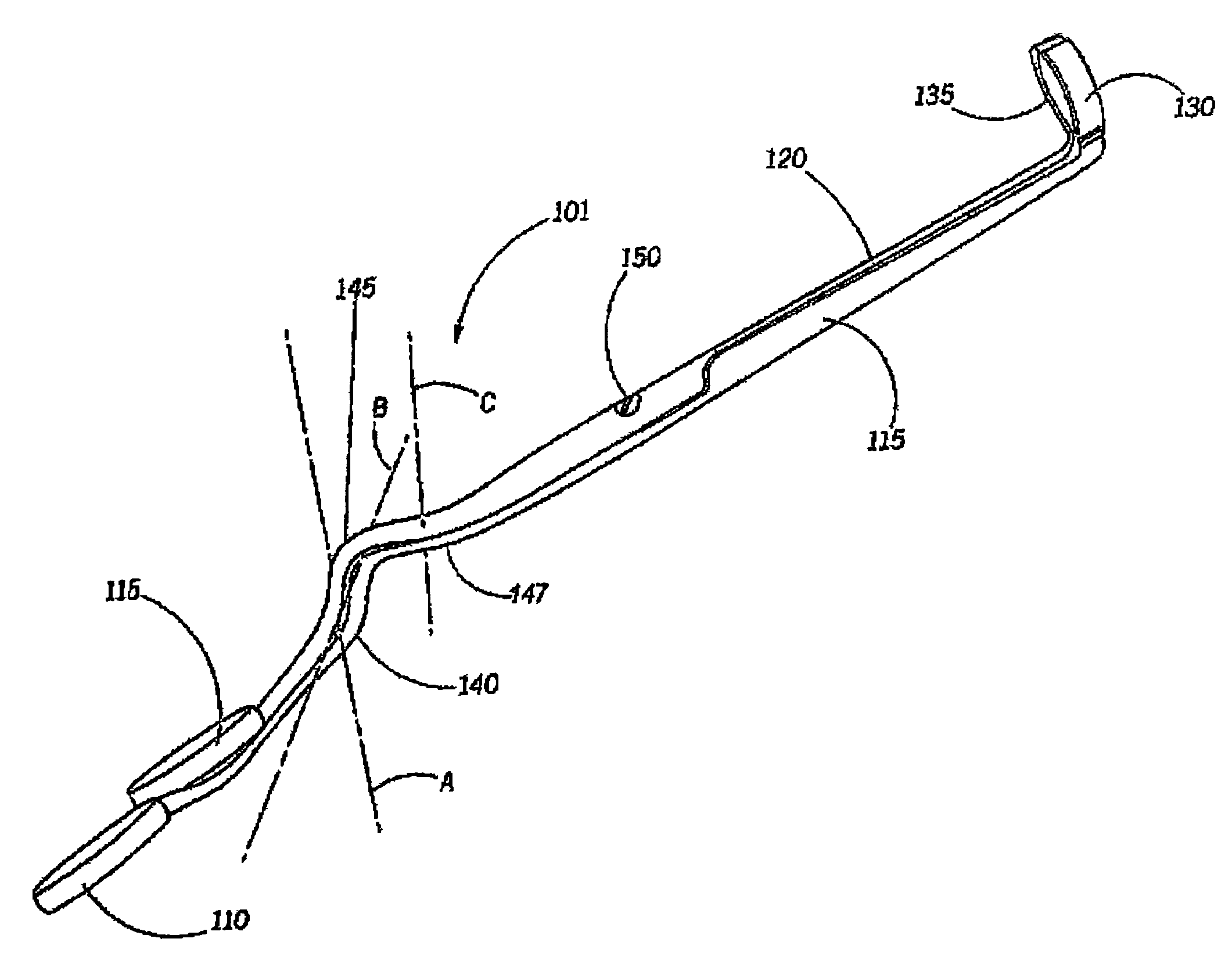

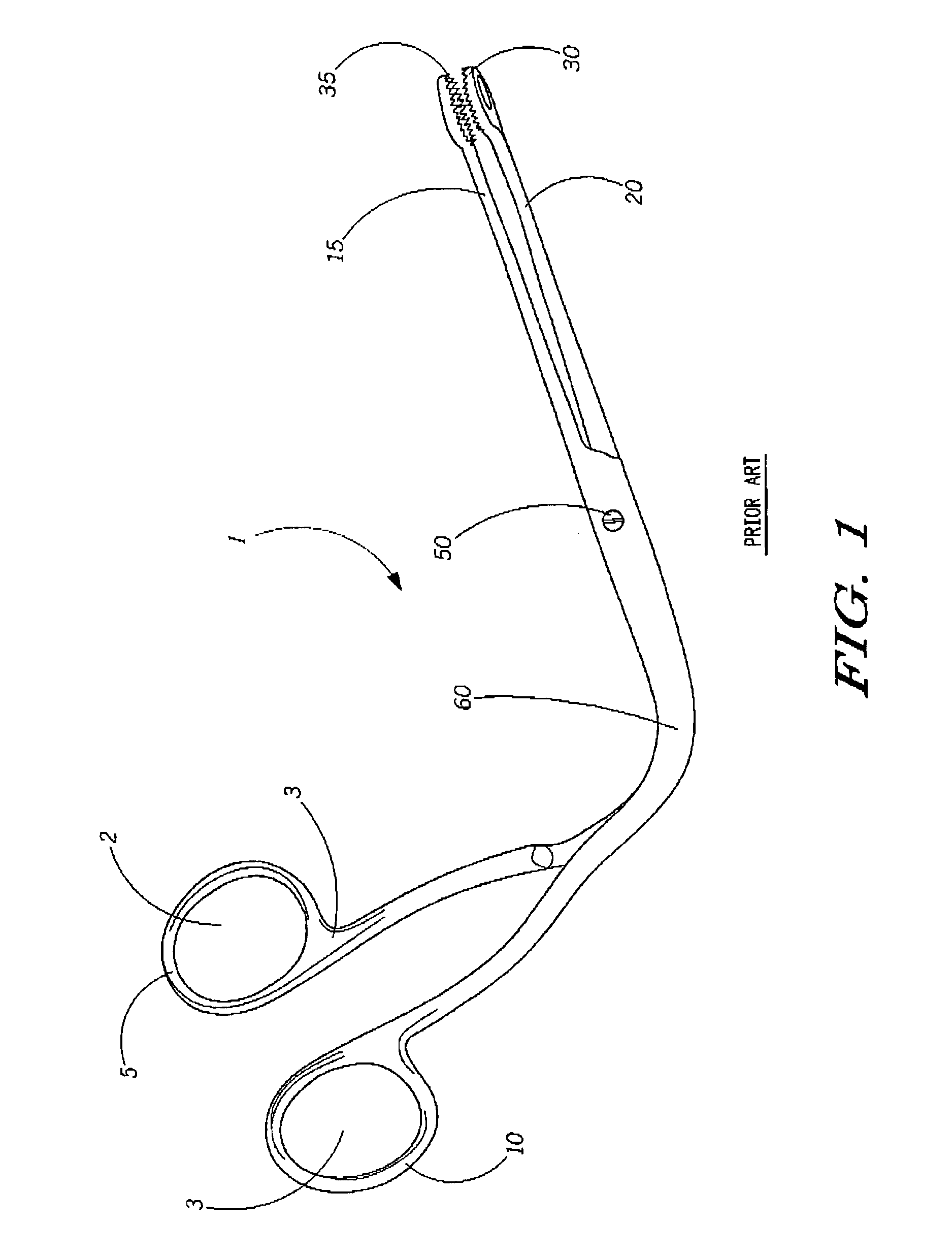

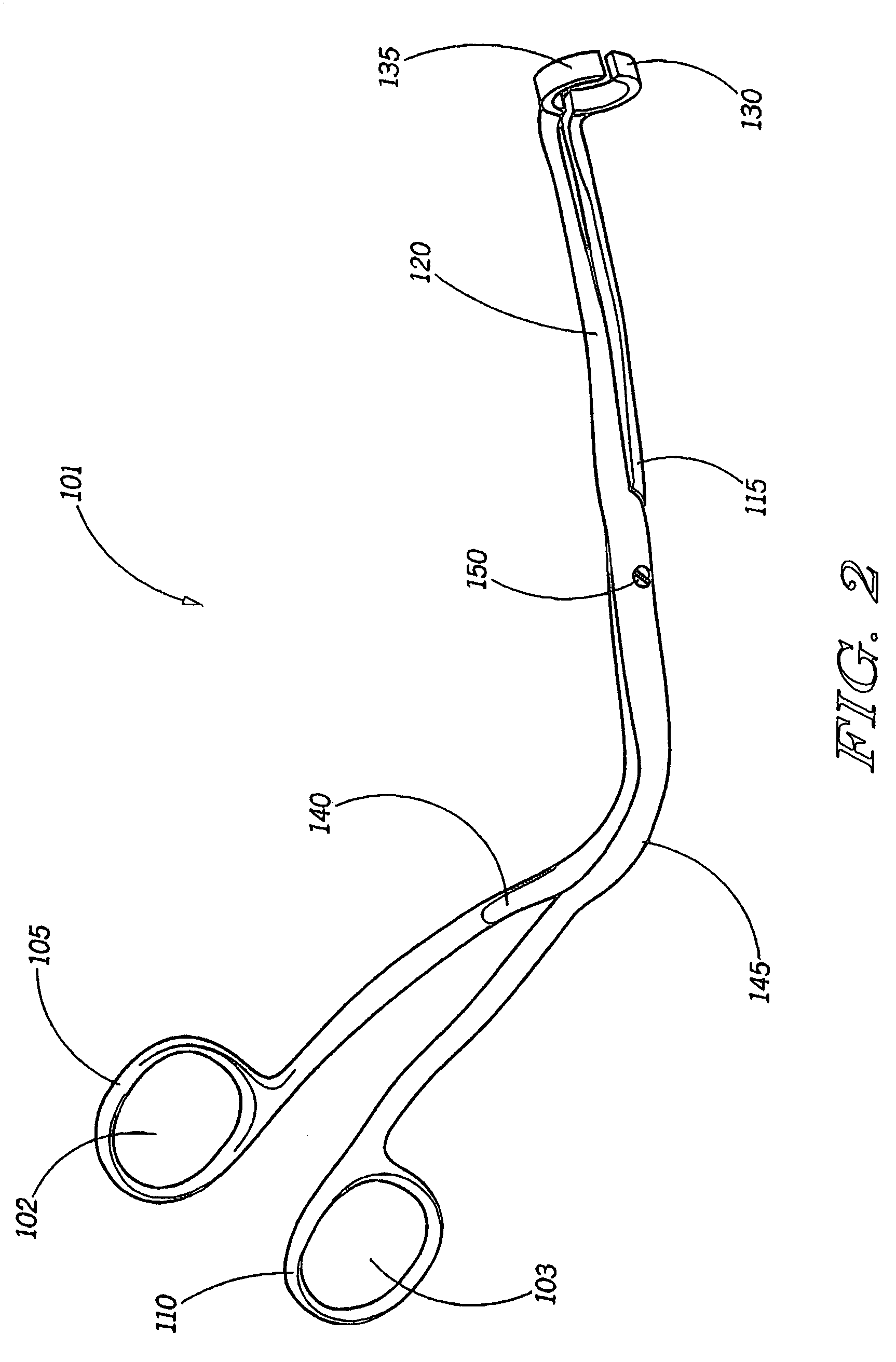

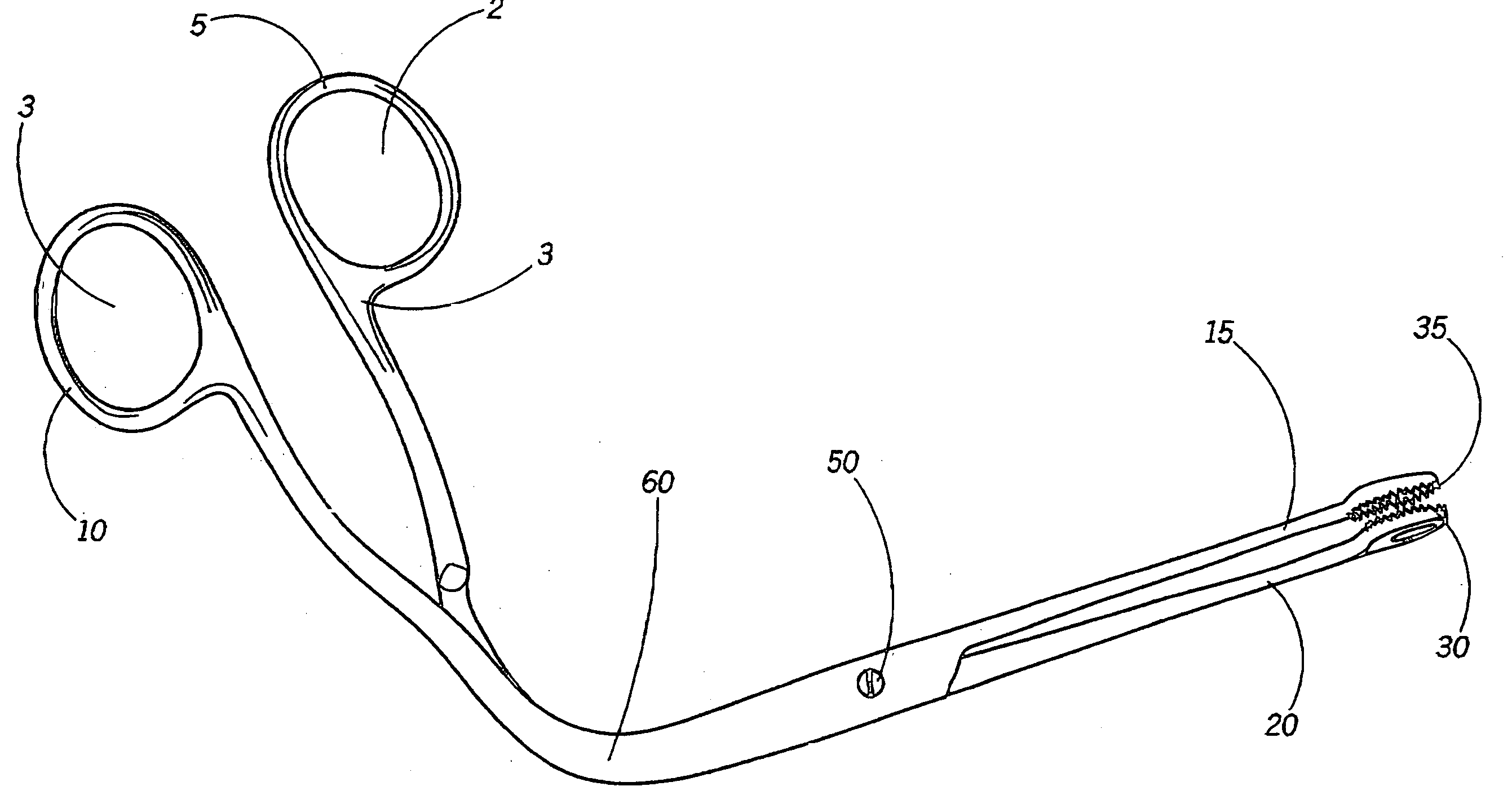

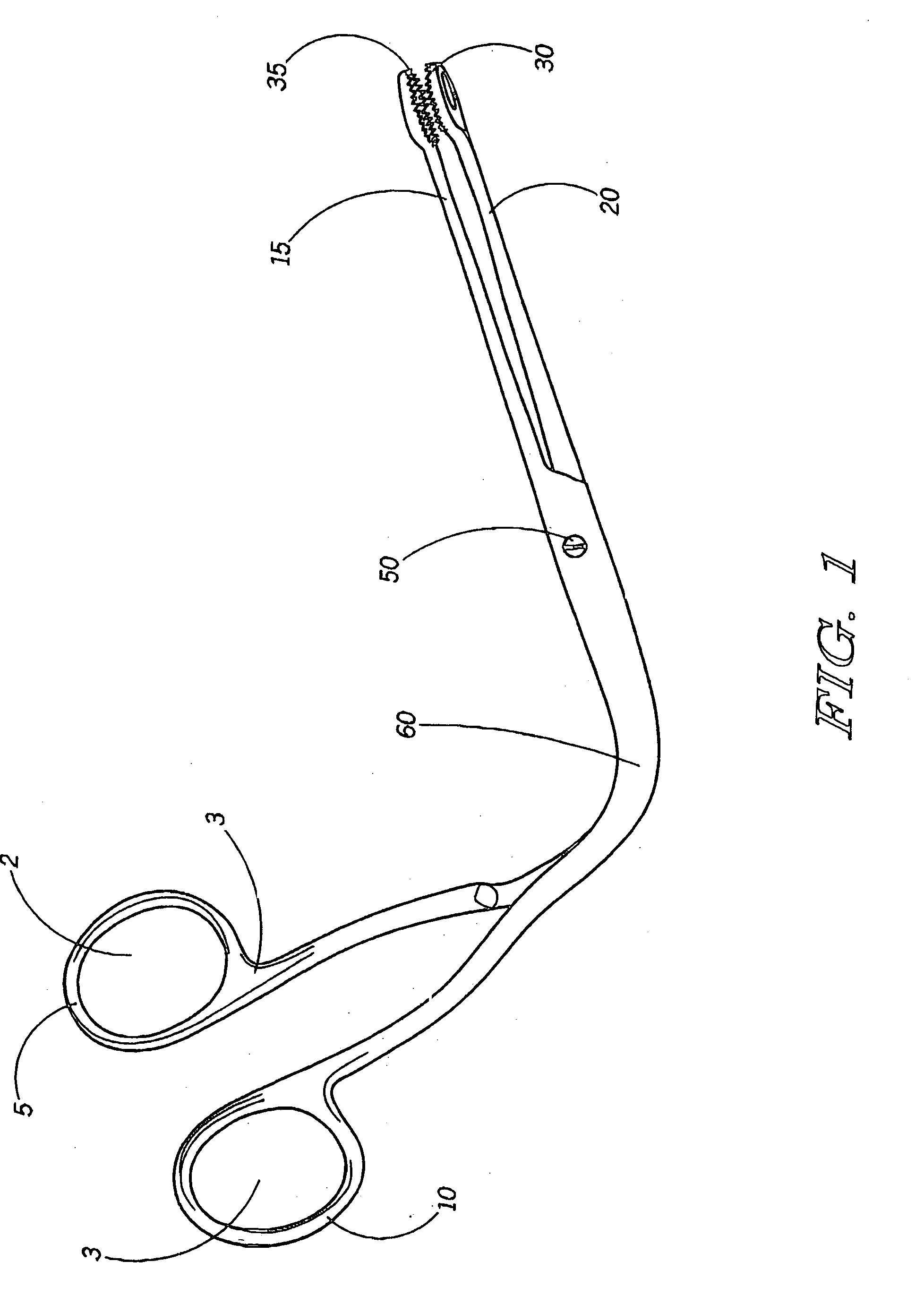

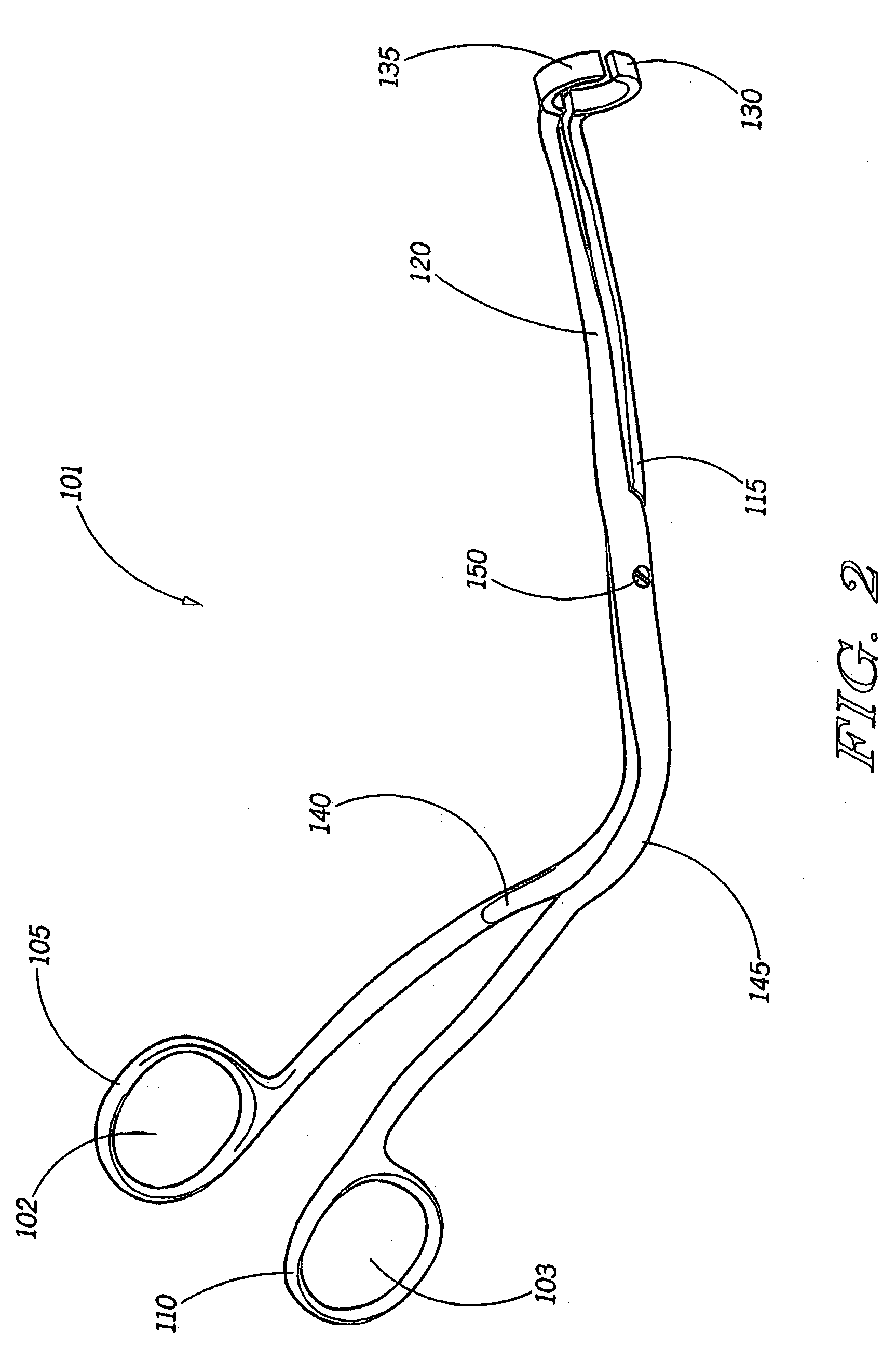

Anesthesia intubating forceps

ActiveUS7438717B2Eliminate the risk of injuryIncrease contactRespiratorsEar treatmentForcepsGuide tube

Forceps with a pair of scissor-like arms that are pivotally connected to each other and that continue past the pivot to form a catheter guide. At least two and preferably three bends are disposed in the arms immediately before the pivot, which allow the medical professional to place the guiding end of the forceps in the correct place while maintaining good visual contact with the patient's vocal cords. An alternative embodiment provides a fourth bend near the guiding end of the forceps that allows for easier insertion of a catheter in some patients, such as children.

Owner:RODINIA

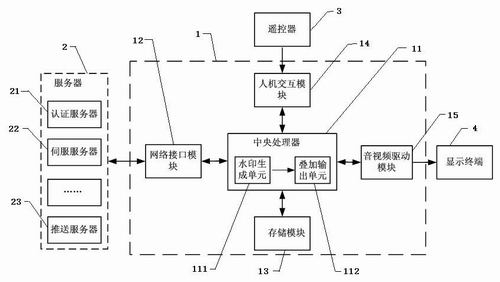

Video output device capable of tracking propagating sources

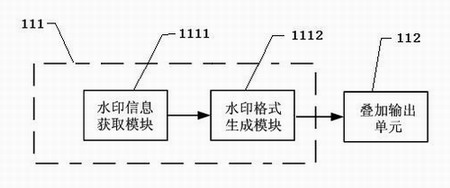

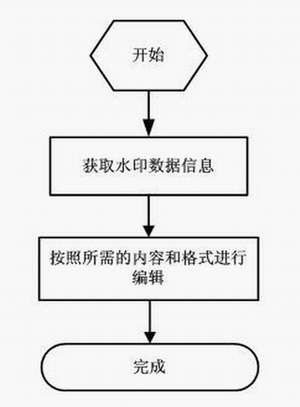

InactiveCN101917611APrecise positioningDoes not affect normal playbackTelevision system detailsPulse modulation television signal transmissionData informationComputer module

The invention discloses a video output device capable of tracking propagating sources, comprising a central processing unit, a network interface module, a memory module, a man-machine interaction module and an audio / video drive module which are respectively connected with the central processing unit, wherein, the central processing unit is provided with a watermark generation unit and a superposition output unit; the watermark generation unit is used for generating watermark data information; and the superposition output unit is used for outputting the watermark data information and video information generated by the watermark generation unit. The video output device capable of tracking the propagating sources of the invention is provided with the watermark generation unit and the superposition output unit, leads that the video information output by the video output device can display or hidden with watermark information when a display terminal plays a video, and extracts watermark information in visual contact or a watermark detection device according to hardware information and user information in the watermark information, thereby positioning the propagating sources thereof, tracking related responsibilities thereof, and maintaining the lawful rights and interests of operators and content providers.

Owner:北京德博正业科技有限公司

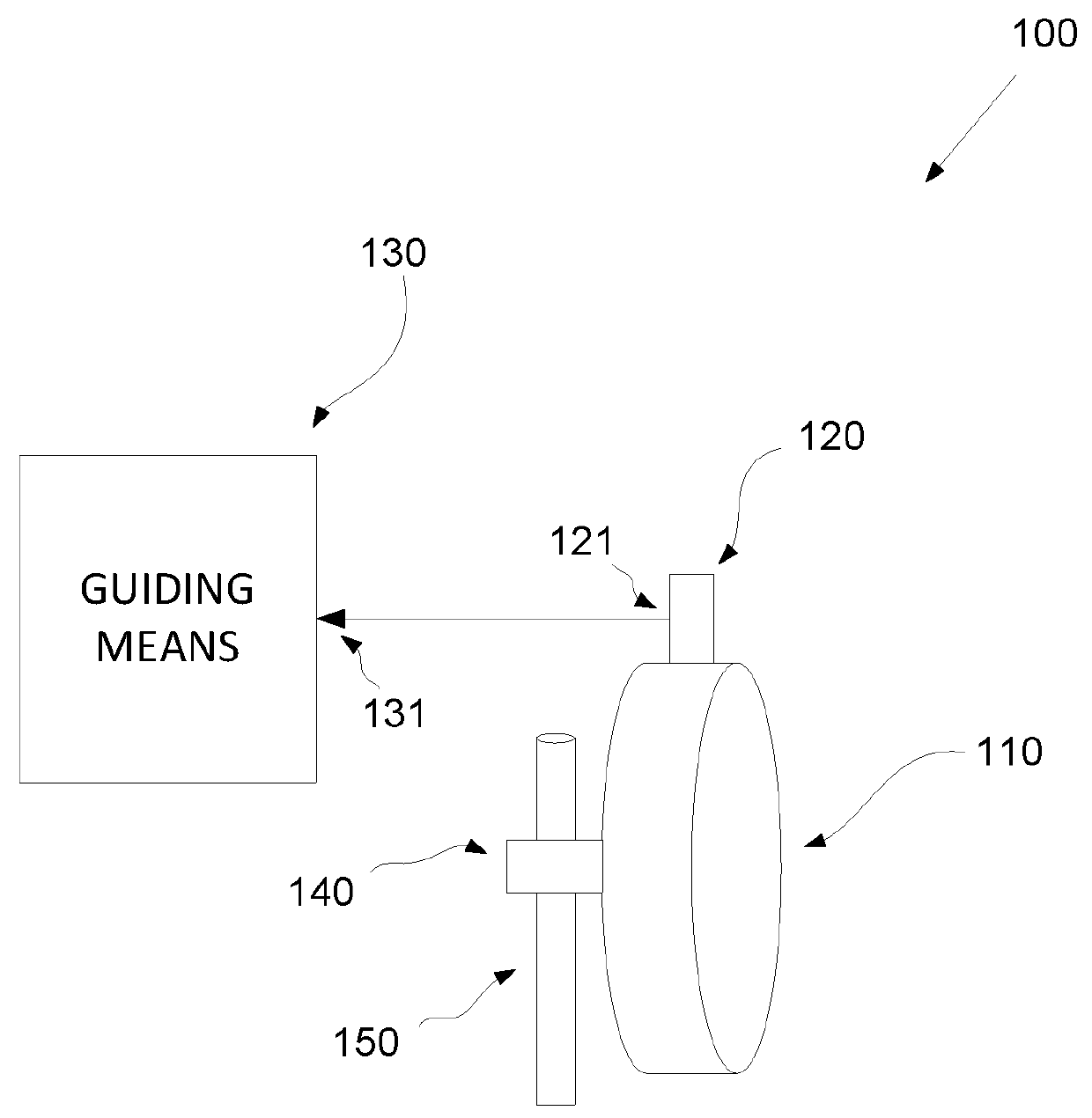

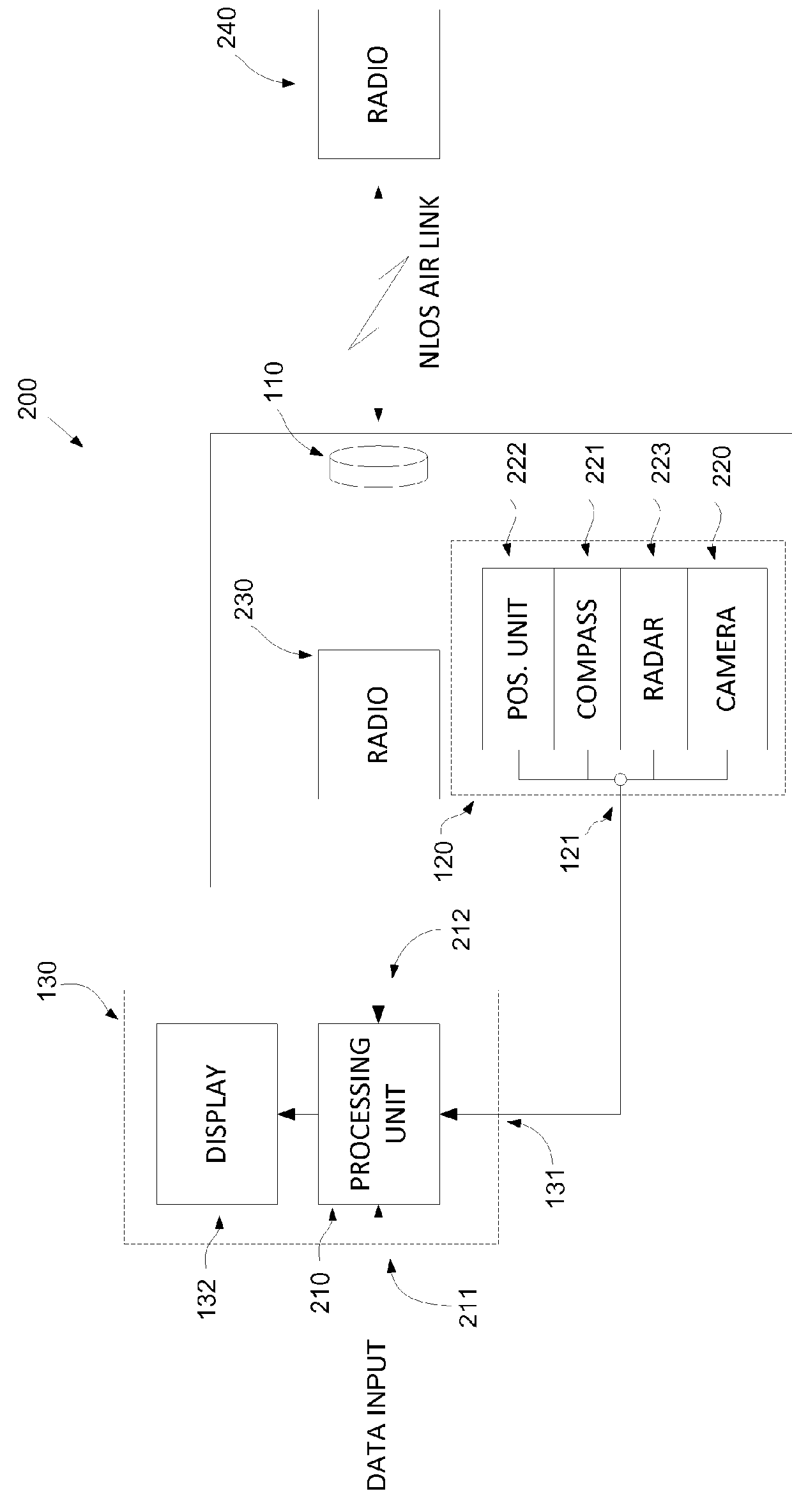

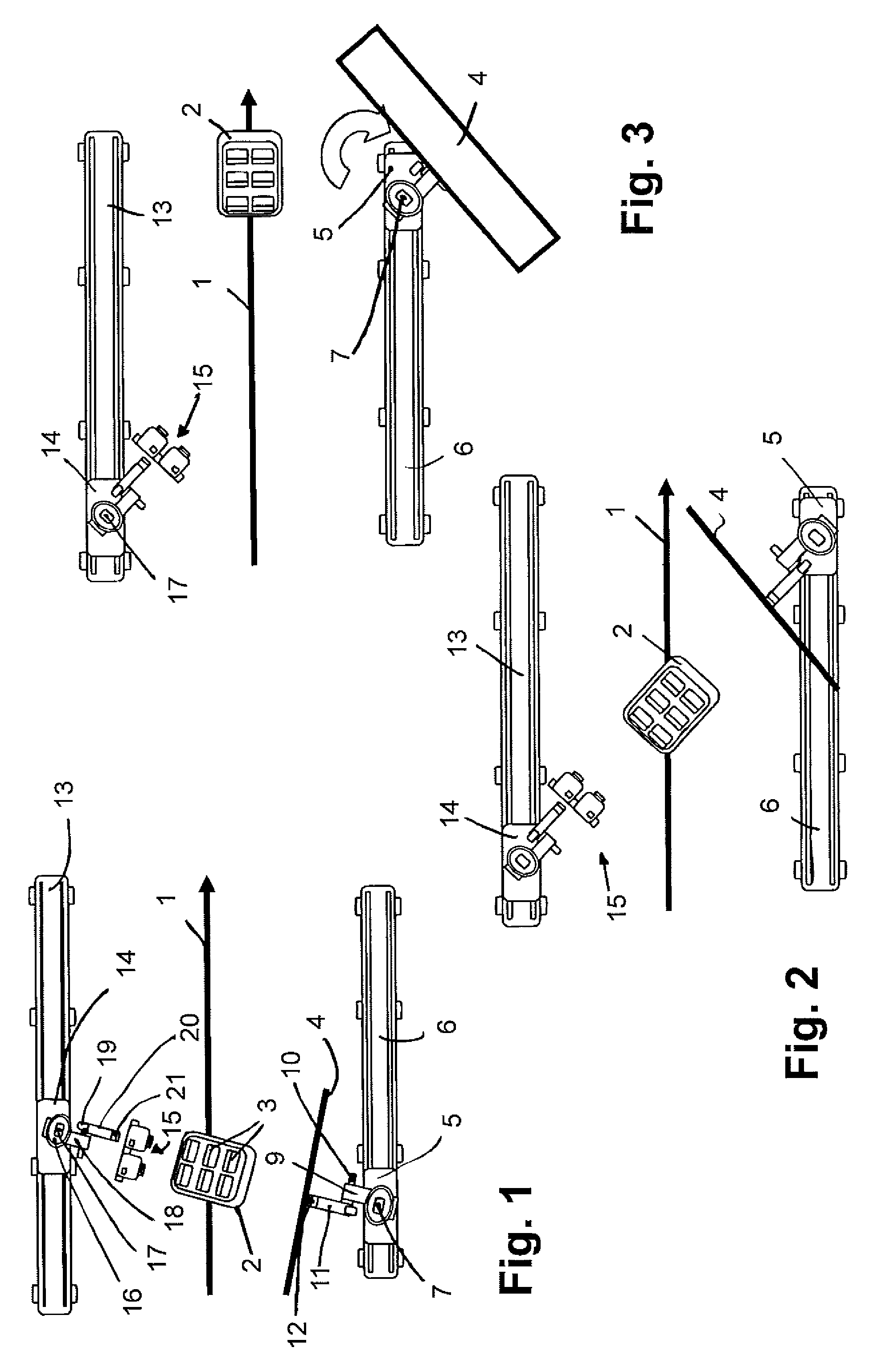

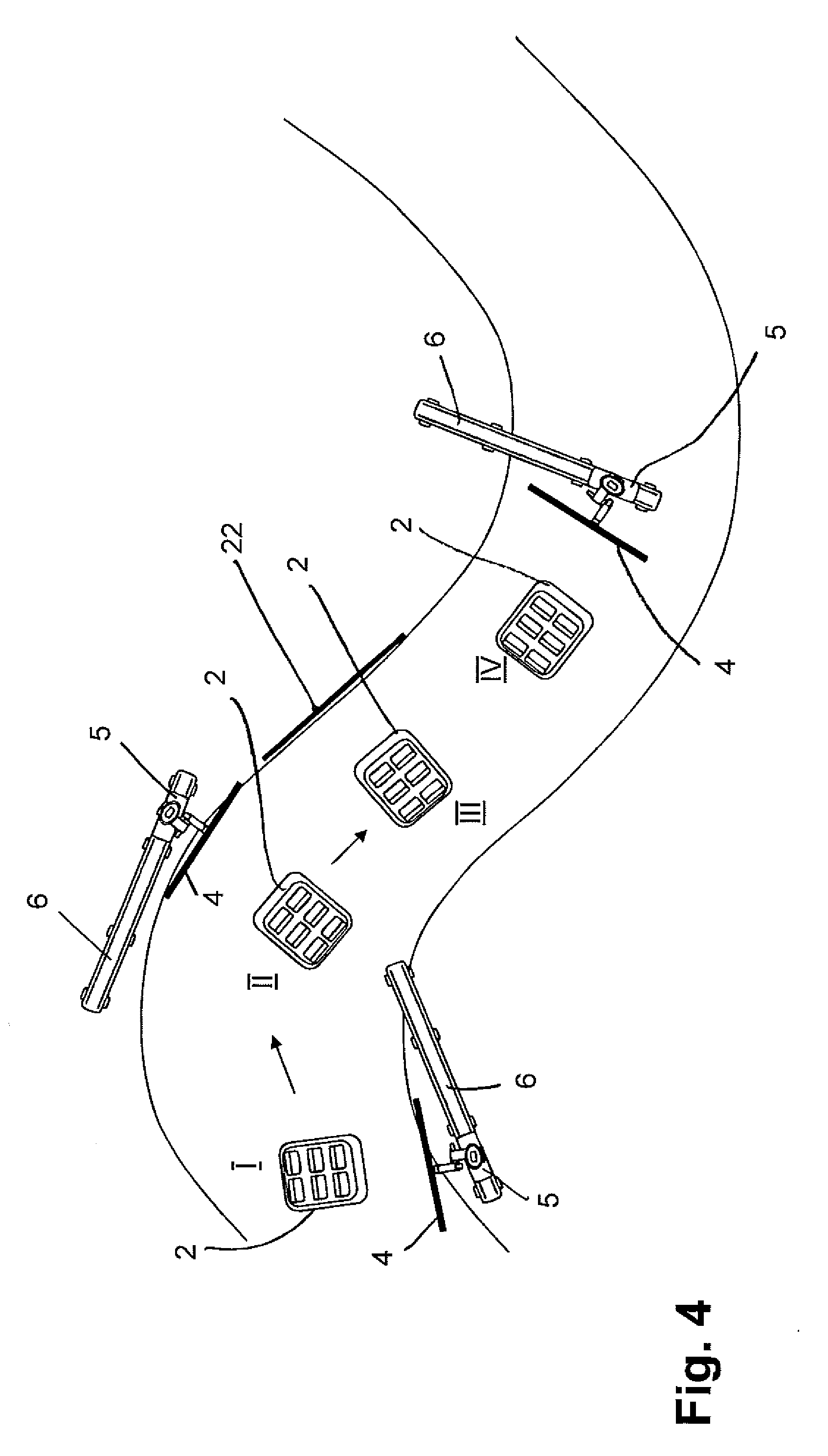

A Radio Antenna Alignment Tool

InactiveUS20160056525A1Quickly and cost-effectivelyEasy alignmentTransmitters monitoringAntenna supports/mountingsSignal qualityDirectional antenna

A radio antenna alignment tool (100) for aligning a first antenna with respect to at least a second antenna is disclosed. The tool comprises a sensor unit (120) disposed in connection to the first antenna (110) comprising means to determine a present direction of the first antenna (110). The radio antenna alignment tool (100) further comprises guiding means (130) adapted to receive, on a first input port, the present direction of the first directive antenna (110) from the sensor unit (120). The guiding means (130) is further arranged to indicate to a user at least one of: the present direction of the first directive antenna (110), the location of the second antenna, and a preferred direction of the first directive antenna, where said preferred direction of the first directive antenna is determined in order to maximize a signal quality metric for communication between the first directive antenna and at least the second antenna. The tool facilitates the alignment of the first directive radio antenna without the user having direct visual contact with the far end antenna.

Owner:TELEFON AB LM ERICSSON (PUBL)

Anesthesia intubating forceps

ActiveUS20060030880A1Good visual contactEliminate the risk of injuryRespiratorsEar treatmentForcepsMedical treatment

Forceps with a pair of scissor-like arms that are pivotally connected to each other and that continue past the pivot to form a catheter guide. At least two and preferably three bends are disposed in the arms immediately before the pivot, which allow the medical professional to place the guiding end of the forceps in the correct place while maintaining good visual contact with the patient's vocal cords. An alternative embodiment provides a fourth bend near the guiding end of the forceps that allows for easier insertion of a catheter in some patients, such as children.

Owner:RODINIA

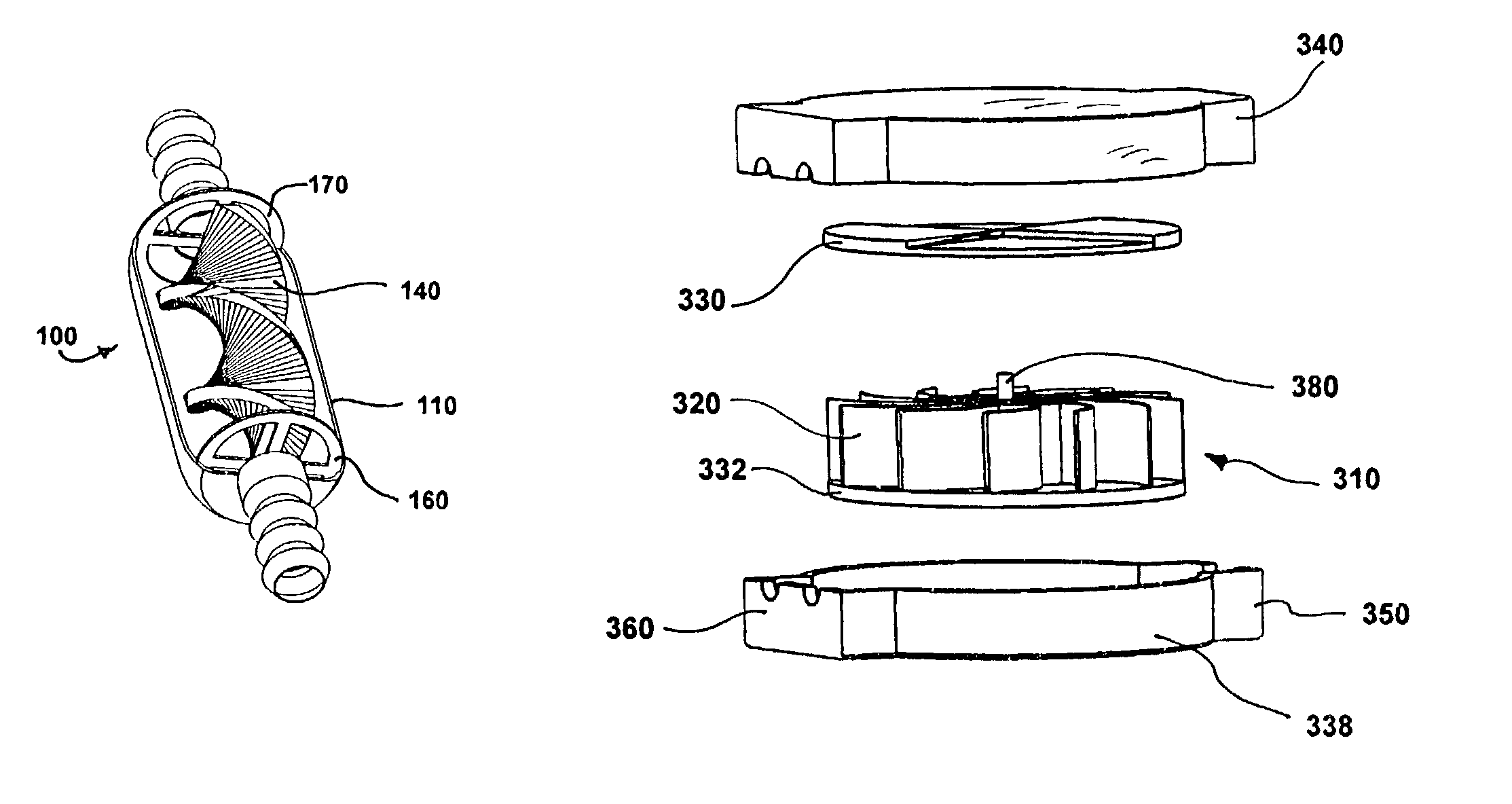

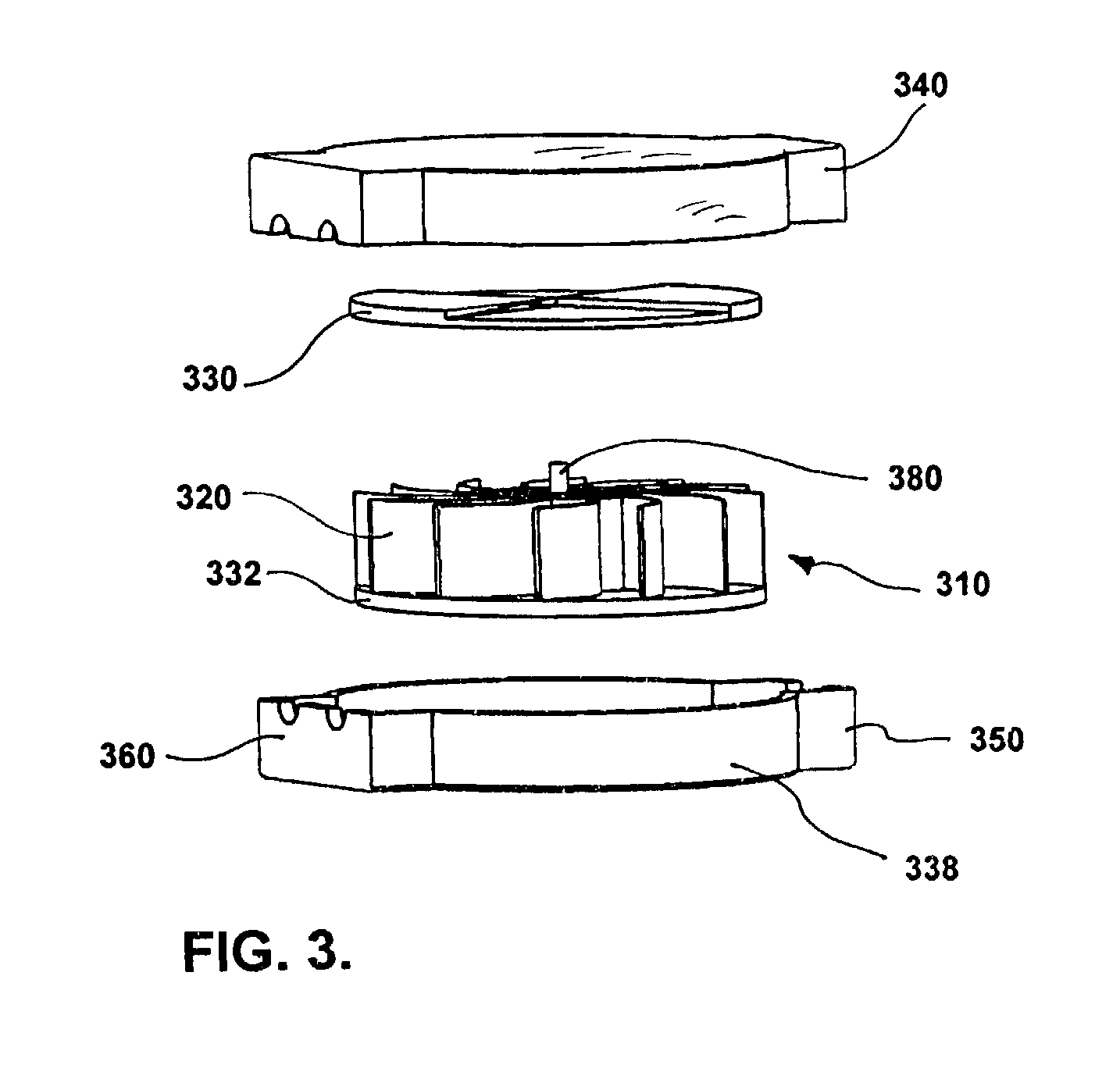

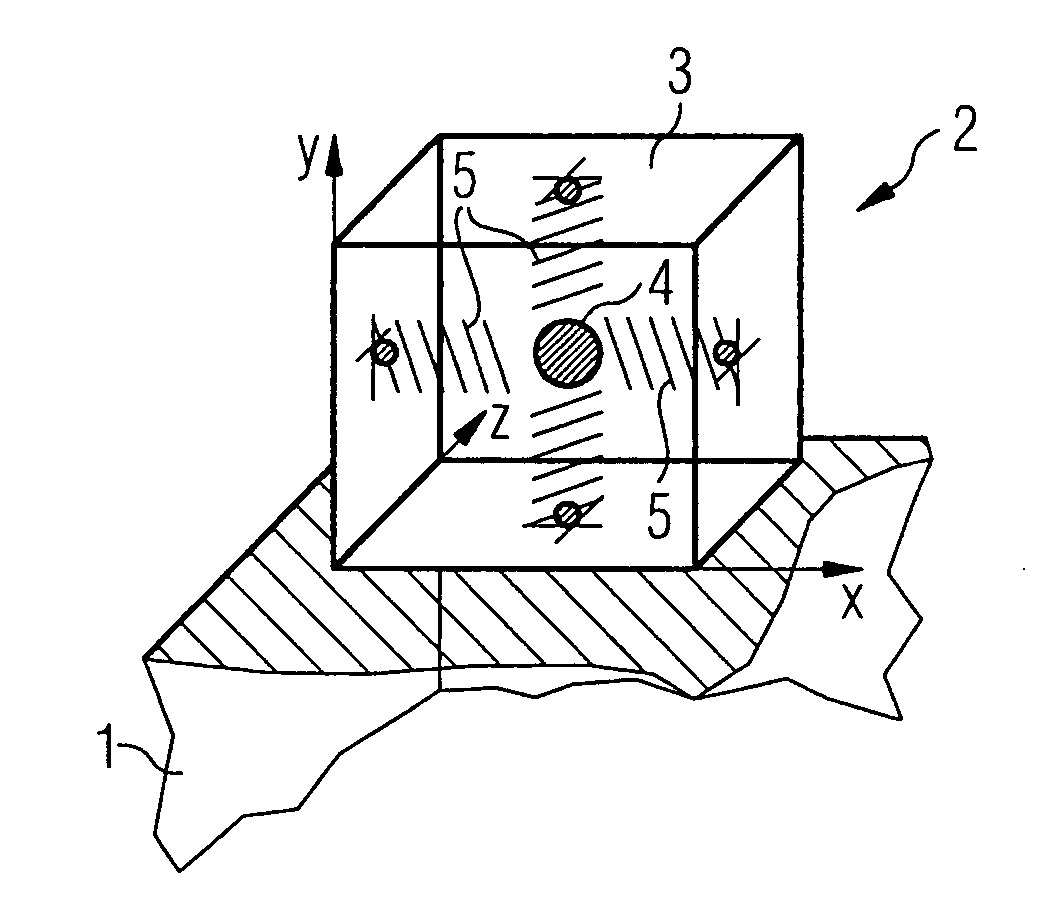

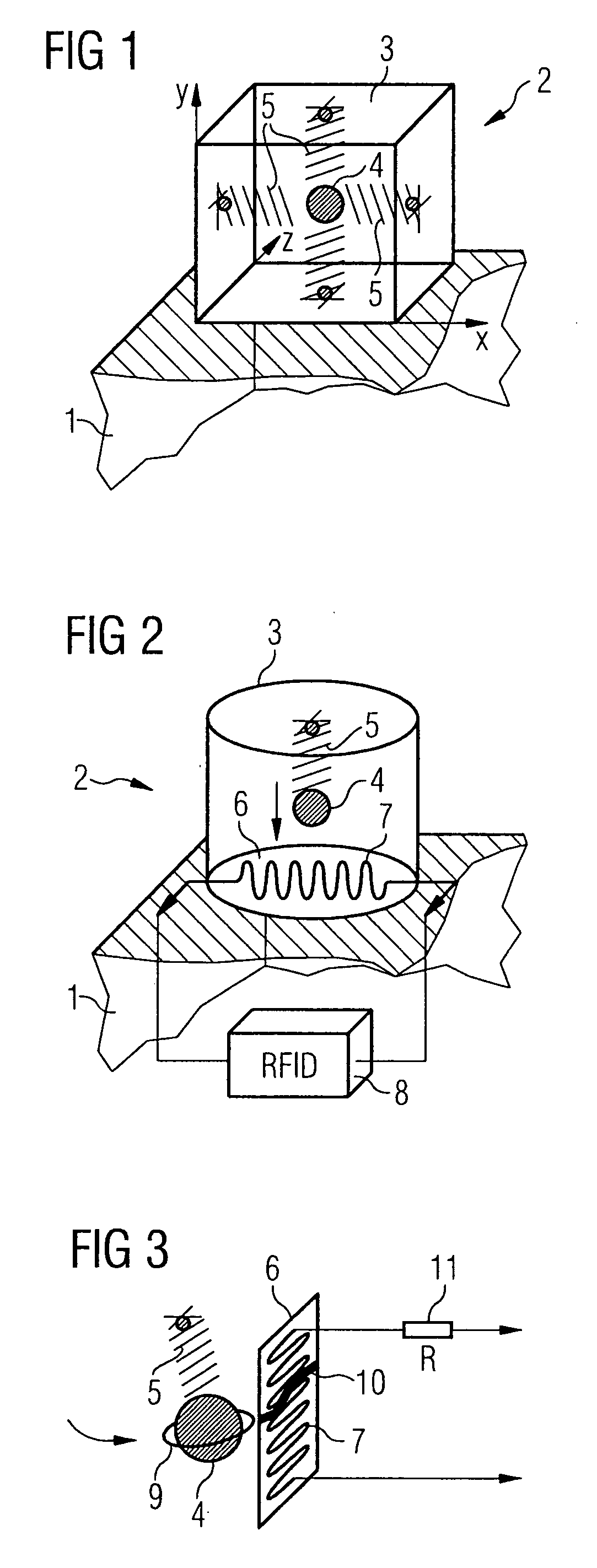

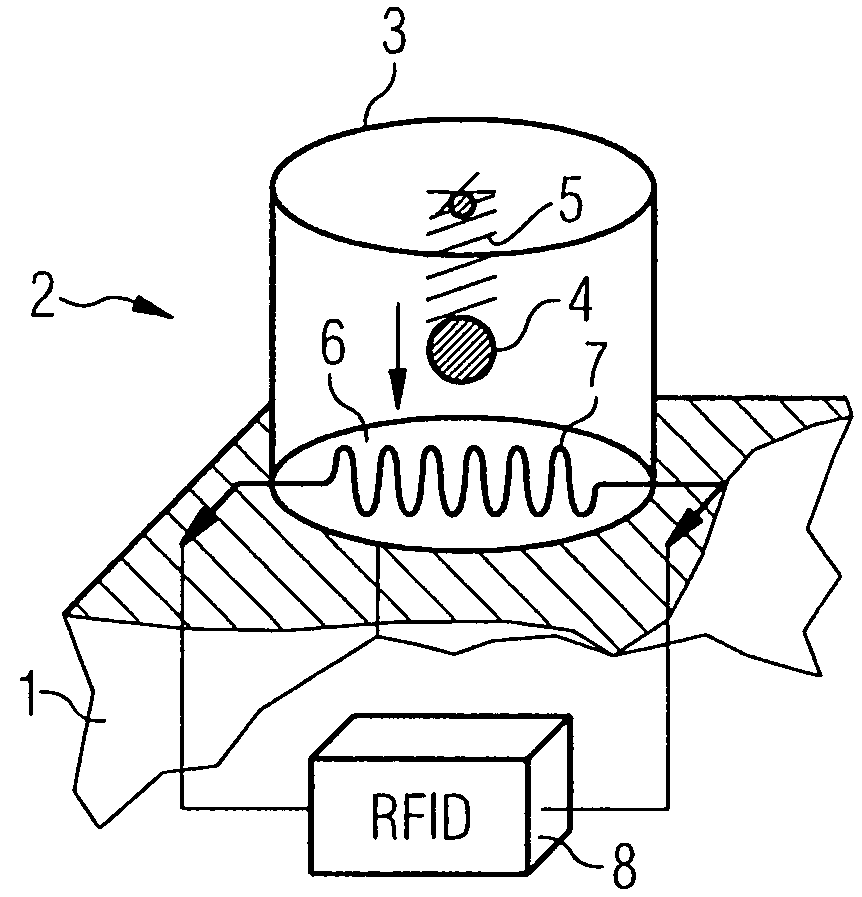

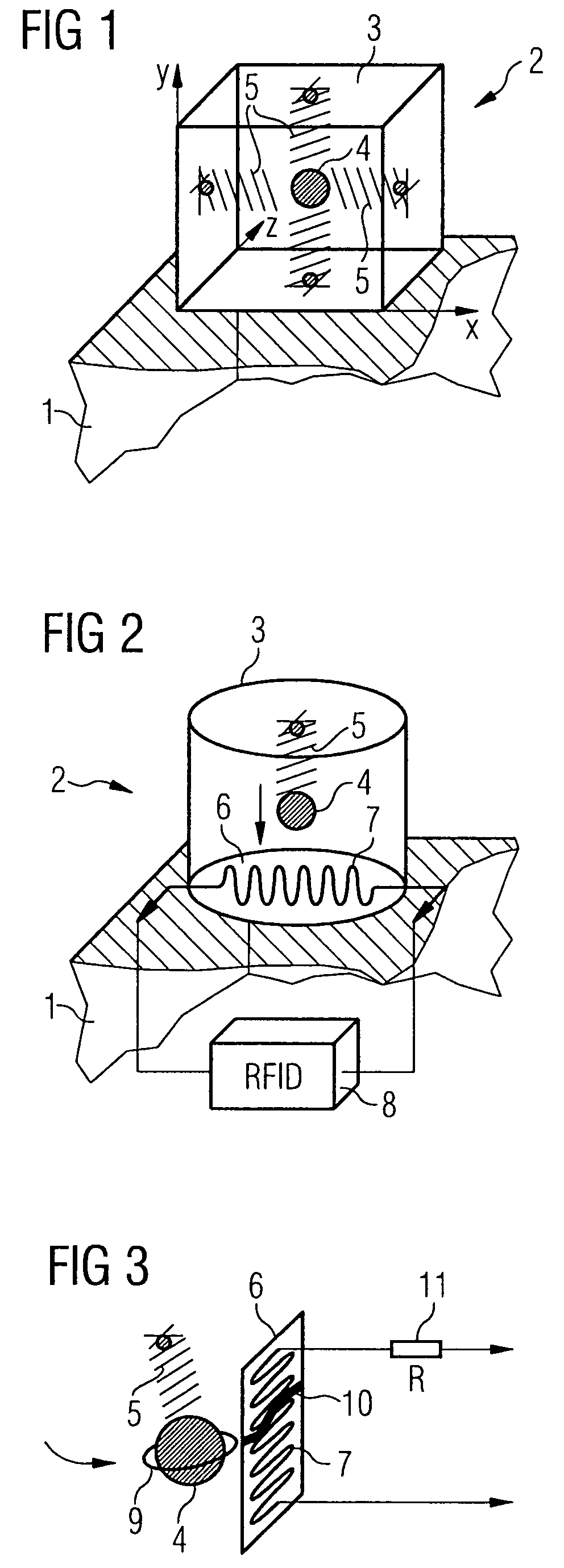

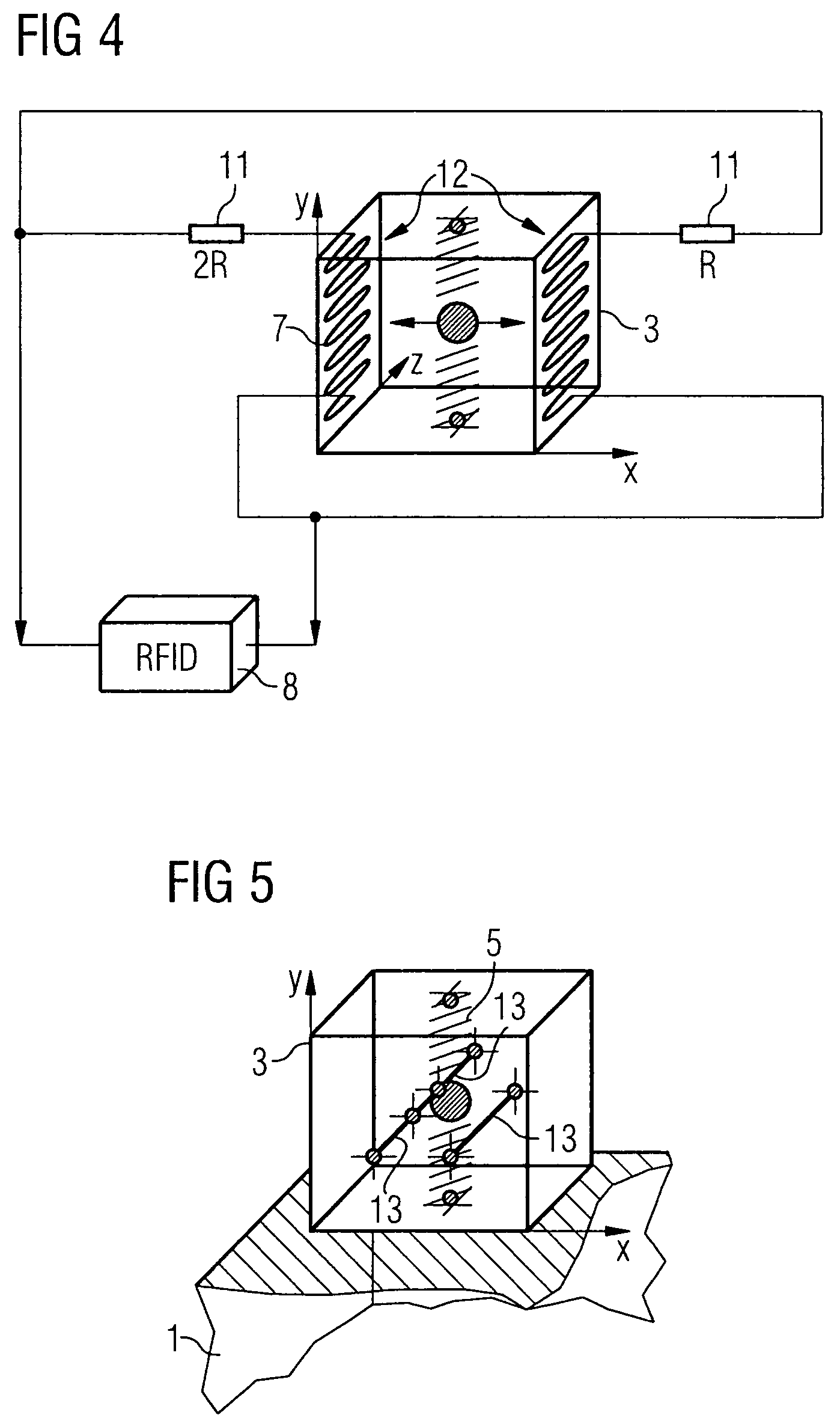

Non-contact shock sensor

InactiveUS20080307884A1Acceleration measurement using interia forcesLinear/angular speed measurementTransceiverCoupling

The invention relates to a sensor device for monitoring accelerations to which an object is subjected. In order to detect whether a value has exceeded or is below a threshold for the acceleration to which objects have been subjected in the past, i.e. without having visual contact with the sensor, the inventive sensor device includes an acceleration sensor, which is permanently linked to the object to be monitored, so that a relative movement between the acceleration sensor and the object is prevented, and an RFID transceiver for non-contact coupling of electrical energy into the acceleration sensor and for sending out radio signals as a function of the physical state of the acceleration sensor.

Owner:SIEMENS HEALTHCARE GMBH

Carnival Ride

ActiveUS20090084285A1Realistic impressionLong-lasting contactSledgesProjectorsSimulationVisual perception

The carnival ride has a travel path for cars with seats and at least one screen arranged adjacent to the travel path. In order to design the carnival ride in such a way that the passengers in the car have an optimal gaming experience, the screen follows the car at least along a section of its travel distance. In this way, the passengers in the car have a very long-lasting visual contact with the screen or with the movie shown on the screen.

Owner:ROBOCOASTER

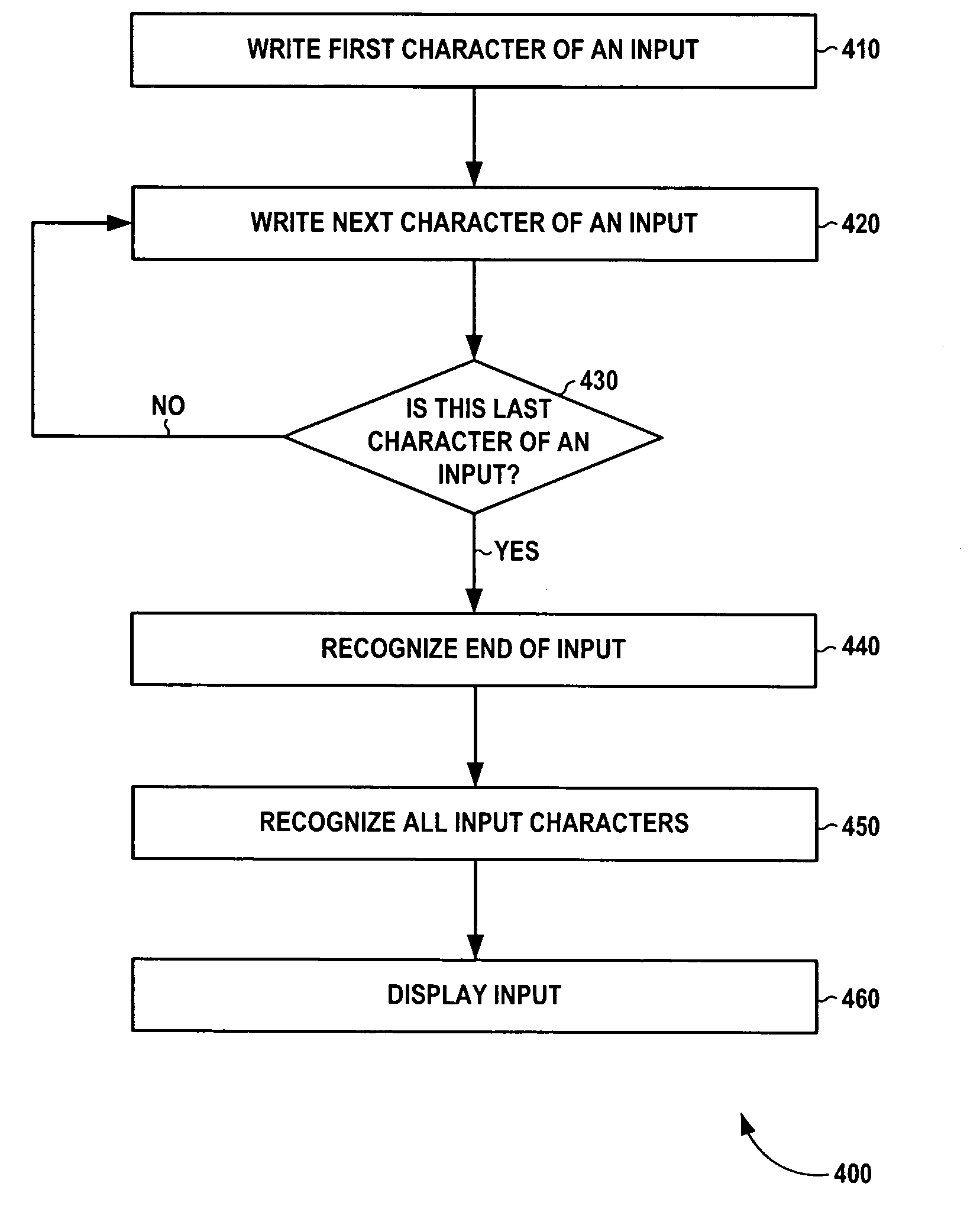

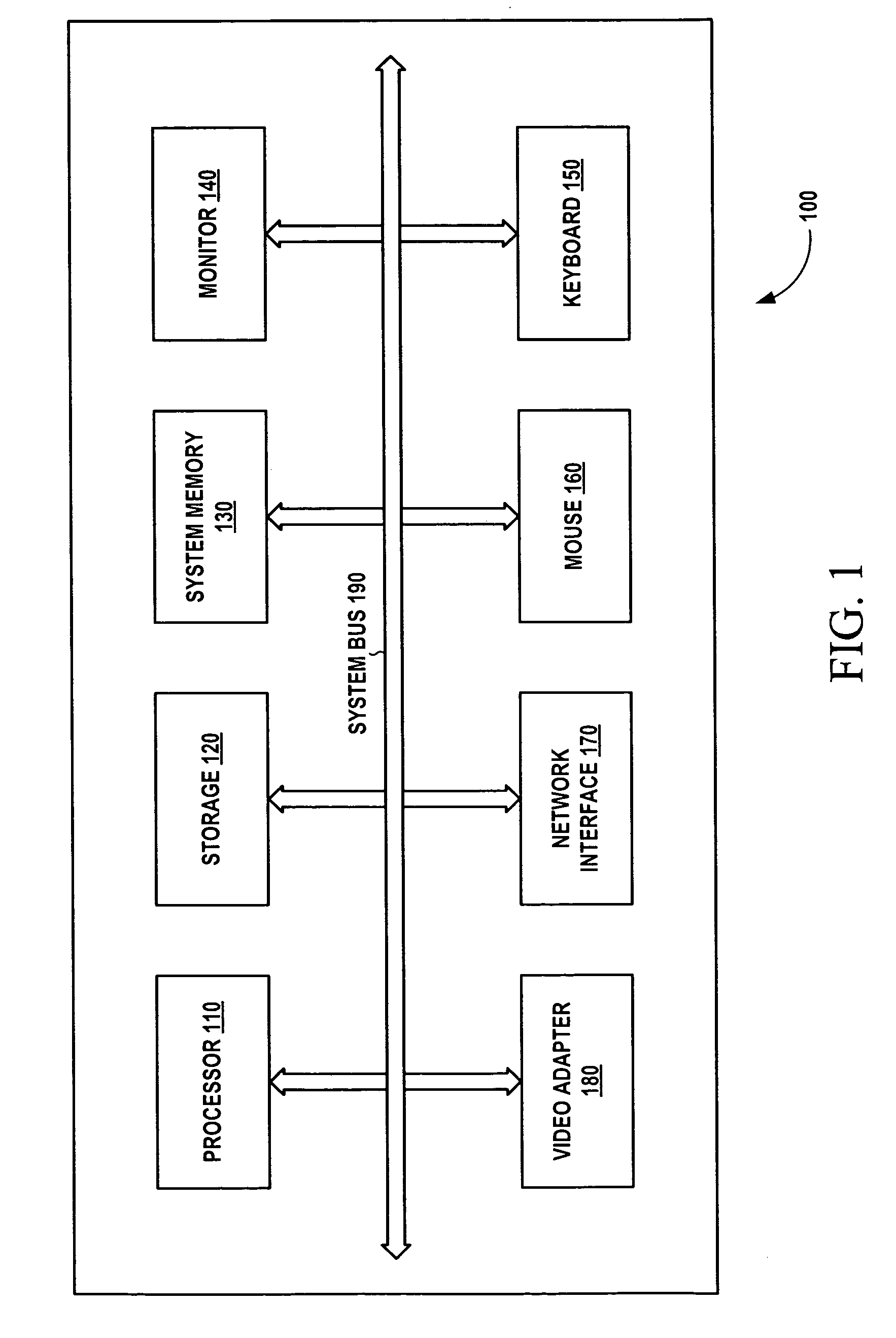

Method And System For Attention-Free User Input On A Computing Device

ActiveUS20080288896A1Digital ink recognitionInput/output processes for data processingUser inputHuman–computer interaction

A method and system for attention-free user input on a computing device is described that allows the recognition of a user input irrespective of the area of entry of the user input on a writing surface (such as a digitizer) without the user having to make a visual contact with the writing surface.

Owner:HEWLETT PACKARD DEV CO LP

Low visibility landing system and method

Examples of the present invention may include a low visibility landing system for guiding aircraft on landing approaches. The low visibility landing system may aid a pilot during landing in low visibility conditions such that an aircraft may descend to lower altitudes without visual contact with the runway than is possible with other landing systems. The system may use various navigational systems to produce a hybrid signal that may be more stable than individual signals of those navigational systems. The hybrid signal is compared to a predetermined landing approach plan to determine the deviation of the aircraft from the landing approach plan and to provide guidance to the pilot to get the aircraft back onto the landing approach plan.; The system may also use multiple navigational systems to perform checks on an operation of a primary navigational system to ensure that the primary navigational system is operating accurately.

Owner:GULFSTREAM AEROSPACE CORP

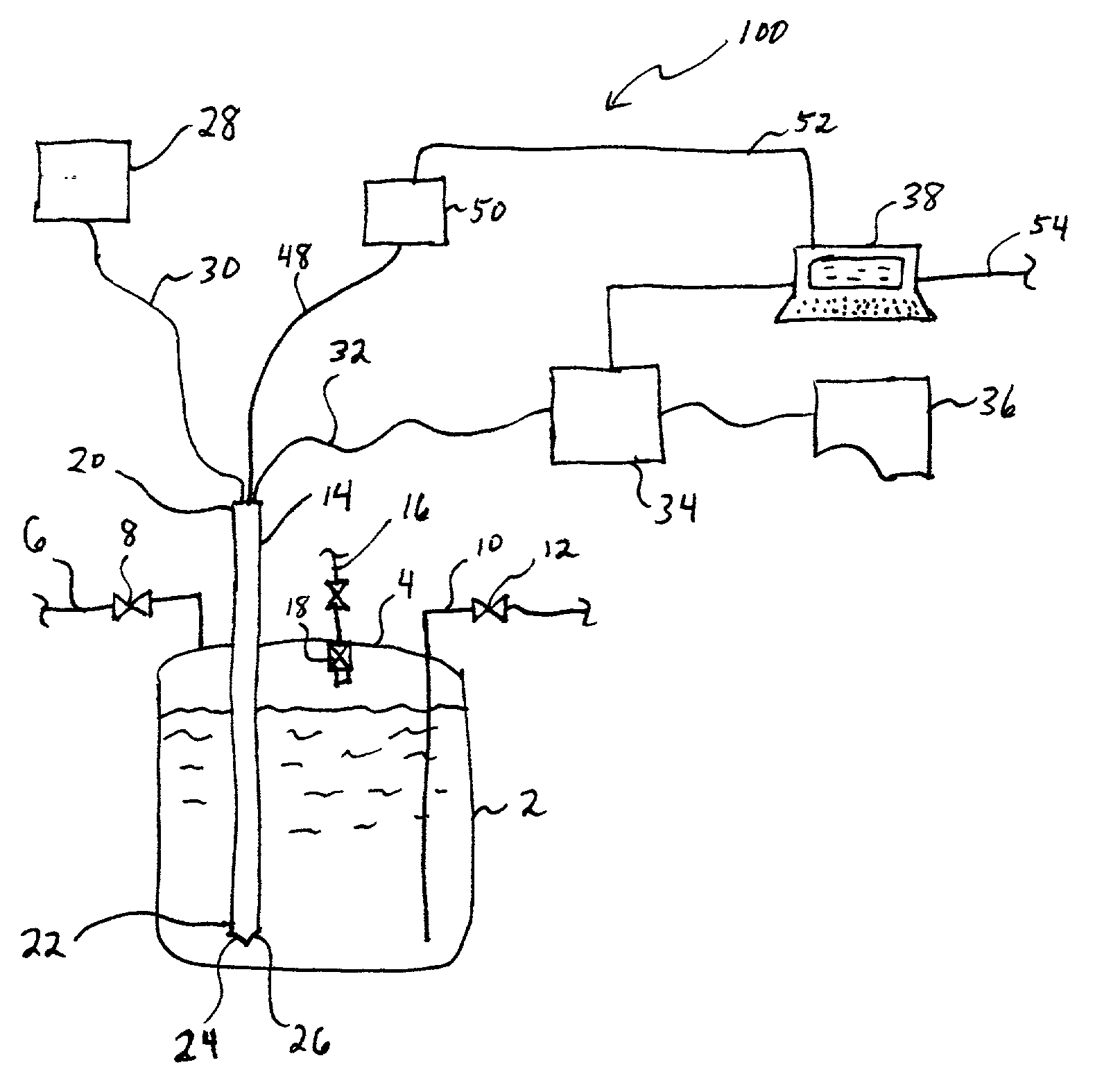

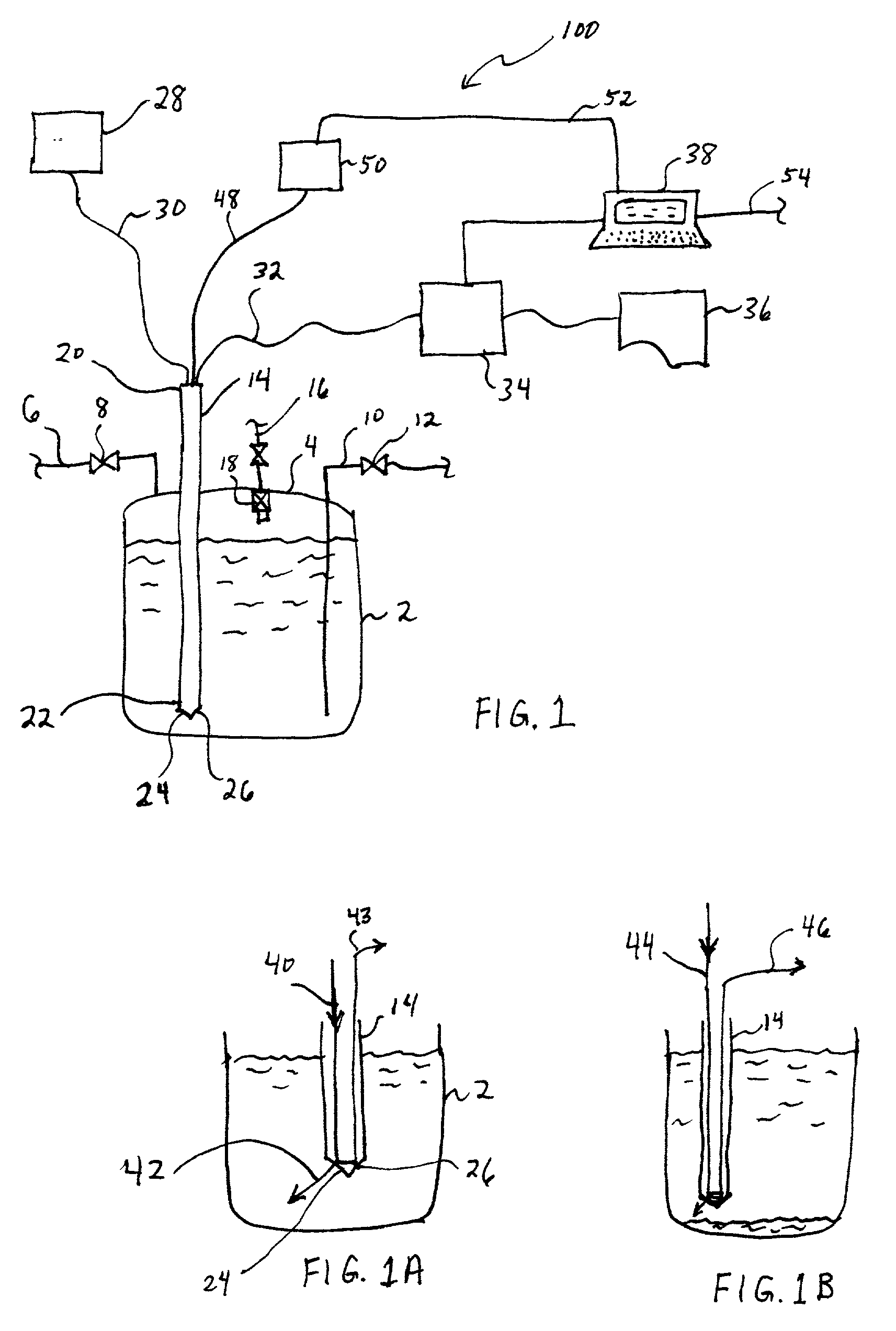

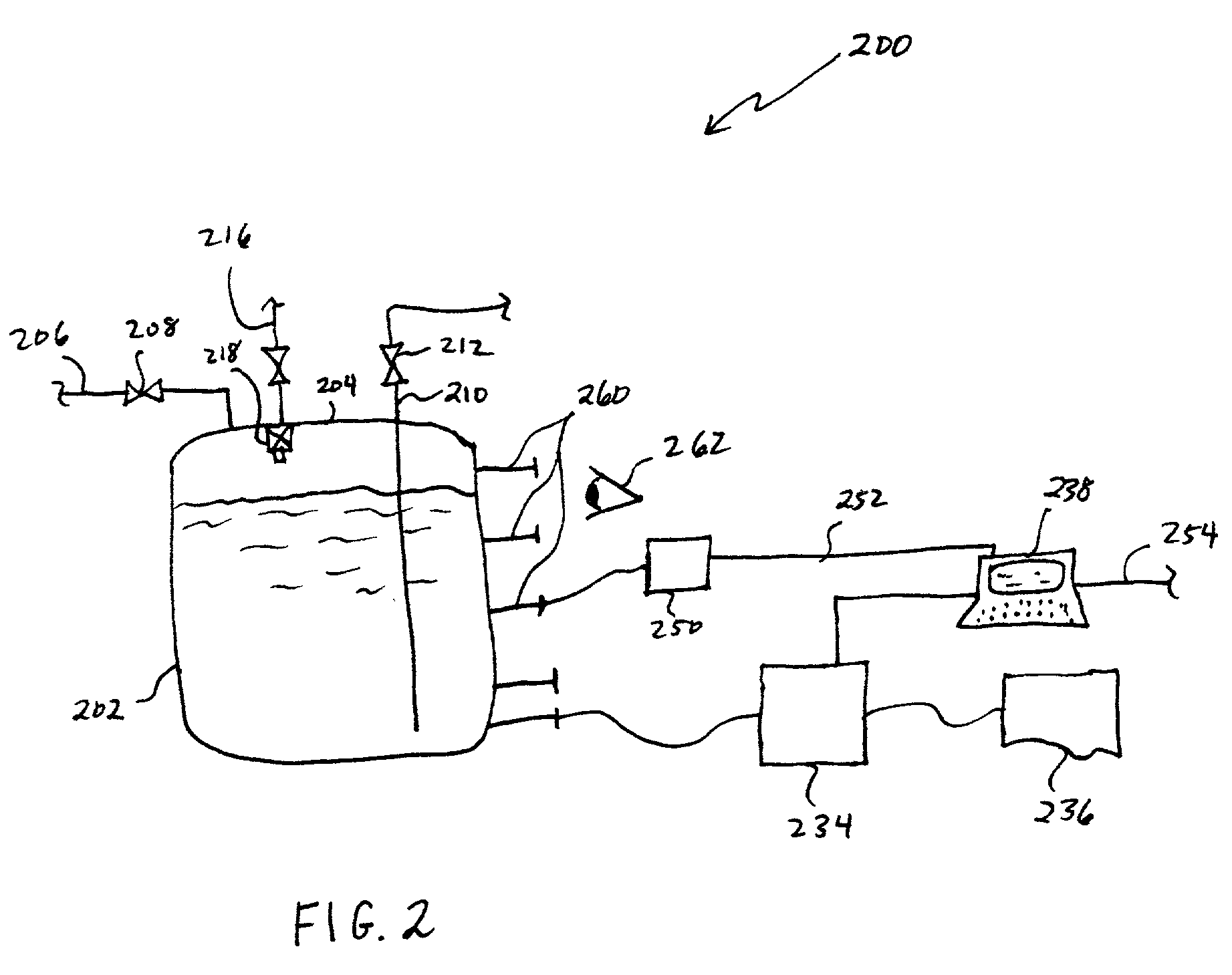

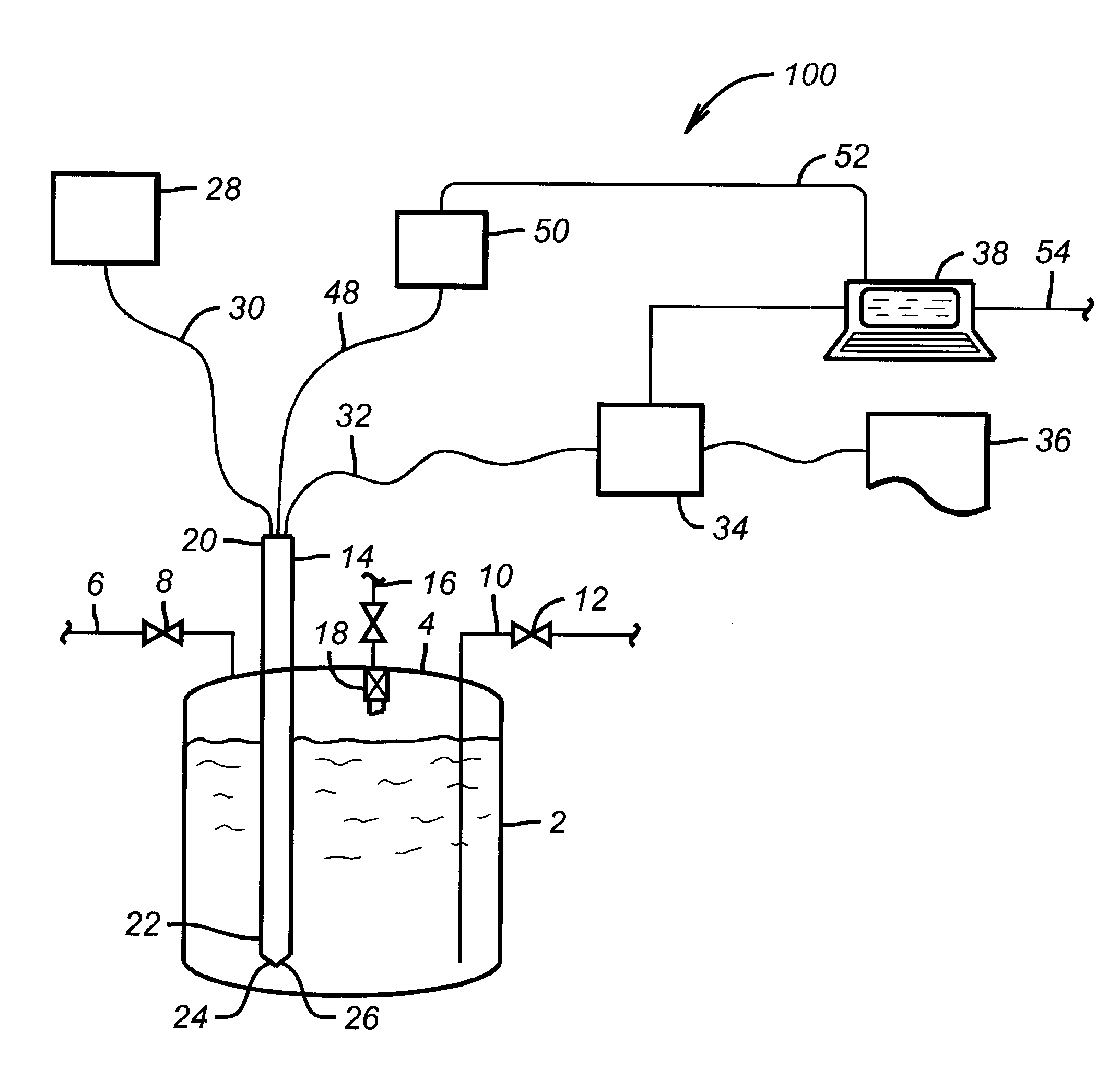

Optical monitoring processes and apparatus for combined liquid level sensing and quality control

InactiveUS20030010396A1Liquid fillingMaterial analysis by optical meansOptical propertyCompound (substance)

Methods and apparatus of measuring both concentration and amount of a liquid in a liquid chemical container are presented, one method comprising the steps of: (a) viewing light emanating from a first optical member that is in visual contact with the liquid, the light emanating from the optical member having a level indicating quality; and (b) routing light from a second optical member that is in visual contact with the liquid to means for optical discrimination between liquid chemical based on different optical properties.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Optical monitoring processes and apparatus for combined liquid level sensing and quality control

An apparatus of measuring both concentration and amount of a liquid in a liquid chemical container is presented, comprising viewing light emanating from a first optical member that is in visual contact with the liquid, the light emanating from the optical member having a level indicating quality; and routing light from a second optical member that is in visual contact with the liquid to means for optical discrimination between liquid chemical based on different optical properties.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

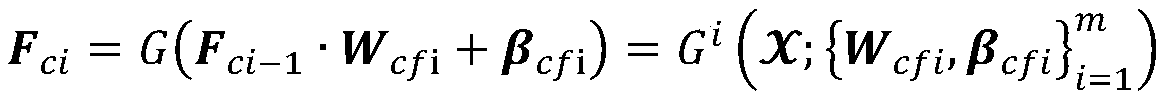

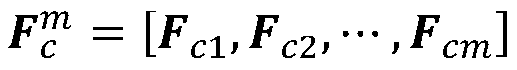

Outdoor mobile robot terrain recognition method based on visual contact fusion

InactiveCN110909637AImprove accuracyAchieving Fusion ReductionCharacter and pattern recognitionTouch PerceptionEngineering

The invention provides an outdoor mobile robot terrain recognition method based on visual touch fusion. The method comprises the steps that firstly, terrain types are selected according to different road surface materials; tactile and visual modal data are collected for different terrains, and a training set and a test set are divided; a cascade width learning network is constructed, and the network is trained by using the tactile training sample set and the visual training sample set; in the training process, tactile and visual preliminary feature extraction is firstly carried out, then tactile and visual fusion feature extraction is carried out, a fused tactile feature matrix and visual feature matrix are processed through a width learning classification algorithm, and a terrain recognition classification result is obtained through generalized inverse approximation of ridge regression to serve as output of a cascade width learning network; and finally, the test set is input into thetrained cascade width learning network to obtain a terrain recognition classification result. According to the method, visual tactile information is fused based on width learning, terrain recognitionof the mobile robot under small data can be achieved, and robustness and accuracy are high.

Owner:TSINGHUA UNIV

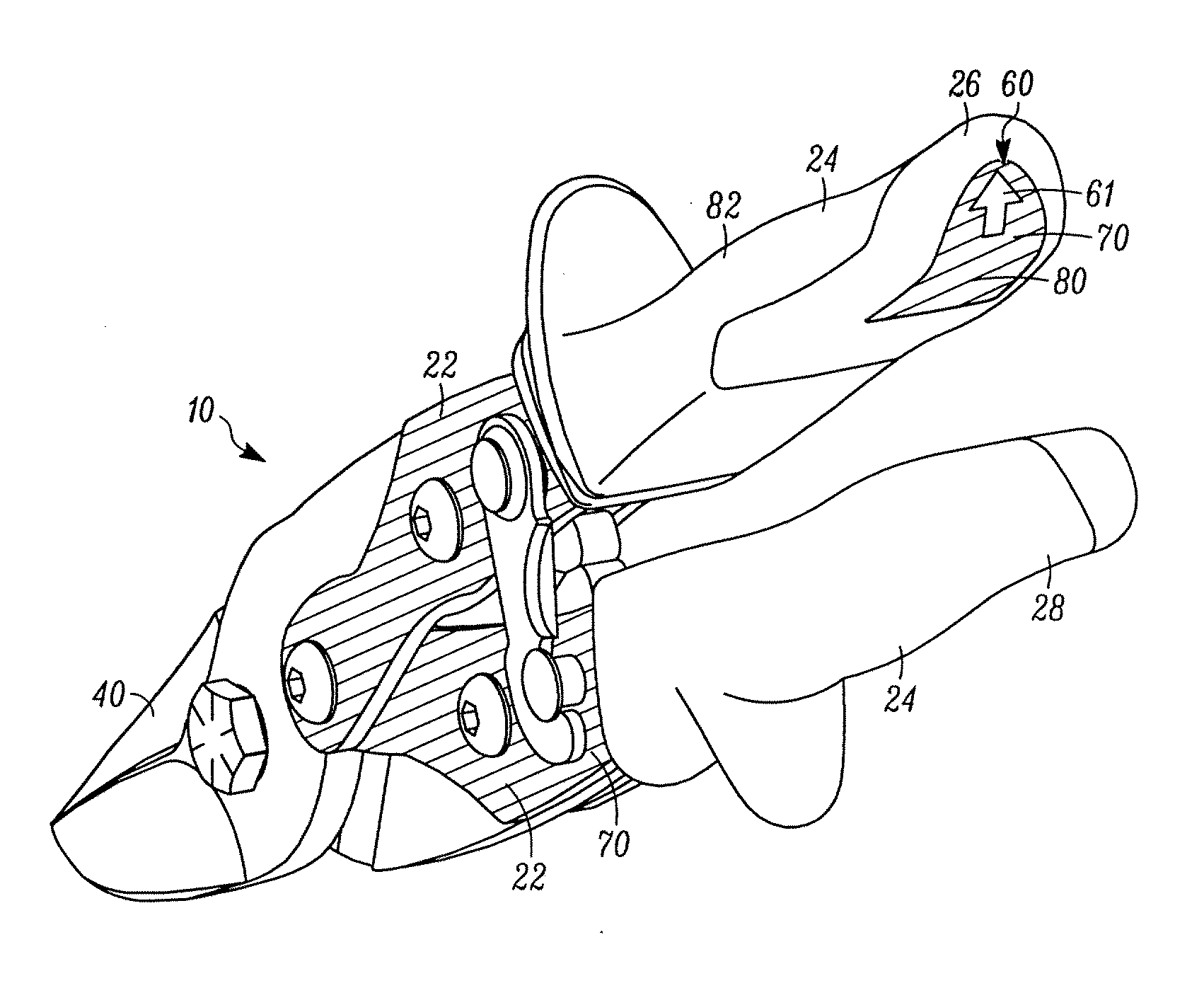

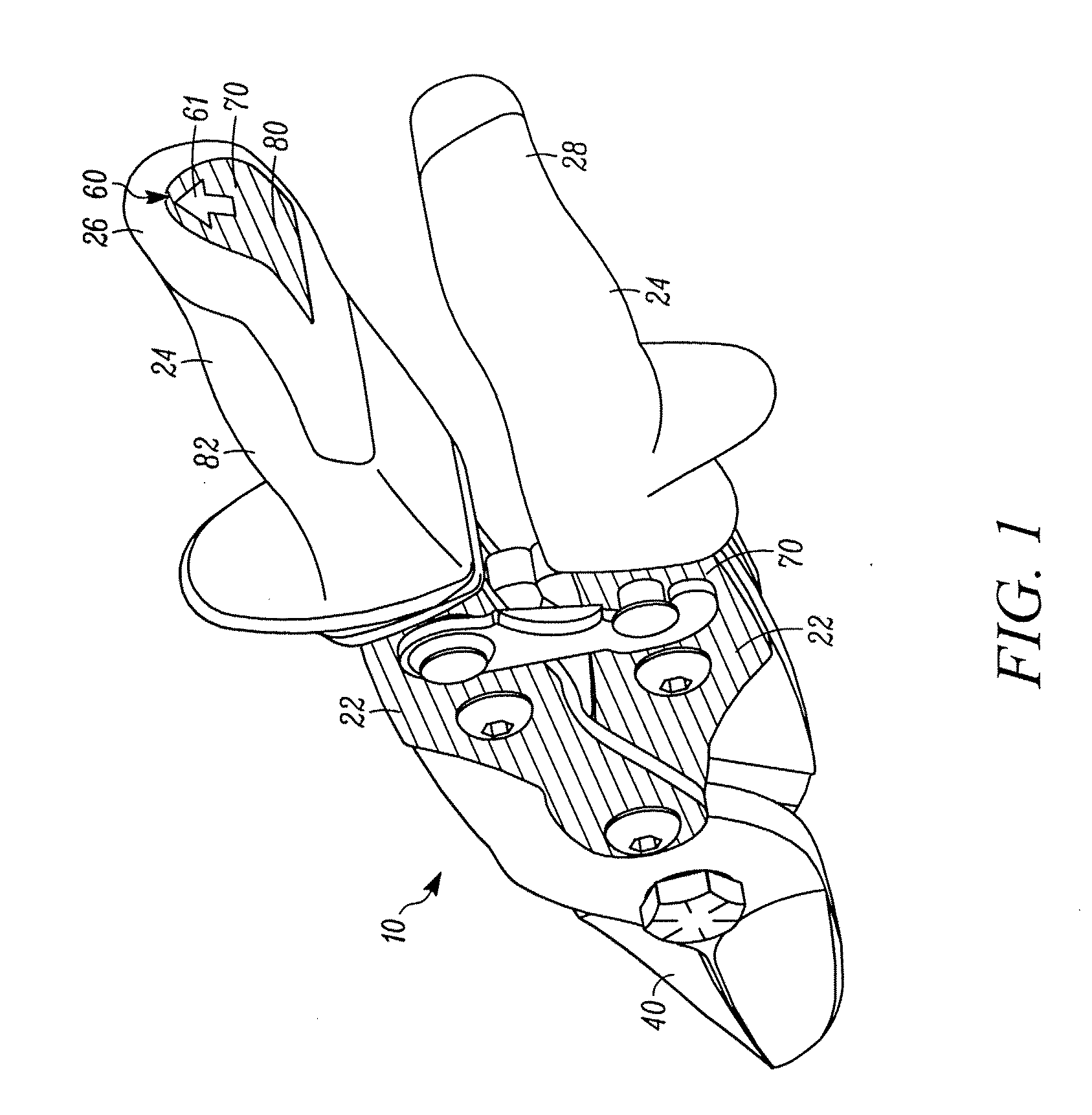

Coded Aviation Snips

A plurality of aviation snips, each snip comprising a visible graphic indicia indicative of the respective type of snip and visibly different from the graphic indicia of every other type of snip. The indicia is placed on the end portion of the upper handle grip to indicate the orientation of the snip relative to the user's hand during use, and is optionally debossed to add a tactile feel element to the indicia such that the user can determine the type of snip by feeling the indicia without visual contact. Each snip is optionally color coded on the spine of the snip to indicate the cutting direction of the snip.

Owner:BLACK & DECKER INC

Seat divider with recessed top panel and two-way viewing window

A seat divider for an automobile configured to create a barrier between children seated in the back seat of an automobile also allows visual contact and communications between them through a two-way viewing window and a top divider panel that can be raised and lowered when needed. The seat divider holds recessed desk top tables that can be extended and supported through their legs or by the armrests on the back seat for use by the children to read, write, watch DVD's, or play with toys. The seat divider also has storage space and trays to hold toys, books and other material as well as pen and pencil holders. The seat divider has specially configured seat belt and shoulder strap hooks that allow the middle seat belt and shoulder strap to be inserted through them to firmly secure the seat divider to the back seat of the vehicle.

Owner:MACLEOD SCOTT +2

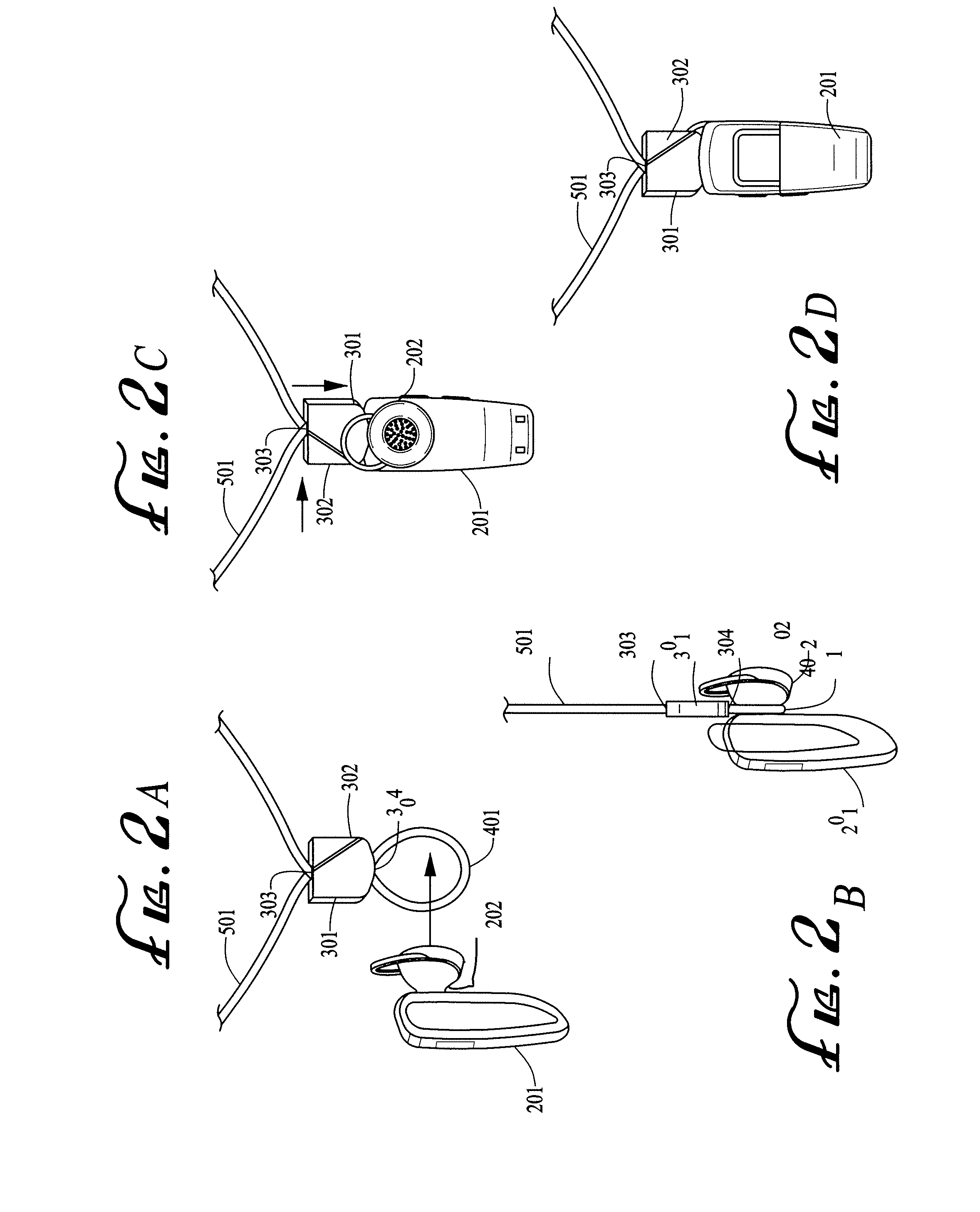

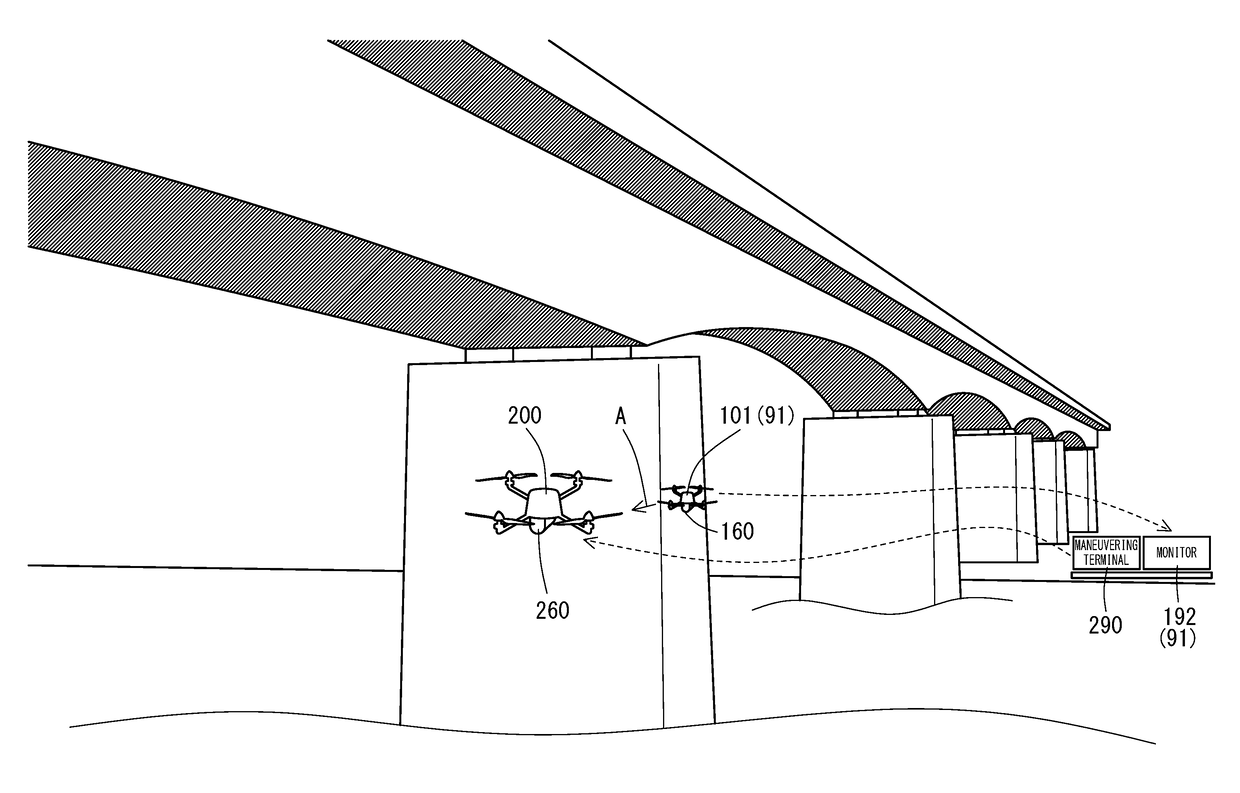

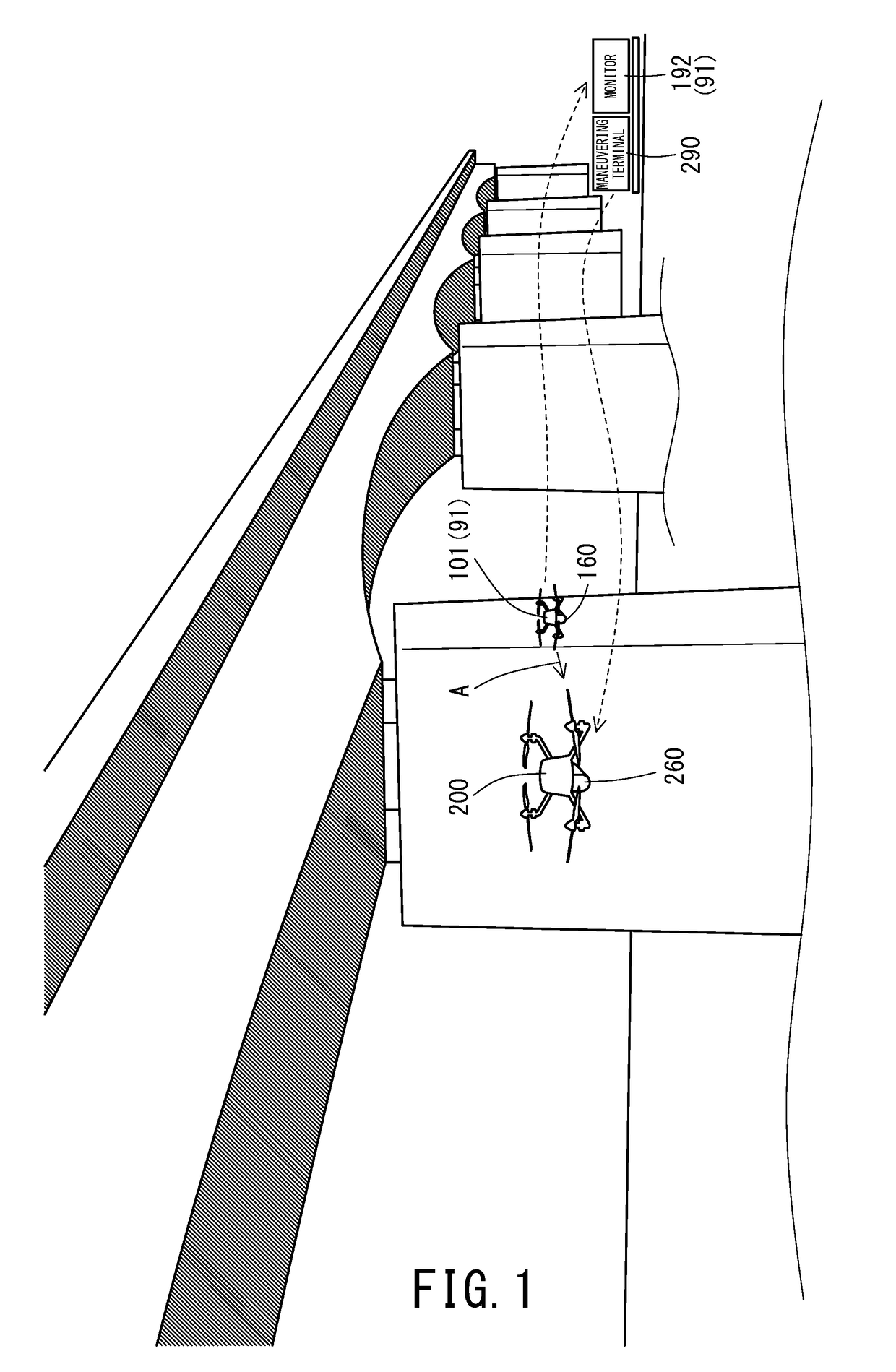

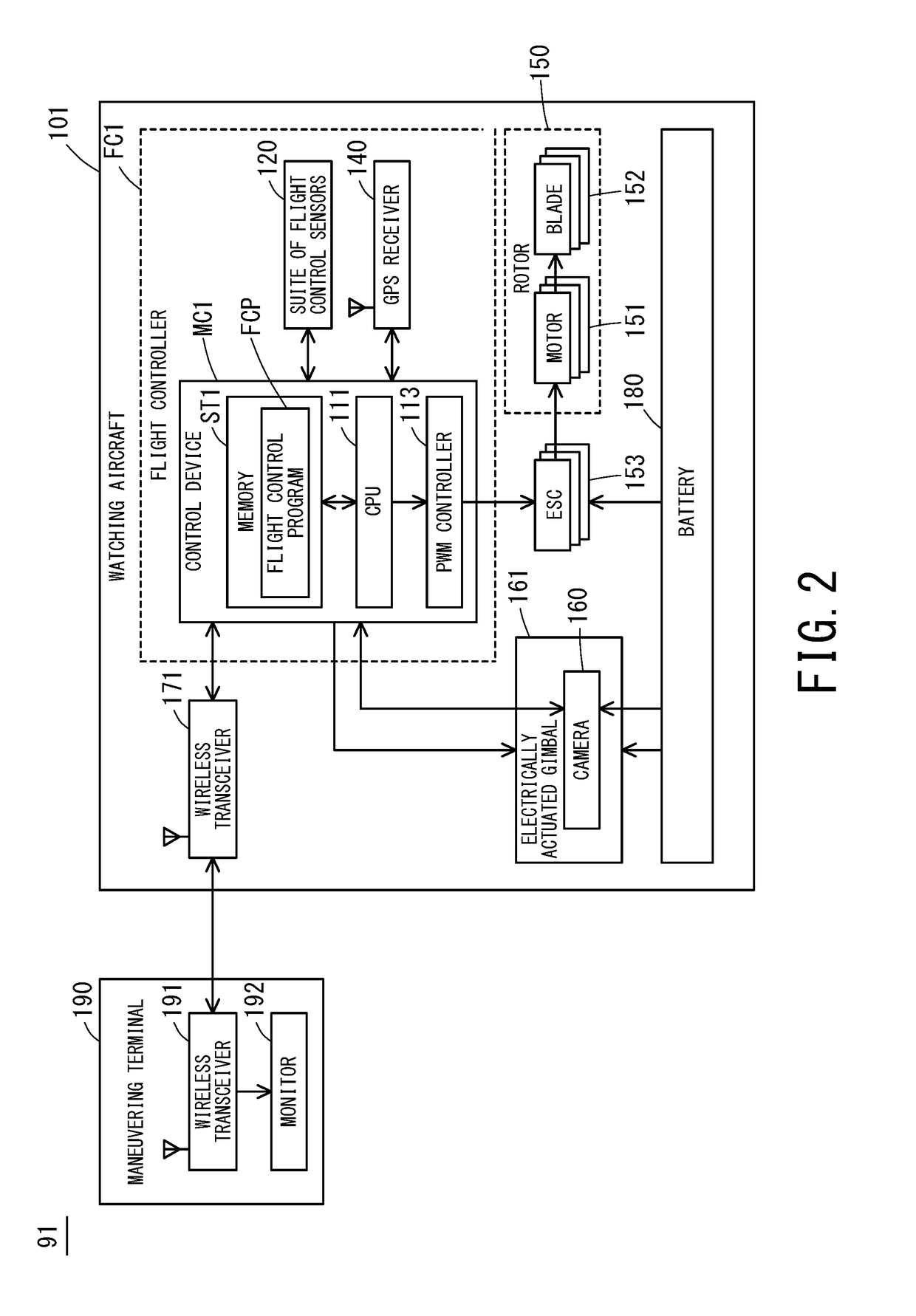

Unmanned moving vehicle piloting method and unmanned moving vehicle watching device

An unmanned moving vehicle piloting method and an unmanned moving vehicle watching device enabling it to pilot an unmanned moving vehicle, while keeping in visual contact with the vehicle from the vicinity of the vehicle from a third person viewpoint. In the vicinity of an unmanned moving vehicle, a watching aircraft is positioned, which is an unmanned aerial vehicle and includes a single or a plurality of rotors and image capturing means capable of capturing an image of surroundings of the watching aircraft and is able to stand still at one point in the air and piloting the unmanned moving vehicle, while viewing a third person viewpoint image captured by the watching aircraft. Moreover, the watching aircraft includes accompanying flight means for causing the watching aircraft to fly automatically, following movement of an unmanned moving vehicle. This enables the manipulator to concentrate solely on piloting the unmanned moving vehicle.

Owner:PRODRONE CO LTD

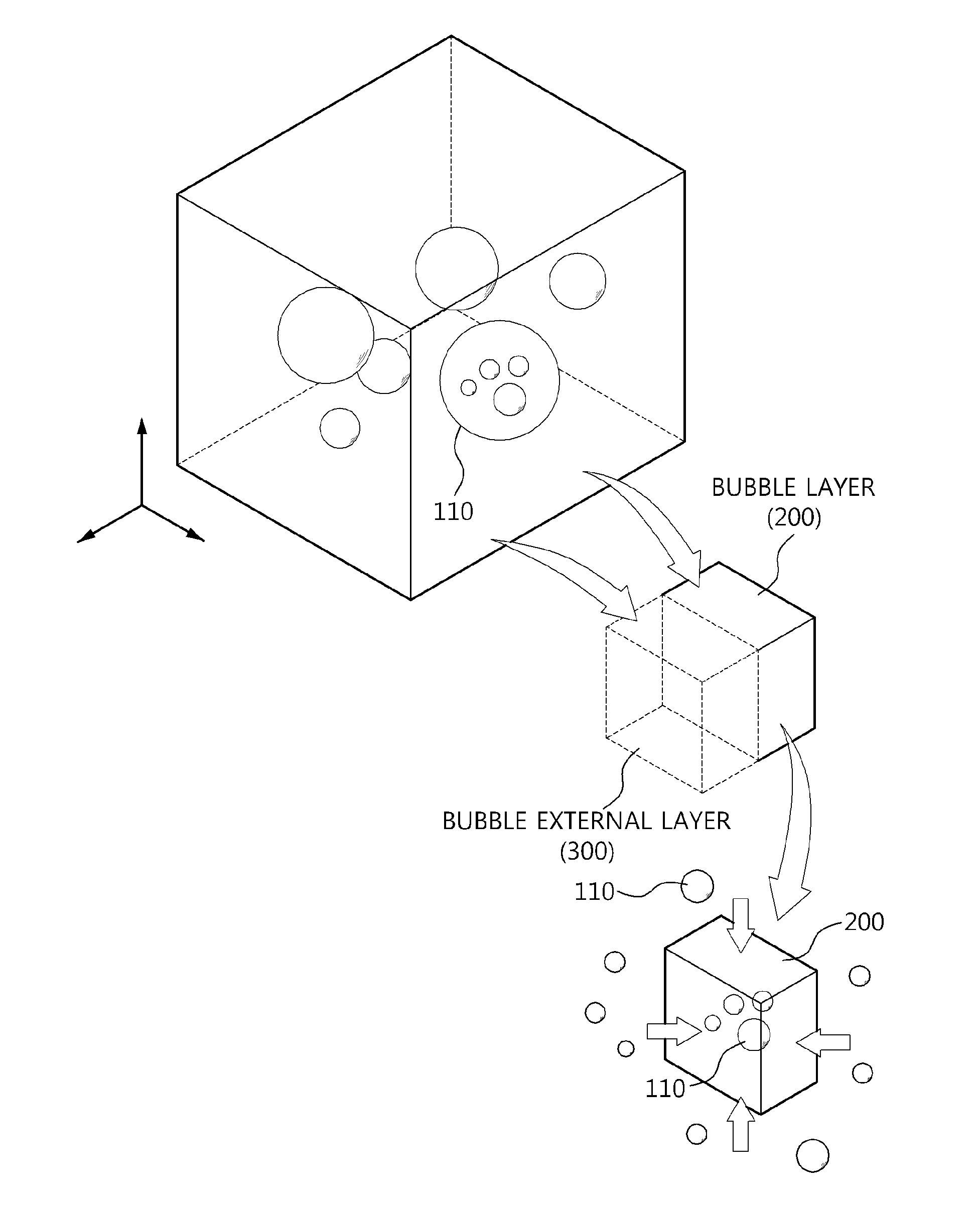

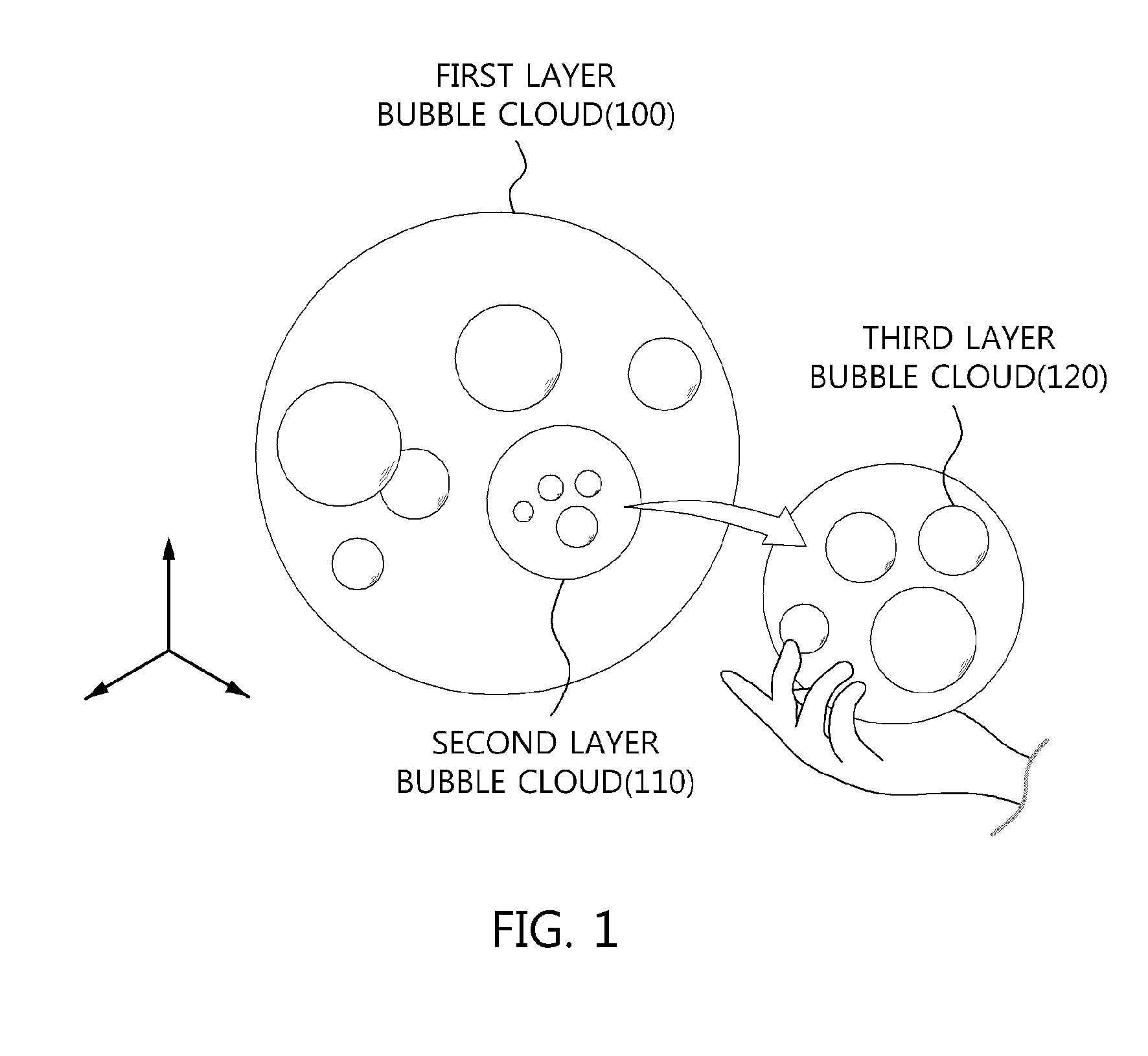

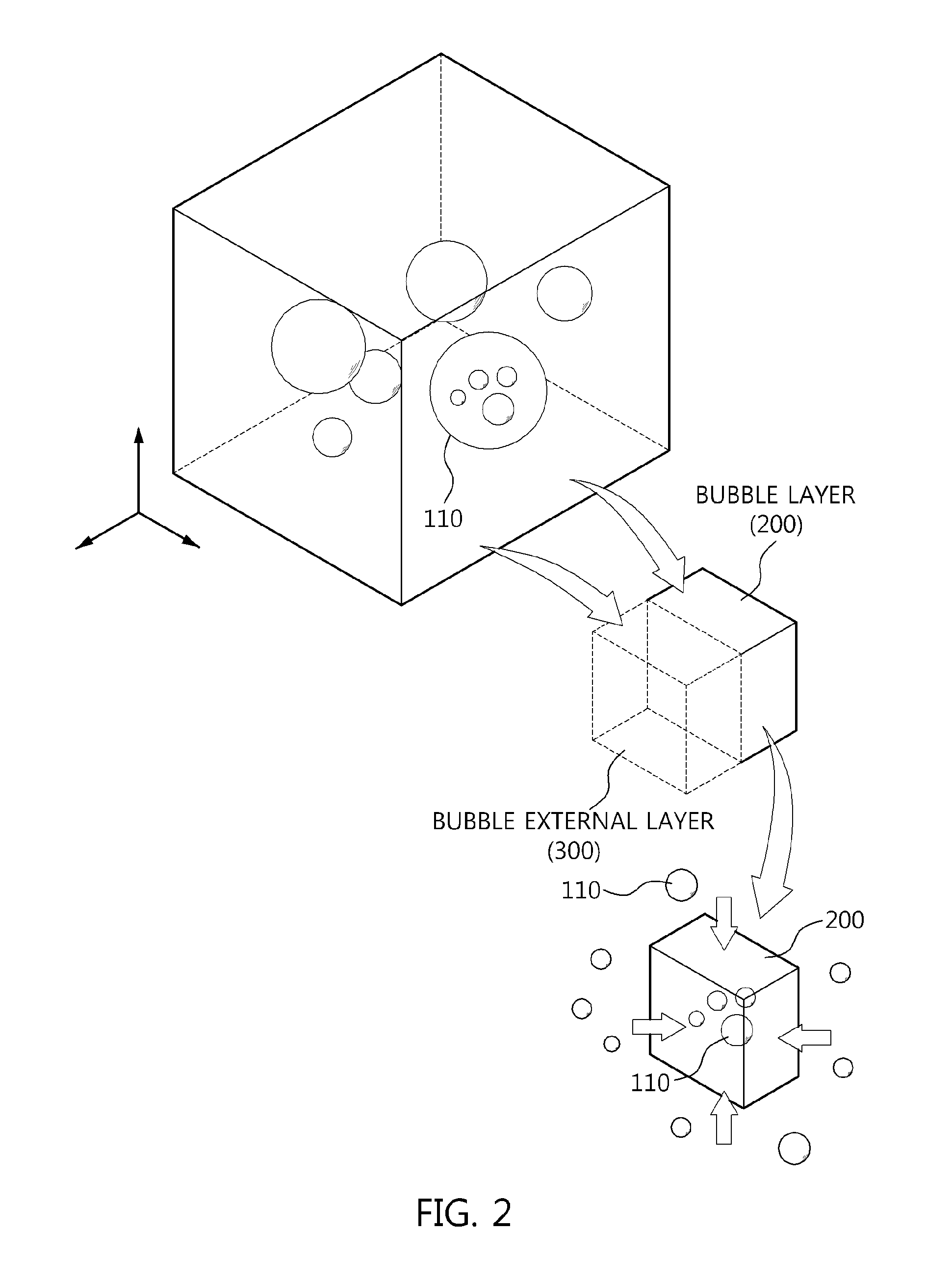

Apparatus and method for providing user interface for recognizing gesture

InactiveUS20130283214A1Efficient managementInput/output processes for data processingVisual perceptionUser interface

Disclosed herein is an apparatus and method for providing a user interface for recognizing a user's gesture in virtual or augmented reality. The user interface provision apparatus includes an image provision unit for providing virtual reality to a 3D area. A manipulation recognition unit is represented in the 3D area and recognizes a gesture based on a user experience using a visual contact effect. A processing unit recognizes the gesture and manipulates one or more bubble clouds. Further, the apparatus provides a user interface for menu manipulation and configuration so that a virtual object is held and manipulated in the same manner as when an object is held with the hand or a tool in the real world, rather than the manner in which 3D model control is performed based on recognition of the gesture made by the hand in augmented reality or virtual reality.

Owner:ELECTRONICS & TELECOMM RES INST

Passenger suite seating arrangement with moveable video monitor

ActiveUS9266614B2Maximizes densityMaximize useVehicle seatsSeating arrangementsVisual perceptionVisual contact

A passenger suite seating arrangement that includes first and second passenger suites positioned side-by-side and including respective first and second seats and first and second video monitors respectively positioned in a viewing position directly forward of the first seat and second seats. Third and fourth passenger suites are positioned side-by-side and facing the first and second passenger suites, and include respective third and fourth video monitors positioned and adapted to move between a stowed position laterally offset from a viewing position and a deployed viewing position forward of the third and fourth seats. In the deployed viewing position the third and fourth video monitors block visual contact between occupants of the first and second seats and the occupants of the third and fourth seats.

Owner:BE AEROSPACE INCORPORATED

Amusement ride

ActiveUS7971537B2Realistic impressionLong-lasting contactSledgesProjectorsSimulationVisual perception

The carnival ride has a travel path for cars with seats and at least one screen arranged adjacent to the travel path. In order to design the carnival ride in such a way that the passengers in the car have an optimal gaming experience, the screen follows the car at least along a section of its travel distance. In this way, the passengers in the car have a very long-lasting visual contact with the screen or with the movie shown on the screen.

Owner:ROBOCOASTER

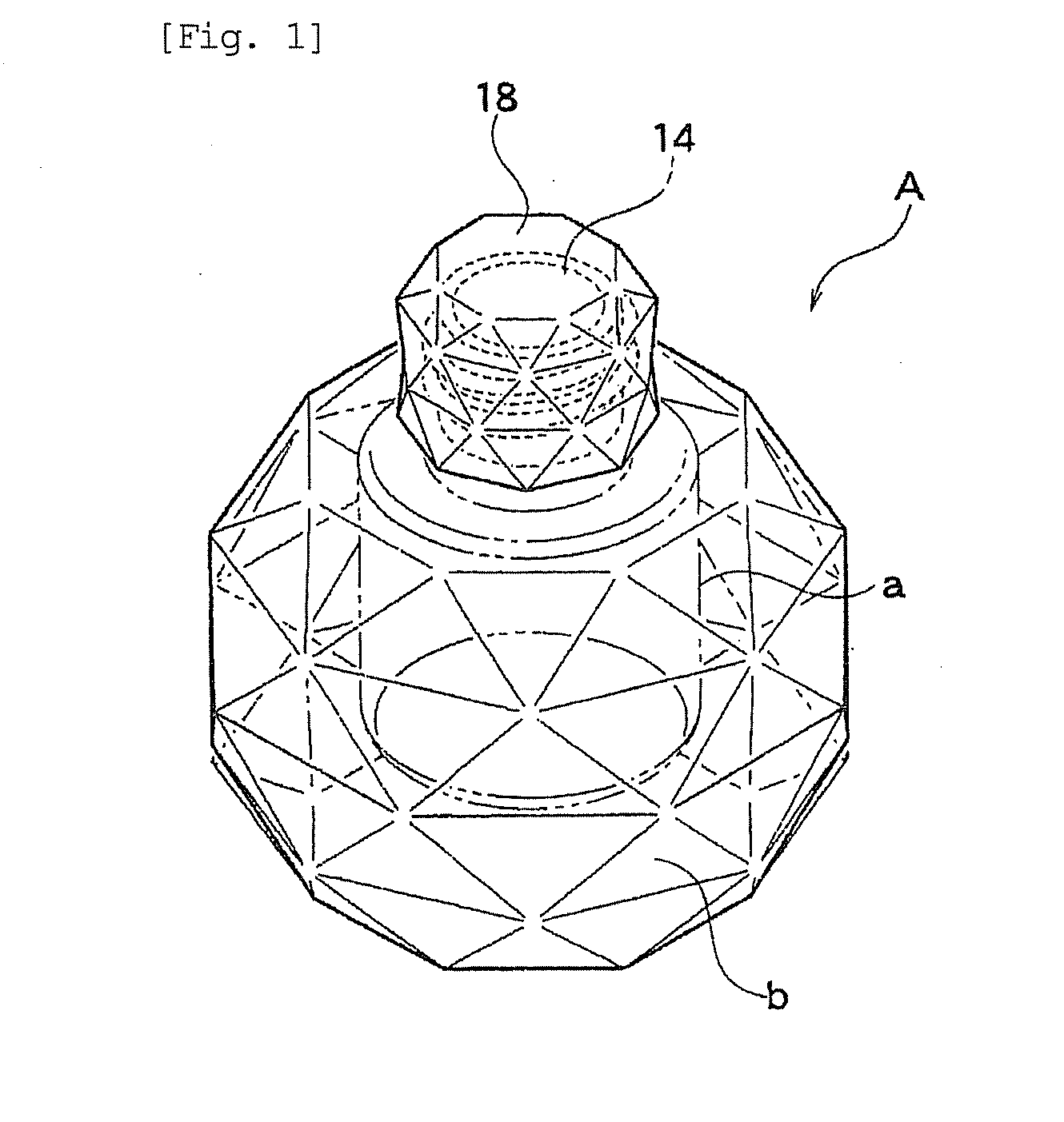

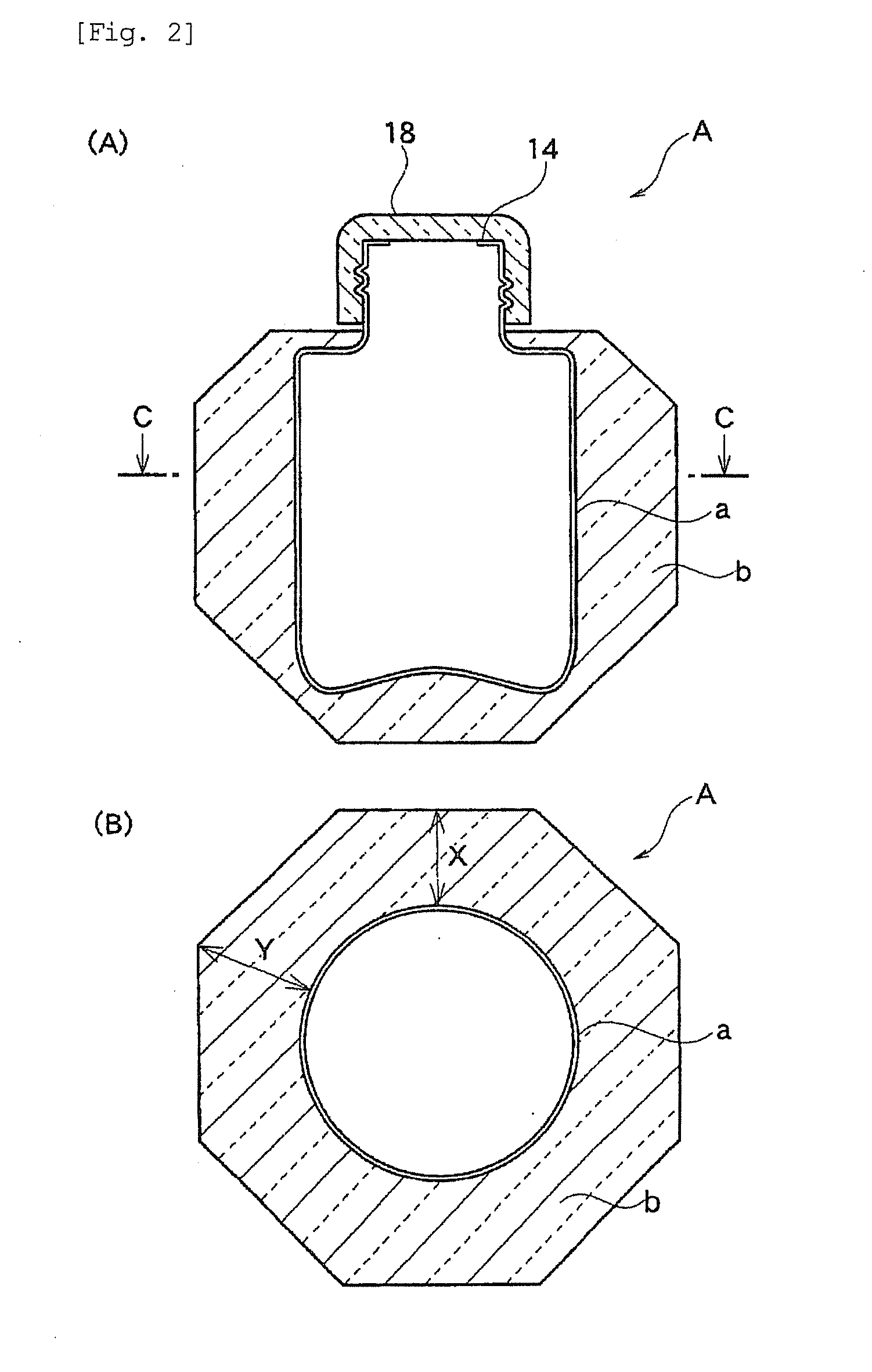

Composite container

InactiveUS20100252477A1Satisfactory decorating propertySimple designPackaging corrosive chemicalsCoatingsPolymer sciencePolymer chemistry

[Problem] It is an object to provide a composite container in which a shape and a profile of a resin hollow molding body can be discriminated with clarity in the case in which a visual contact is carried out to the inside resin hollow molding body via an outside transparent resin sheathing body, whereby a design property can be displayed to a satisfactory extent, and in which a design property can be displayed to a satisfactory extent even by a combination of the resin hollow molding body and the outside transparent resin sheathing body.[Means for Resolution] A composite container comprises a hollow molding body (a) made of a resin having a hollow inside and a highly transparent resin sheathing body (b) that has been integrated with an outside of the hollow molding body (a), wherein as a thickness of the highly transparent resin sheathing body (b) for a cross section in a horizontal direction getting across the hollow molding body (a) and the highly transparent resin sheathing body (b) at the major portion of the composite container, a minimum thickness (X) of the highly transparent resin sheathing body (b) is at least 0.1 mm and a difference of a maximum thickness (Y) and the minimum thickness (X) is at least 2 mm.

Owner:MITSUI LTD

Defect repair method of high-temperature alloy casting

The invention discloses a defect repair method of a high-temperature alloy casting, and belongs to the technical field of precision casting of metallurgical casting. A defect communicated with the surface of the casting is changed into a closed defect by using electron beam surface blocking, and then hot isostatic pressing is performed on the closed defect, so that the qualification rate of the casting is improved. The electron beam surface blocking process comprises the following steps and control technical parameters: detecting through visual contact, fluorescence and X-ray to determine a loose region and level; machining a square or circular groove with an area of being greater than that of the defect and depth of 3-5 mm on the surface with the defect of the casting if a defect beyond tolerance communicated with the surface exists; machining a matchable cover plate with thickness equal to that of the groove and gap of 0.1-0.5, placing the cover plate on the groove and spot-welding at 3-4 positions by using argon arc welding for fixation; sealing and welding the cover plate at the groove of the casting by using an electron beam under the condition that the vacuum degree is 10<-4> to 10<-1> Pa. The method has the advantages that the electron beam surface defect blocking and hot isostatic pressing defect closing are combined, the effectiveness for repair of the casting through the hot isostatic pressing is improved, and the method can be used for producing high-temperature alloy composite members.

Owner:BEIJING CISRI GAONA TECH

Non-contact shock sensor

InactiveUS7673513B2Acceleration measurement using interia forcesElectric switchesTransceiverCoupling

The invention relates to a sensor device for monitoring accelerations to which an object is subjected. In order to detect whether a value has exceeded or is below a threshold for the acceleration to which objects have been subjected in the past, i.e. without having visual contact with the sensor, the inventive sensor device includes an acceleration sensor, which is permanently linked to the object to be monitored, so that a relative movement between the acceleration sensor and the object is prevented, and an RFID transceiver for non-contact coupling of electrical energy into the acceleration sensor and for sending out radio signals as a function of the physical state of the acceleration sensor.

Owner:SIEMENS HEALTHCARE GMBH

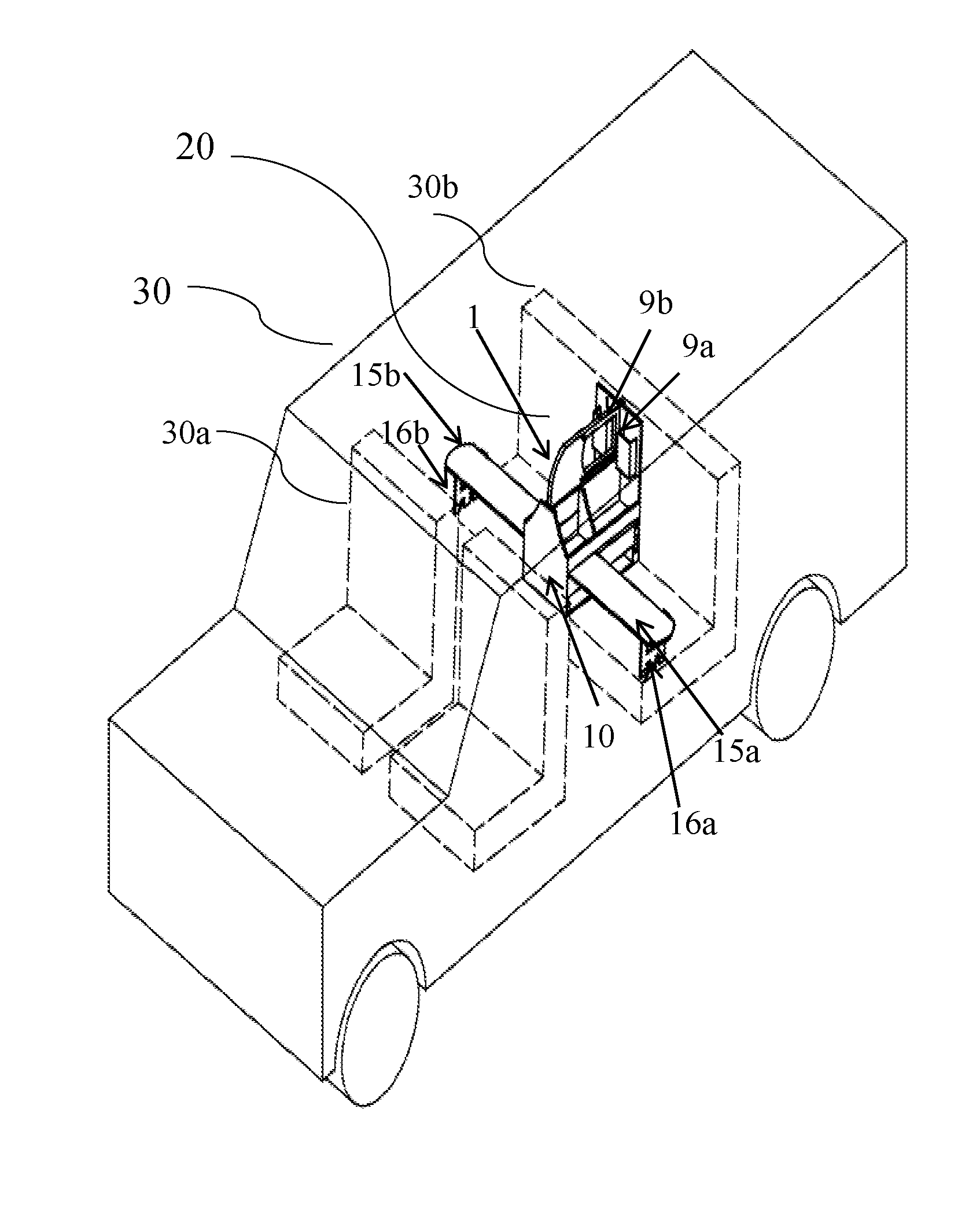

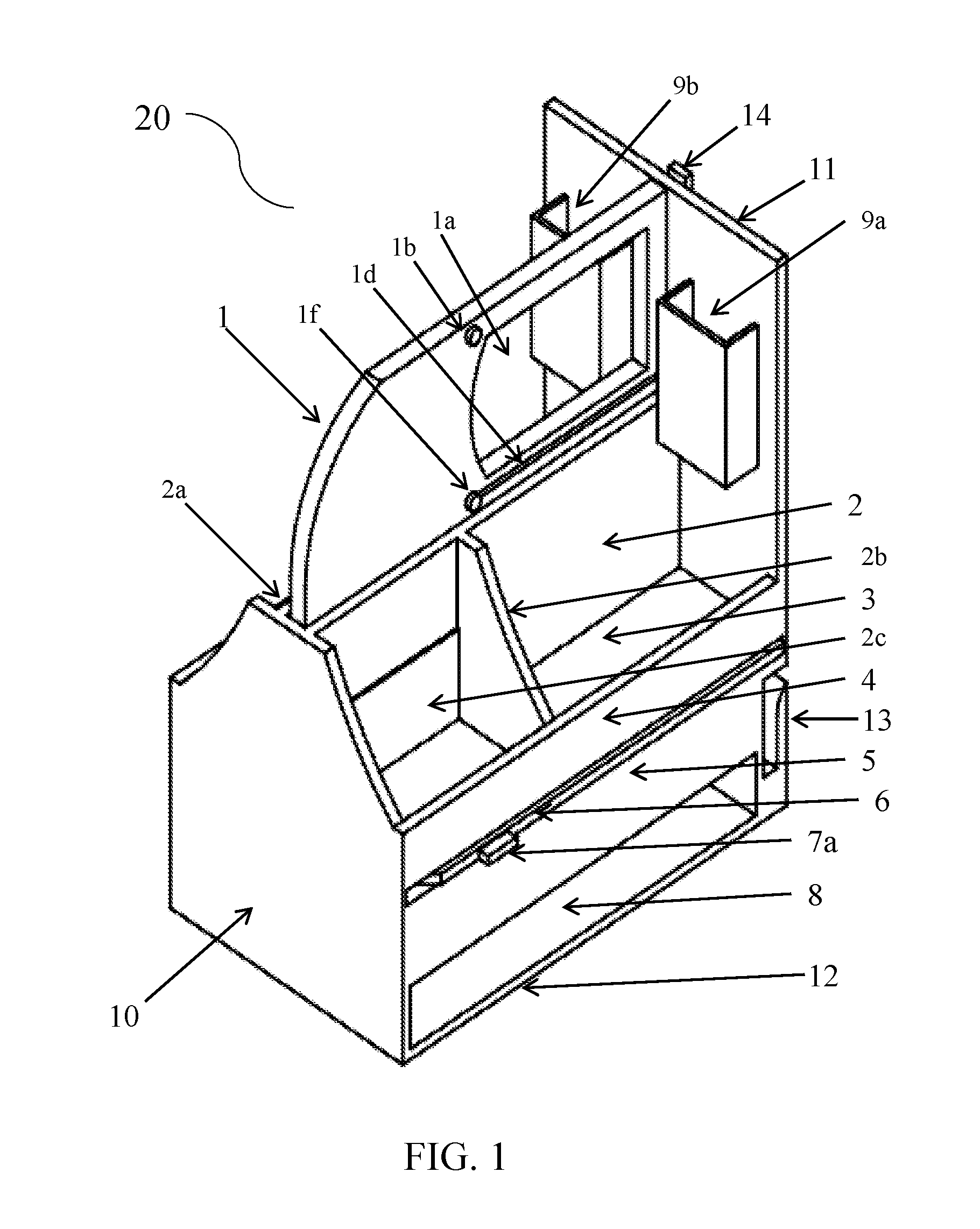

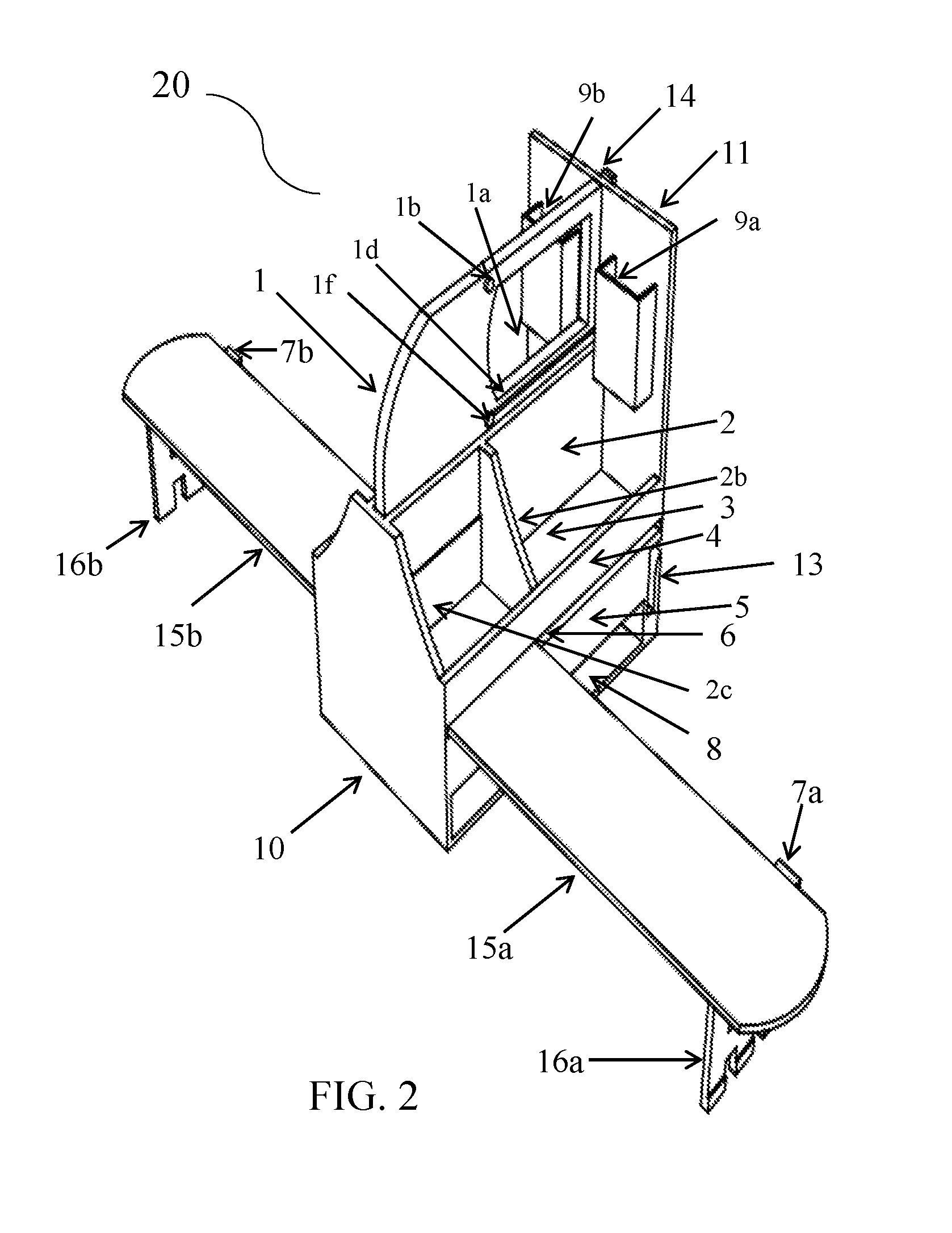

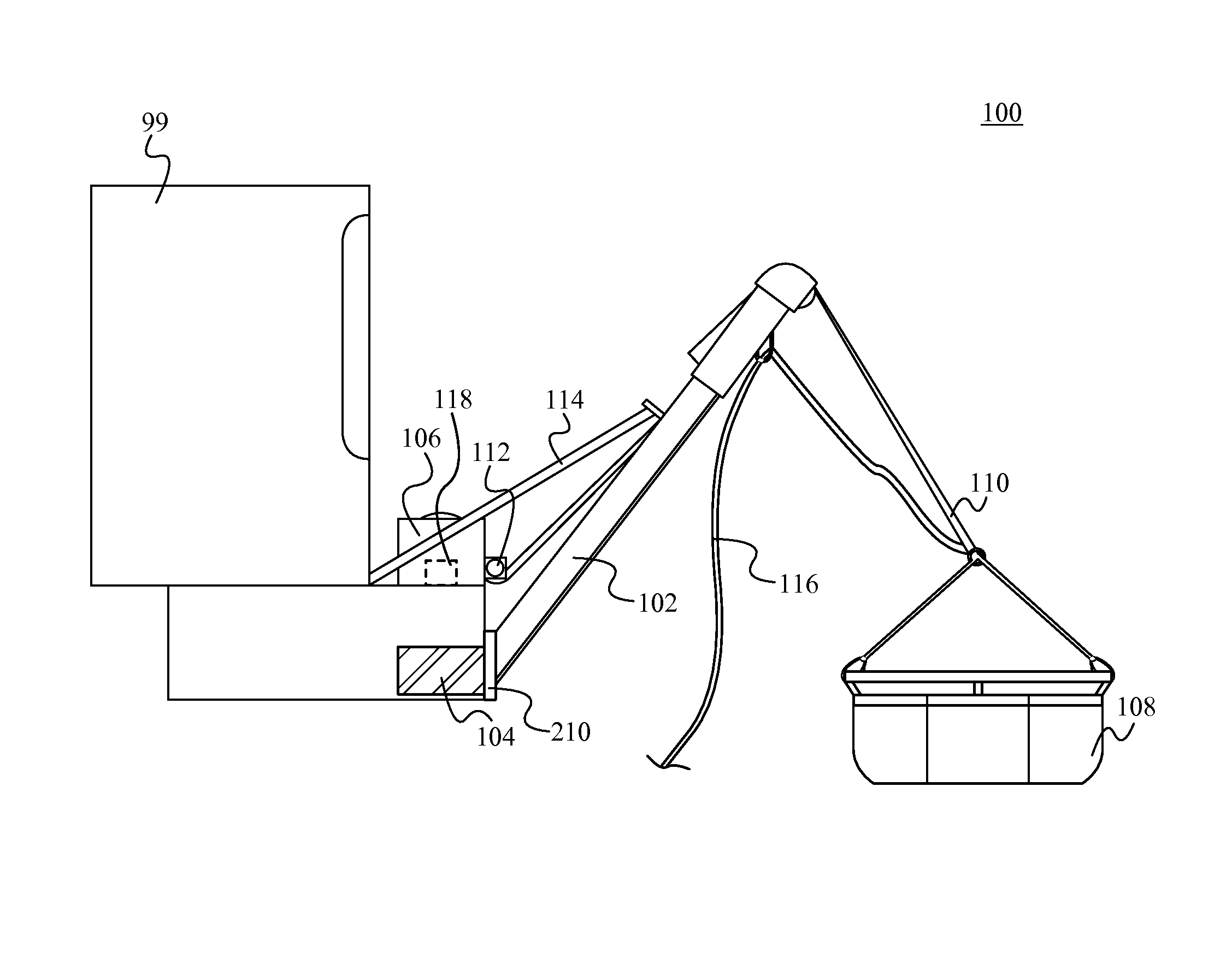

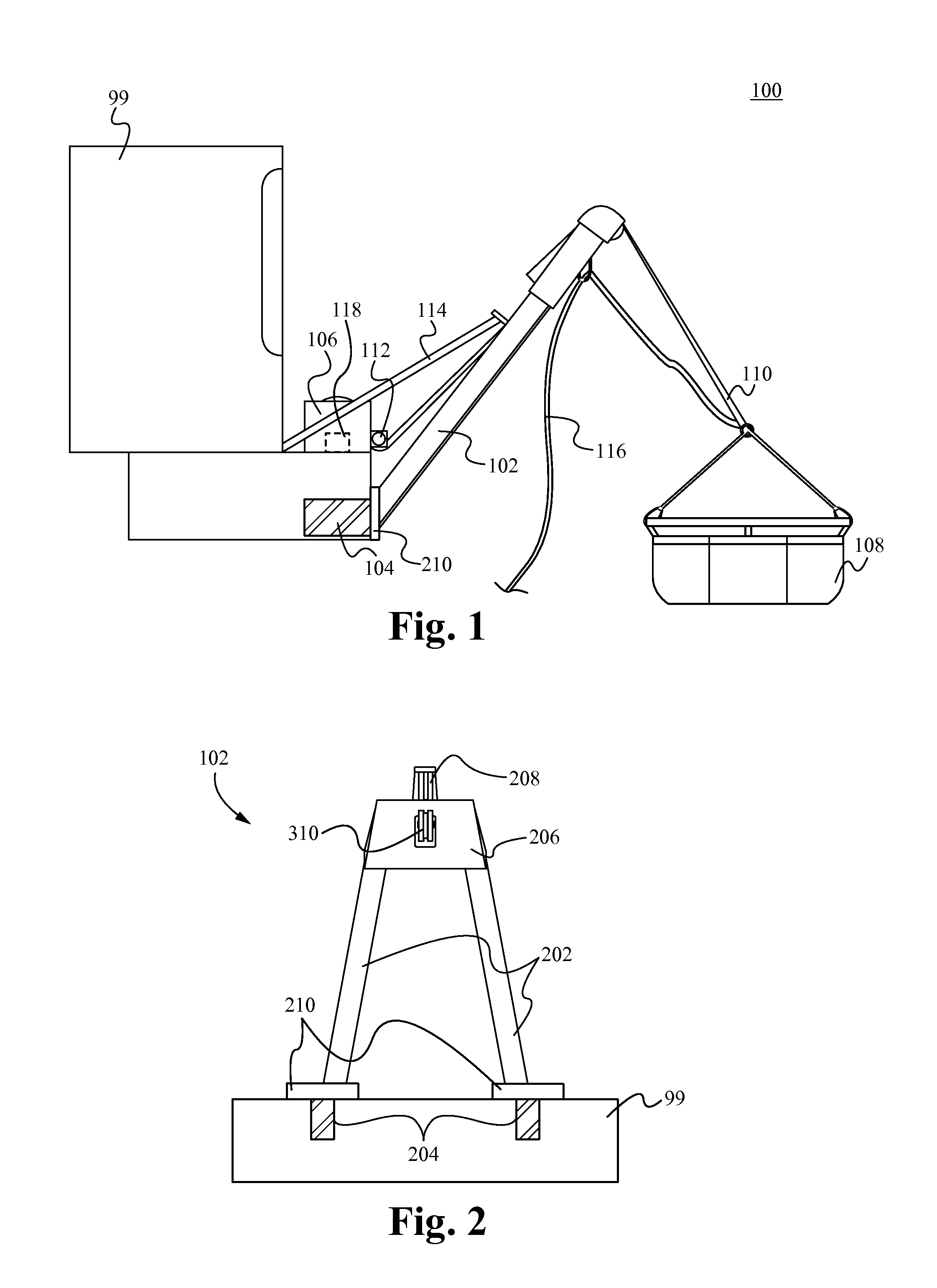

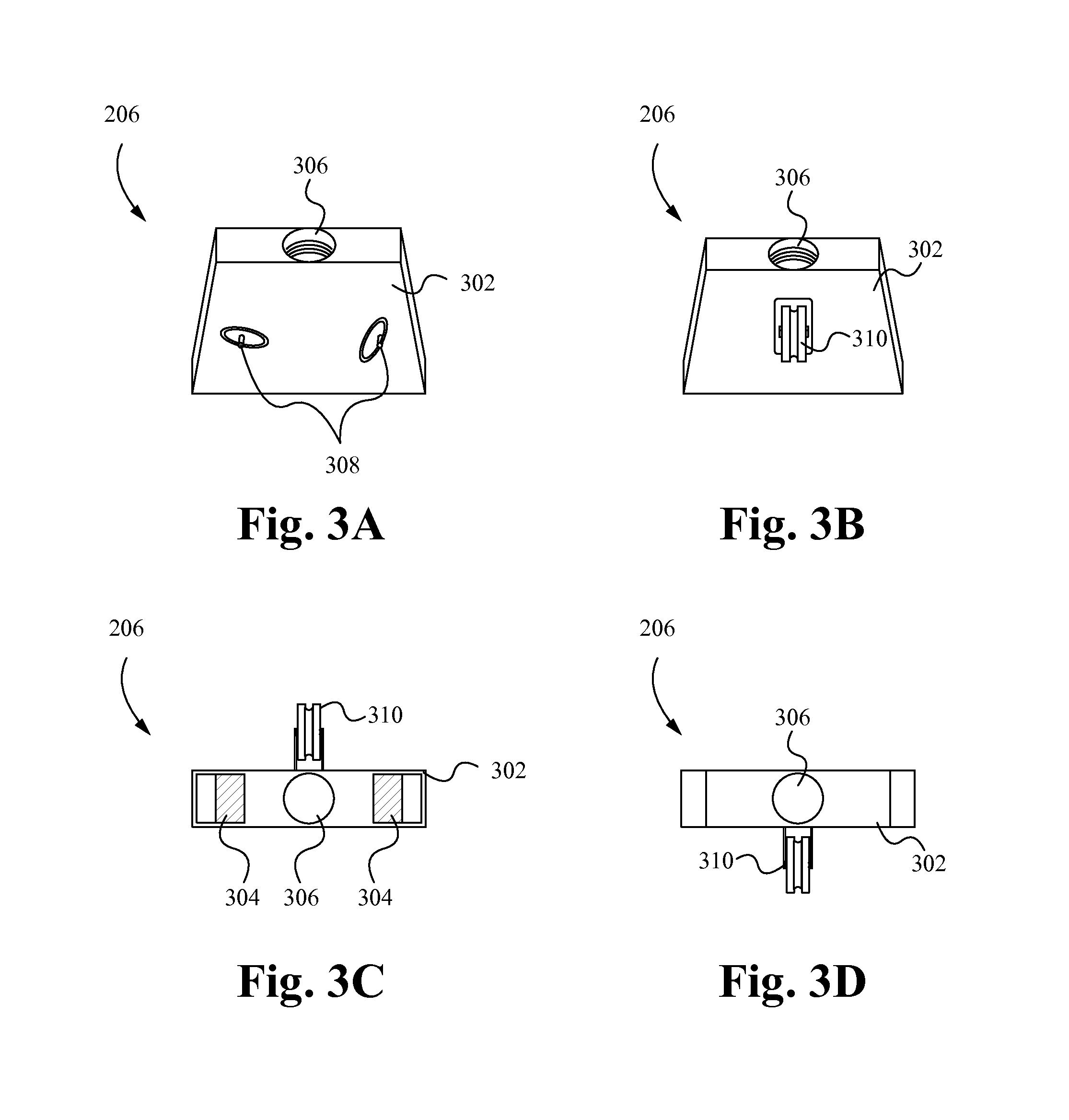

Victim retrieval system, method and apparatus

ActiveUS9278236B1Reduce physical exertionShorten the timeBreathing protectionMachine supportsSafety wireRemote control

A victim retrieval apparatus for use with a vehicle. In some embodiments, the rescue basket comprises one or more wheels. The articulating head of the boom comprises a rotatable pulley for receiving the rescue line and is able to allow the vehicle to be parked in any position necessary while rescuing the victim. A knot-passing pulley enables a safety line (with emergency brake device) to be coupled to the basket thereby ensuring the safety of the victim in the basket at all times. The rescue basket comprises a remote control for controlling the winch speed that is able to be located at the winch itself, or be of a hand-held nature and attached at the rescue basket instead of at the vehicle if visual contact is problematic.

Owner:FLARESUN FIRE GRP

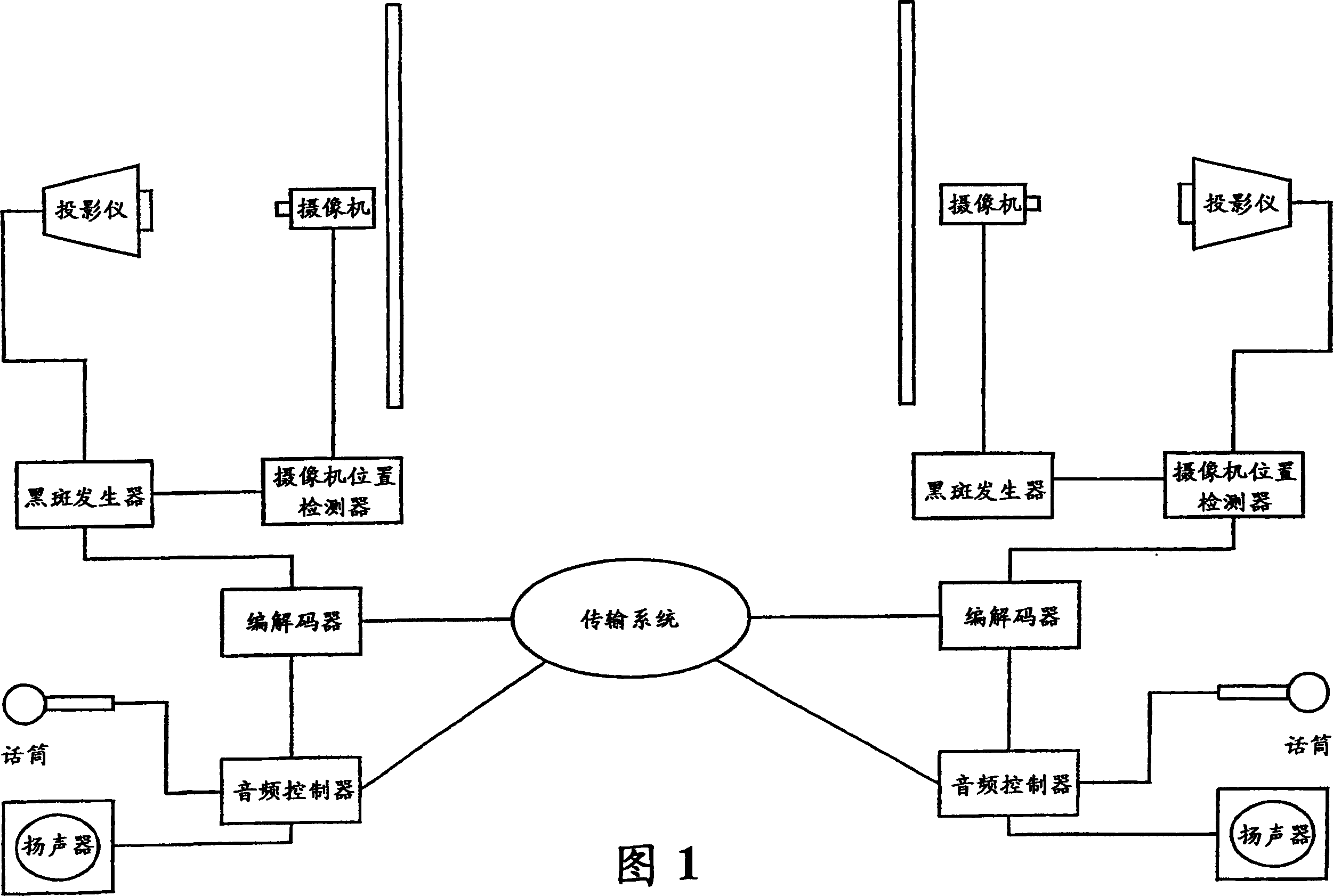

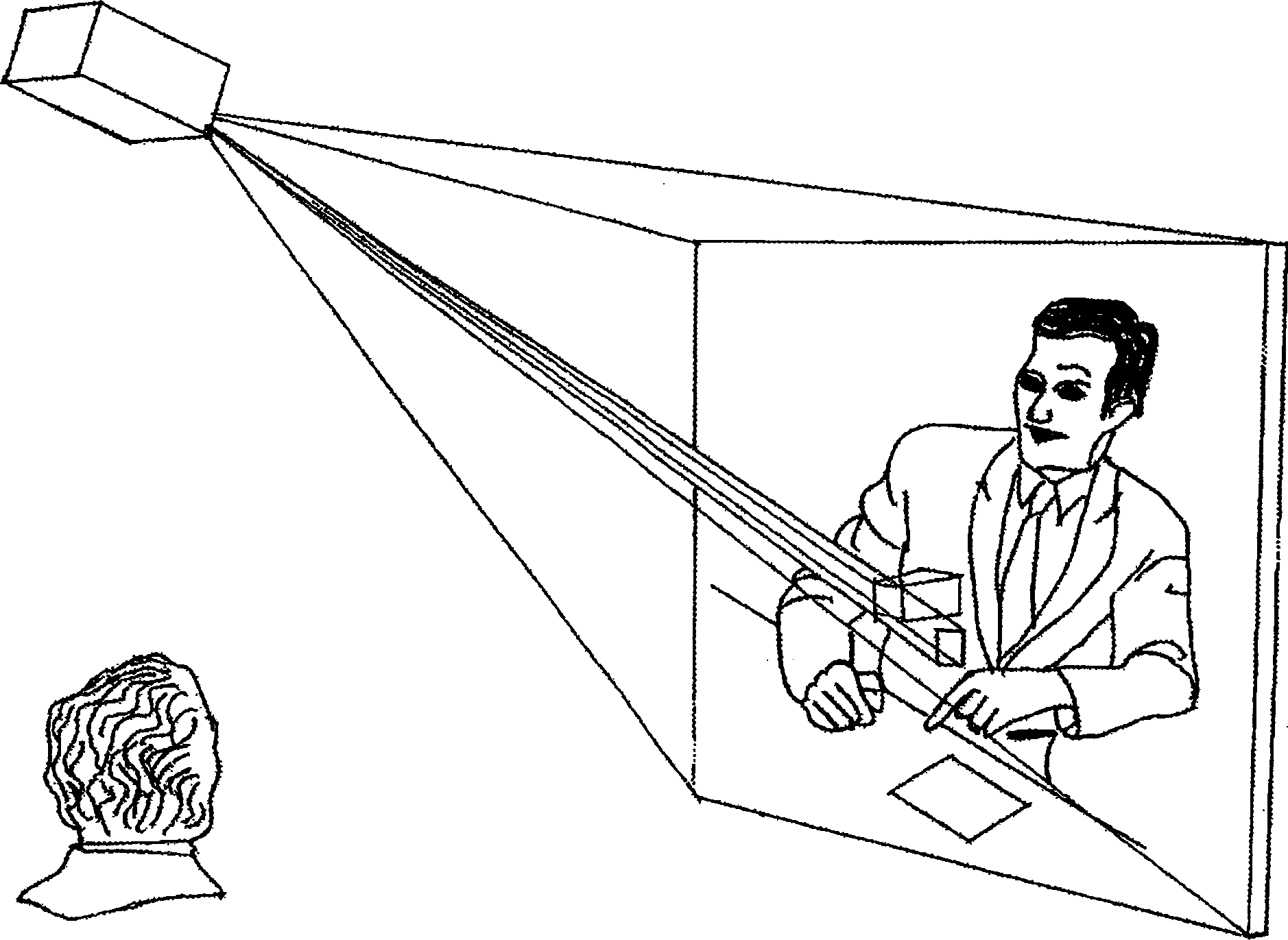

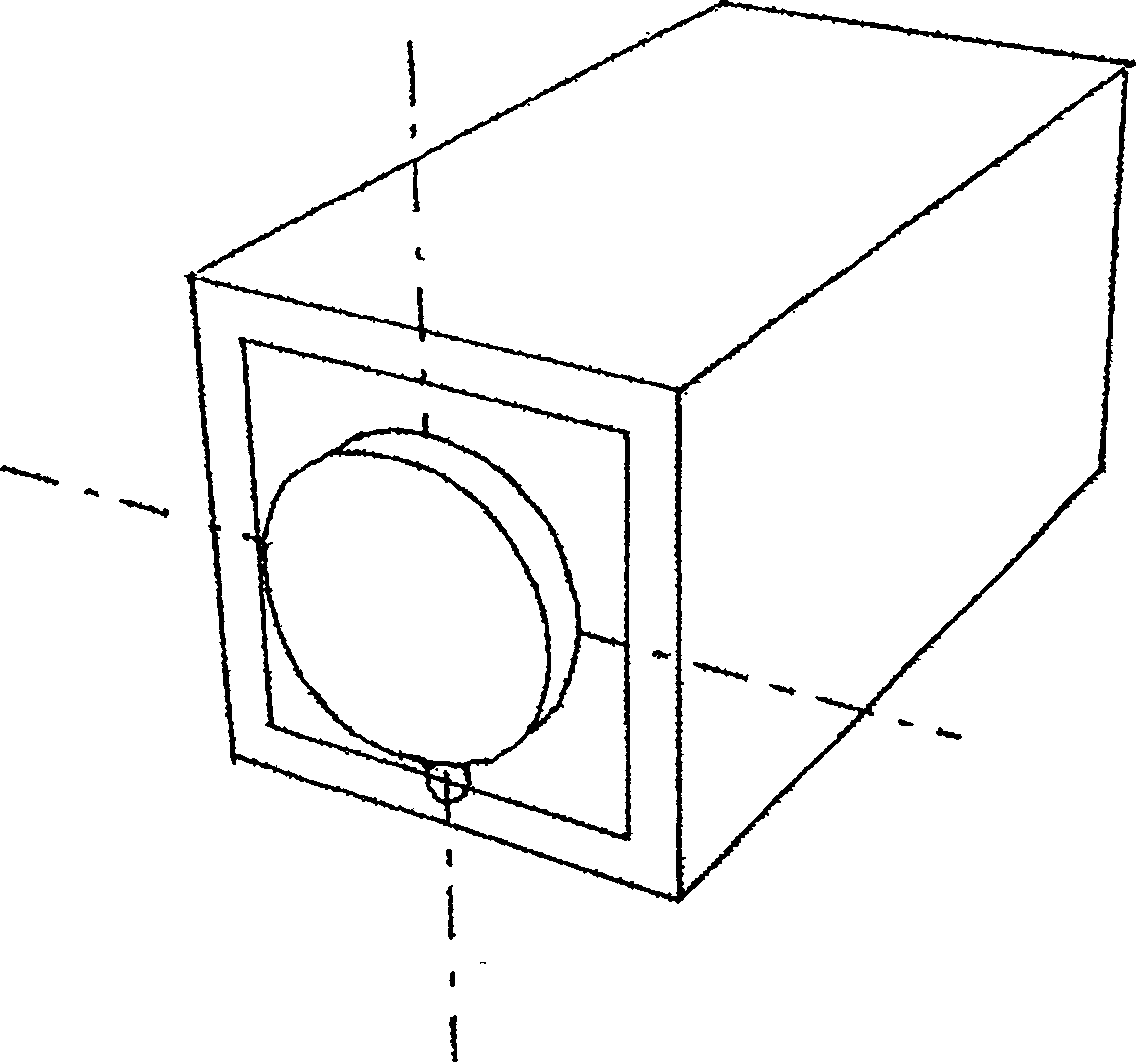

An arrangement and method for permitting eye contact between participants in a videoconference

The invention discloses a device and method for a video conference endpoint, which provide visual contact between participants in different venues. The present invention allows a conference camera to be placed in the beam of a projector device without the quality of the view captured by the camera being degraded by the light from the projector. This is achieved by creating a black spot in the beam, covering the camera lens, and adjusting the position and / or size of the black spot based on a camera position detector, which can be the camera itself or near the camera lens or Multiple light sensors around.

Owner:CISCO SYST INT R L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com