Optical monitoring processes and apparatus for combined liquid level sensing and quality control

a technology of optical monitoring and liquid level sensing, applied in liquid handling, instruments, packaged goods types, etc., can solve the problems of significant health hazards, degradation cannot be tolerated in critical semiconductor manufacturing steps, and many semiconductor manufacturing processes involve very expensive chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

second embodiment

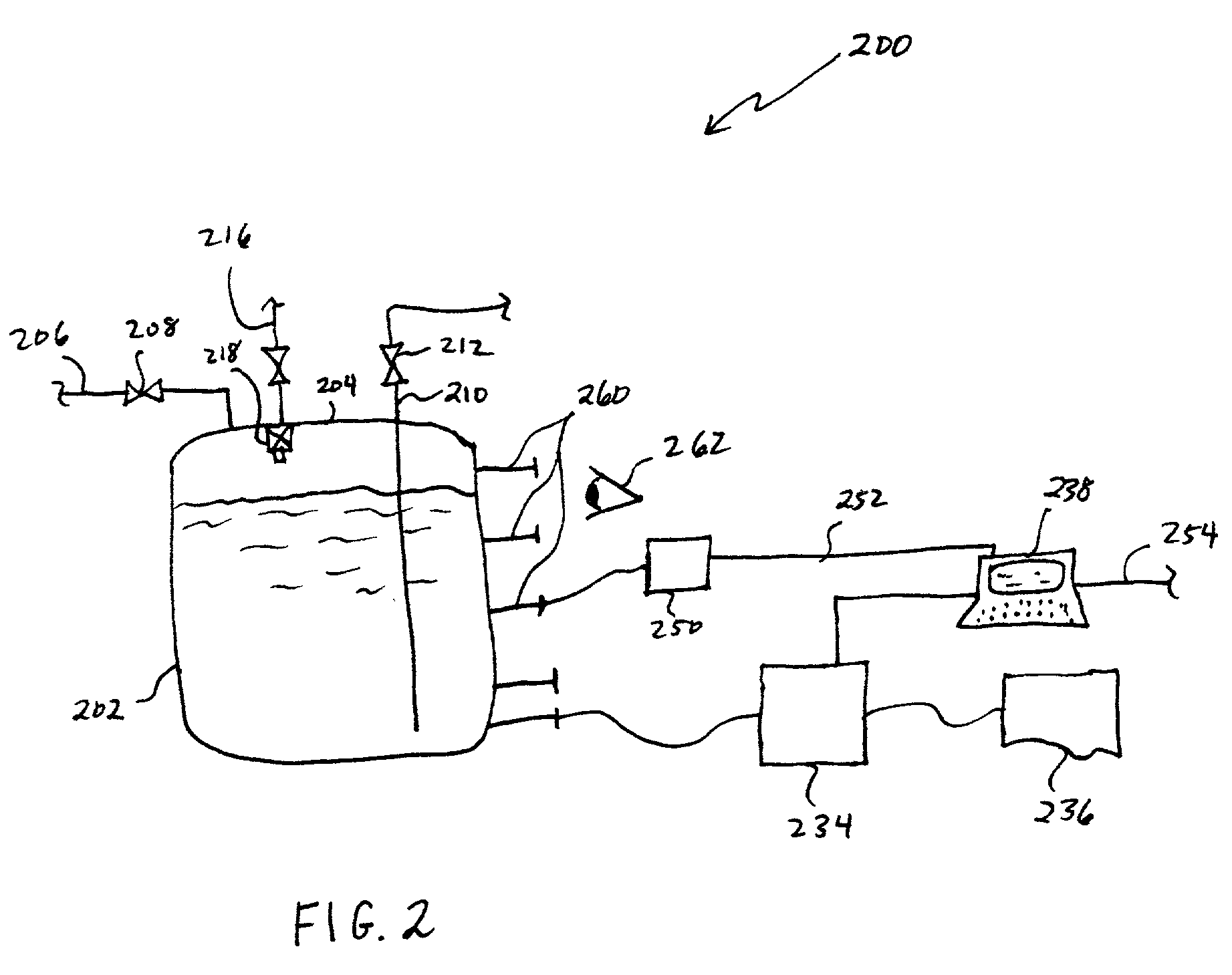

[0036] In a second embodiment, use of optical monitoring "level sensing" fibers that extend out of the sides of the liquid chemical container are used to monitor both intensity for liquid level, as in the present design, and also spectral profile for chemical color or turbidity characteristics for quality / purity information.

third embodiment

[0037] A third embodiment employs a single optical feed through connection, preferably made on or near the top of the container, and light propagation directed perpendicularly to the liquid surface. Using more sophisticated spectral interpretation of light from the fibers, both liquid level and chemical purity can be assessed. Such installation minimizes manufacturing costs as well as limits the number of container seals required, thereby reducing potential sites for leaks and chemical degradation from sealing materials required in the optical connections to the container.

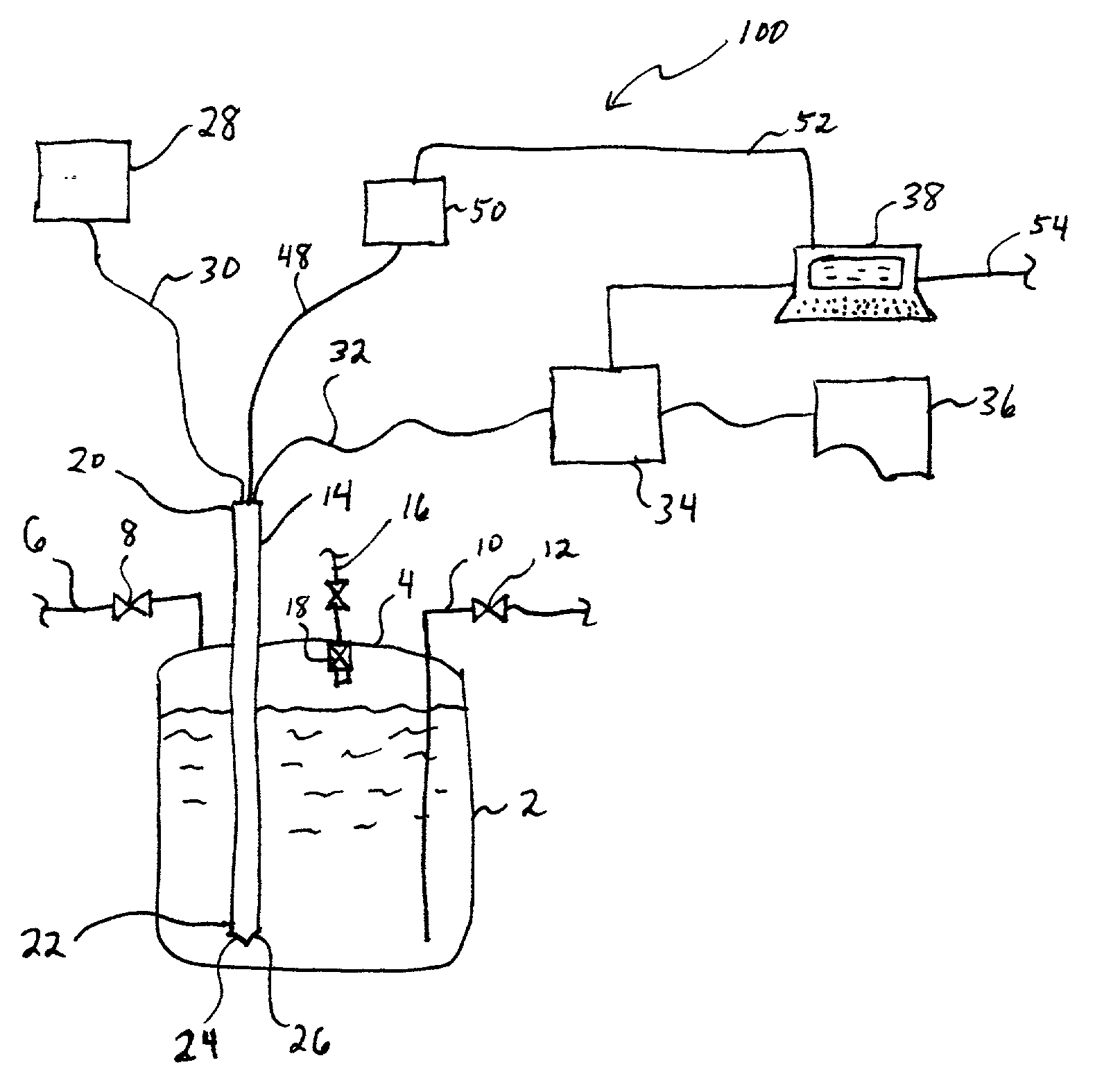

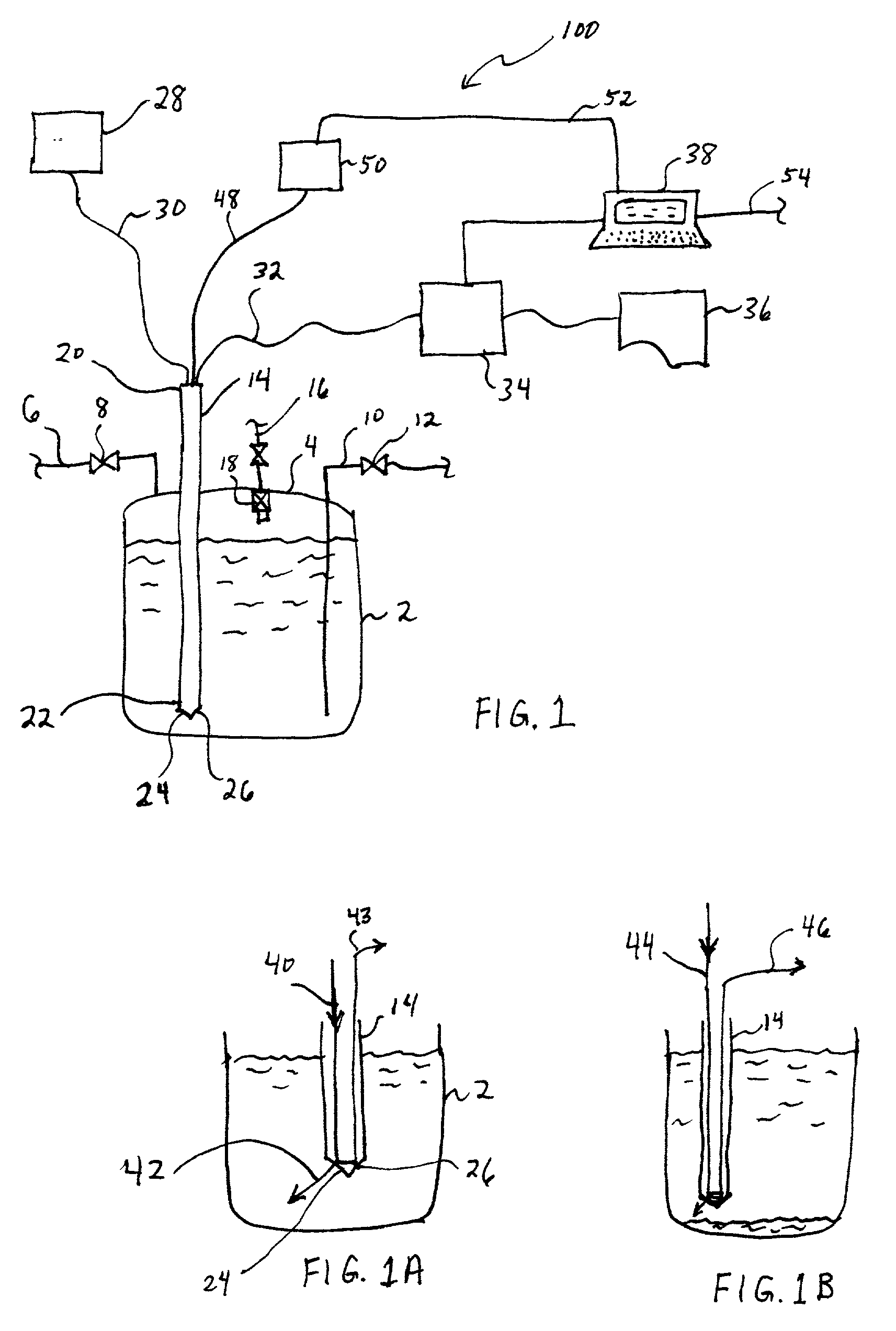

[0038] Referring now to the drawing figures, FIG. 1 illustrates a first embodiment 100 of an apparatus in accordance with the invention. Apparatus 100 includes a container 2 having a container top 4, a liquid inlet conduit 6 and control valve 8, and a liquid chemical outlet conduit 10 and control valve 12. Present is an optical element 14, an optional gas inlet 16 with gas filter 18, gas filter 18 preferably compri...

embodiment 100

[0043] FIG. 3 illustrates another embodiment of an apparatus in accordance with the present invention, illustrating a container 302 having liquid chemical inlet conduit 306 and control valve 308, and liquid chemical outlet conduit 310 and control valve 312. An optional gas inlet conduit 316 is illustrated, as well as optional gas filtration media cartridge 318. Container 302 has a top 304, through which an optical member 314 protrudes. While this is similar to the embodiment 100 in FIG. 1, note that distal end 322 does not protrude into or contact liquid within container 302. Optical member 314 is connected via optical fiber 330 to a light source 328. Light that is transmitted or reflected through optical member 314 indicating liquid level is transmitted through an optical fiber 348 into light receptor 350, which may have an output via connection 352 to computer 338. Simultaneously, quality determination of liquid within container 302 may be obtained through optical fiber 332 connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| optical properties | aaaaa | aaaaa |

| optical discrimination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com