Patents

Literature

35results about How to "Turndown ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

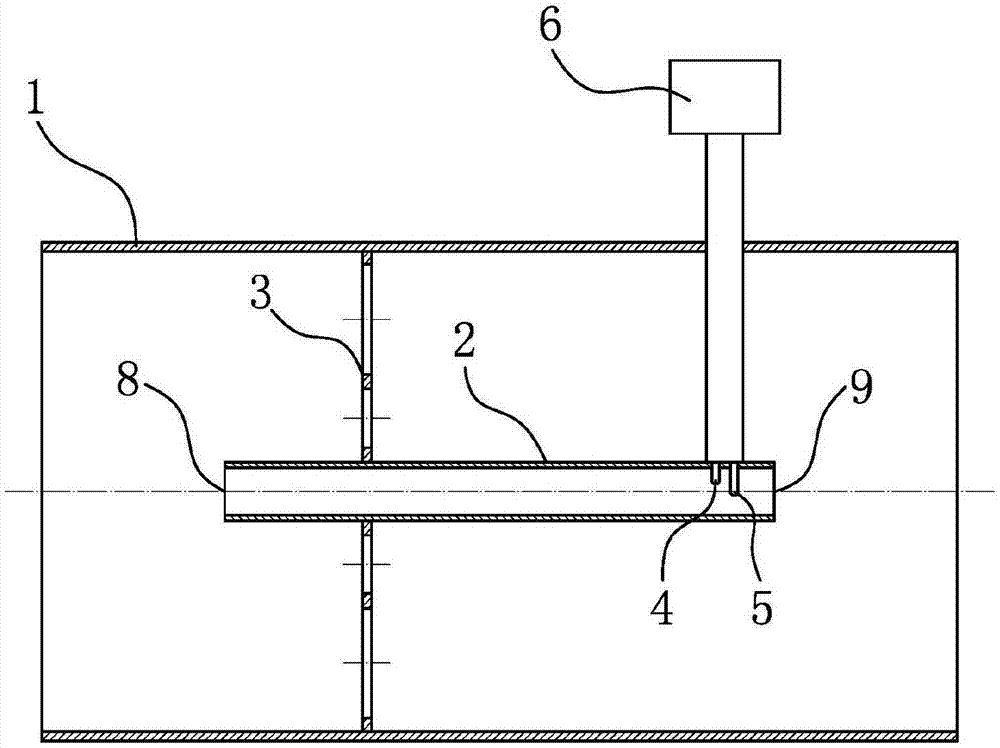

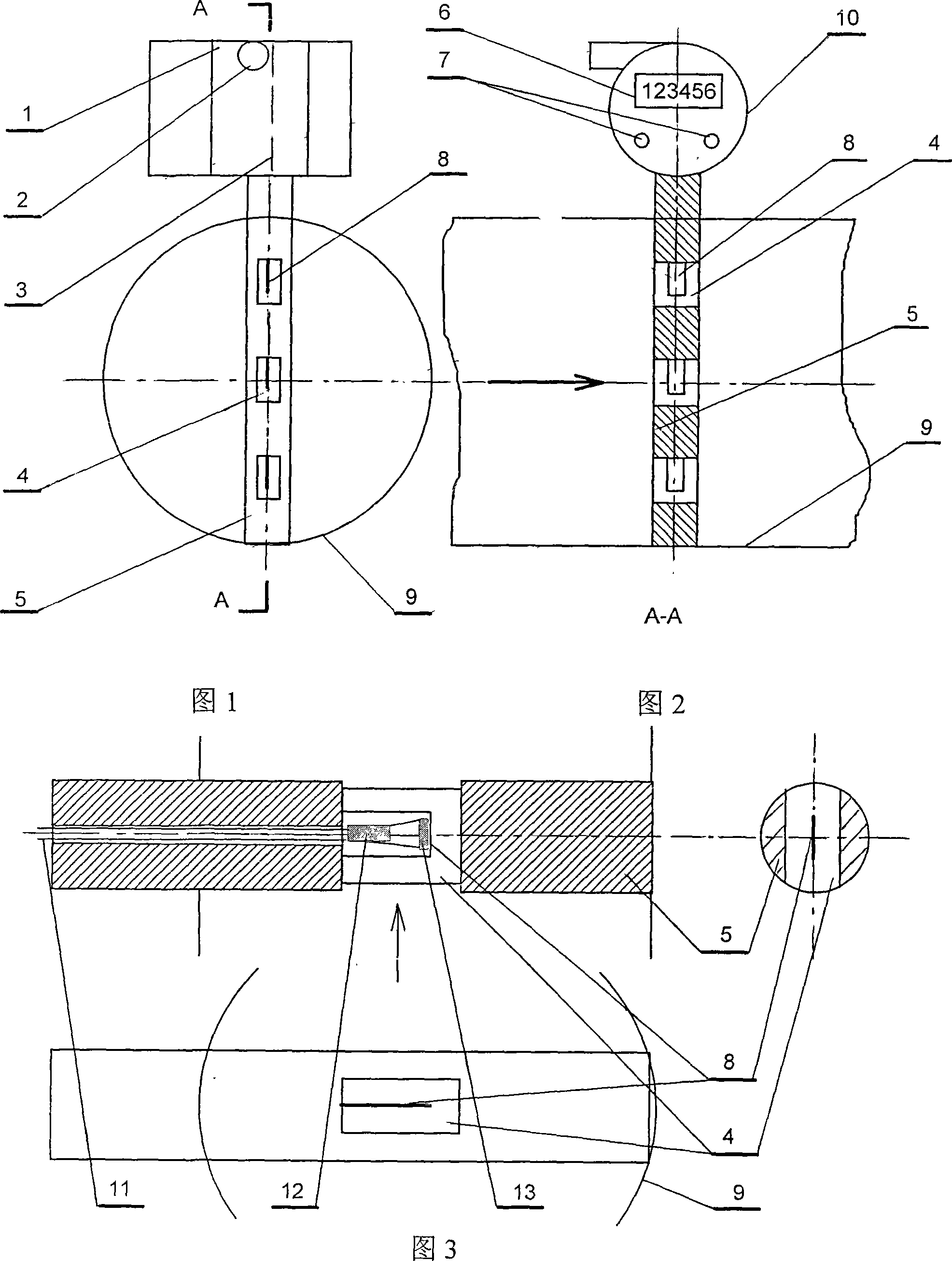

Electronic gas meter for mass and flow

InactiveCN101126652AImprove accuracyEasy to collectVolume meteringIndirect mass flowmetersGas meterProcess engineering

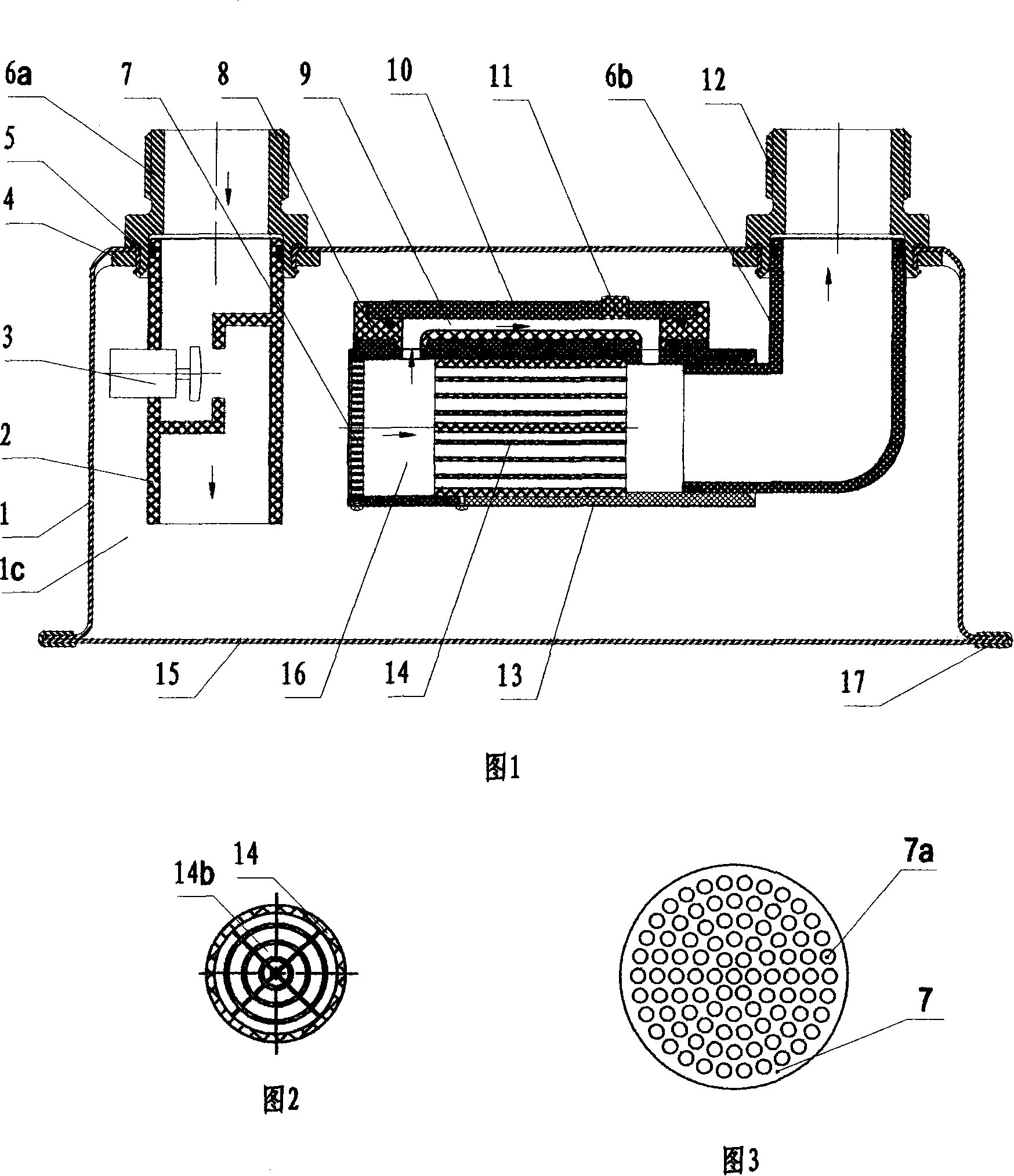

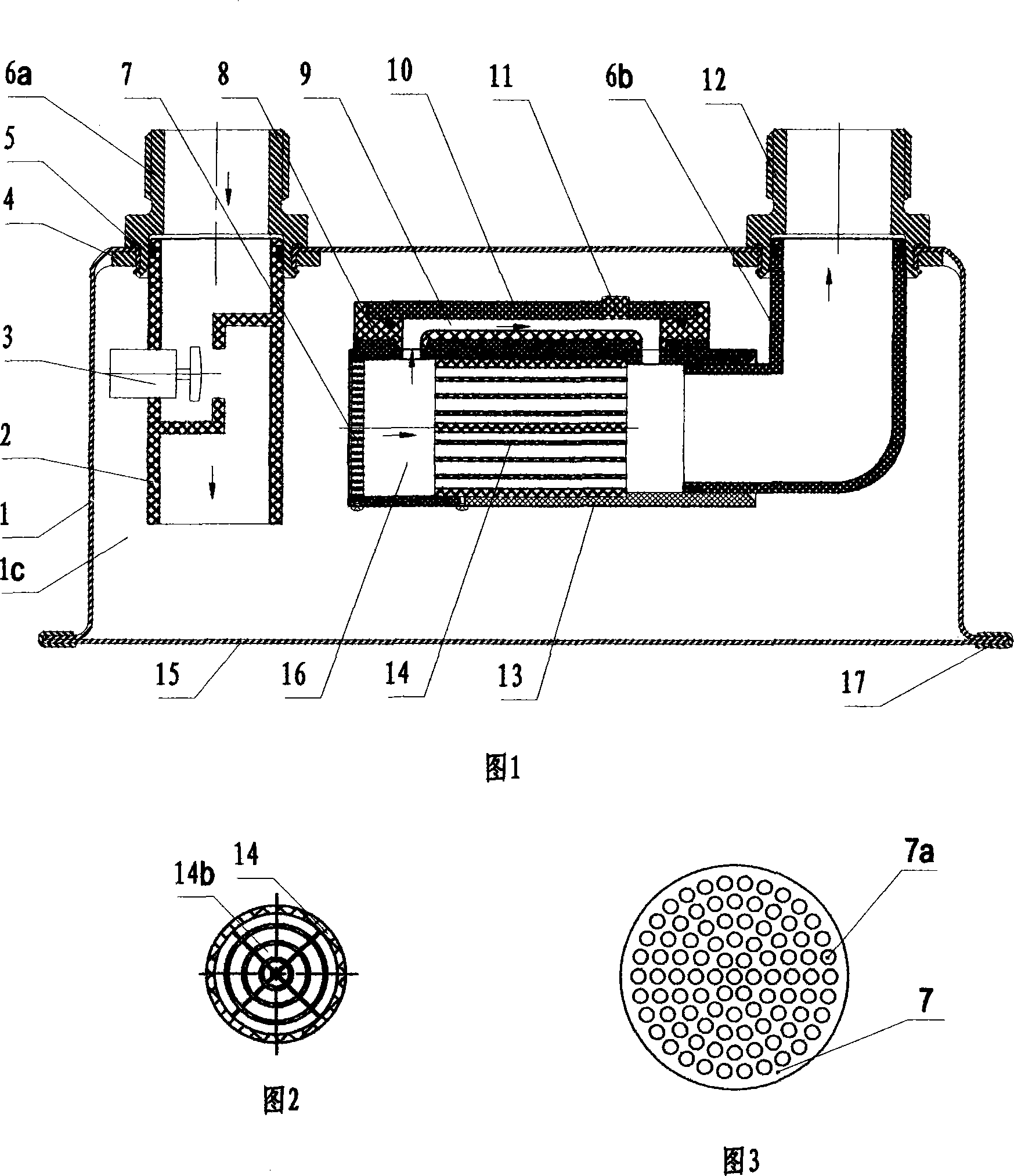

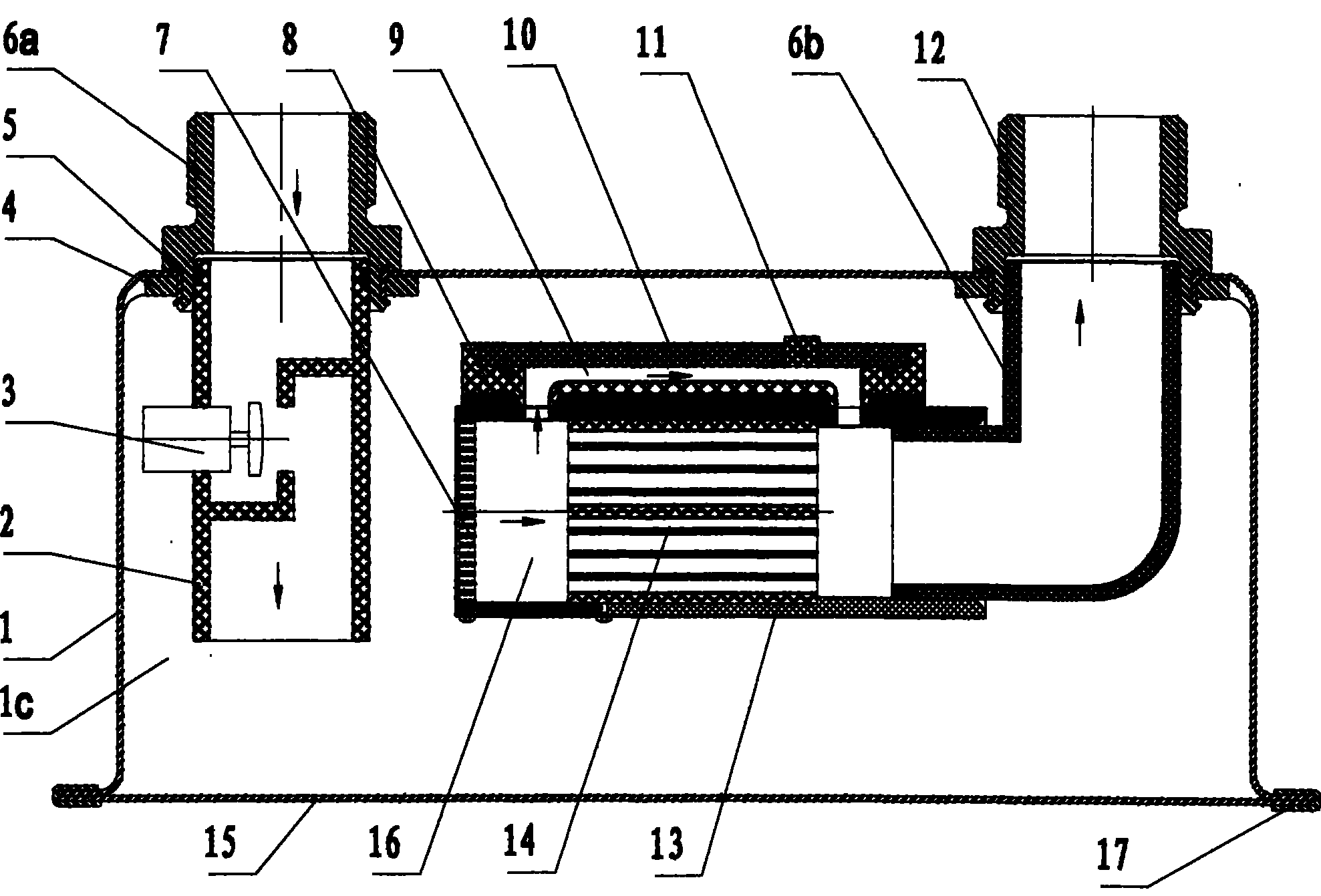

The utility model discloses an electronic mass flow gas meter; an airtight cavity is arranged in the casing of the gas meter. The gas pipelines in the casing are divided into an independent gas inlet pipe, and a flow testing tube and gas outlet pipe, which are connected together. The gas inlet and outlet pipes are respectively connected with the gas outlet and inlet interfaces of the casing. The lower end of the flow testing tube is connected with the gas outlet pipe and horizontally suspended inside the casing. A main flow airway and a bypass airway are arranged in the flow testing tube; wherein, a by-passing device is arranged in the main flow airway and arranged between the two through holes for communicating the bypass airways. The cross-sectional area of the bypass airway is smaller than that of the main flow airway, and a signal sensing module of thermal mass flow sensors is arranged on the inner wall of the bypass airway for detection. The utility model can carry out mass flow measurement of the passing gas, and can prevent the dust in the gas from attaching to the sensing element, thus improving the measuring accuracy and service life of the gas meters.

Owner:CHONGQING QIANWEI SCI & TECH GRP +1

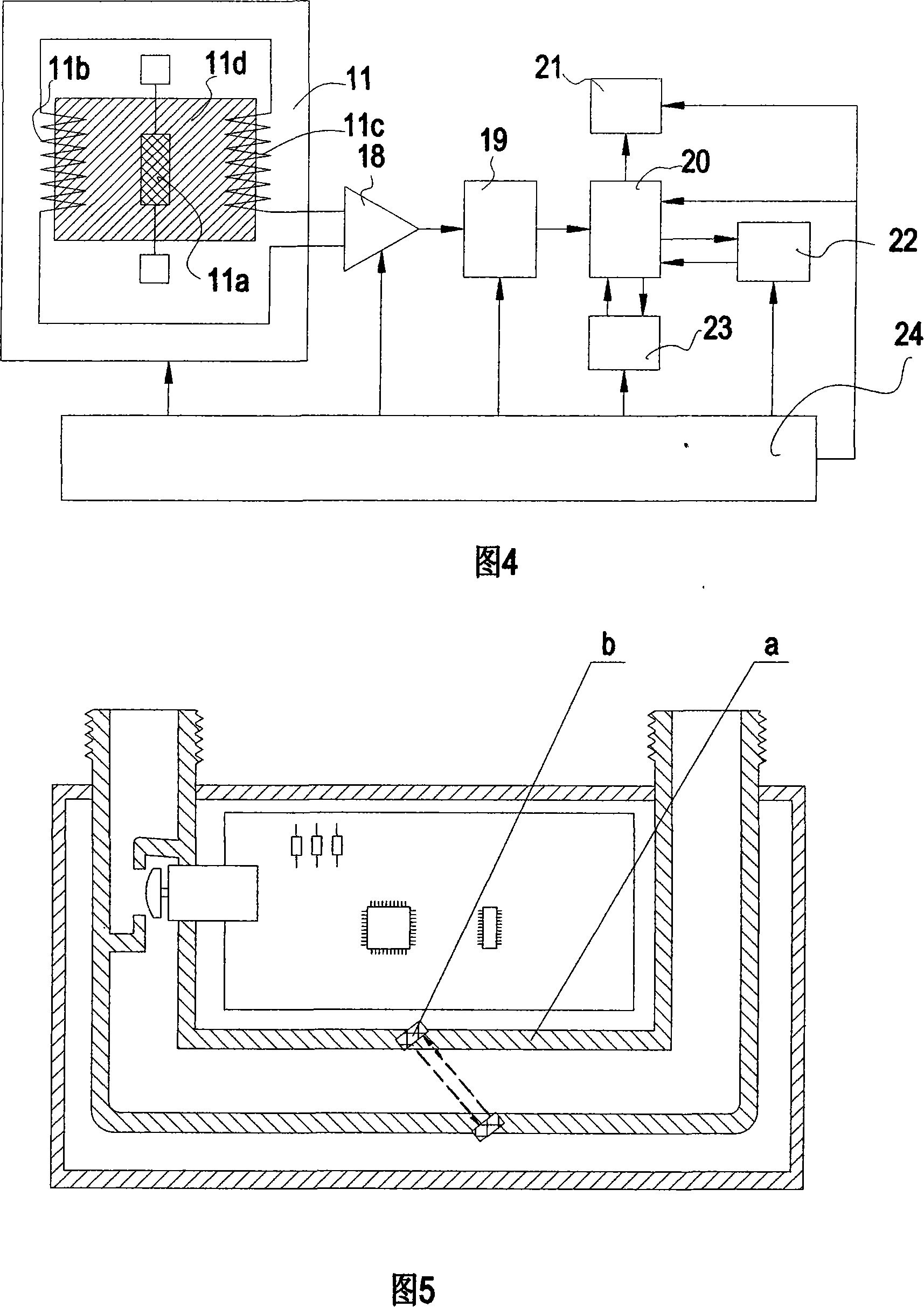

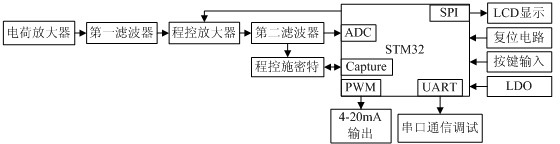

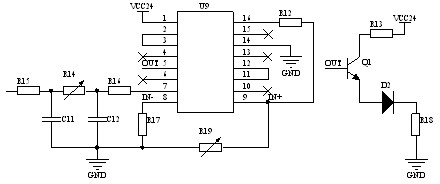

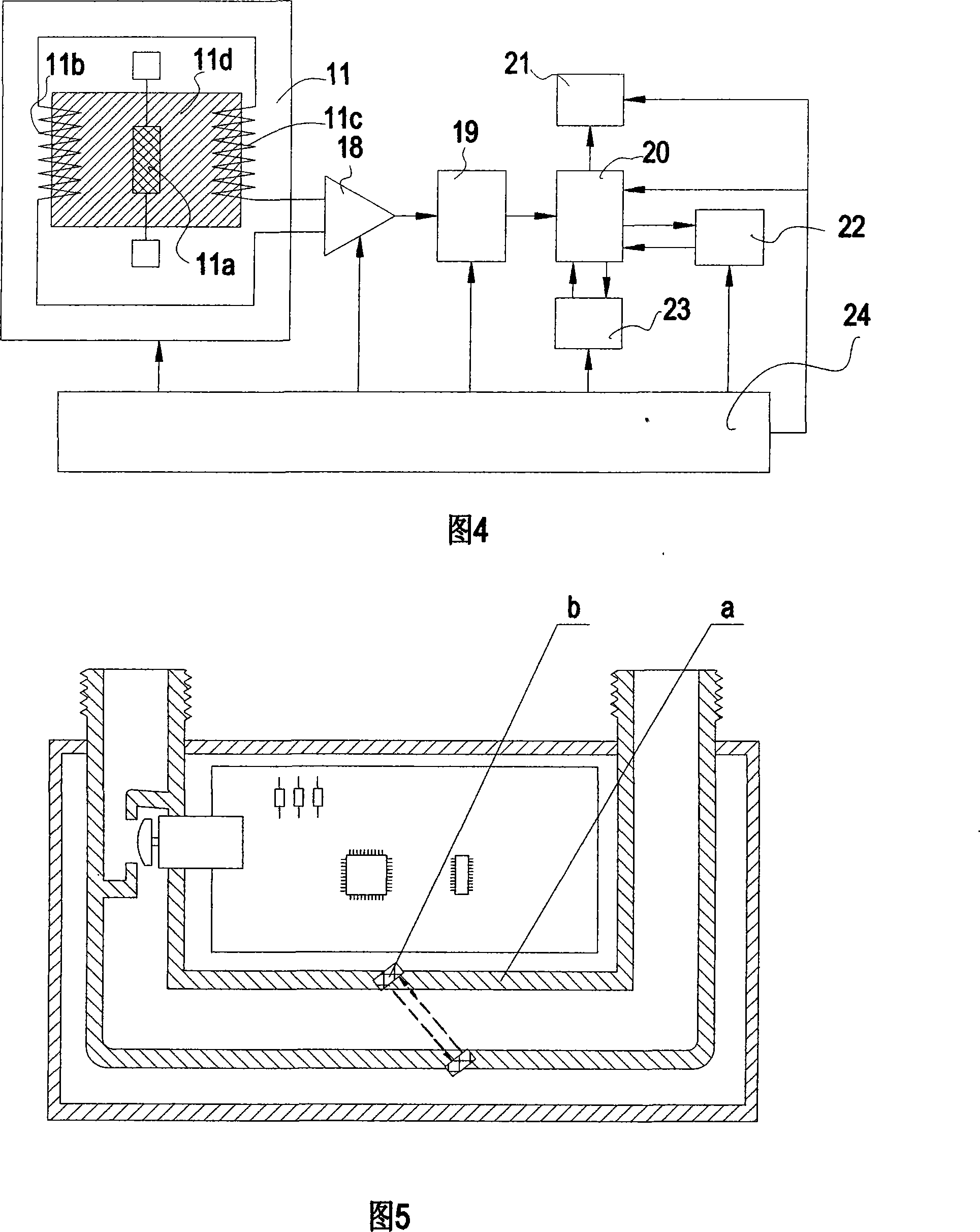

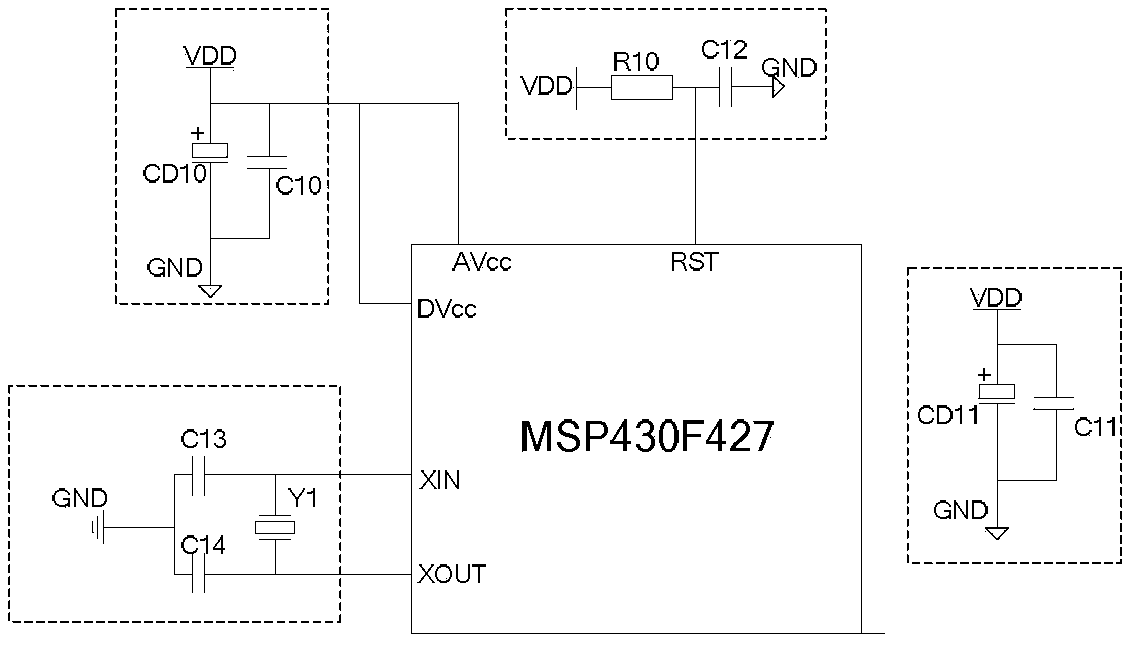

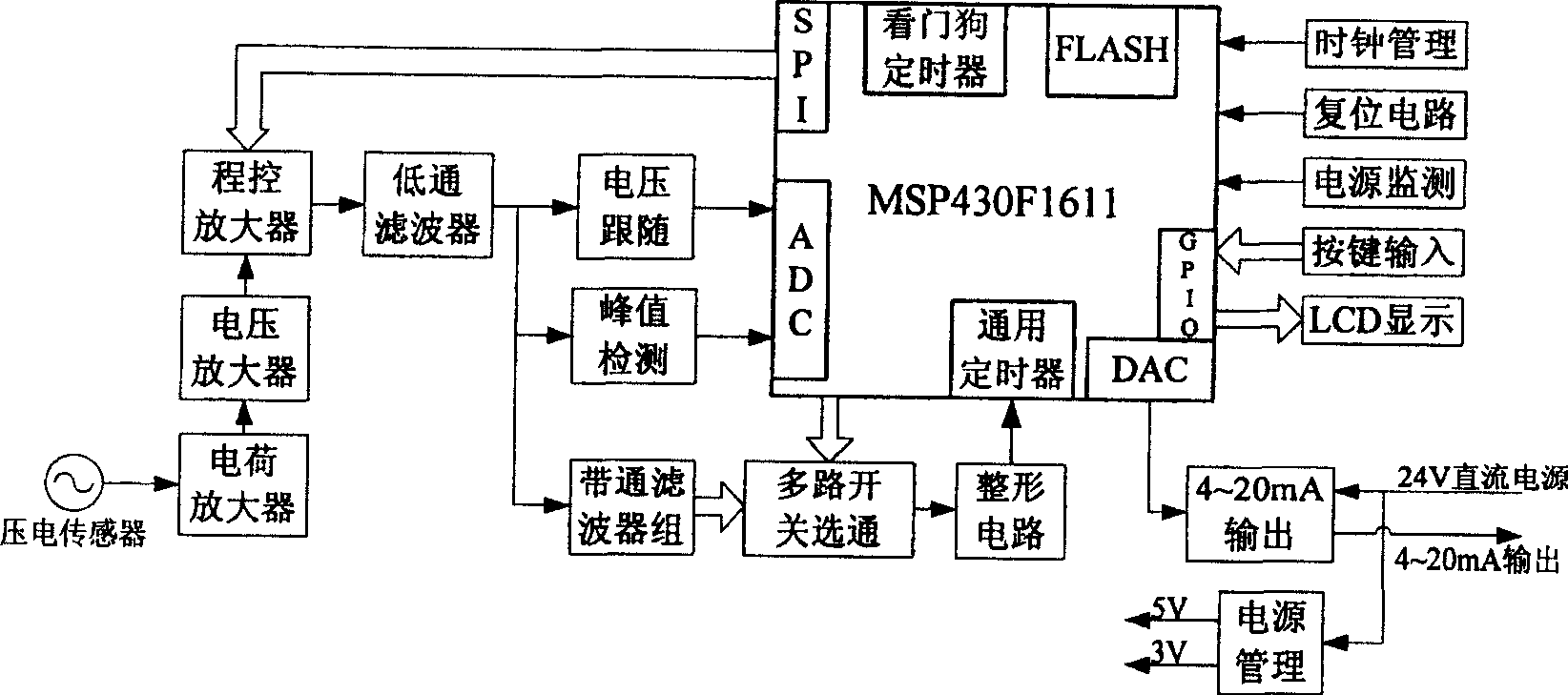

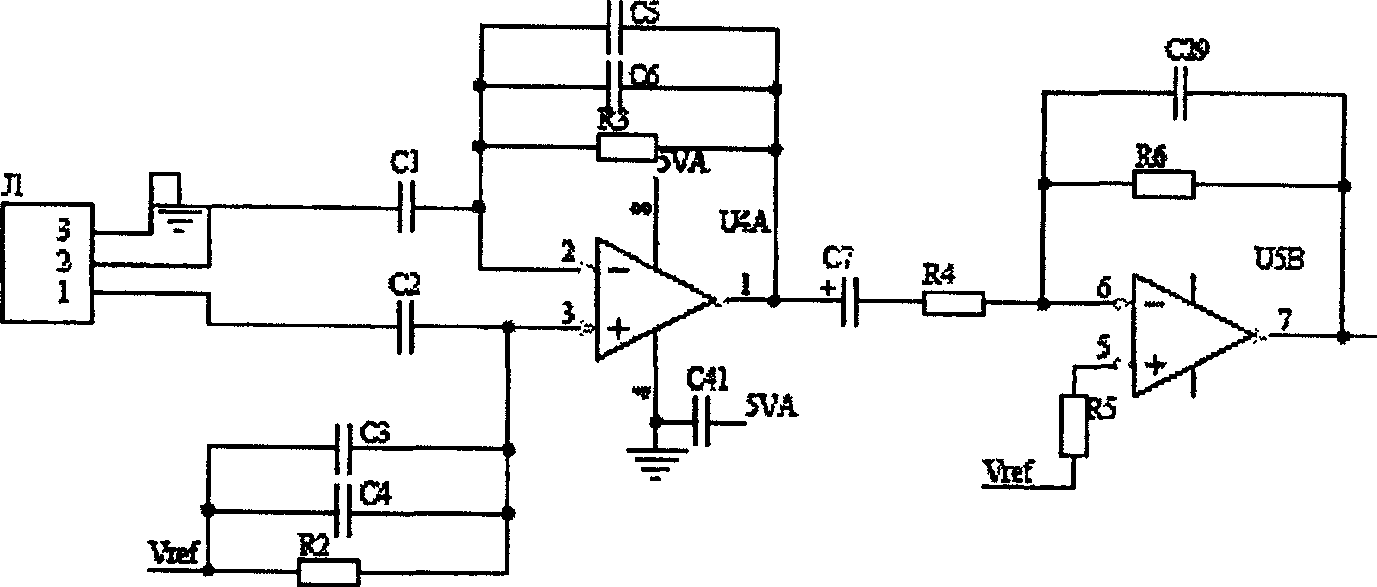

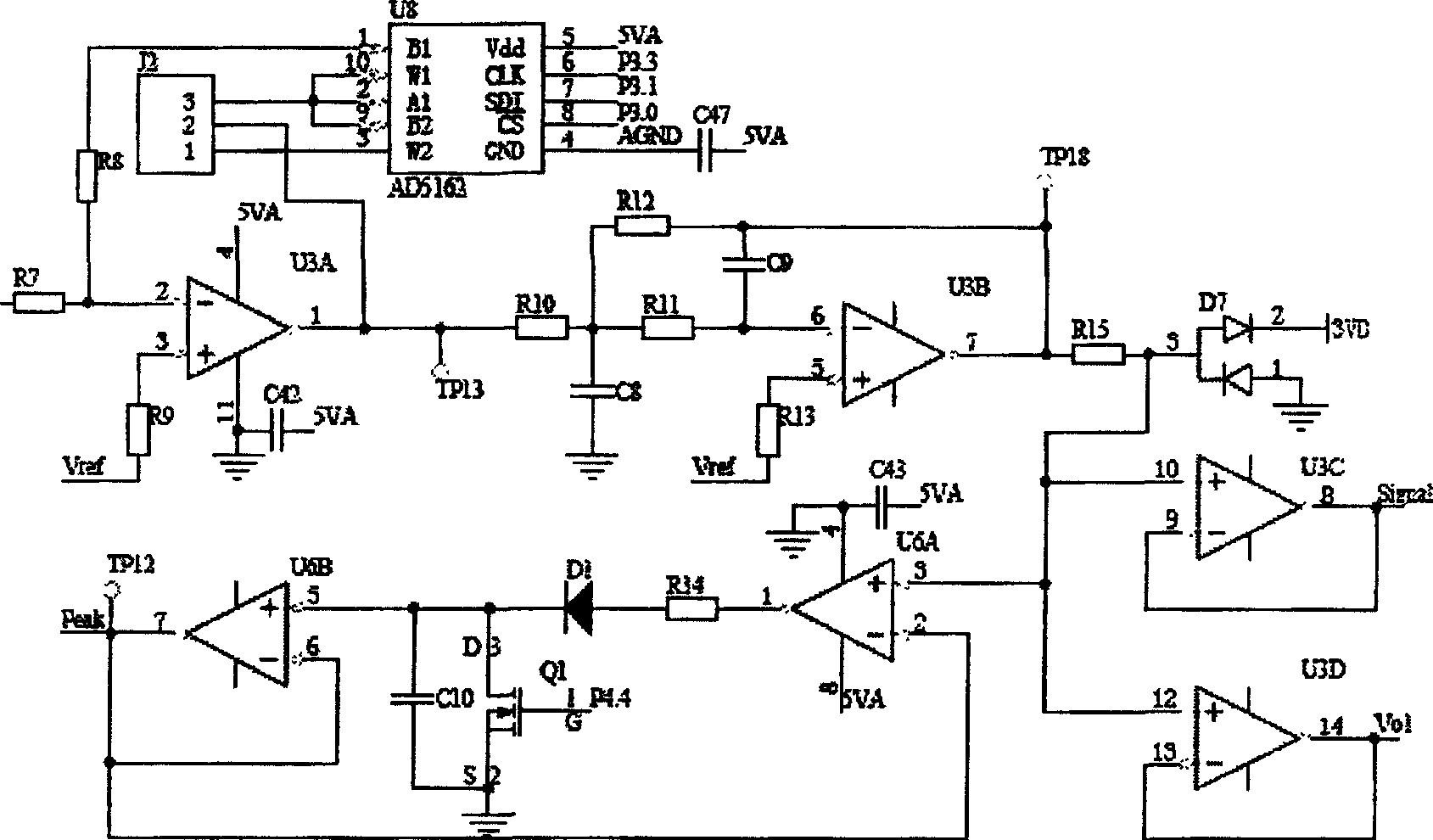

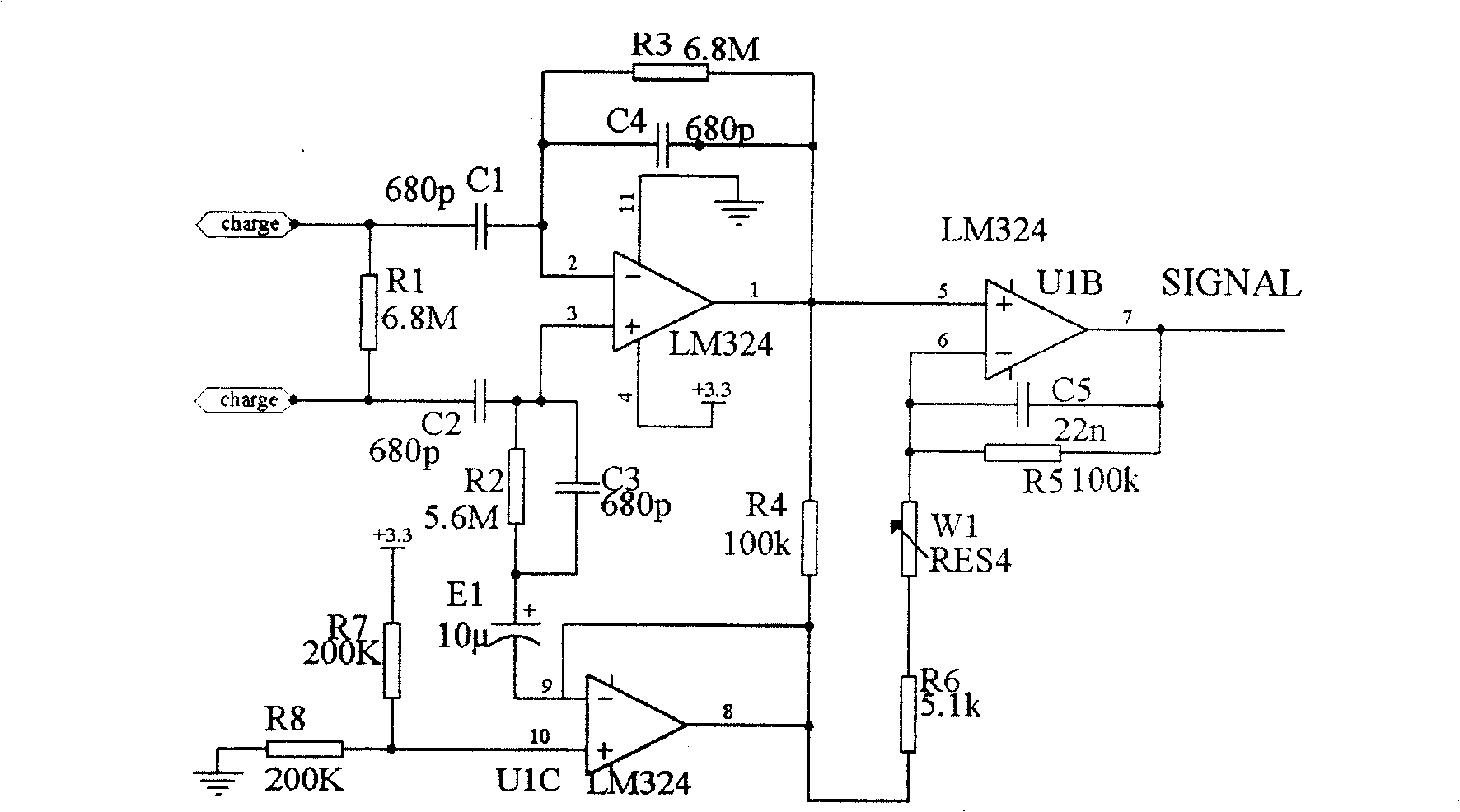

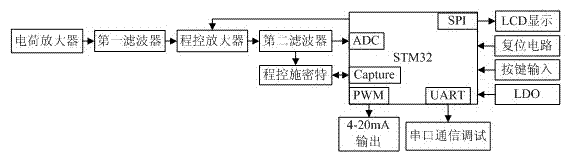

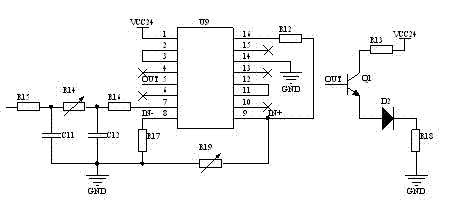

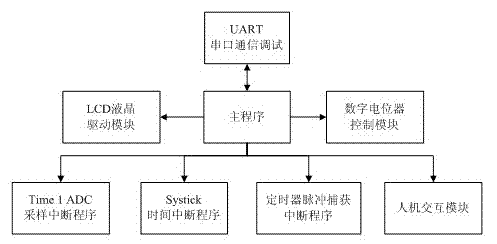

Vortex shedding flow meter based on self-adaptive fast Fourier transformation

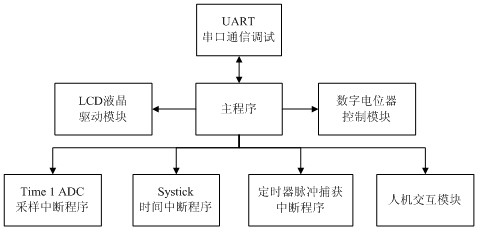

InactiveCN102322904AAccurate pulse signalHigh precision measurementVolume/mass flow by dynamic fluid flow effectMicrocontrollerSchmitt trigger

The invention relates to a vortex shedding flow meter based on self-adaptive fast Fourier transformation, which comprises a charge amplifier, a first filter, a program-controlled voltage amplifier, a second filter, a program-controlled scmitt trigger, a bias voltage circuit, a singlechip computer, an LDO (Low Dropout Regulator) circuit, a reset circuit, a key input, a 4-20mA output circuit and an LCD (Liquid Crystal Display) circuit. A signal generated by a vortex shedding sensor is connected with the charge amplifier; the output of the charge amplifier is connected with the first filter; the output of the first filter is connected with the program-controlled voltage amplifier; the output of the program-controlled voltage amplifier is connected with the second filter; the output of the second filter is divided into two paths, wherein one path is connected with the singlechip computer; the other path is connected with the program-controlled scmitt trigger; and the program-controlled scmitt trigger is connected with the singlechip computer. According to the vortex shedding flow meter disclosed by the invention, various noises can be effectively inhibited and low-flow and high-precision measurement is realized, thereby the measuring range ratio is enlarged and the measuring precision and the sensitivity are improved.

Owner:HANGZHOU DIANZI UNIV

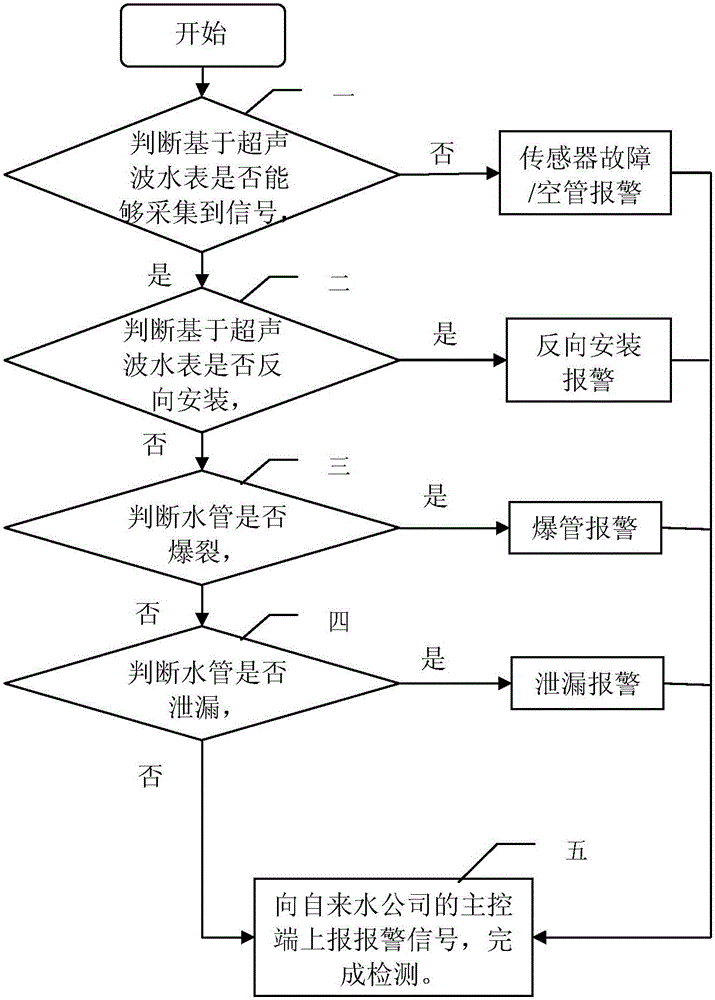

Pipeline leak and pipe burst detection method of ultrasonic water meter

InactiveCN105806429AEffective monitoringEfficient managementMeasurement of fluid loss/gain rateVolume/mass flow measurementEngineeringWater company

The invention relates to the technical field of water meter pipeline detection, in particular to a pipeline leak and pipe burst detection method of an ultrasonic water meter. The pipeline leak and pipe burst detection method of the ultrasonic water meter aims at solving the problem that due to various defects of an existing mechanical water meter, pipeline leak or pipe burst can not be reasonably detected. According to the pipeline leak and pipe burst detection method of the ultrasonic water meter, data collected by the water meter is compared step by step, then whether a sensor fault / pipe emptiness, water meter reverse installation, water pipe burst and water pipe leak happen to the water meter or not is judged step by step, and thus the water pipe state is reliably and effectively detected. The pipeline leak and pipe burst detection method of the ultrasonic water meter can be widely applied to water supply metering of water supply companies.

Owner:HARBIN SHENGCHANG TECH DEV

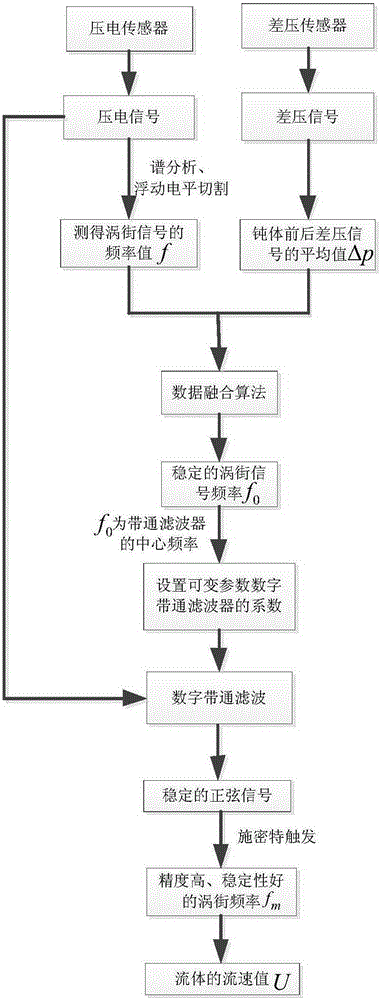

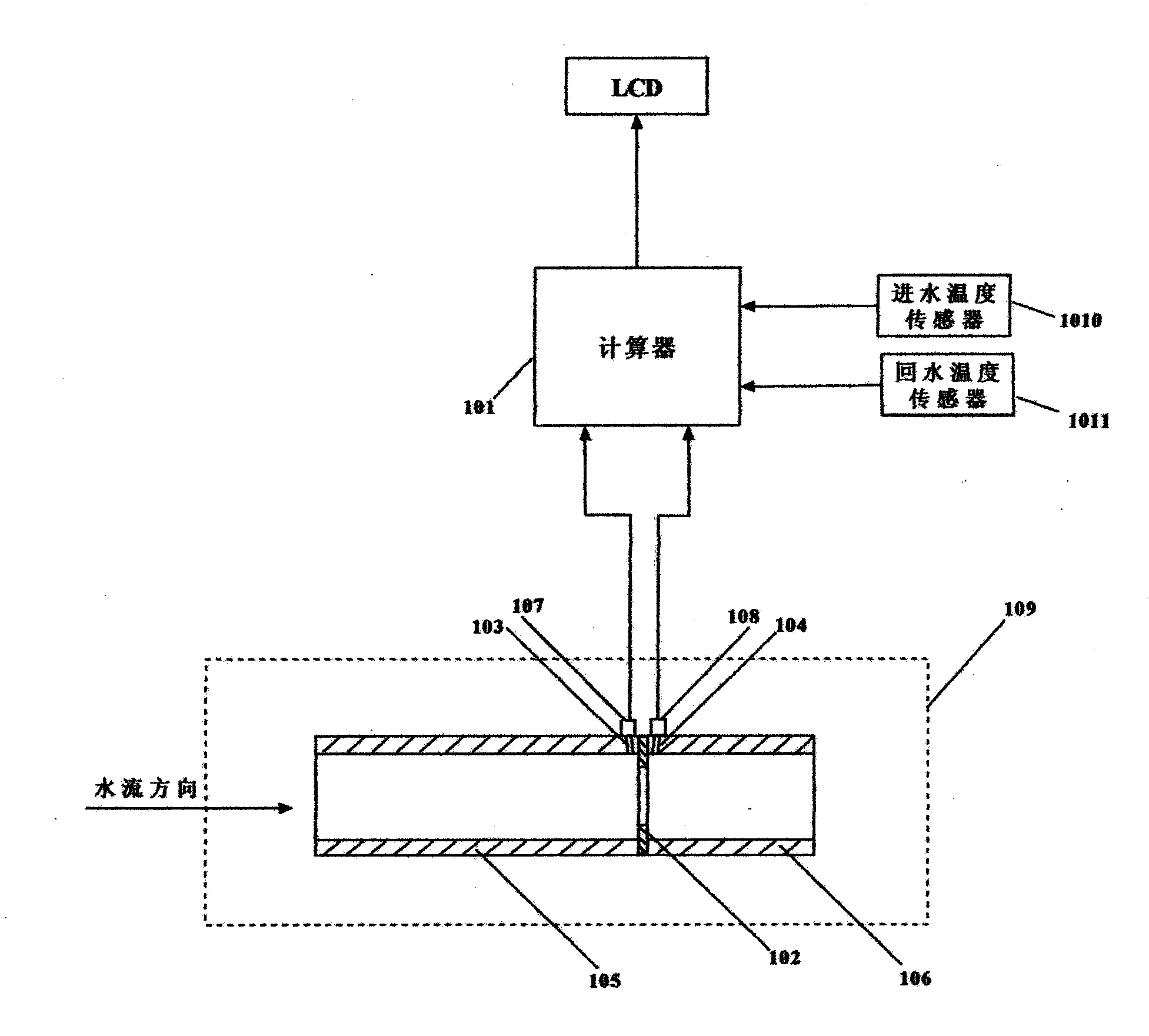

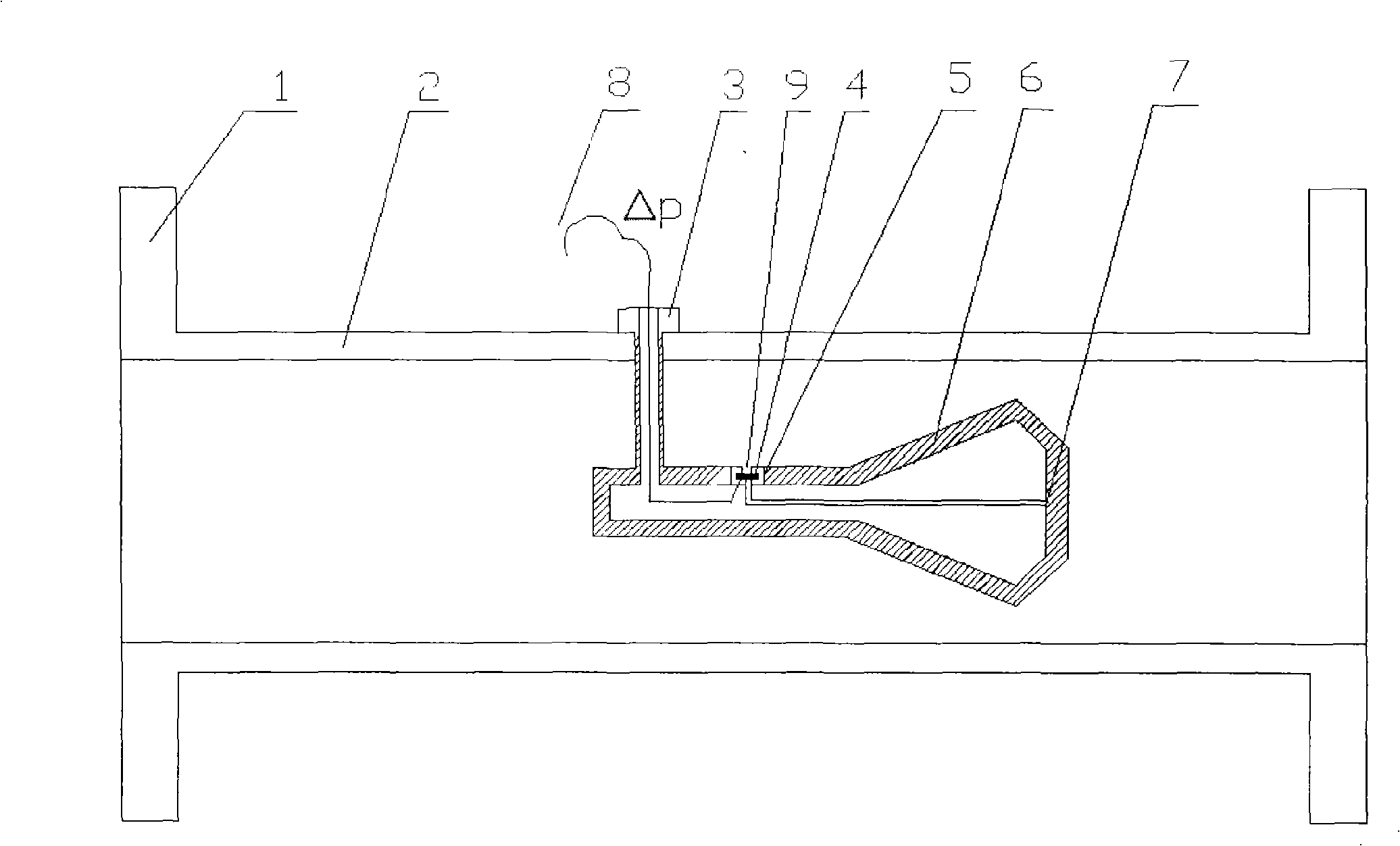

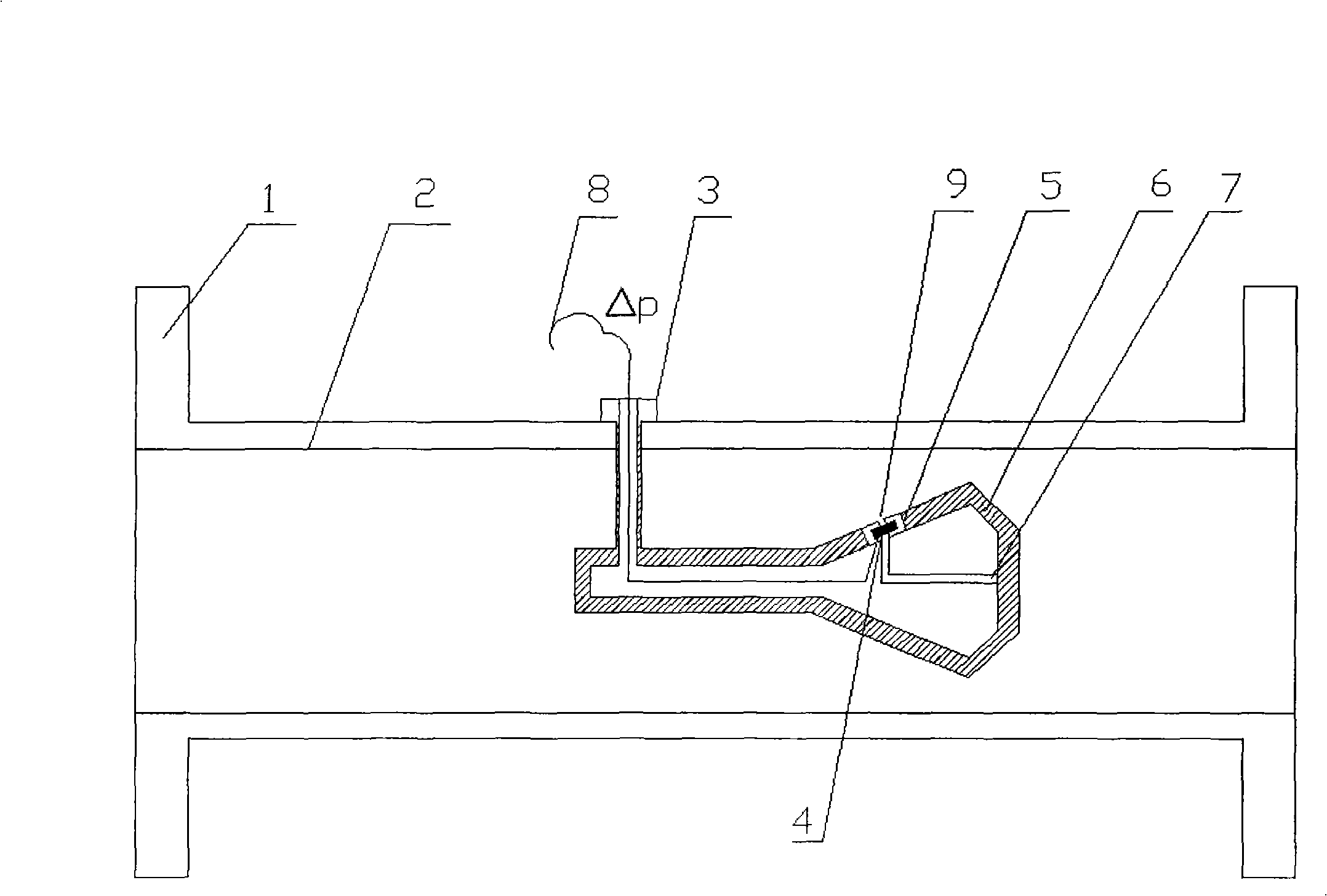

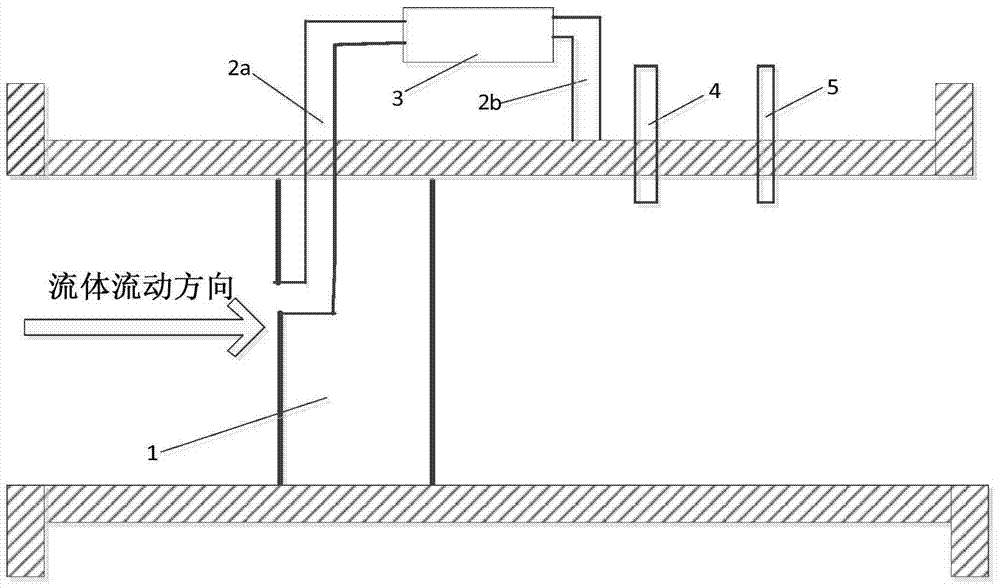

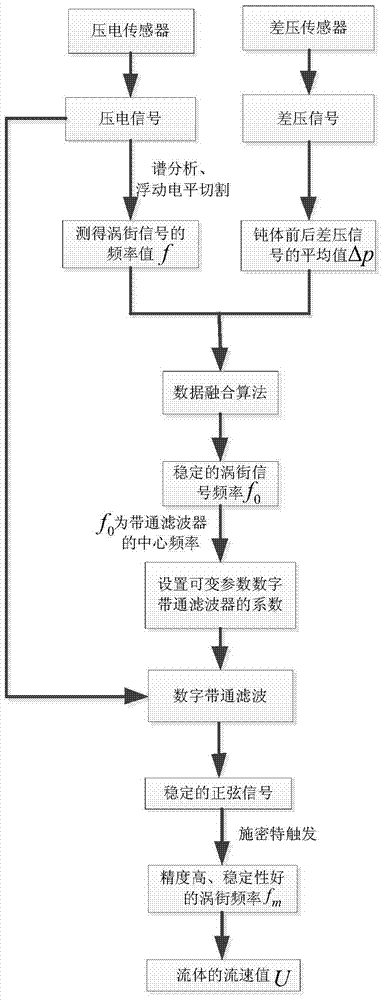

Vortex flowmeter based on multi-sensor information fusion

ActiveCN105181031AImprove filtering effectImprove signal-to-noise ratioVolume/mass flow by dynamic fluid flow effectElectricityLower limit

The invention discloses a vortex flowmeter based on multi-sensor information fusion. The vortex flowmeter has functions of effectively inhibiting an interference of a strong periodic vibration noise in a piezoelectric transducer signal, extracting a useful vortex signal from the piezoelectric transducer signal and accurately measuring the flow speed of fluid. The vortex flowmeter is characterized in that a temperature sensor and a differential pressure sensor with high vibration resistance are added on a traditional piezoelectric vortex flowmeter; the temperature sensor can be used for compensating the temperature drifts of the piezoelectric transducer and the differential pressure sensor; a multi-sensor data fusion algorithm based on an unscented Kalman Filter is used; Data fusion between an average value of the differential pressure which is output by the differential pressure sensor and a frequency of a piezoelectric signal that is obtained by the piezoelectric sensor is performed. The precision in locking a digital bandpass filter is improved. The vortex flowmeter has advantages of improving a measured signal-to-noise ratio of the vortex signal, improving vibration resistance of the piezoelectric vortex flowmeter, reducing a measurement lower limit of a least flow speed, enlarging a measuring range ratio, etc.

Owner:HANGZHOU ZIWU INSTR

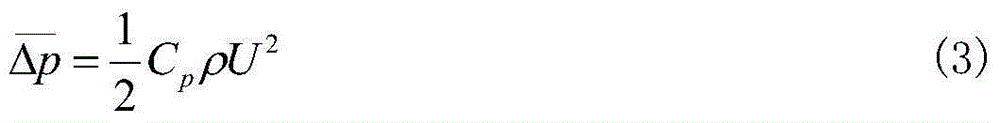

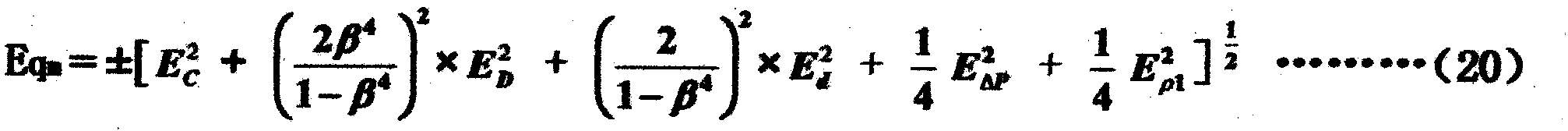

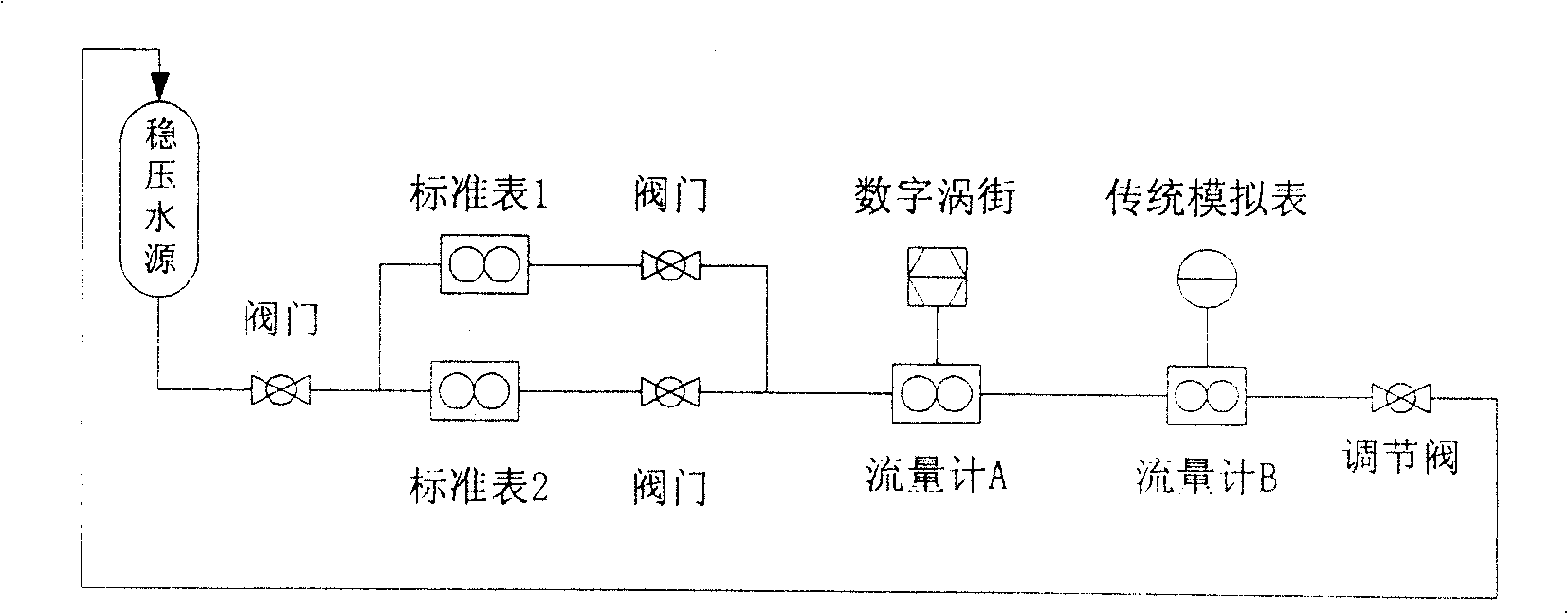

Large-diameter standard throttle device-type heat meter and calibration method thereof

InactiveCN104075828AHigh sensitivityHigh differential pressure accuracyCalorimeterDevice typeEngineering

The invention discloses a large-diameter standard throttle device-type heat meter, which comprises a calculator, a water inlet temperature sensor, a backwater temperature sensor and a large-diameter flow sensor composed of a large-diameter standard throttle device, an upstream pressure sensor and a downstream pressure sensor. The standard throttle device is composed of a standard throttle piece, a standard pressure tapping, a front measurement tube and a back measurement tube. The invention also provides a calibration method of the large-diameter standard throttle device-type heat meter. The method comprises the following steps of calibration of the large-diameter standard throttle device flow sensor in a geometrical calibration method, calibration of pressure sensors, calibration of temperature sensors and calibration of the calculator. The large-diameter standard throttle device-type heat meter adopts the intelligent real-time detection technology and the data processing method, thereby improving the measurement precision and expanding a span ratio. The calibration method of the invention is a low-cost, low-energy consumption and advanced dry calibration method. The problem that the large-diameter heat meter can not be detected at present can be solved.

Owner:纪周

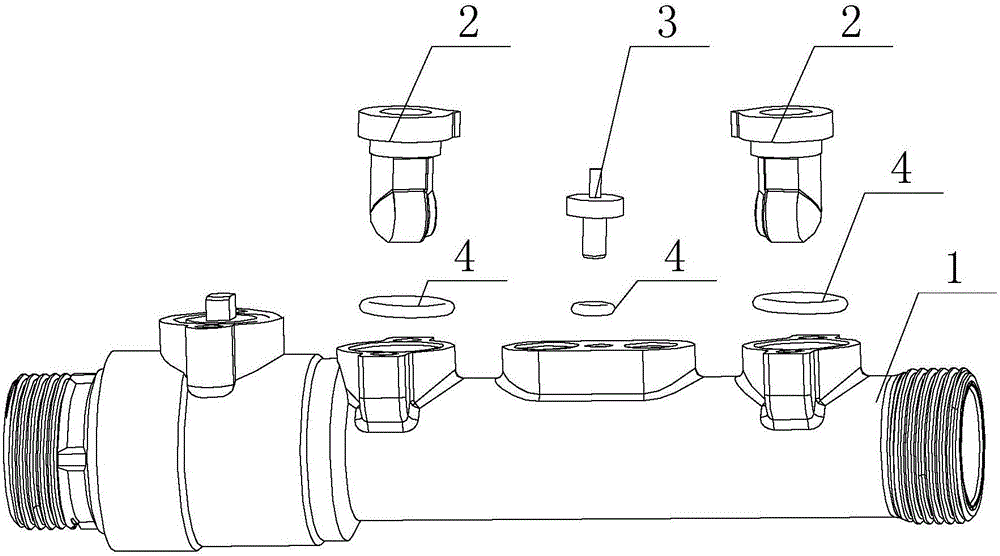

Stainless-steel ultrasonic water meter

InactiveCN105758478AEfficient managementReliable data collection and management systemVolume/mass flow measurementPropagation timeWater quality

The invention discloses a stainless-steel ultrasonic water meter, and relates to the field of water meters. The stainless-steel ultrasonic water meter aims at solving the problem that multiple defects exist in a mechanical water meter used by an existing inhabitant. According to the stainless-steel ultrasonic water meter, the ultrasonic time difference principle is adopted, a full-electronic water meter made by industrial-grade electronic components is adopted, and compared with a mechanical water meter, the full-electronic water meter has the advantages that accuracy is high, reliability is good, the range ratio is wide, the service life is long, no moving part exists, parameters do not need to be set, and installing is carried out at any angle. On the basis of the metering mode of the ultrasonic water meter, the wireless collecting and reading characteristic and the valve control characteristic are also added. A pair of ultrasonic transducers are applied to receiving and sending ultrasonic waves at a flow measurement part in the opposite directions, the flow velocity of fluid is indirectly measured by observing the propagation time difference of downstream and upstream of the ultrasonic waves in a medium, and then the flow is calculated through the flow velocity. The stainless-steel ultrasonic water meter is high in measuring accuracy, convenient to use and prone to digital management; compared with water meters made of existing materials, the water quality is guaranteed; the stainless-steel ultrasonic water meter is suitable for measuring the water yield of a tap water pipe.

Owner:HARBIN SHENGCHANG TECH DEV

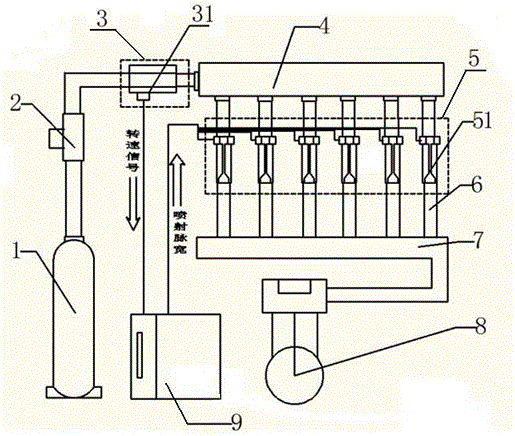

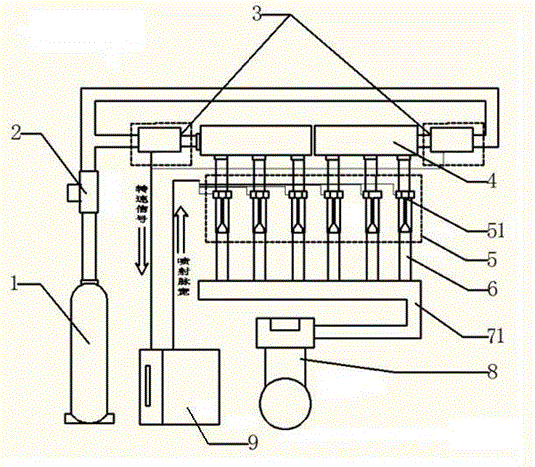

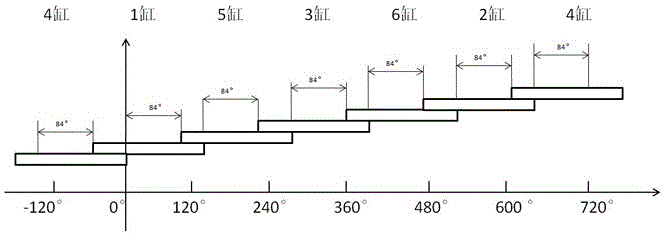

System and method for controlling uniformity of gas injection amount of natural gas engines for vehicles

InactiveCN105840372AImprove uniformityMaintain stable torque outputFuel injection apparatusMachines/enginesSpray nozzleProcess engineering

The invention discloses a gas injection quantity uniformity control system and control method of a natural gas engine for a vehicle, which includes an ECU, a natural gas supply bottle and an injection system equal to the number of cylinders of the engine, and each injection system includes at least one gas rail and The injection unit connected to the ECU has a metering unit between the air inlet of each air rail and the high-pressure solenoid valve. Each metering unit includes a millisecond-level rotameter connected to the ECU. The millisecond-level The rotameter can measure the transient flow of natural gas at the millisecond level. After adopting the above-mentioned structure and method, the uniformity of natural gas injection volume can be significantly improved, the control problem caused by the consistency of nozzles in the natural gas engine control system can be solved, the state of the injection system can be monitored in real time, and the stable torque output of the natural gas engine can be maintained, which is beneficial The development of in-cylinder direct injection lean-burn natural gas engine is applicable to natural gas engines of various displacements.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

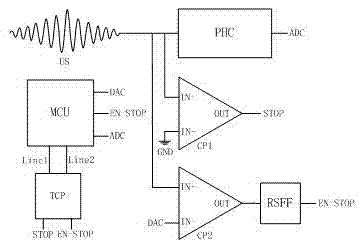

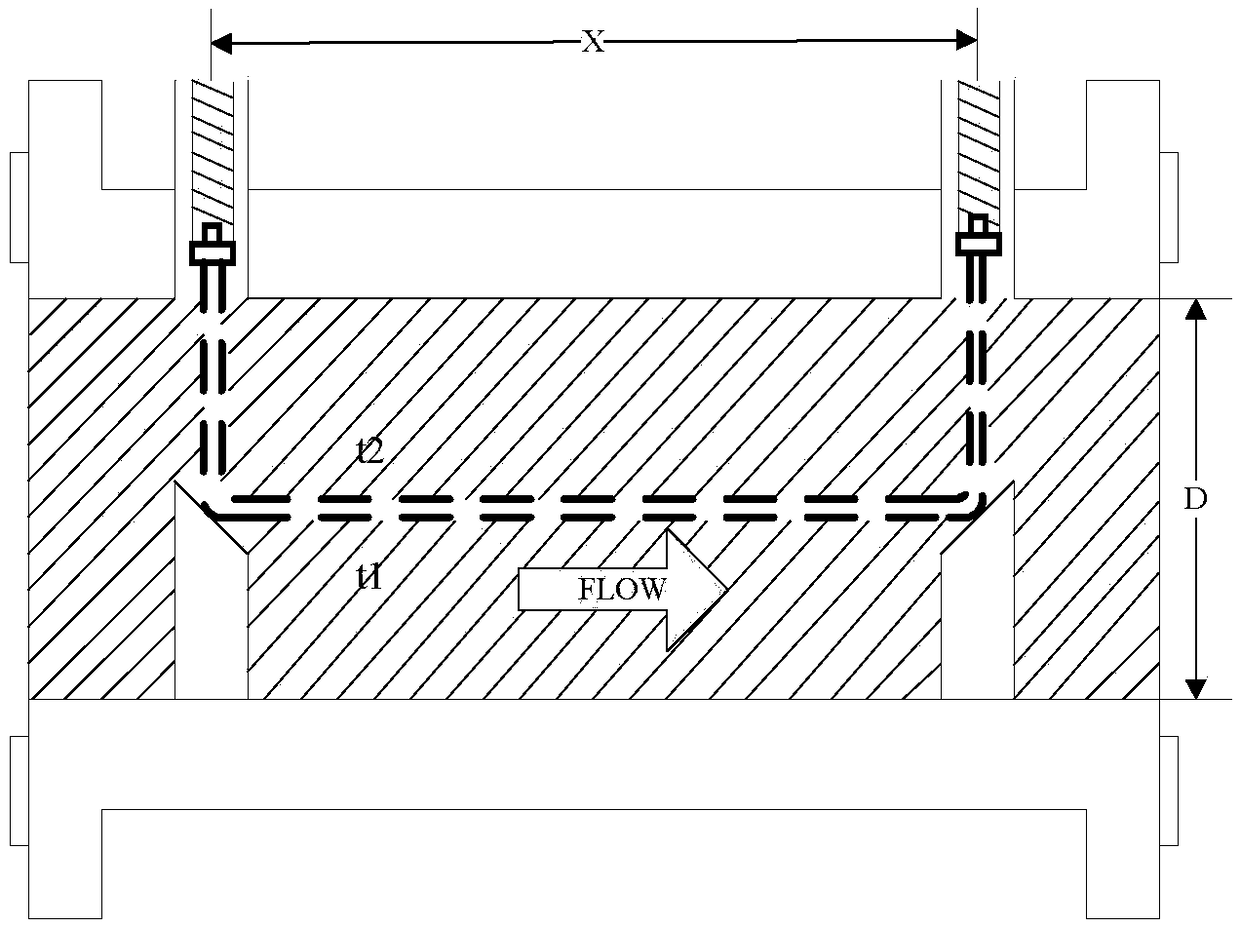

Time detection method for increasing anti-interference capability of time difference type ultrasonic flowmeter

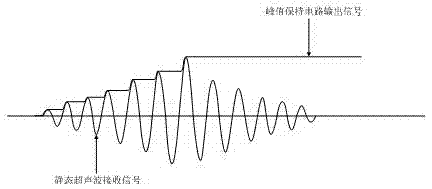

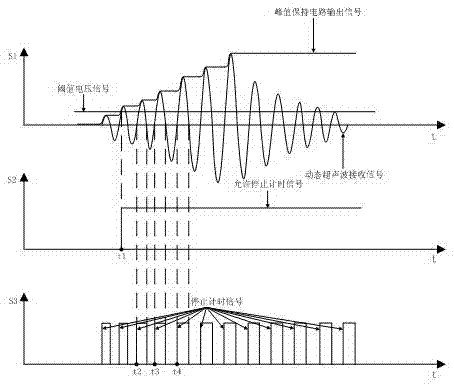

InactiveCN106932038AImprove anti-interference abilityRaise the upper limit of measurementVolume/mass flow measurementSignal onInterference factor

The invention discloses a time detection method for increasing the anti-interference capability of a time difference type ultrasonic flowmeter. The method comprises the following steps: receiving a determination method for signal peak sequence positions and obtaining information on supersonic wave peak position; utilizing a timing chip to obtain three and more time value of zero crossing points of ultrasonic receiving signals after receipt signals reach threshold voltage for the first time; utilizing a self-adaptive algorithm for propagation time value according to position information on wave peaks, selecting one of obtained time value of zero crossing points of ultrasonic receiving signals as propagation time value for ultrasonic receiving signals; achieving accurate measurement of propagation time value for ultrasonic receiving signals on the condition that interference factors change. The time detection method for increasing the anti-interference capability of the time difference type ultrasonic flowmeter has the following beneficial effects: the capability to resist the interference factors is increased; on the harsh working condition, accuracy of measurement for propagation time value for ultrasonic receiving signals is ensured; measurement precision is increased; and measurement upper limit and the ratio of measuring range are increased.

Owner:ZHEJIANG UNIV

Electronic gas meter for mass and flow

InactiveCN101126652BImprove accuracyEasy to collectVolume meteringIndirect mass flowmetersGas meterProcess engineering

Owner:CHONGQING QIANWEI SCI & TECH GRP +1

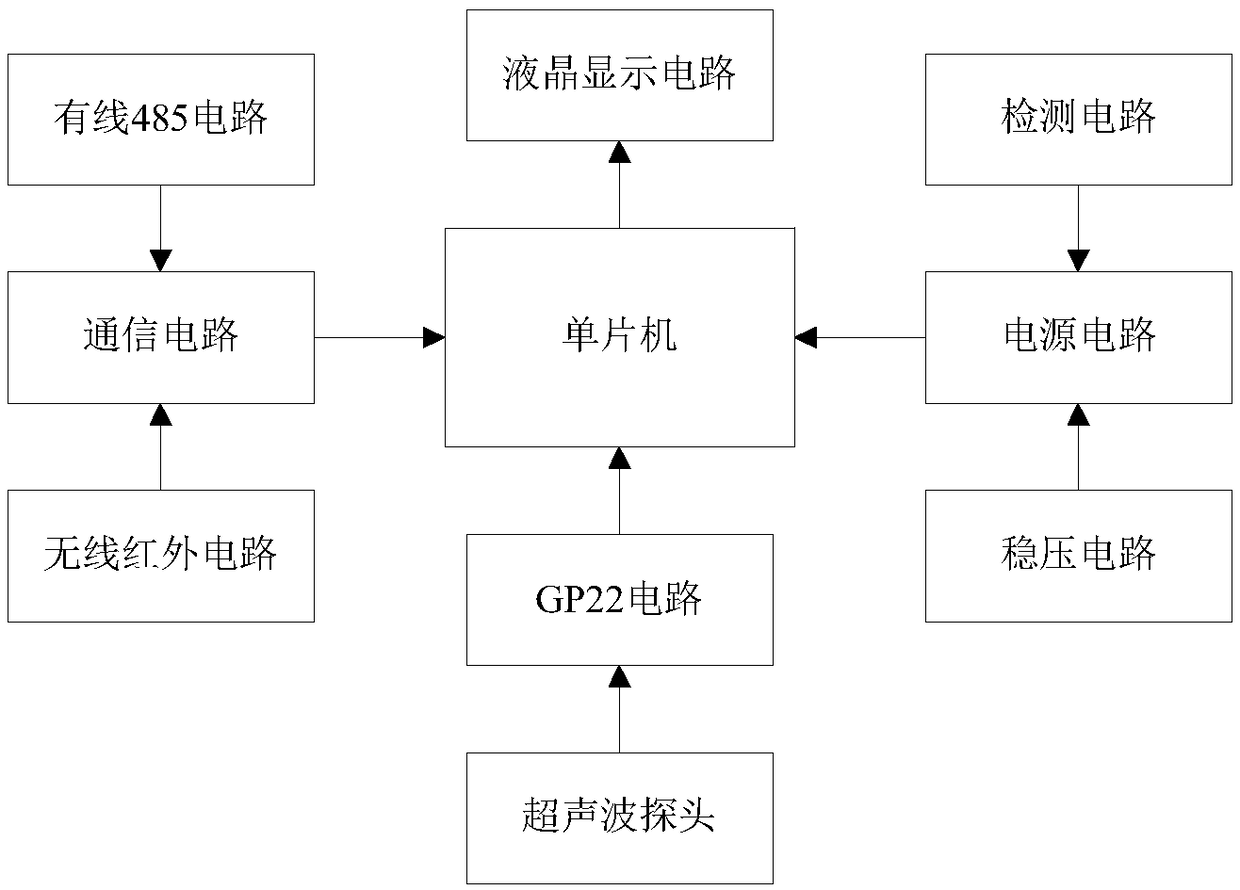

Wireless valve control ultrasonic water meter

InactiveCN105758477ABeautiful appearanceAccurate measurementVolume/mass flow measurementTime differenceMoving parts

The invention provides a wireless valve control ultrasonic water meter and relates to the field of water meters. The wireless valve control ultrasonic water meter aims at solving the problem that existing mechanical water meters used by residents have multiple defects. The ultrasonic time difference principle is adopted, the full-electronic water meter is manufactured from industrial-grade electronic components, and compared with the mechanical water meters, the wireless valve control ultrasonic water meter has the advantages that precision is high, reliability is good, the range ratio is large, the service life is long, no moving part is arranged, parameter setting is not needed, and the water meter can be installed at any angle. Based on the metering mode of the ultrasonic water meter, the advantages of wireless centralized collecting and valve control are added. A pair of ultrasonic transducers is applied to a flow measuring part for oppositely receiving and transmitting ultrasonic waves, the flow speed of fluid is indirectly measured by observing the fair flow and reverse flow propagation time difference of the ultrasonic waves in a medium, and the flow is calculated through the flow speed. The wireless valve control ultrasonic water meter can be widely applied to water supply metering of a running water company.

Owner:HARBIN SHENGCHANG TECH DEV

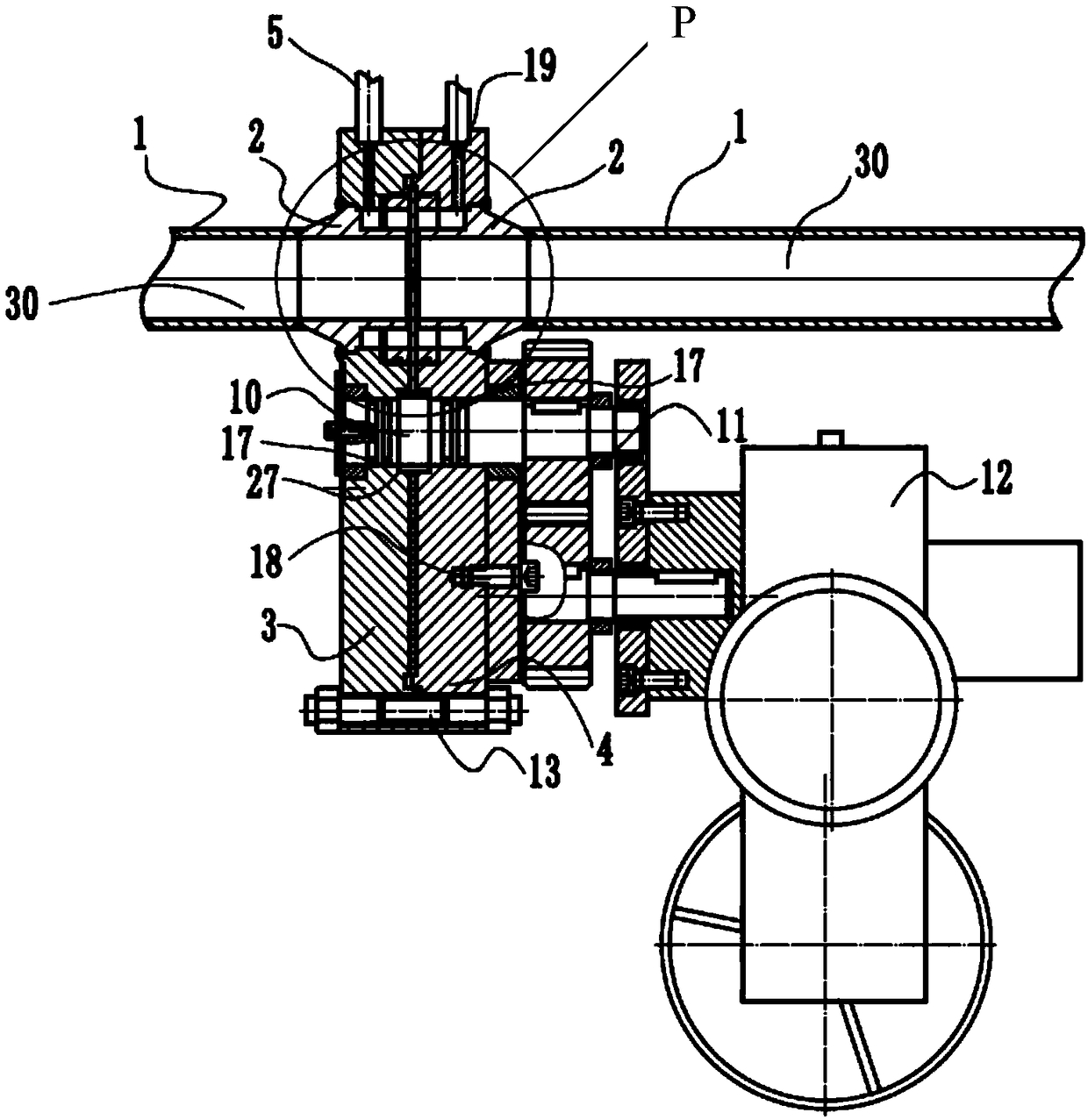

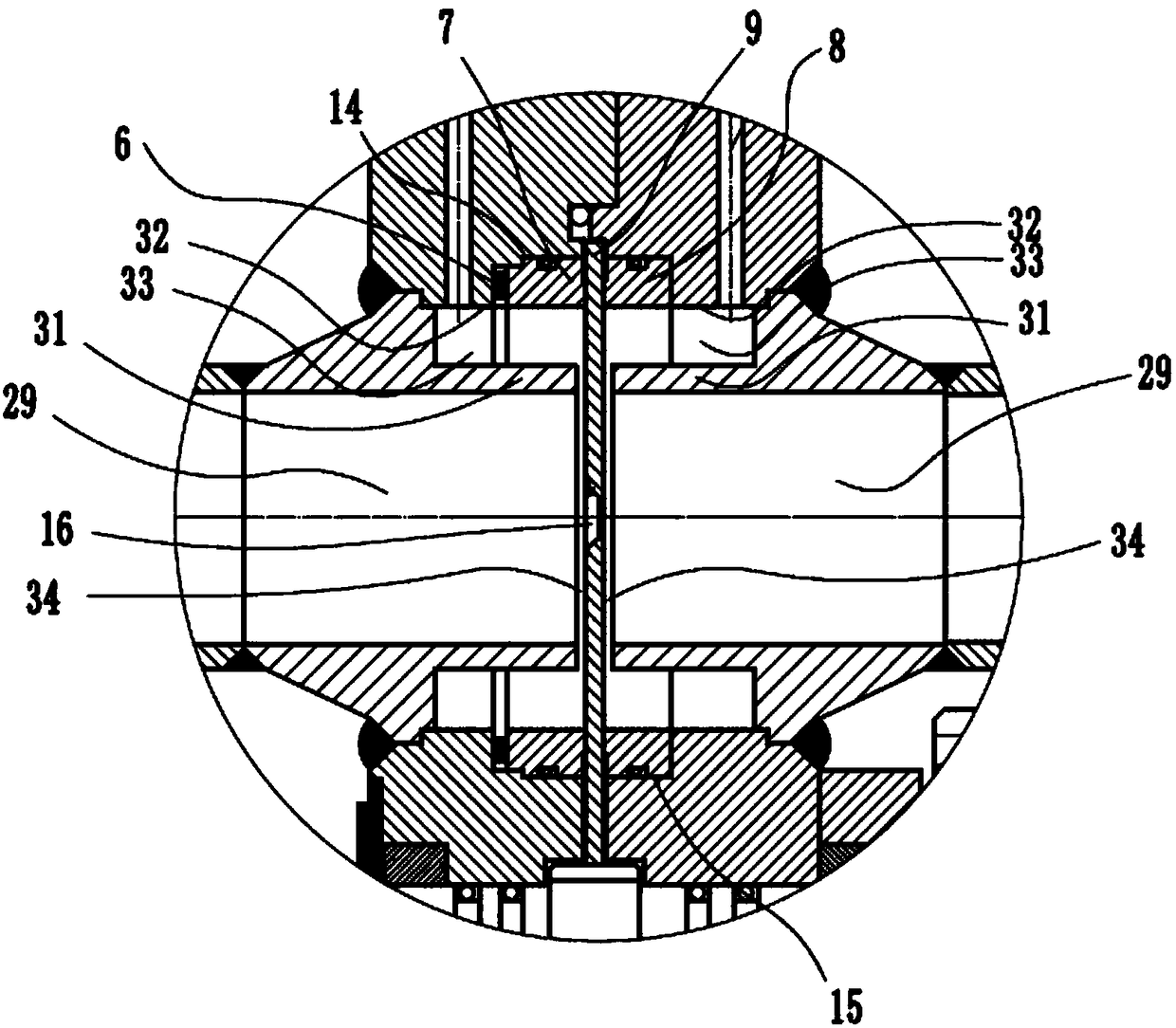

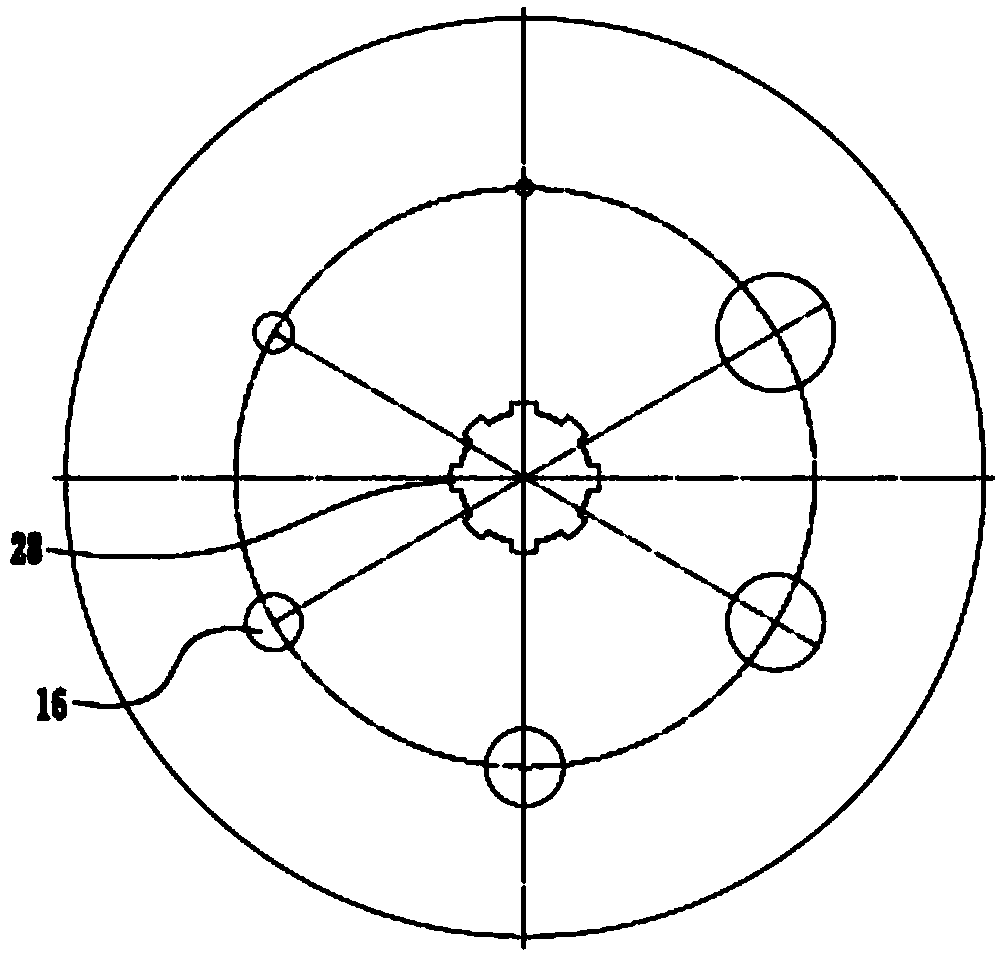

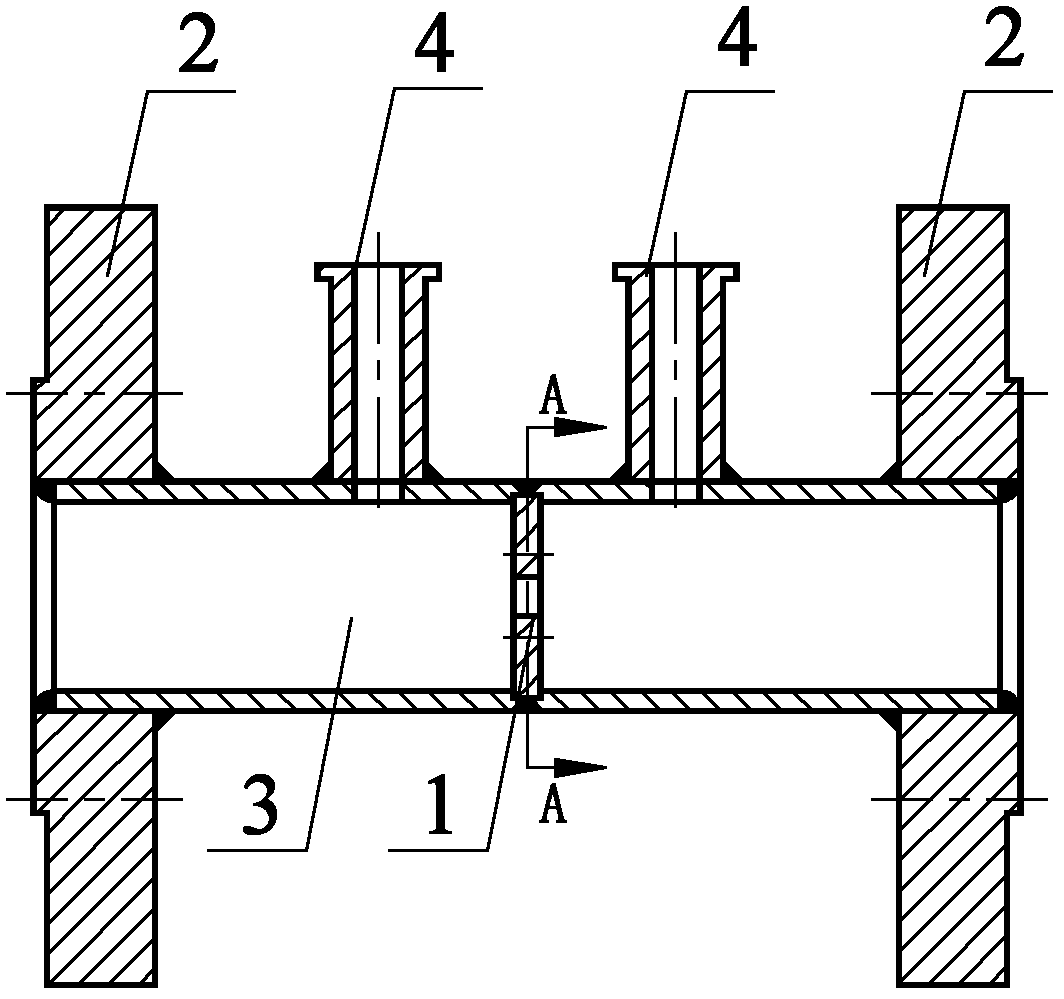

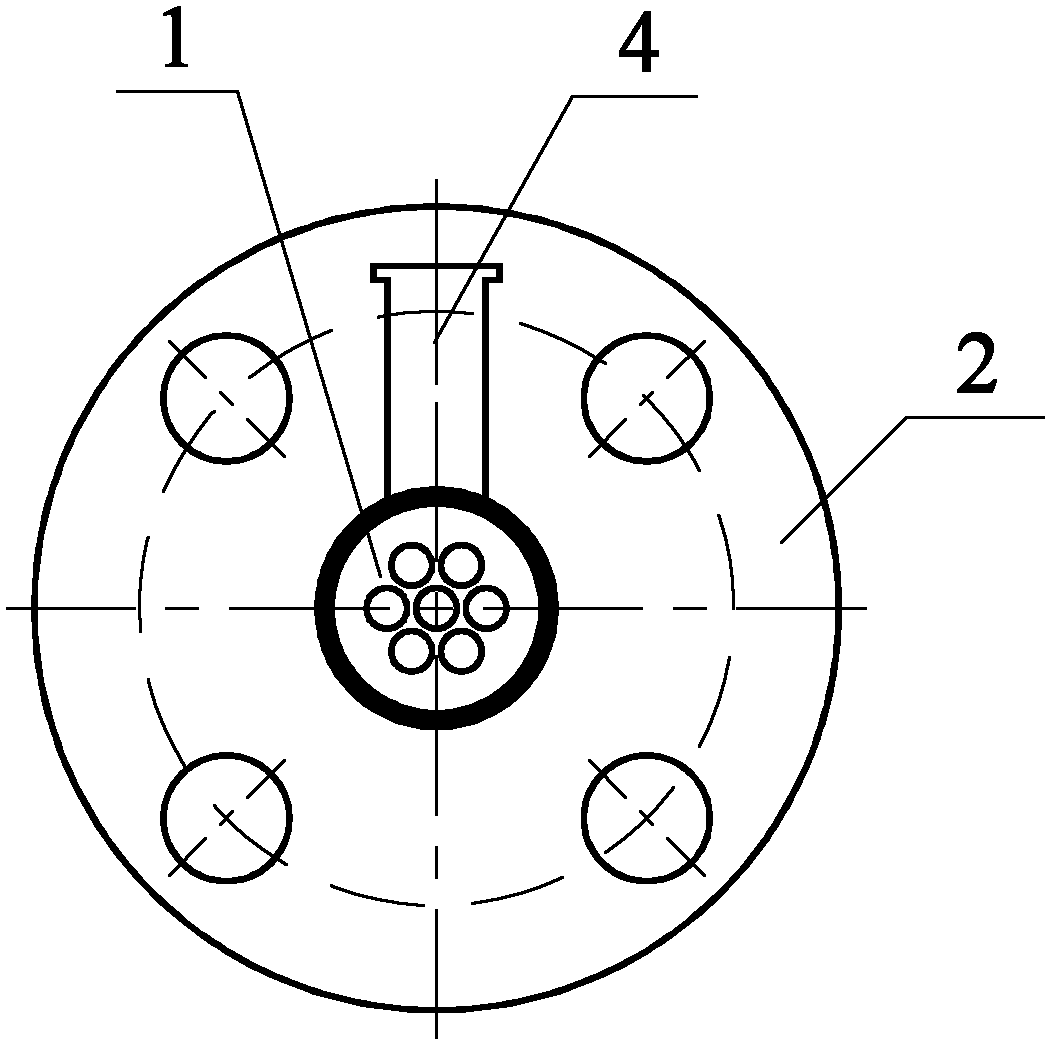

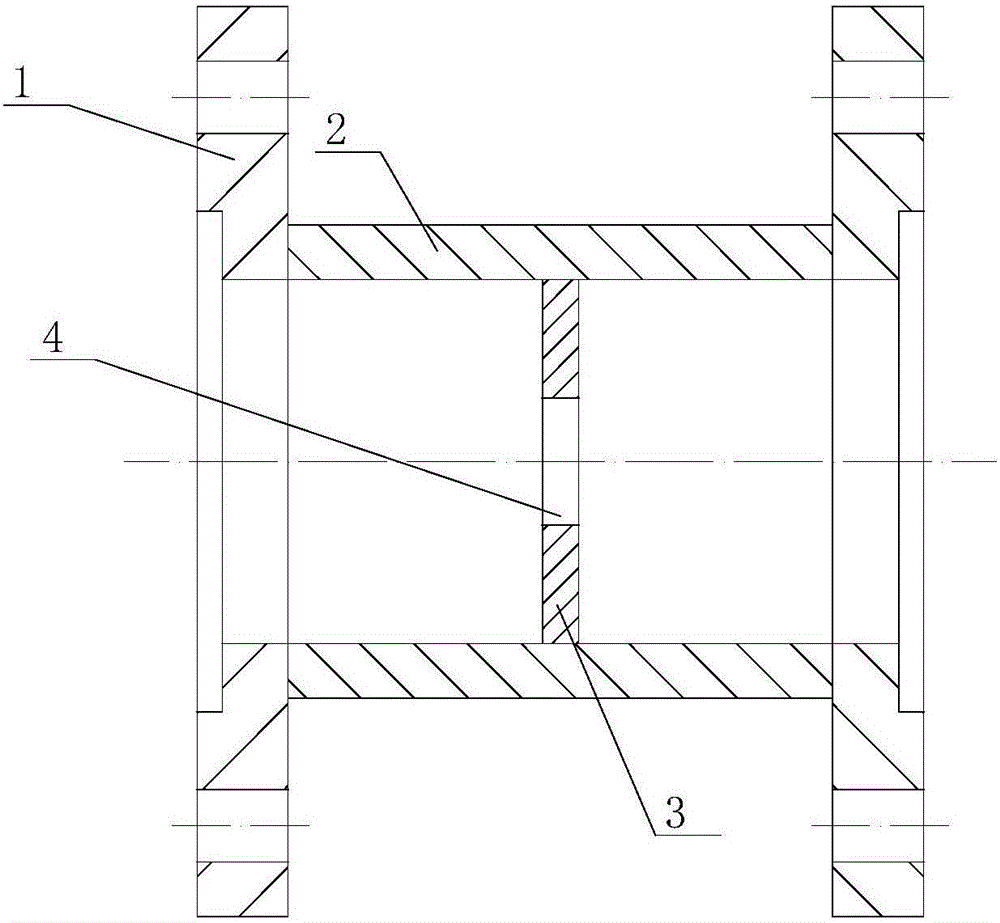

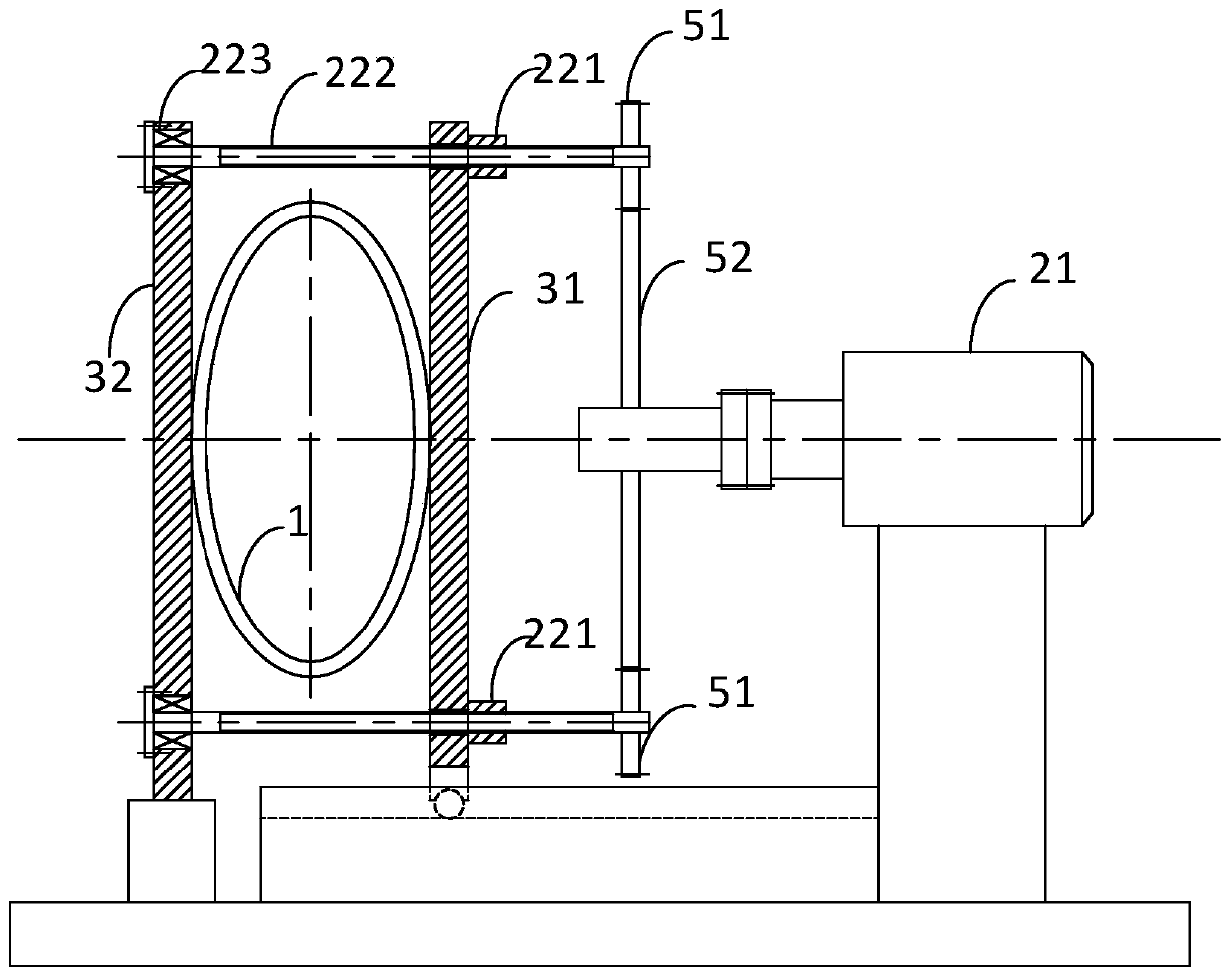

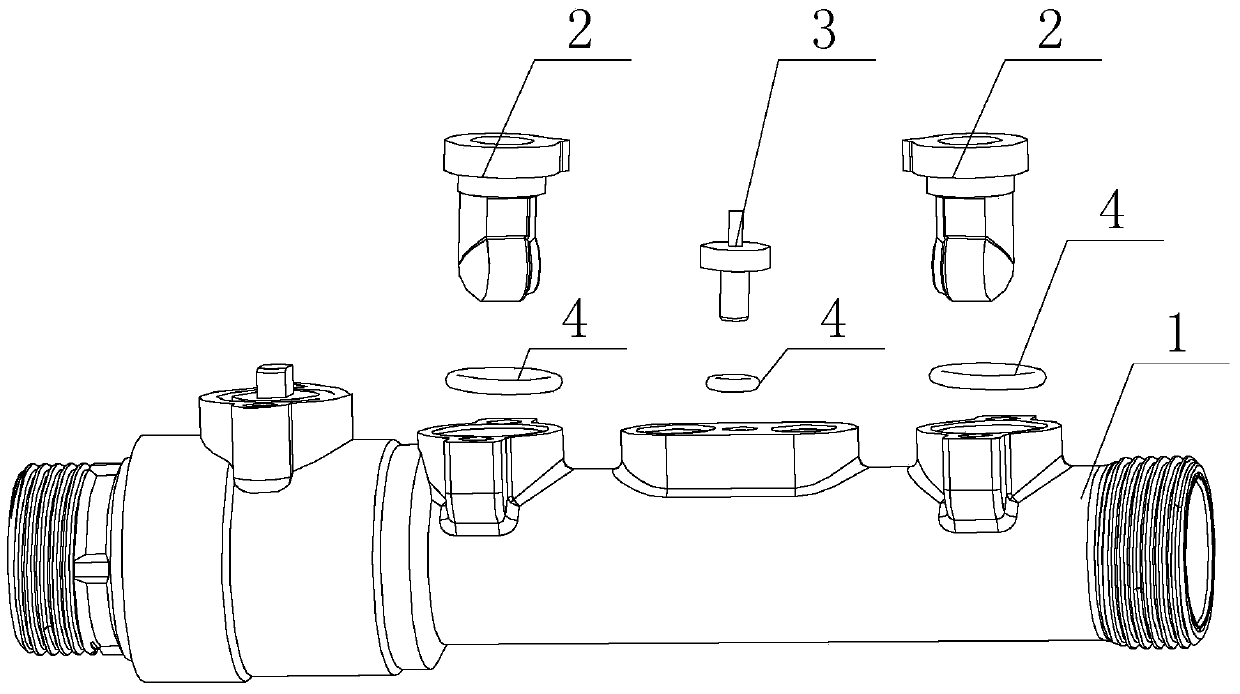

Rotating pore plate flow metering device

PendingCN108168627ATurndown ratioLow costVolume/mass flow by differential pressureVena contracta diameterButt joint

The invention provides a rotating pore plate flow metering device. The edge of a left clamping plate and the edge of a right clamping plate are connected together through a stud, two connecting pipesare installed on the cut-off portion of a straight pipe section and welded to the straight pipe section, and a gap is formed in the butt joint of the two connecting pipes. A round pore plate body is arranged in the gap between the two connecting pipes, the center of the pore plate body coincides with the center of a rotating shaft, the rotating shaft is sleeved with the pore plate body, the pore plate body is driven by the rotating shaft to rotate, and multiple throttling holes with different calibers are further evenly formed in the pore plate body at intervals in the circumferential direction. In the rotating process, the axes of the throttling holes coincide with the axes of the connecting pipes. A pressure difference is formed on the two sides of the throttling holes of the pore platebody by a measuring medium, a driver drives the pore plate body to rotate through a gearbox and the rotating shaft, the throttling holes with different calibers in the pore plate body are switched tobe sequentially located in a measuring pipeline, the measuring device is provided with the throttling holes with different beta values, and the device has a wider range ratio.

Owner:北京大漠石油工程技术有限公司

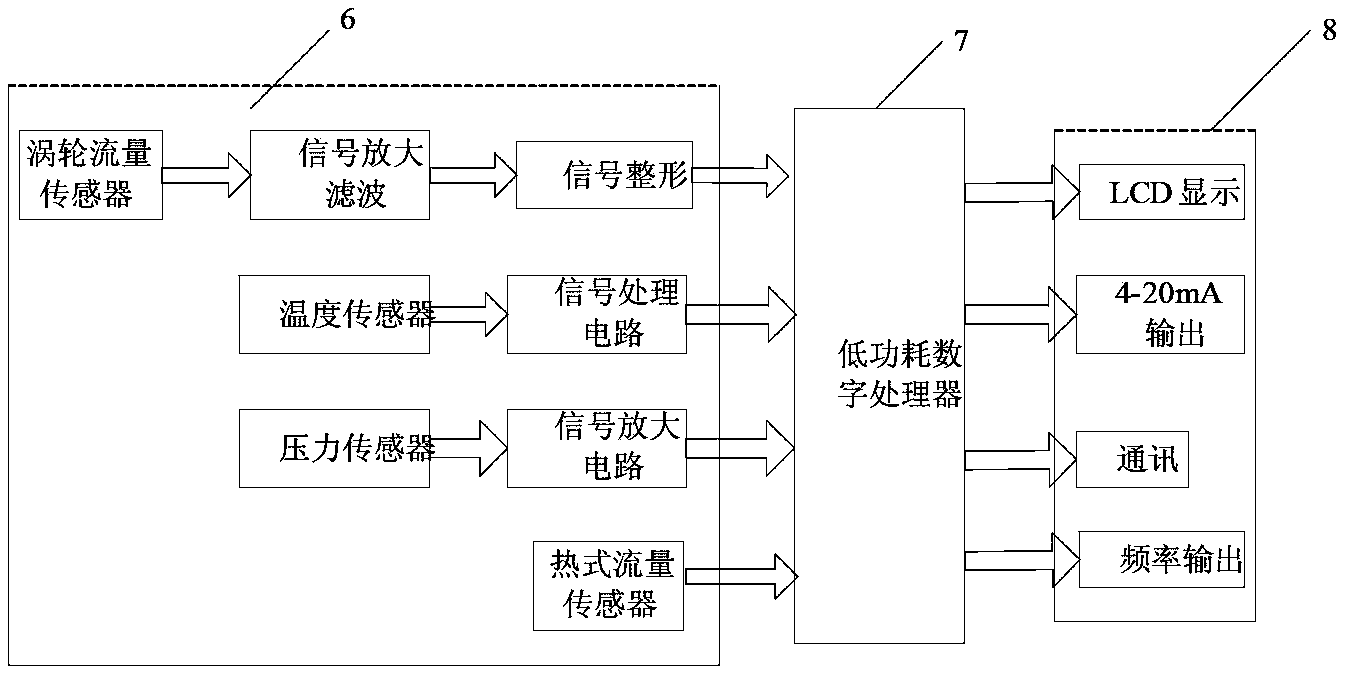

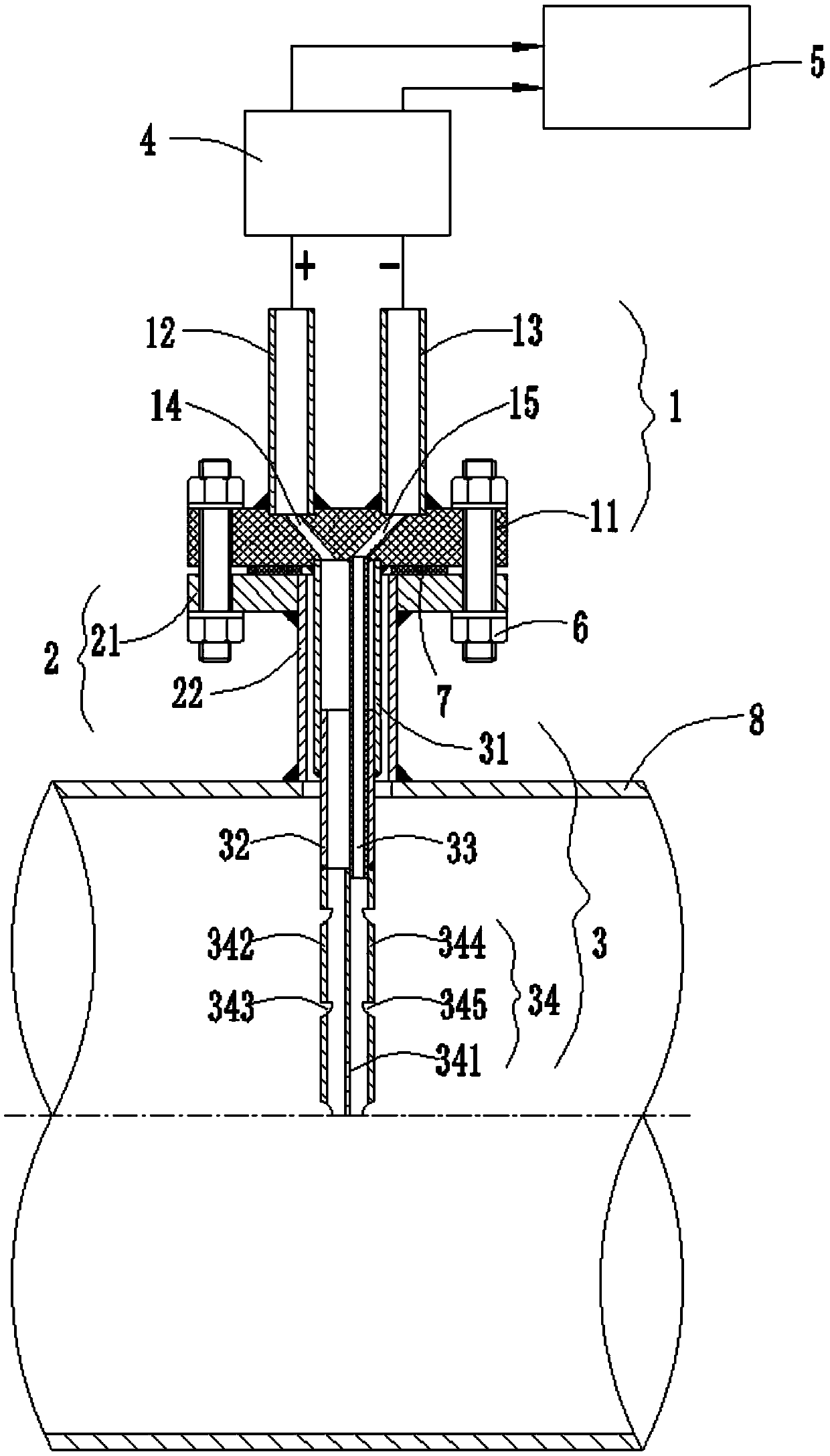

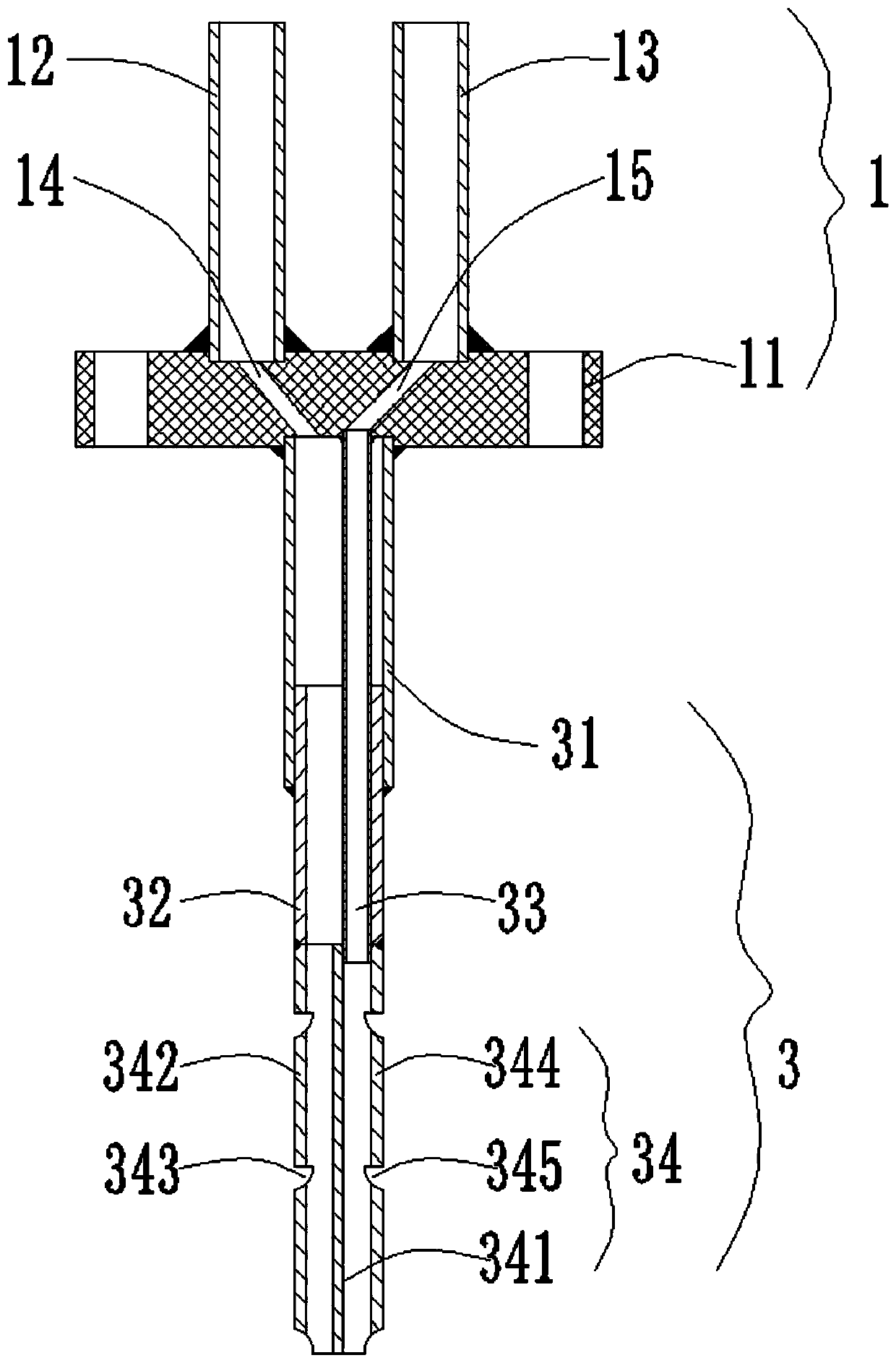

Natural gas energy meter

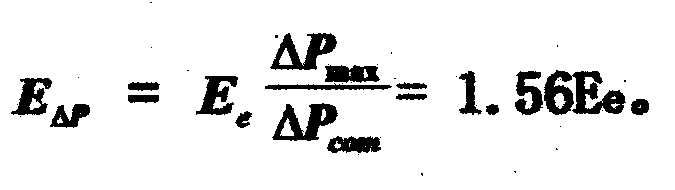

InactiveCN103453967ASimple structureTurndown ratioTesting/calibration apparatusEngineeringNatural gas

The invention relates to a natural gas energy meter comprising a turbine flow sensor, a pressure sensor, electric valves, a thermal mass flow sensor and a temperature sensor. The turbine flow sensor is mounted on a main pipe of a pipeline, an inlet and outlet of a branch pipe are respectively formed in front and rear of the turbine flow sensor, the thermal mass flow sensor is mounted on the branch pipe, the electric valves are mounted in front and rear of the thermal mass flow sensor respectively and are used for controlling the open and close states of the branch pipe, the pressure sensor is mounted on the main pipe of the pipeline in front of the inlet of the branch pipe, and the temperature sensor is mounted on the main pipe of the pipeline in rear of the outlet of the branch pipe. The natural gas energy meter is simple in structure, a feature of utilizing small flow to calibrate large flow is adopted, and range ratio is expanded; the method of on-line calibration is adopted, the process of disassembling for detecting can be avoided, accuracy of the turbine flow sensor is guaranteed, using time is also guaranteed, and operating efficiency is improved greatly.

Owner:CHINA JILIANG UNIV

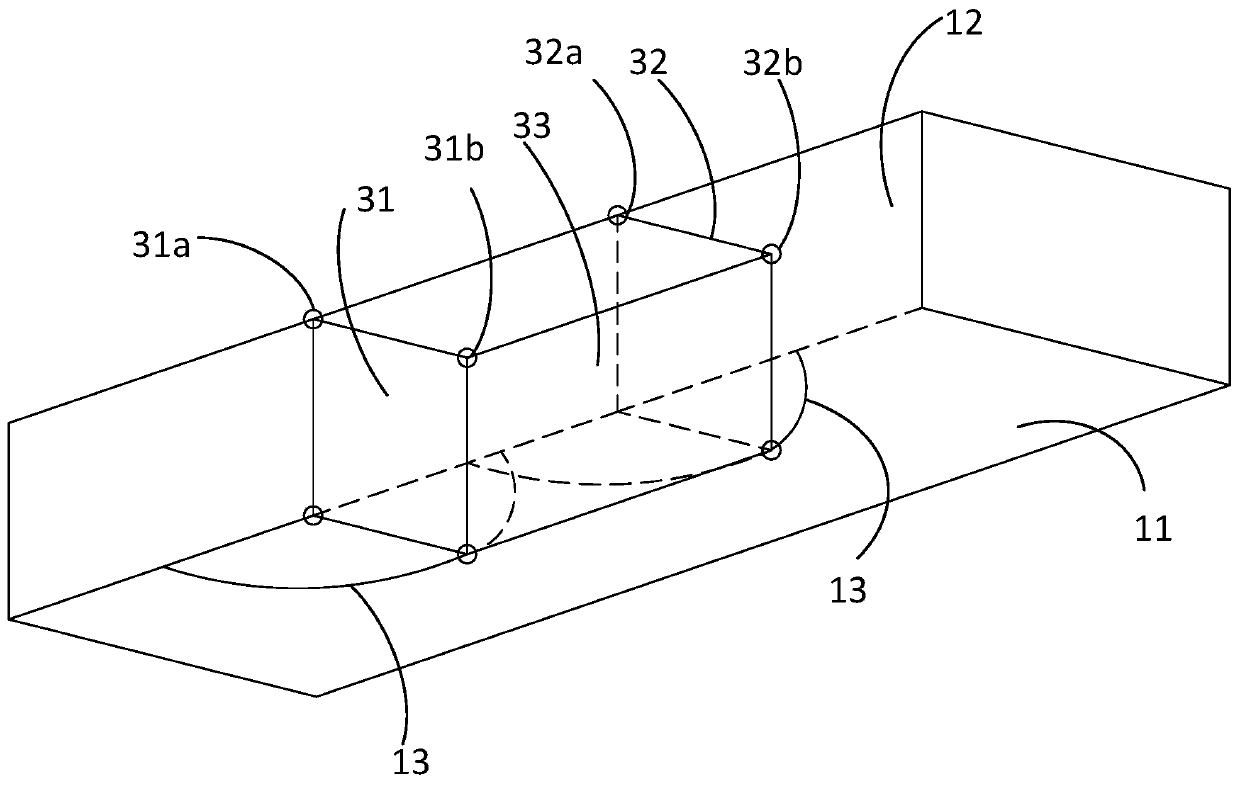

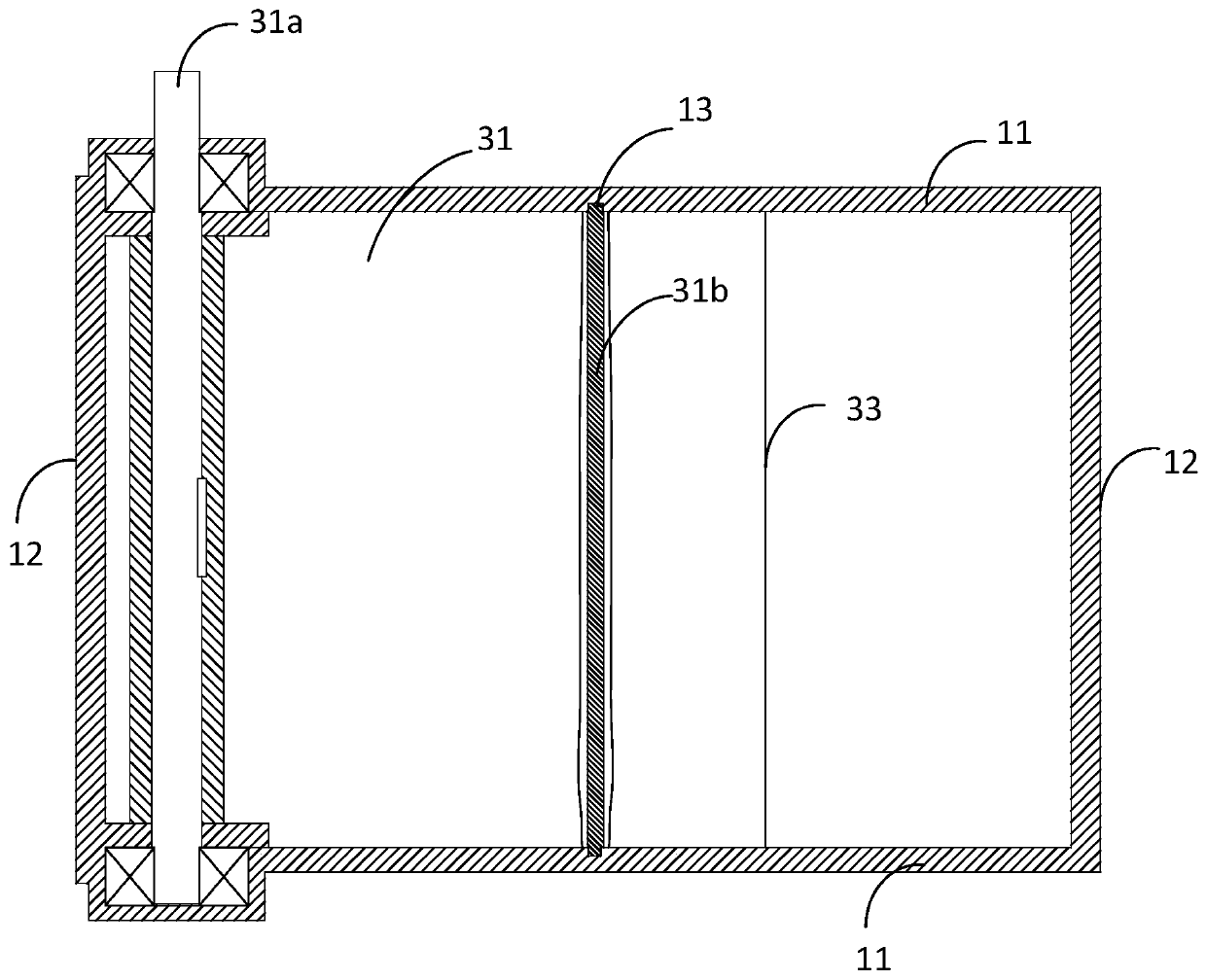

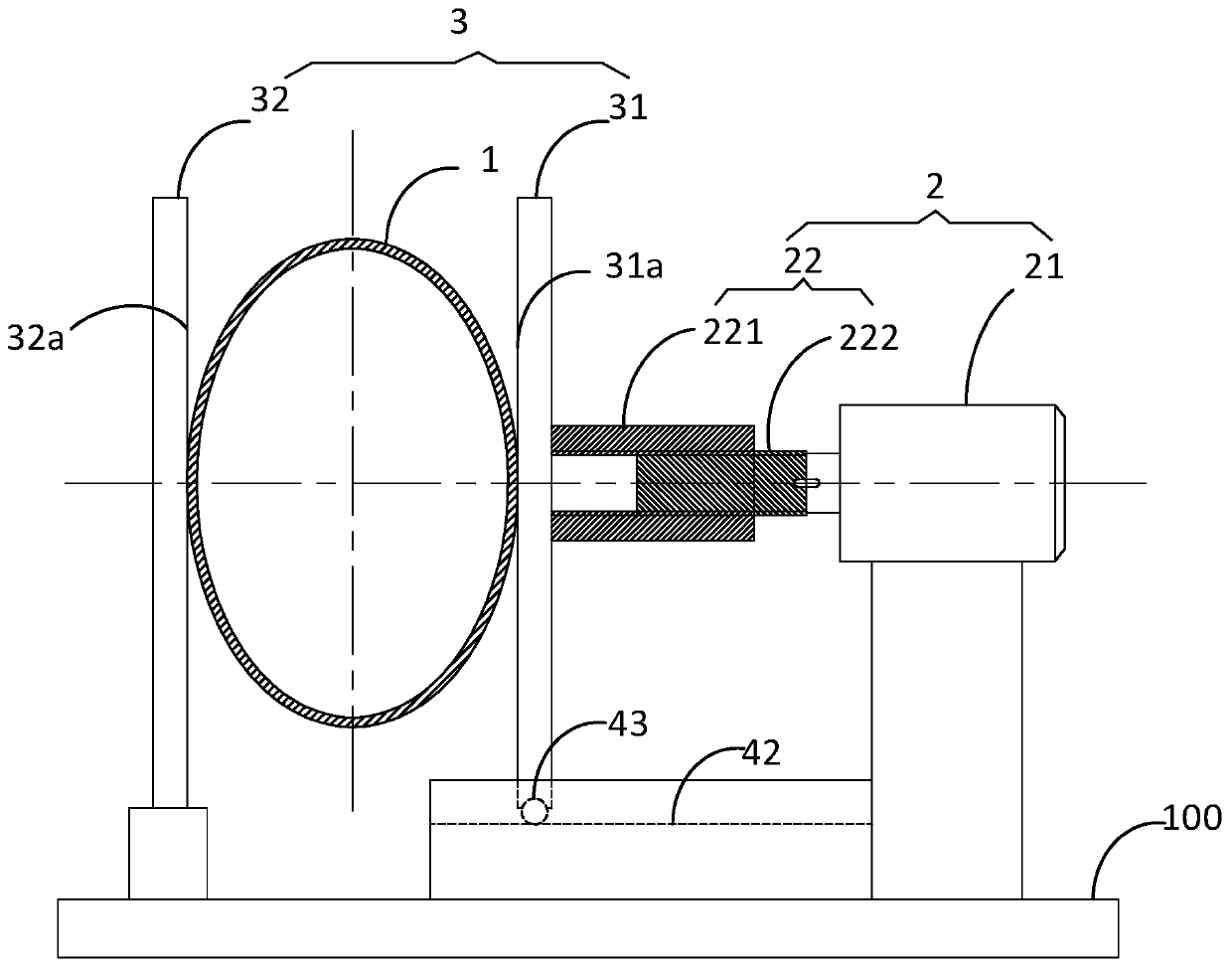

Rigid variable cross-section device

PendingCN110987094ATurndown ratioMeet measurement needsVolume meteringVolume/mass flow by differential pressureStructural engineeringPower output

The invention discloses a rigid variable cross-section device, which comprises a detection pipeline, a driving component and an executing component, wherein the detection pipeline is used for allowinga to-be-detected fluid to pass through and is made of a rigid material; the driving component is used for providing driving force for an executing component; and the executing component is in transmission connection with the power output end of the driving component, is mounted on the inner wall of the detection pipeline and comprises at least one deformation unit which can act under the action of the driving force so as to change a gap between the executing component and the mounting wall surface, and the cross section area in the detection pipeline is changed through the deformation unit. The problem that the detection pipeline is complex, high in cost, large in mounting space and the like in the prior art is solved, the measuring range ratio is increased by changing the cross section of the detection pipeline online, the cost is greatly reduced, the mounting space is reduced, the implementability of variable cross section of the rigid detection pipeline is provided, the action is flexible and reliable, the sensitivity is high, and the operation is easy.

Owner:姜春林

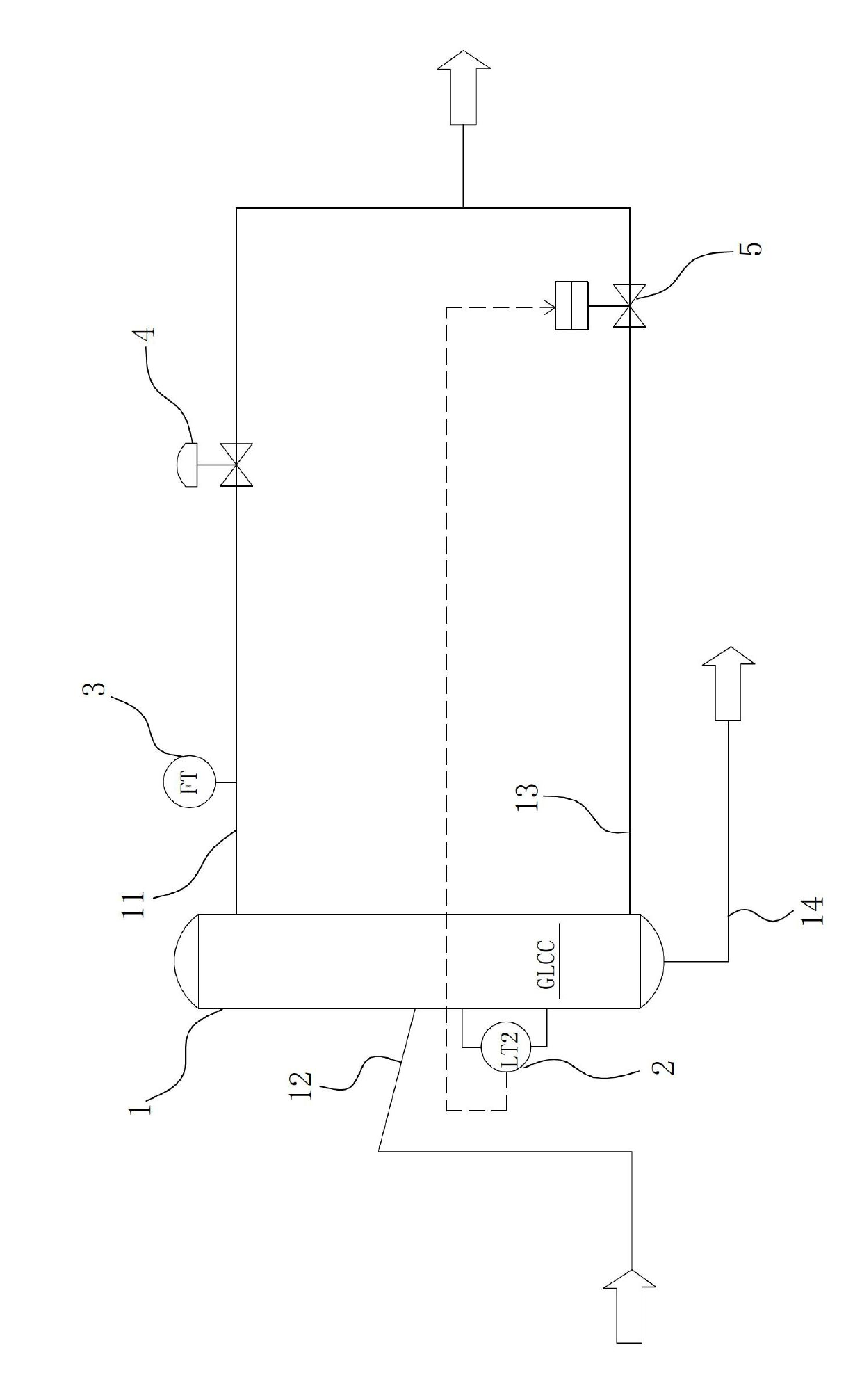

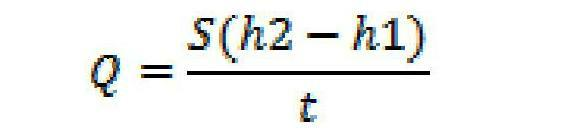

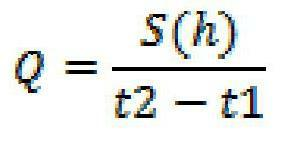

Gas-liquid measurement method with super-small flow

InactiveCN102636223AReal-time reflection of production changesGuaranteed uptimeVolume meteringVolume/mass flow by differential pressureVapor–liquid separatorGas phase

The invention relates to a gas-liquid measurement method with super-small flow, which comprises the following steps that (1) after mixture to be measured enters into a measuring system from a primary liquid input pipe, the gas and the liquid of the mixture to be measured are separated through a gas-liquid separator; (2) the gas phase of a gas-phase substance which is separated is measured through a gas phase flowmeter which is connected onto a gas outlet pipe; and (3) a liquid-phase substance which is separated enters a liquid-phase switch valve which is arranged on a liquid outlet pipe through the liquid outlet pipe, and the liquid phase is measured under the joint action of the liquid phase switch valve, a liquid level transmitter and the gas-liquid separator. Compared with the prior art, the gas-liquid measurement method with super-small flow has the advantages that the gas-liquid measurement can be realized when the amount of liquid is extremely small; the method can ensure that the operation is reliable and has a wider range ratio; and the most important is that the measurement method can reflect the production change of a single well in real time.

Owner:宁波威瑞泰默赛多相流仪器设备有限公司

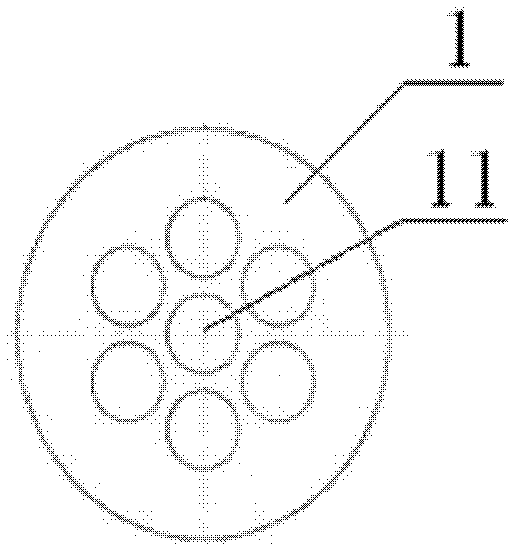

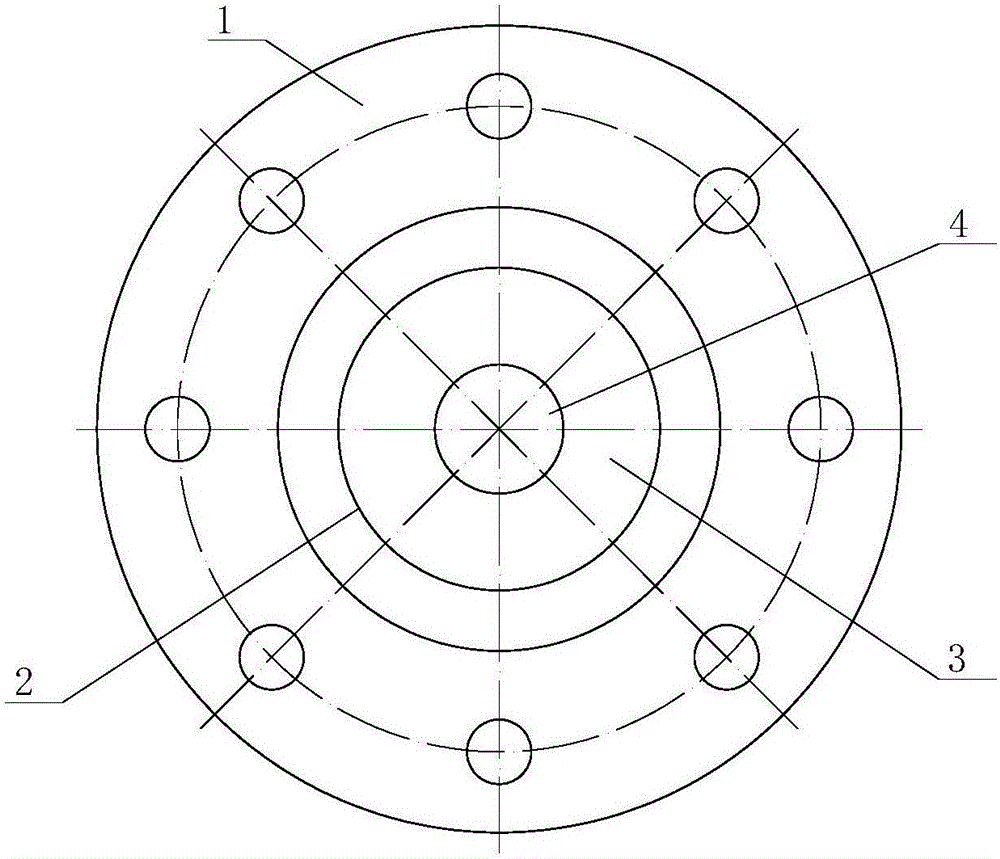

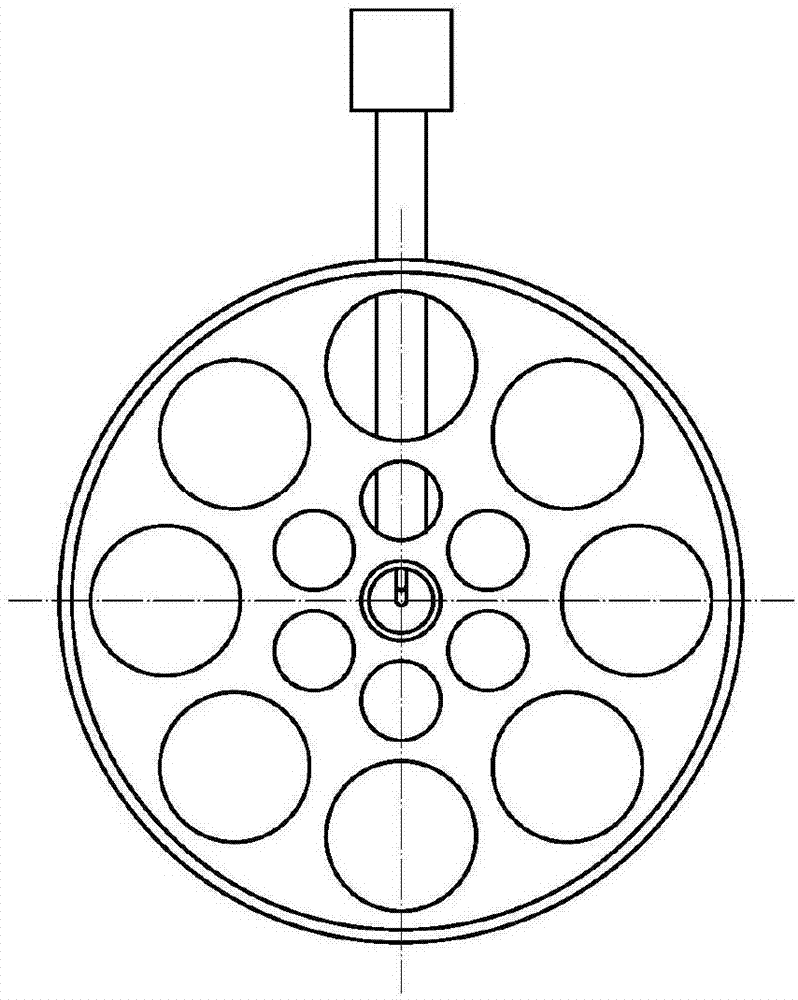

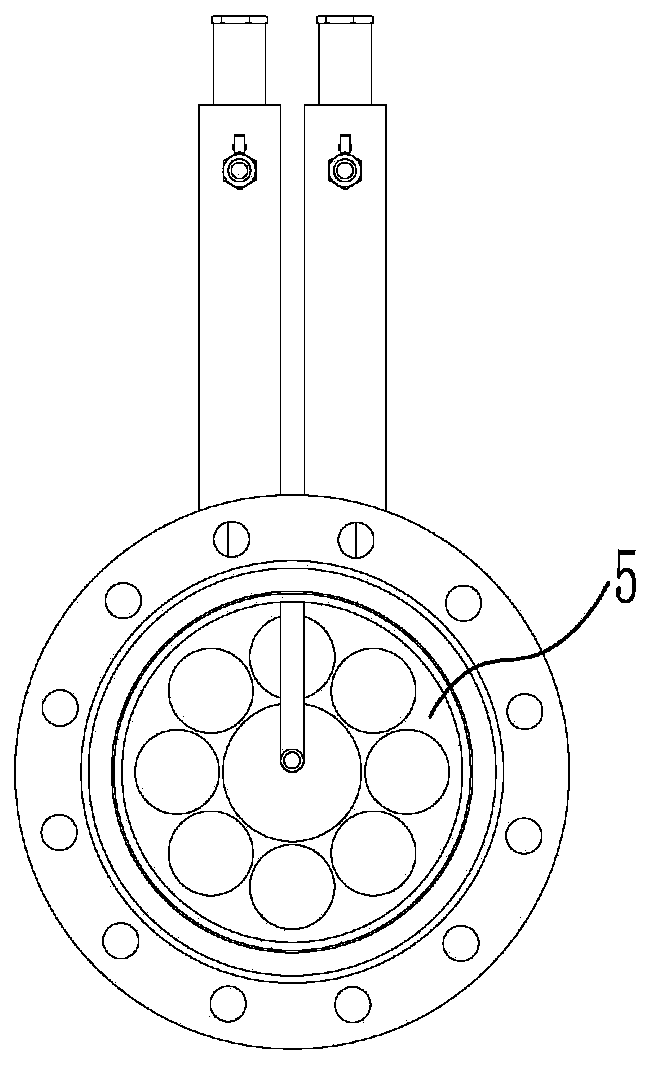

Super-minor-caliber three-diamond-type flowmeter

InactiveCN103033222ACompact structureIngenious designVolume/mass flow by differential pressureStraight tubeDifferential pressure

The invention relates a super-minor-caliber three-diamond-type flowmeter. The super-minor-caliber three-diamond-type flowmeter is installed inside the surface body of a diversion pipe. Differential pressure division pipes are connected on the surface body of the diversion pipe. The three-diamond-type flowmeter is in a circular structure. The diameter of the three-diamond-type flowmeter is in accordance with the inner diameter of the surface body of the diversion pipe. A round hole is formed in the centre of the three-diamond-type flowmeter. Six round holes are symmetrically distributed around the round hole. A regular hexagon shape is formed by the six round holes. Compared with the prior art, the super-minor-caliber three-diamond-type flowmeter is compact in structure and skillful in design. Due to the fact that the rectification and the detection are combined into one, the accuracy and repeatability of a measurement are increased. The super-minor-caliber three-diamond-type flowmeter has the advantages of being wide in measuring range ratio, small in loss of pressure, abrasion resistant, long in service life, short in an installation straight pipe section and the like.

Owner:上海安锐自动化仪表有限公司

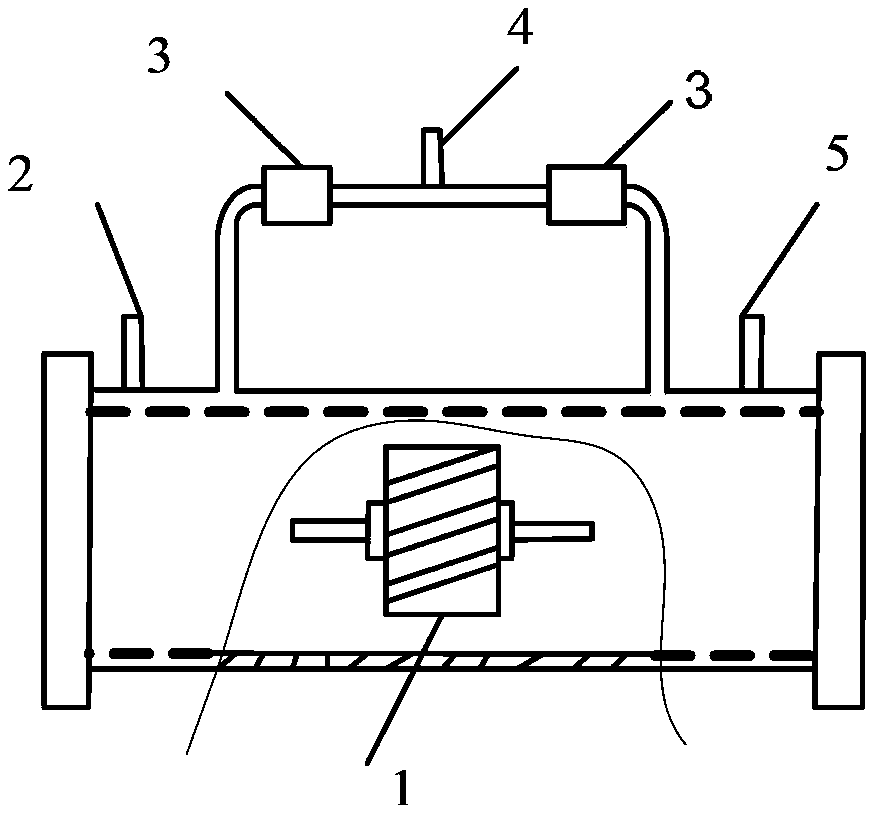

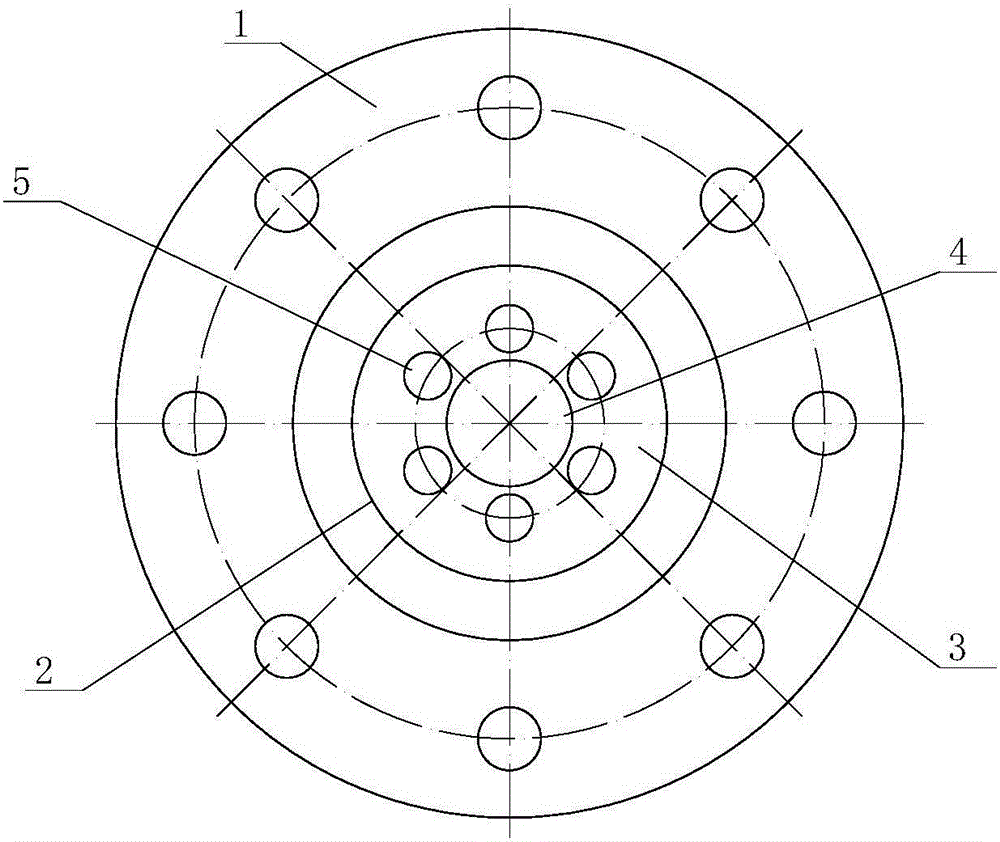

Air flow measurement device

PendingCN106525159AEasy to implement dry labelImprove the balance ratioVolume/mass flow by differential pressureVena contracta diameterEngineering

The invention relates to an air flow measurement device. The air flow measurement device comprises a tube wall and an orifice plate, wherein the orifice plate is arranged on the tube wall in a fixing mode, the orifice plate is perpendicular to the axis direction of the tube wall, and the center of the orifice plate is perpendicular to the axis of the tube wall and is provided a circular-type main orifice, a plurality of satellite orifices are formed and uniformly distributed on the outer edges of the main orifice. The air flow measurement device makes an air fluid formed an ideal fluid in the measurement, and improves the measurement accuracy.

Owner:太原市普瑞兴生仪表有限公司

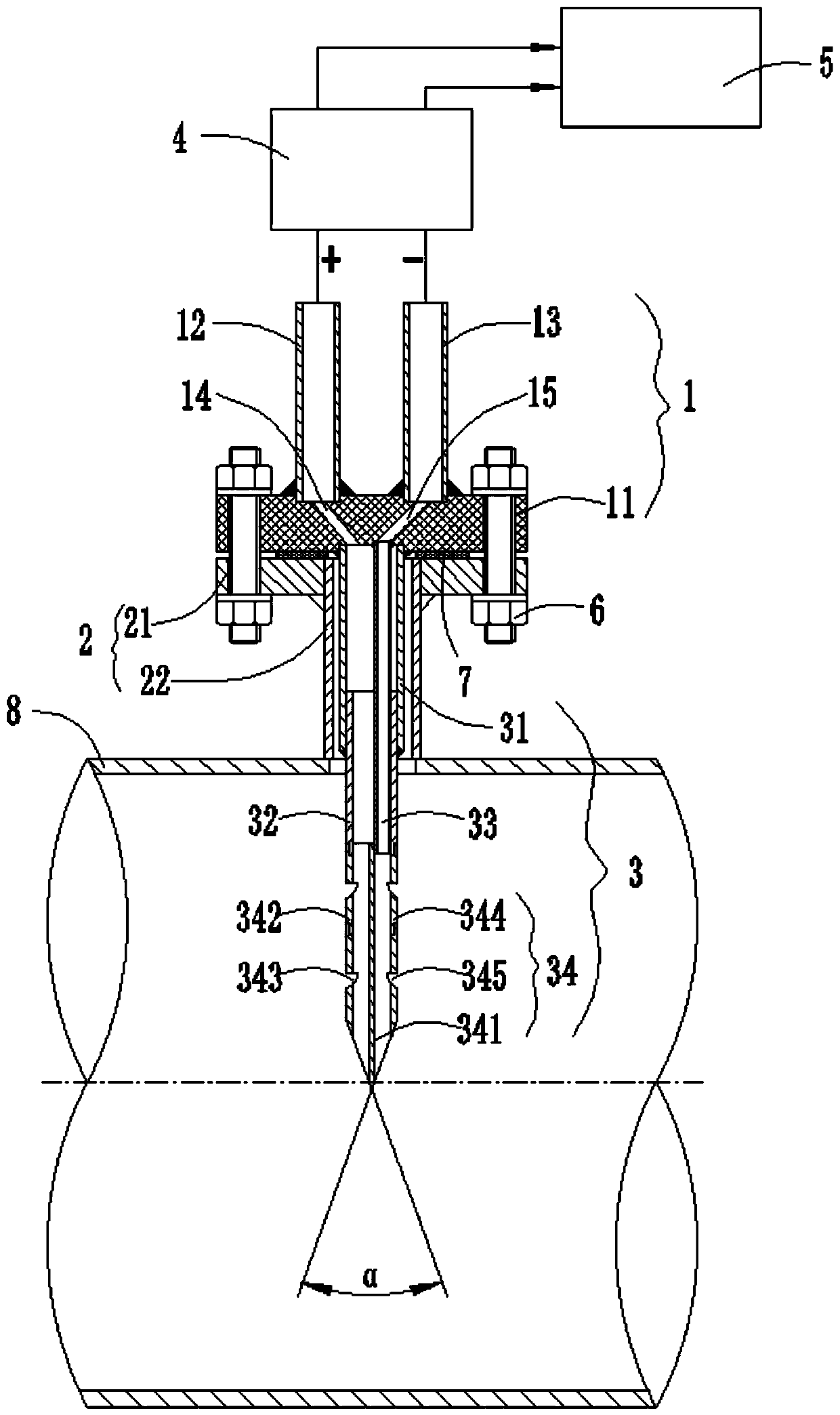

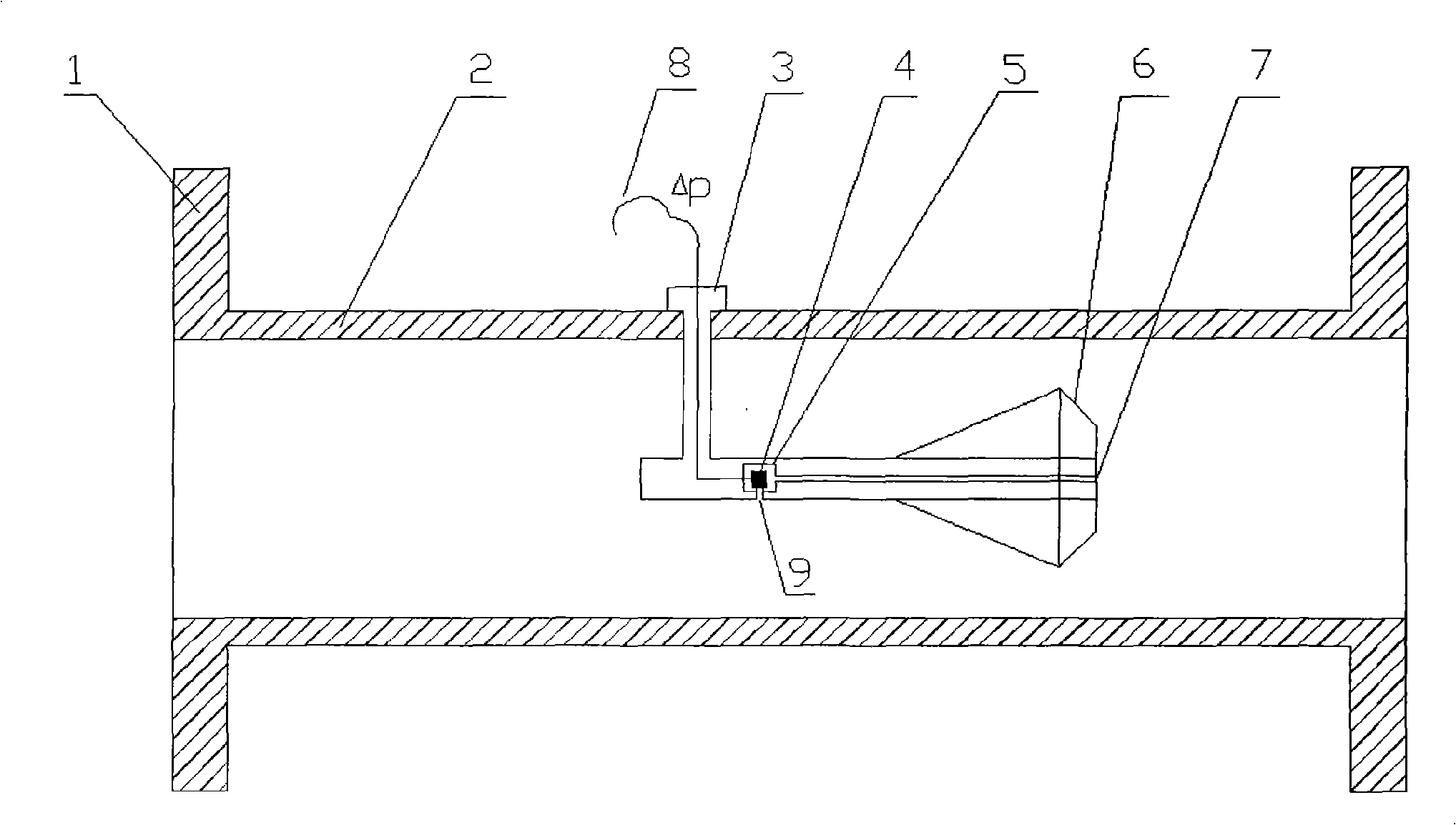

Plug-in type semi-parabola multi-point pressure tapping flow sensor

InactiveCN110487337AAvoid cloggingEasy dischargeVolume meteringVolume/mass flow by differential pressurePositive pressureDifferential pressure

The invention belongs to the technical field of flow measurement, in particular to a plug-in type semi-parabola multi-point pressure tapping flow sensor. The plug-in type semi-parabola multi-point pressure tapping flow sensor comprises a pressure tapping structure, a T-shaped mounting pipe base and a pressure detection element. A fluid flows through a pressure detection pipe, total pressure is measured at one side of a positive pressure hole of an incident flow surface, static pressure is measured at one side of a negative pressure hole of a back flow surface, the two pressure becomes stable and reliable after being equalized by means of a positive pressure equalizing pipe and a negative pressure equalizing pipe, a pressure difference is generated between the two pressure, and the pressuredifference is transmitted to a differential pressure transmitter and a flow totalizer by means of a positive pressure tapping pipe and a negative pressure tapping pipe, so that flow measurement is realized. The plug-in type semi-parabola multi-point pressure tapping flow sensor adopts semi-parabola pressure tapping, improves the precision and stability of the flow sensor, and greatly increases the measuring range ratio of the flow sensor, so that the differential pressure type flow sensor has better application prospects, and the plug-in type semi-parabola multi-point pressure tapping flow sensor has the advantages of high precision, wide measuring range, high reliability, small pressure loss and the like.

Owner:银川融神威自动化仪表厂(有限公司)

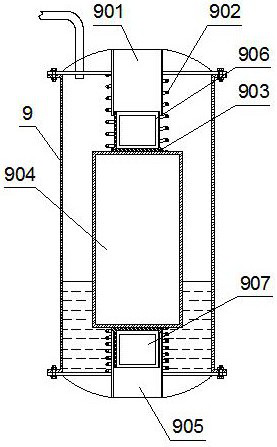

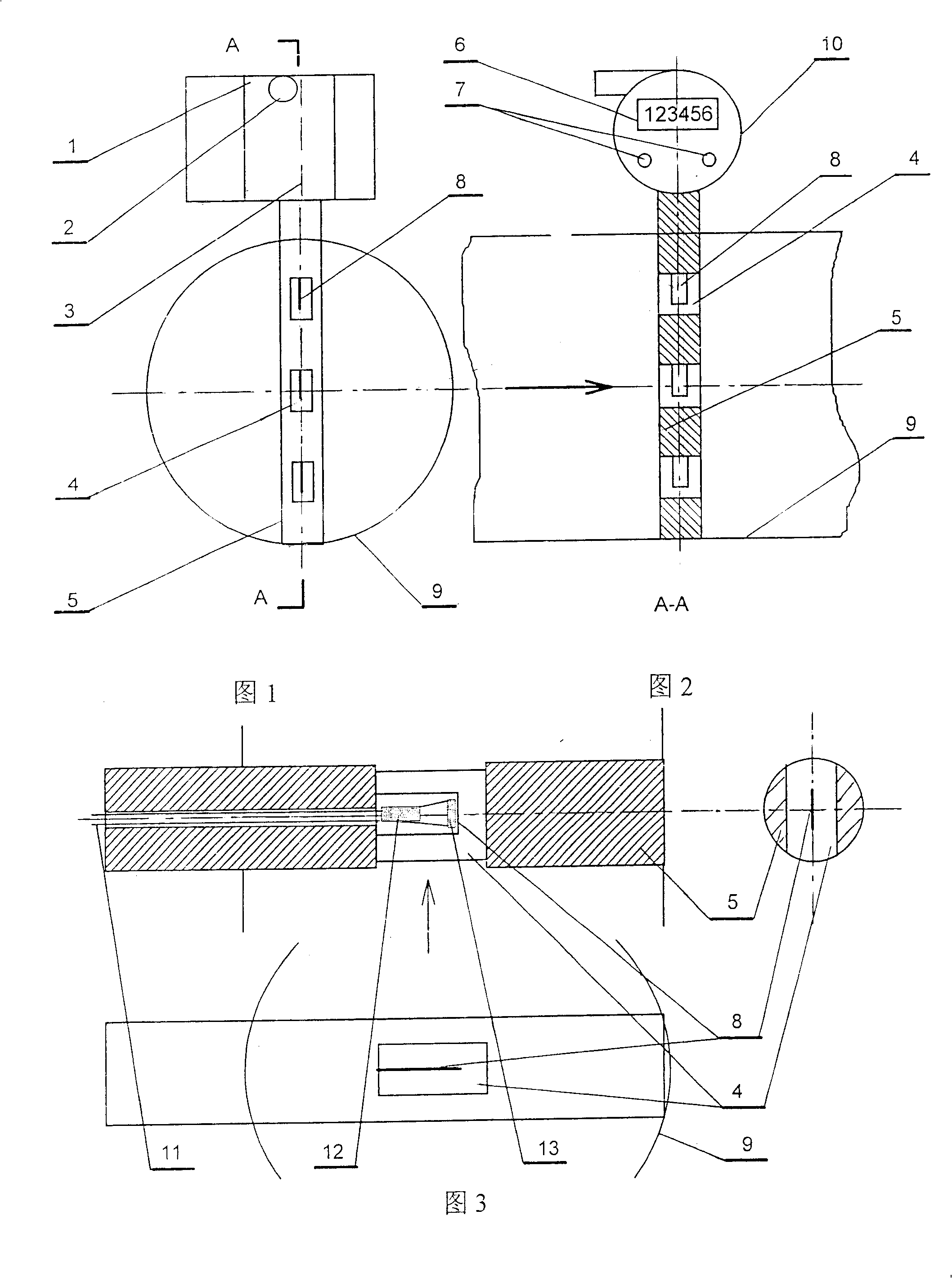

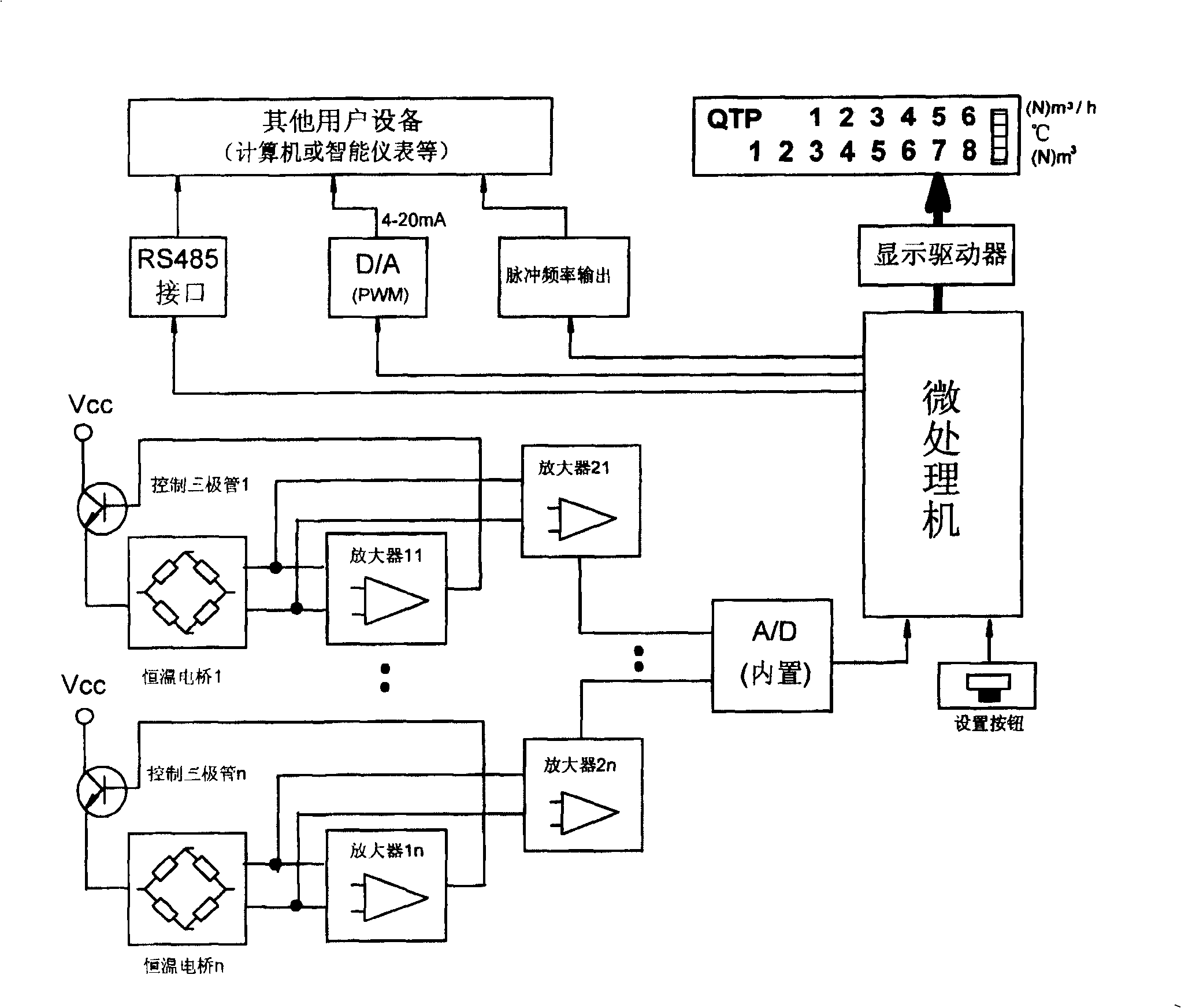

Thermal type perforated plate gas flowmeter applied to non-uniform flow field

InactiveCN107990945AHigh sensitivityHigh precisionVolume meteringVolume/mass flow by differential pressureTransformerEngineering

The invention discloses a thermal type perforated plate gas flowmeter applied to a non-uniform flow field. The thermal type perforated plate gas flowmeter applied to the non-uniform flow field comprises an outer sleeve, an inner sleeve, a first perforated plate, a temperature sensor, a speed sensor and a signal transformer; the first perforated plate is arranged inside the outer sleeve, and the plane where the first perforated plate is located is perpendicular to the axial direction of the outer sleeve; the inner sleeve is arranged inside the outer sleeve, one end of the inner sleeve is an upper port, the other end of the inner sleeve is a lower port, and the lower port of the inner sleeve penetrates through the first perforated plate; the temperature sensor and the speed sensor are installed inside the inner sleeve, and the temperature sensor and the speed sensor are connected with the signal transformer. The thermal type perforated plate gas flowmeter is particularly applicable to gas flow measurement of the non-uniform flow field with pipelines of large diameters being DN100 or above, the thermal type perforated plate gas flowmeter has the remarkable advantages of being high insensitivity and precision, wide in range ratio, small in throttling loss and the like, and meanwhile the thermal type perforated plate gas flowmeter can be applicable to the occasions that some components in gas measurement are condensed, crystallized and the like when cooled.

Owner:南京博沃科技发展有限公司

Two-wire system vortex street flowmeter

InactiveCN100470207CEliminate live noiseHigh measurement accuracyMultiple-port networksCharge amplifiersLow-pass filterBand-pass filter

The present invention relates to the flow detection field, in particular to a low power consumption two-wire system vortex street flowmeter which consists of a piezoelectric transducer, a charge amplifier, a voltage amplifier, a program-controlled amplifier, a lowpass, a voltage follower, a peak detection circuit, a band-pass filter set, a multiway switch gate circuit, a wave shaping circuit, a singlechip, a man-machine interface circuit and a 4-20 mA output and power management circuit, wherein, the singlechip detects the peak value and the frequency of the vortex street signal to amplify and filter the vortex flow signals by controlling the program-controlled amplifier and the band-pass filter. The technology overcomes the problems that the prior art can not achieve low power consumption while measuring small flow, expanding measuring range rate and improving measuring precision effectively. While ensuring measuring small flow, expanding measuring range rate and improving measuring precision effectively, the invention achieves low power consumption of outputting the direct current of 4-20 mA and the operating current less than 4mA and achieves the two-wire system operation.

Owner:HEFEI UNIV OF TECH

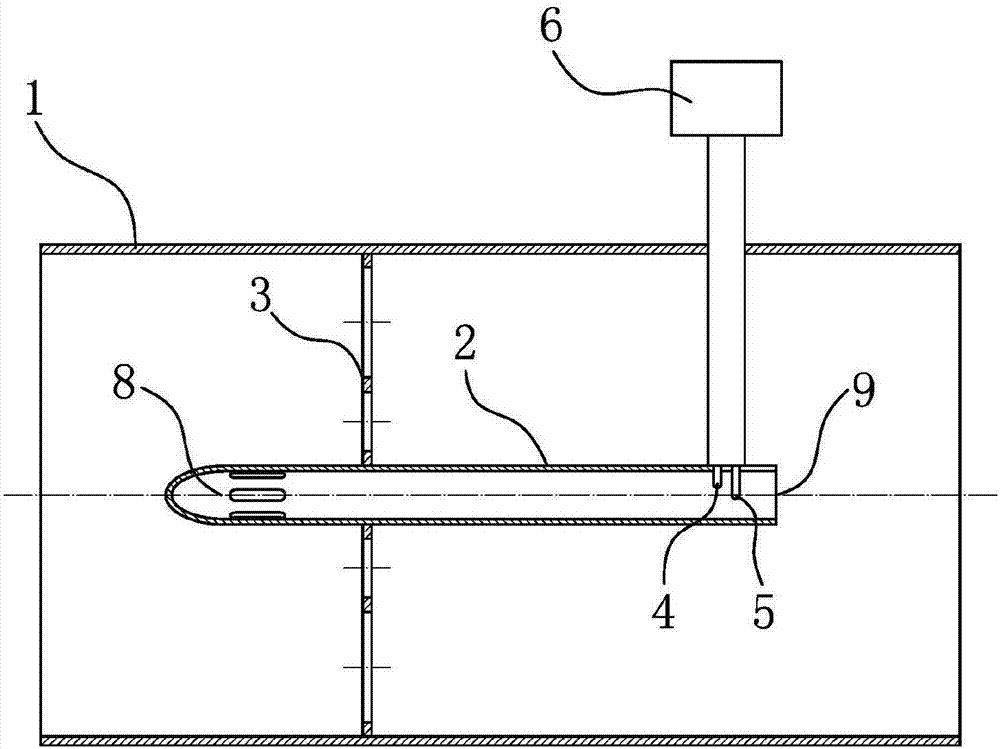

Combined platinum film gas flow measuring method and flow meter

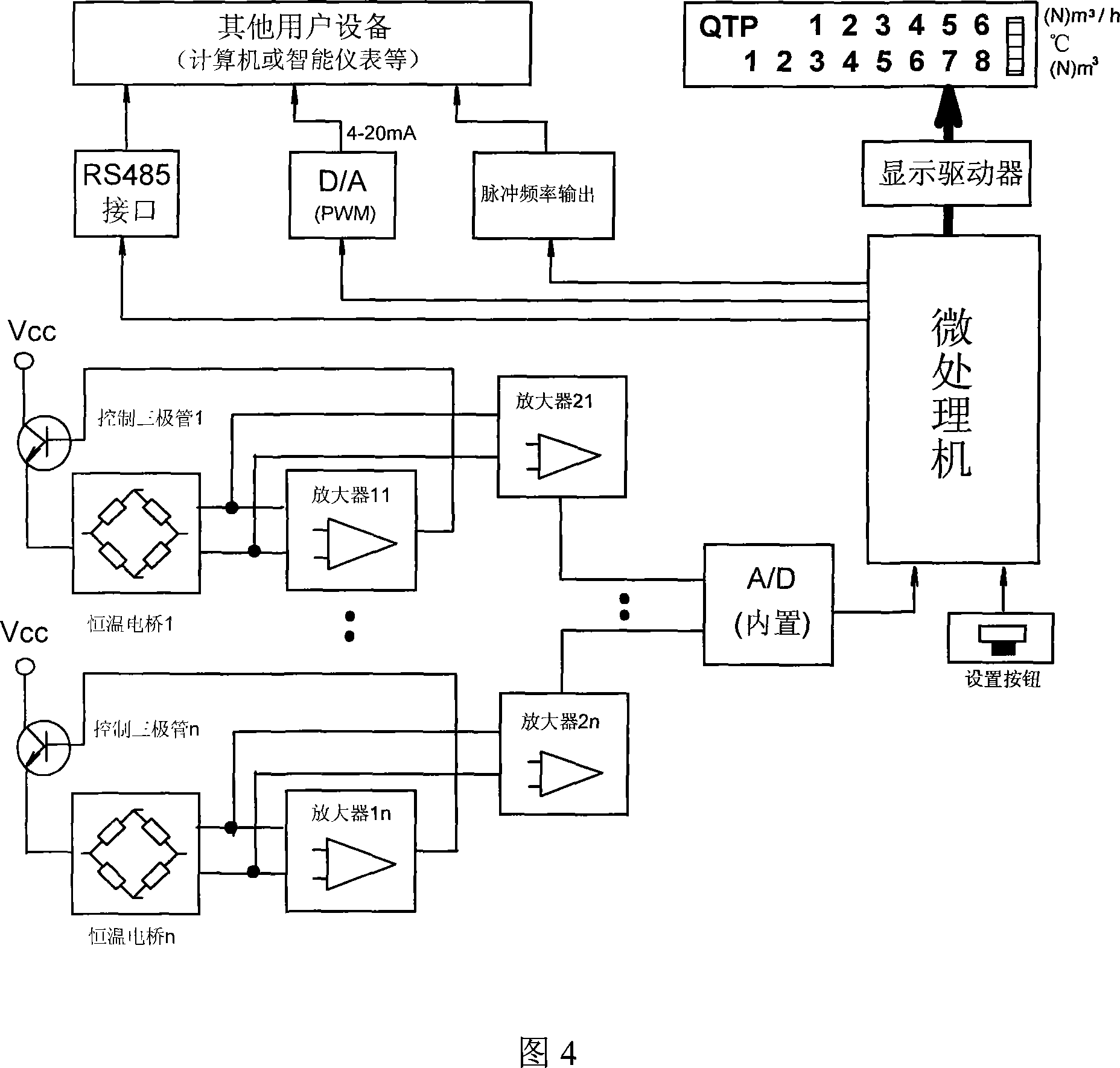

InactiveCN101122493ASimple structureLow investment costIndirect mass flowmetersEngineeringStreamflow

The invention discloses a combined platinum film gas flow measurement method and a flow meter. The detection rod is inserted into the measuring pipe from the diameter direction, and one or more platinum film probes integrating a flow probe and a temperature probe are fixedly installed on the detection rod, and each probe can sense the gas flow and temperature signals at the same time . The flow and temperature signals are collected and processed to obtain the mass flow of the gas, and the display and remote transmission of the flow and temperature values are realized. The combined platinum membrane gas flowmeter has the characteristics of simple structure, low investment cost, high precision, small pressure loss, wide range ratio (up to about 100 times), and the lower flow limit is almost zero. Among the gas flow detection instruments, there is no flow instrument with such a simple structure and excellent comprehensive performance, and the economic benefits are very obvious. The instrument has an integrated structure and has multi-parameter measurement functions such as flow and temperature.

Owner:CHINA JILIANG UNIV

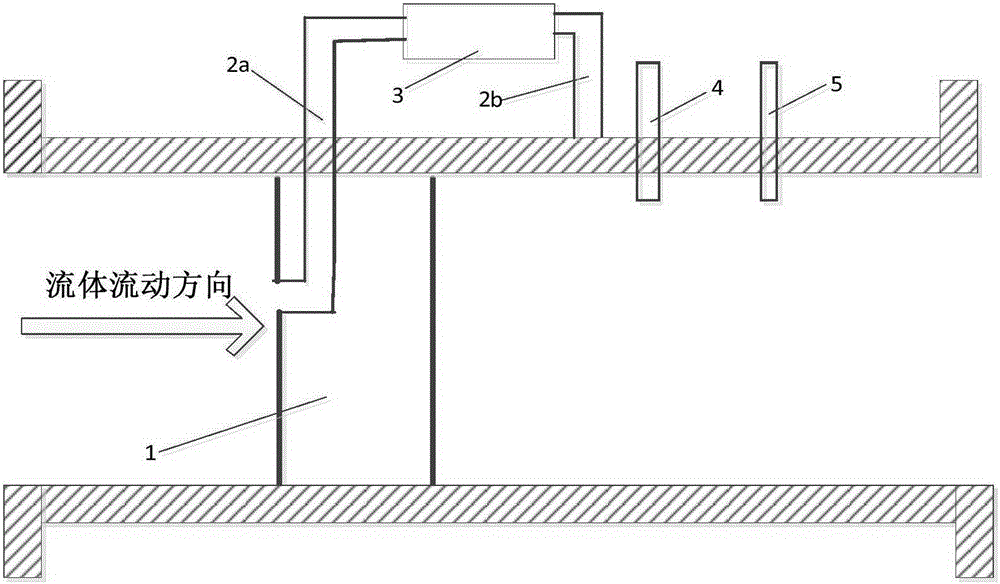

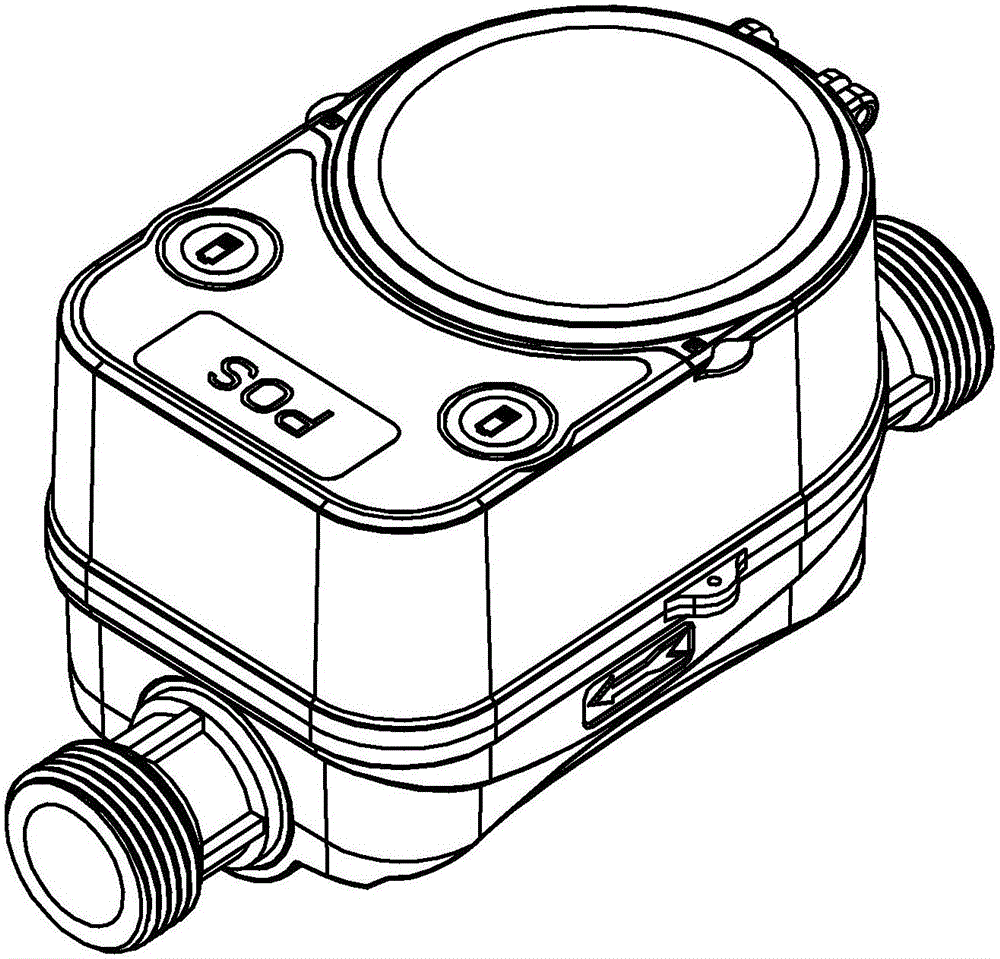

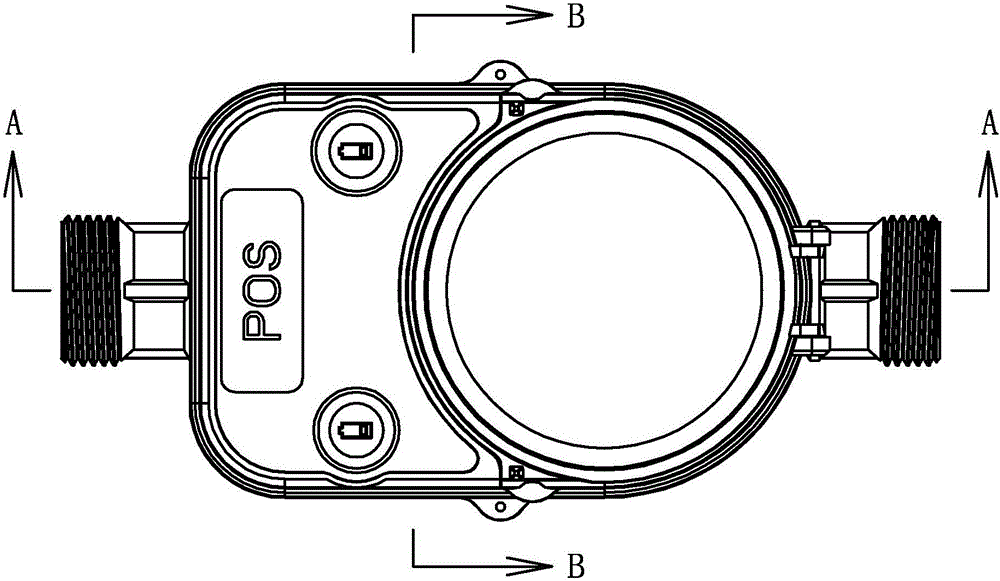

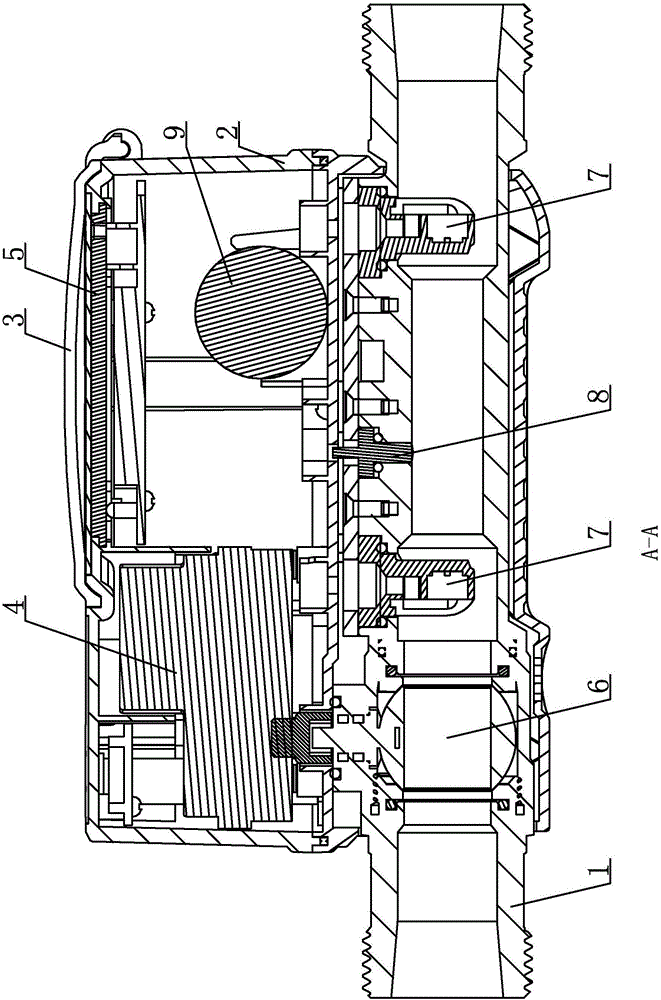

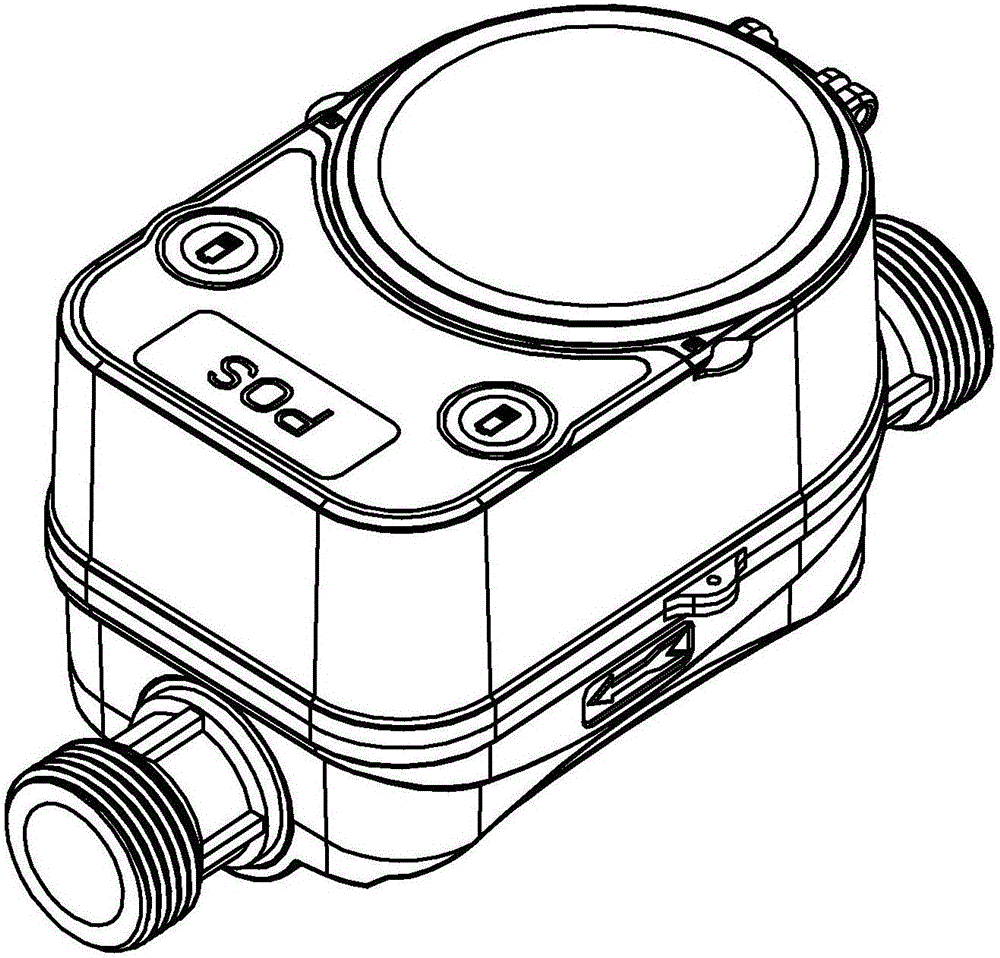

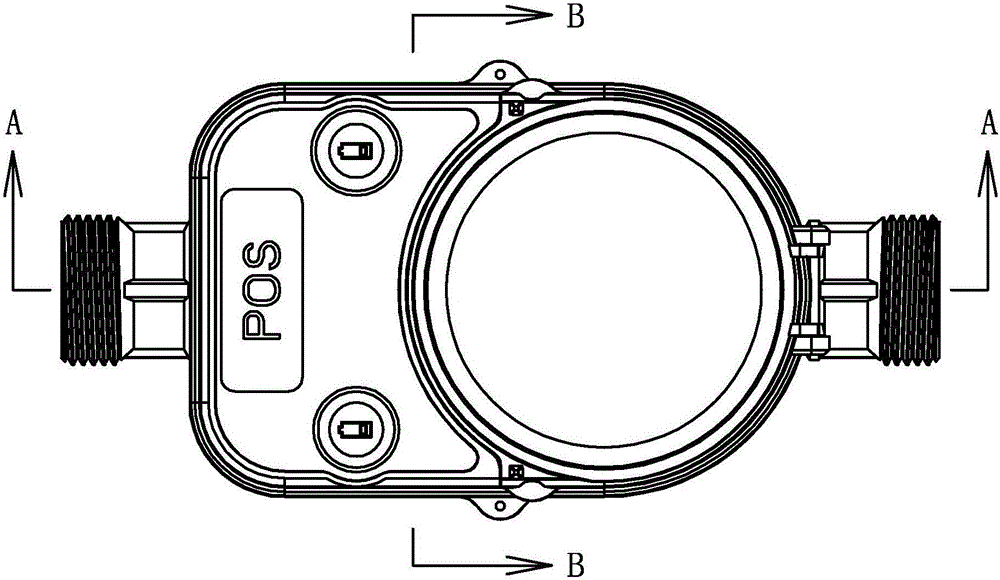

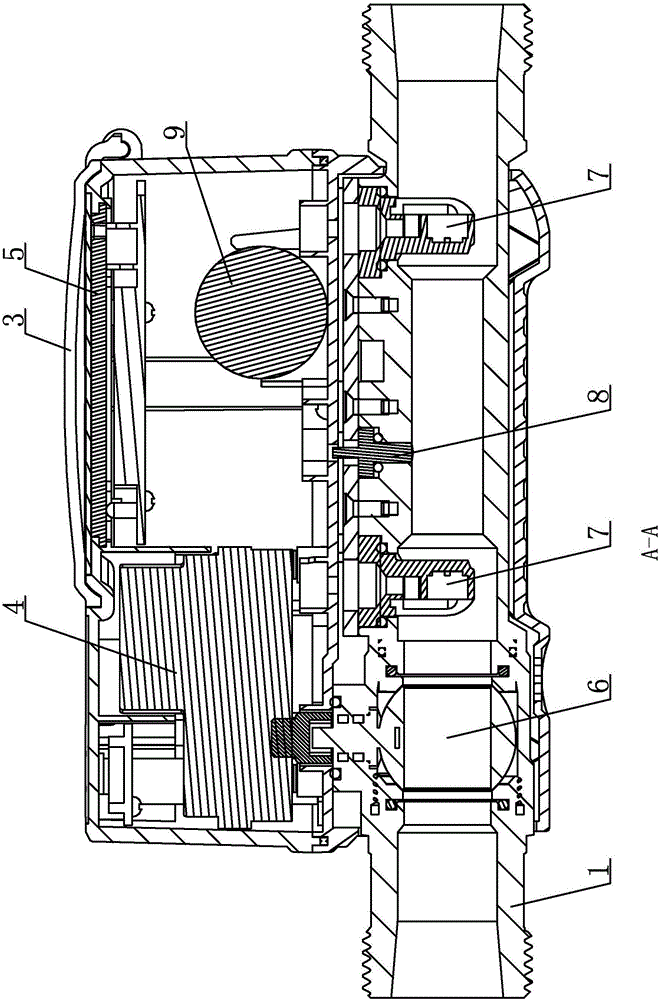

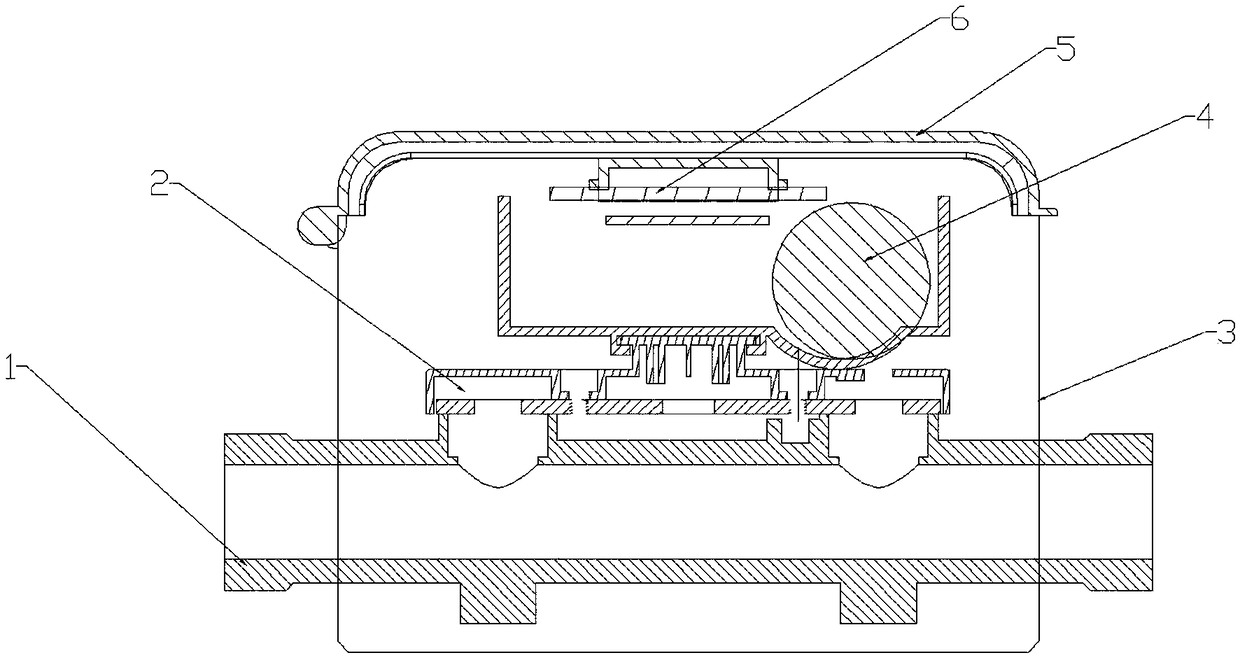

Ultrasonic water meter

InactiveCN109029601AHigh precisionImprove reliabilityVolume/mass flow measurementEngineeringPower circuits

The invention discloses an ultrasonic water meter. The water meter comprises a pipe section, a flow sensor, a meter box, a flip cover and a circuit board; the flip cover is hinged to the meter box, and forms a closed space together with a meter box shell to contain the circuit board; and the flow sensor is arranged on the inner wall of the pipe section, is used for measuring a flow speed of a liquid in the pipe section and is electrically connected with the circuit board. The circuit board is divided into five parts, namely, a main control part, a power supply part, a communication part, a measuring part and a display part; each part is provided with a corresponding slot; a main control circuit, a power circuit, a communication circuit, a measuring circuit and a display circuit are inserted into the corresponding slots respectively; and the main control circuit is a core, and is connected with the power supply circuit, the communication circuit, the measuring circuit and the display circuit. The water meter solves the problem of time and labor consumption because professional tools are needed to dismount and mount the water meter and a professional staff is needed to repair the water meter when the water meter needs to be replaced due to damage.

Owner:JIANGSU SAIDA ELECTRONICS SCI & TECH

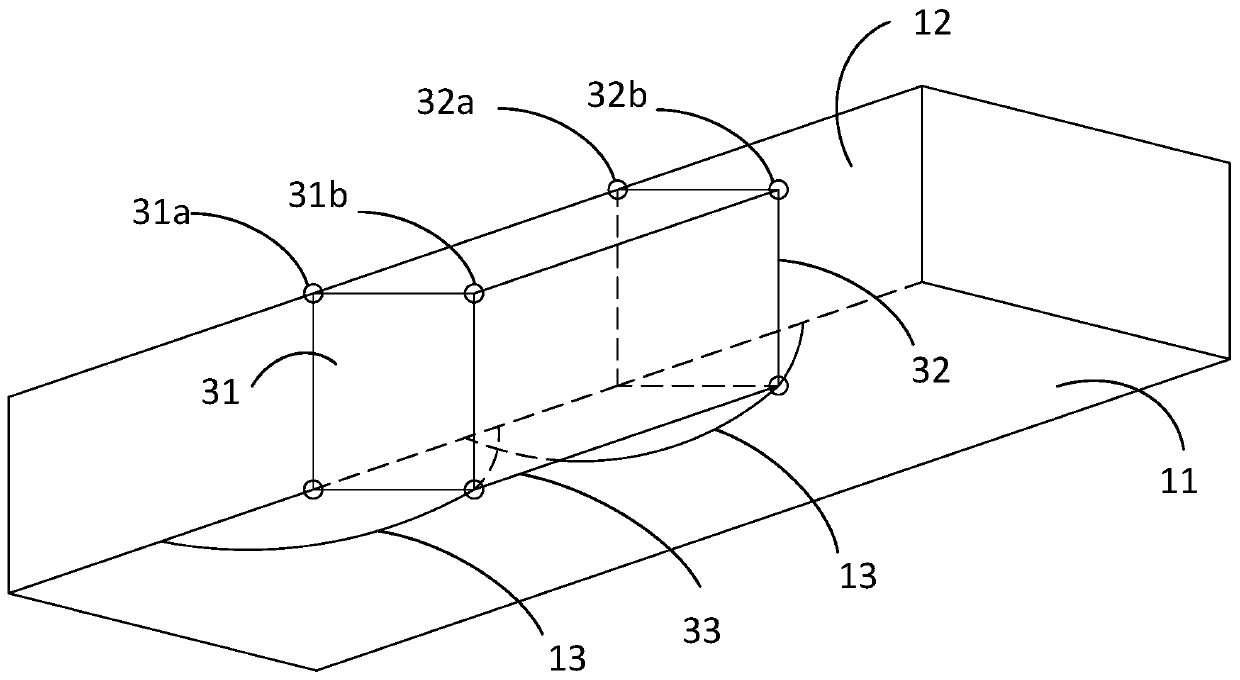

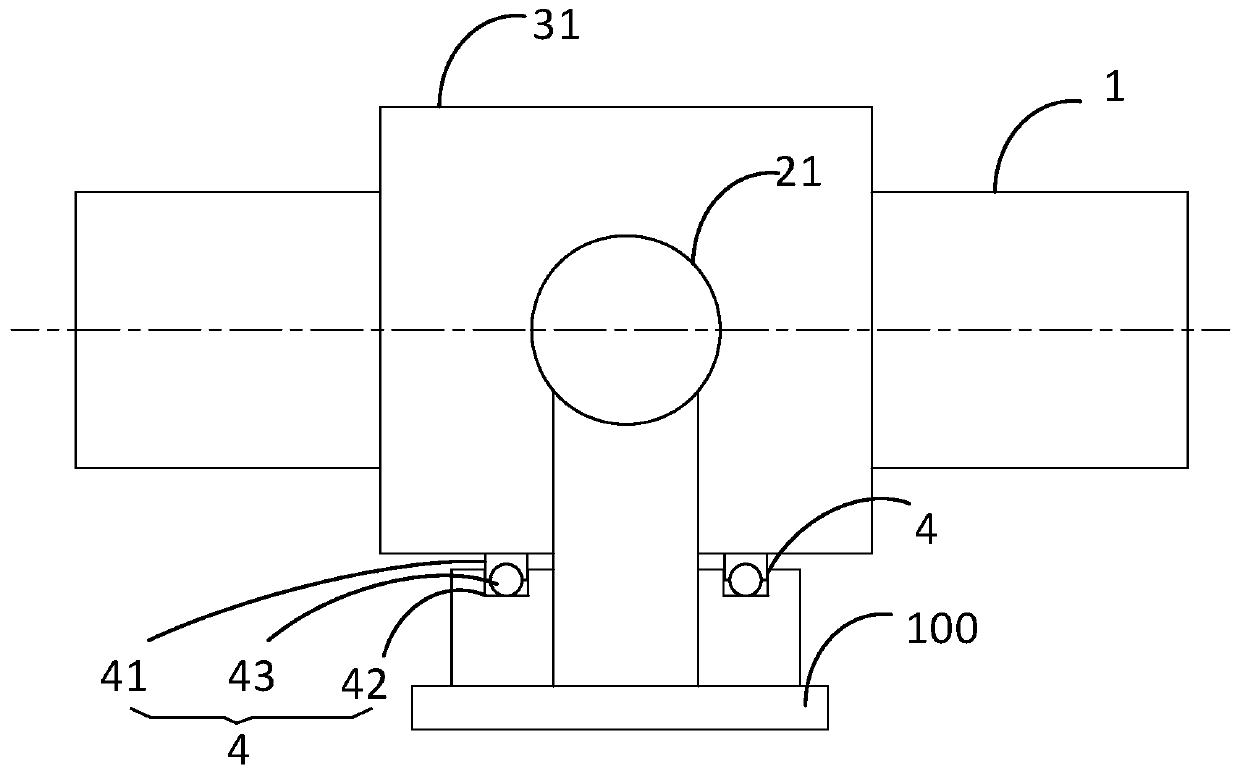

Elastic variable cross-section device

PendingCN111006727AReduce the cross-sectional areaIncrease the cross-sectional areaVolume/mass flow by differential pressureStructural engineeringMechanics

The invention discloses an elastic variable cross-section device, which comprises a detection pipeline, an axial deformation compensation pipe, a driving part and an execution part, and is characterized in that the detection pipeline is used for allowing a to-be-detected fluid to pass through and is made of an elastic material; the axial deformation compensation pipe is connected between the two ends of the detection pipeline and the flow pipeline to be detected and used for compensating axial length changes caused in the extrusion deformation process of the detection pipeline. The driving part is used for providing driving force for the executing part; and the execution part is in transmission connection with the power output end of the driving part, and extrudes or releases the detectionpipeline under the action of driving force, so that the cross sectional area in the detection pipeline is changed. The problems of complex detection pipeline, high cost, large installation space andthe like in the prior art are solved, the measuring range ratio is widened by changing the cross section of the detection pipeline on line, the cost is greatly reduced, and the installation space is reduced; simple structure and easy operation are realized.

Owner:姜春林

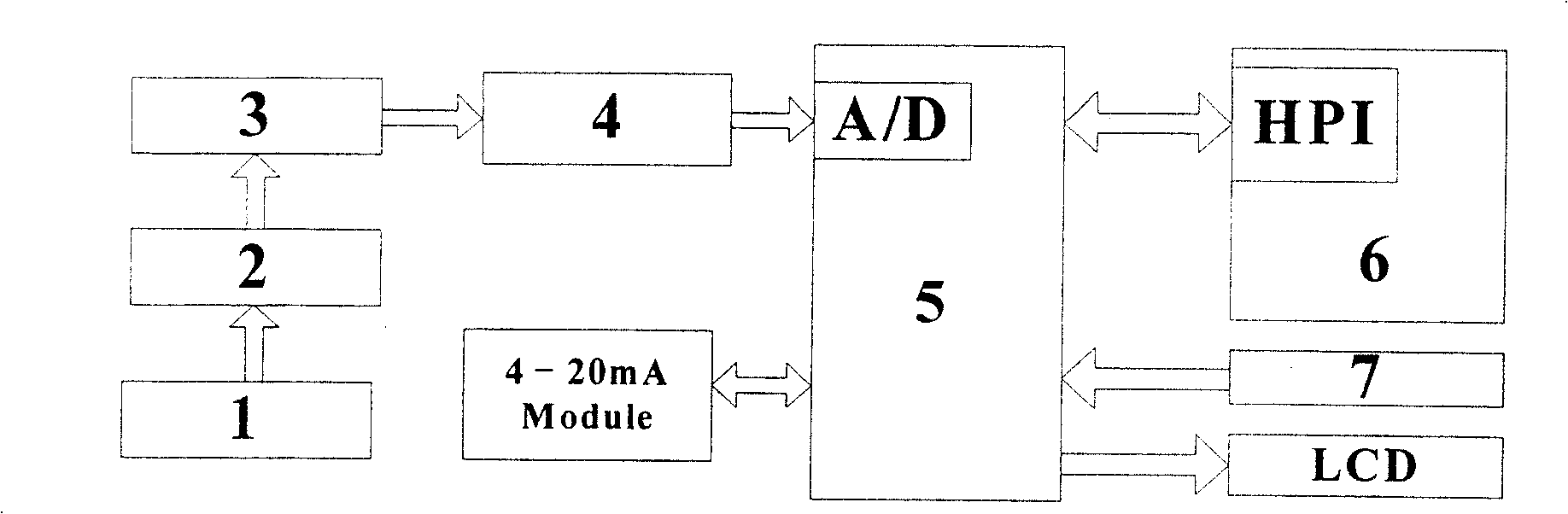

Low power consumption digital vortex street flower

InactiveCN100451561CReduce power consumptionReduce voltageVolume/mass flow by dynamic fluid flow effectDigital signal processingDifferential amplifier

The flowmeter is composed of vortex street type sensing head, charge amplifier, differential amplifier, filter of resisting mixing and piling, embedded type micro control unit (MCU), and digital signal processor (DIP). MCU and DSP constitute dual kernel CPU. With A / D conversion being carried out in MCU, signal though interface is transferred to DSP. Processed data through HPI interface are transferred back to MCU, which completes functions of displaying, controlling, storing and remote transferring. The flowmeter is capable of picking up information under strong noise background without need of changing circuits depended on calibers, gases and liquids. Specification of the flowmeter is as following: velocity of flow 0.18m / s- 6.22m / s, range ratio 1:35, Reynolds number 4.90-10 to the power 2.

Owner:TIANJIN UNIV

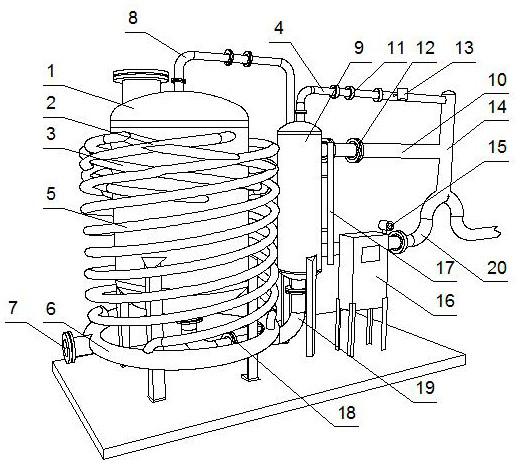

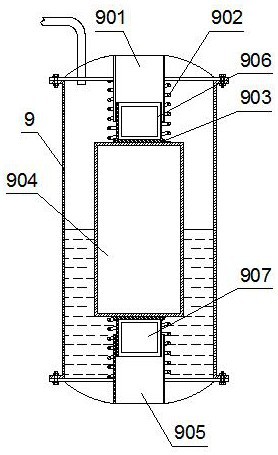

Multiphase Flow Rapid Separation Metering Device

A multi-phase flow rapid separation metering device, which relates to the technical field of oil field equipment, includes a separation tank, a liquid level control tank and a control box. A device frame is provided at the bottom of the separation tank, and an annular pipe is arranged around the device frame. One side of the annular pipe is It communicates with the feed port, and the ring pipe is equipped with a separation mechanism, which is coiled outside the separation tank. The end of the liquid level control tank is connected to the bottom end of the liquid level control tank through the pipe four, the top of the liquid level control tank is connected to the pipe six through the two pipes, the upper part of the liquid level control tank is connected to the six pipes through the three pipes, and the lower part of the liquid level control tank is connected to the six pipes through the five pipes Connected, the tank body of the liquid level control tank is provided with a liquid level gauge. The multi-phase flow rapid separation metering device achieves the purpose of multi-phase flow rapid read separation and continuous metering.

Owner:大庆市欣正科技发展有限公司

Vortex shedding flow meter based on self-adaptive fast Fourier transformation

InactiveCN102322904BHigh precision measurementSuppress noiseVolume/mass flow by dynamic fluid flow effectMicrocontrollerSchmitt trigger

The invention relates to a vortex shedding flow meter based on self-adaptive fast Fourier transformation, which comprises a charge amplifier, a first filter, a program-controlled voltage amplifier, a second filter, a program-controlled scmitt trigger, a bias voltage circuit, a singlechip computer, an LDO (Low Dropout Regulator) circuit, a reset circuit, a key input, a 4-20mA output circuit and anLCD (Liquid Crystal Display) circuit. A signal generated by a vortex shedding sensor is connected with the charge amplifier; the output of the charge amplifier is connected with the first filter; theoutput of the first filter is connected with the program-controlled voltage amplifier; the output of the program-controlled voltage amplifier is connected with the second filter; the output of the second filter is divided into two paths, wherein one path is connected with the singlechip computer; the other path is connected with the program-controlled scmitt trigger; and the program-controlled scmitt trigger is connected with the singlechip computer. According to the vortex shedding flow meter disclosed by the invention, various noises can be effectively inhibited and low-flow and high-precision measurement is realized, thereby the measuring range ratio is enlarged and the measuring precision and the sensitivity are improved.

Owner:HANGZHOU DIANZI UNIV

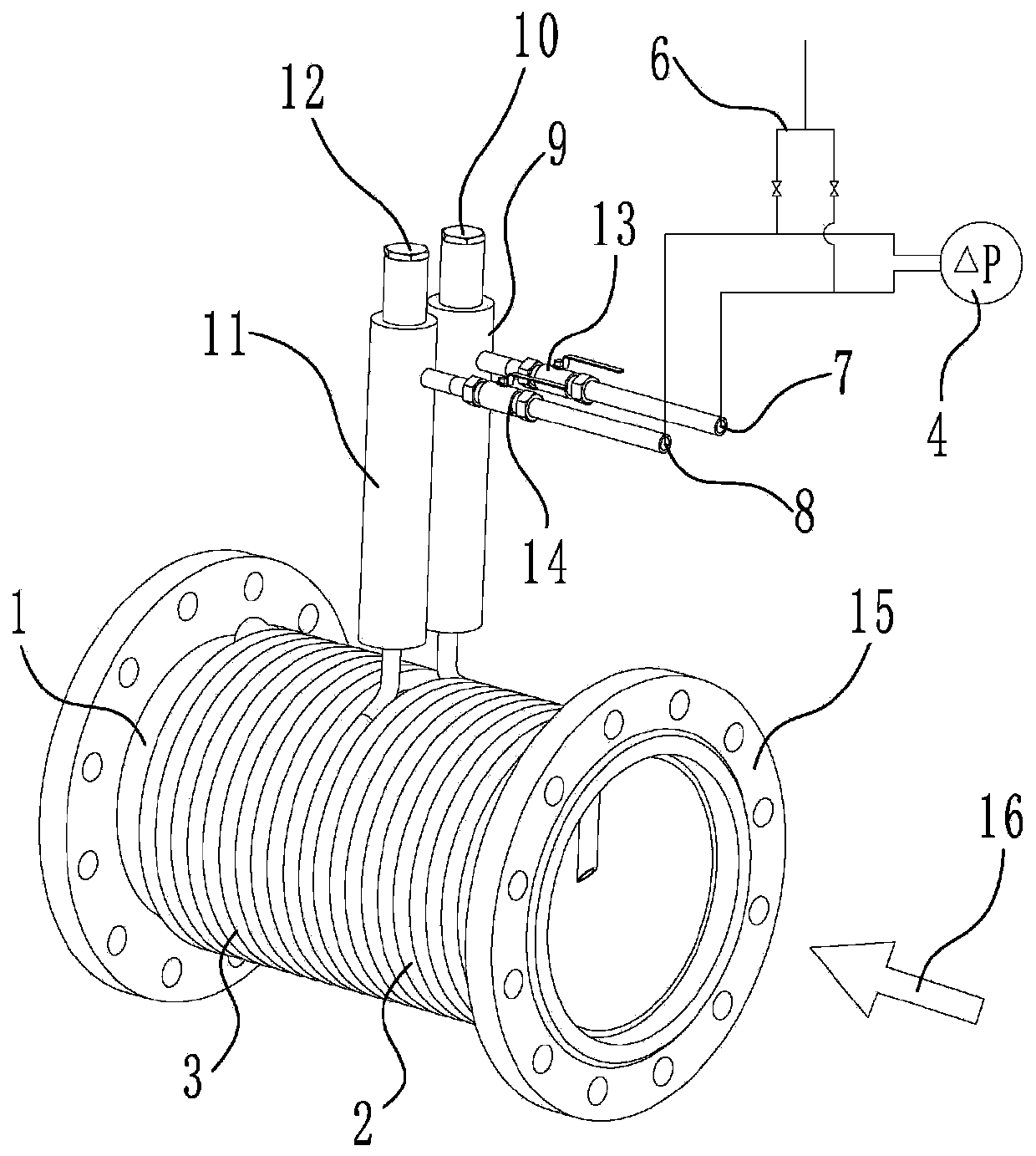

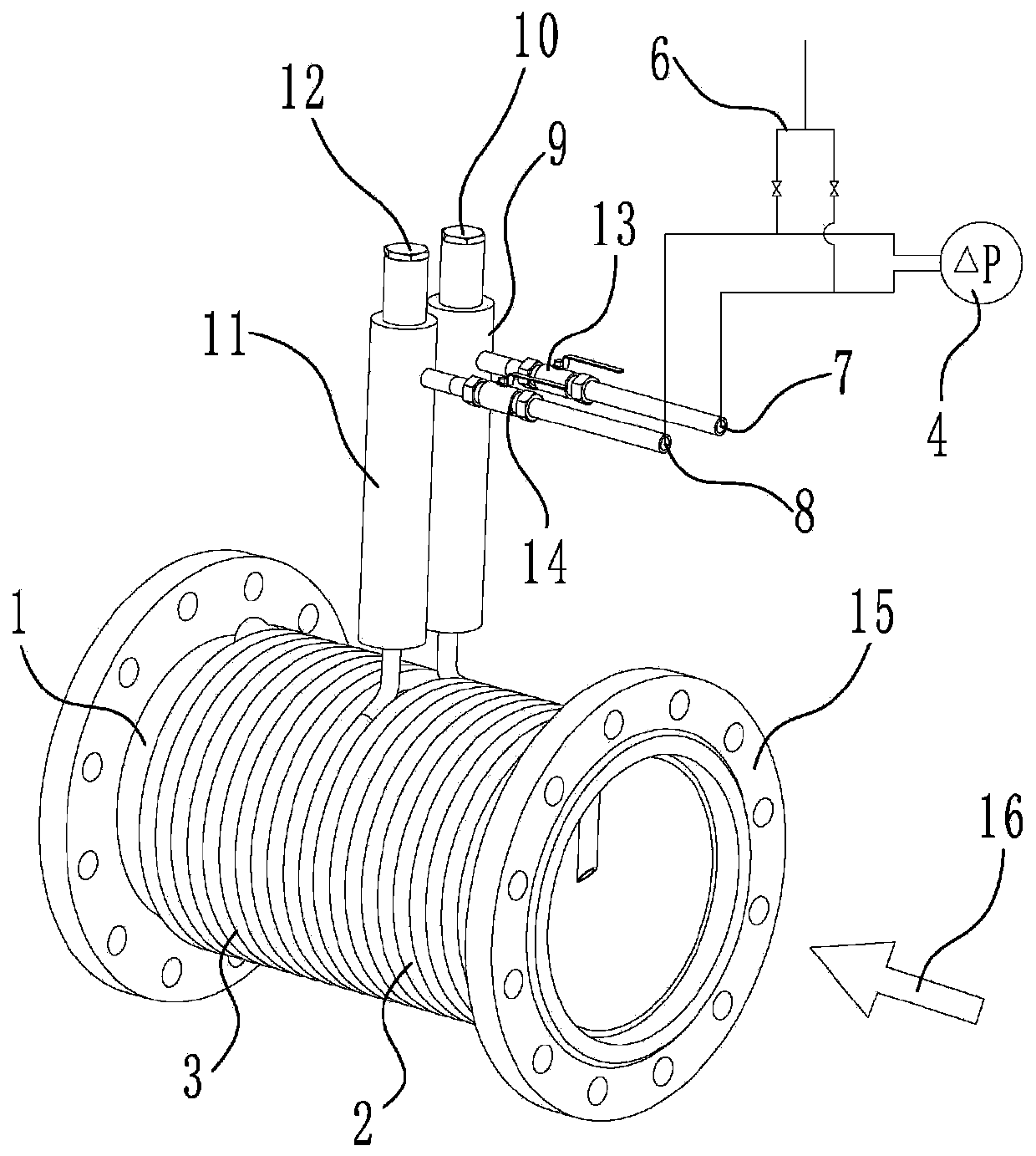

Denitration and ammonia spraying pipeline flow monitoring device taking reducing agent as urea and application thereof

ActiveCN109990848AAvoid cloggingHigh sensitivityDispersed particle separationVolume meteringDifferential pressureEngineering

The invention discloses a denitration and ammonia spraying pipeline flow monitoring device taking a reducing agent as urea. The device comprises a high temperature measurement pipeline, an upstream pressure coil, an upstream connection pipe, a downstream pressure coil, a downstream connection pipe and a differential pressure gauge, wherein the upstream pressure coil and the downstream pressure coil are respectively coiled on the outer wall of the high temperature measurement pipeline; both the coiling cycles of the upstream pressure coil and the downstream pressure coil are greater than or equal to 2; one end of the upstream pressure coil is communicated with the upstream in the high temperature measurement pipeline; and the other end of the upstream pressure coil is connected with a high-pressure port of the differential pressure gauge through the upstream connection pipe. One end of the downstream pressure coil communicates with the downstream in the high temperature measurement pipeline; and the other end of the downstream pressure coil is connected with a low-pressure port of the differential pressure gauge through the downstream connection pipe. The device is particularly suitable for gas flow measurement of non-uniform flow fields of large-caliber pipelines, has the technical advantages of being high in sensitivity, high in accuracy, wide in range ratio and small in throttling loss and preventing blockage, and is particularly suitable for the occasions with the problem that certain components in gas measurement mediums are condensed and crystalized with cold.

Owner:南京博沃科技发展有限公司

V-taper flow meter based on MEMS sensor

InactiveCN101344410ASmall structureImprove standardizationVolume/mass flow by differential pressurePositive pressureMems sensors

The invention relates to a flow measuring device, in particular to a V-cone flow measuring device that is based on an MEMS sensor and consists of a flange, a measuring tube, a supporting frame, an MEMS sensitive core, an encapsulating structure, a positive pressure tapping, a negative pressure tapping, a V-shaped cone component and signal wires. The MEMS sensitive core is arranged inside the V-shaped cone, and the pressure tappings are arranged inside the measuring tube, thus canceling the structure that pressure of traditional V-cone flow meters need to be extracted from the tube. According to a mathematical relation model between the flow rate and the pressure difference as well as real calibration on the spot, the V-cone flow measuring device realizes dynamic and steady-state flow measurement, solves the problems that traditional V-cone flow meters have bad dynamic property, large error and high loss, etc.; furthermore, the invention creates required conditions for the standardization of the V-cone flow meters and is favorable for the popularization and application of the V-cone flow meters.

Owner:DALIAN MARITIME UNIVERSITY

A Vortex Flowmeter Based on Multi-sensor Information Fusion

ActiveCN105181031BImprove filtering effectImprove signal-to-noise ratioVolume/mass flow by dynamic fluid flow effectBandpass filteringElectricity

The invention discloses a vortex flowmeter based on multi-sensor information fusion, which can effectively suppress the interference of strong periodic vibration noise in the piezoelectric sensor signal, extract useful vortex signals therefrom, and accurately measure the flow velocity of the fluid. Its core is that a temperature sensor and a strong vibration-resistant differential pressure sensor are added to the traditional piezoelectric vortex flowmeter, and the temperature sensor can be used to compensate the temperature drift of the piezoelectric sensor and differential pressure sensor; The multi-sensor data fusion algorithm of Unscented Kalman Filter (UKF) integrates the average value of the differential pressure output by the differential pressure sensor and the frequency value of the piezoelectric signal obtained by the piezoelectric sensor, which improves the digital band-pass filter. The accuracy of the device lock. The invention can improve the signal-to-noise ratio of the vortex street signal measurement, has the advantages of enhancing the vibration resistance of the piezoelectric vortex street flowmeter, reducing the minimum flow rate measurement lower limit, widening the range ratio and the like.

Owner:HANGZHOU ZIWU INSTR

Combined platinum film gas flow measuring method and flow meter

The invention discloses a method and a flow meter for measuring combined platinum-film gas flow. A detecting rod is adopted to be inserted in a measuring pipe in diameter direction. The detecting rod is fixed with one or a plurality of platinum-film probes, which integrate a combination of a flow probe and a temperature probe. Every probe can feel the flow and the temperature signals of the gas. The quality flow of the gas can be obtained when the flow and temperature signals are acquired and processed. The flow value and the temperature value can be displayed and remotely sent. The combined platinum-film gas flow meter has the advantages of simple structure, low investment, high precision, little press loss, wide range ratio (being capable of reaching to about one hundred times), almost zero flux lower limit, etc. No such flow meter with simple structure and perfect comprehensive performance exists in gas flow detecting meters. Therefore, the economic benefits are very obvious. The meter is equipped with an integrated structure and multi-parameter measuring functions of flow, temperature, etc.

Owner:CHINA JILIANG UNIV

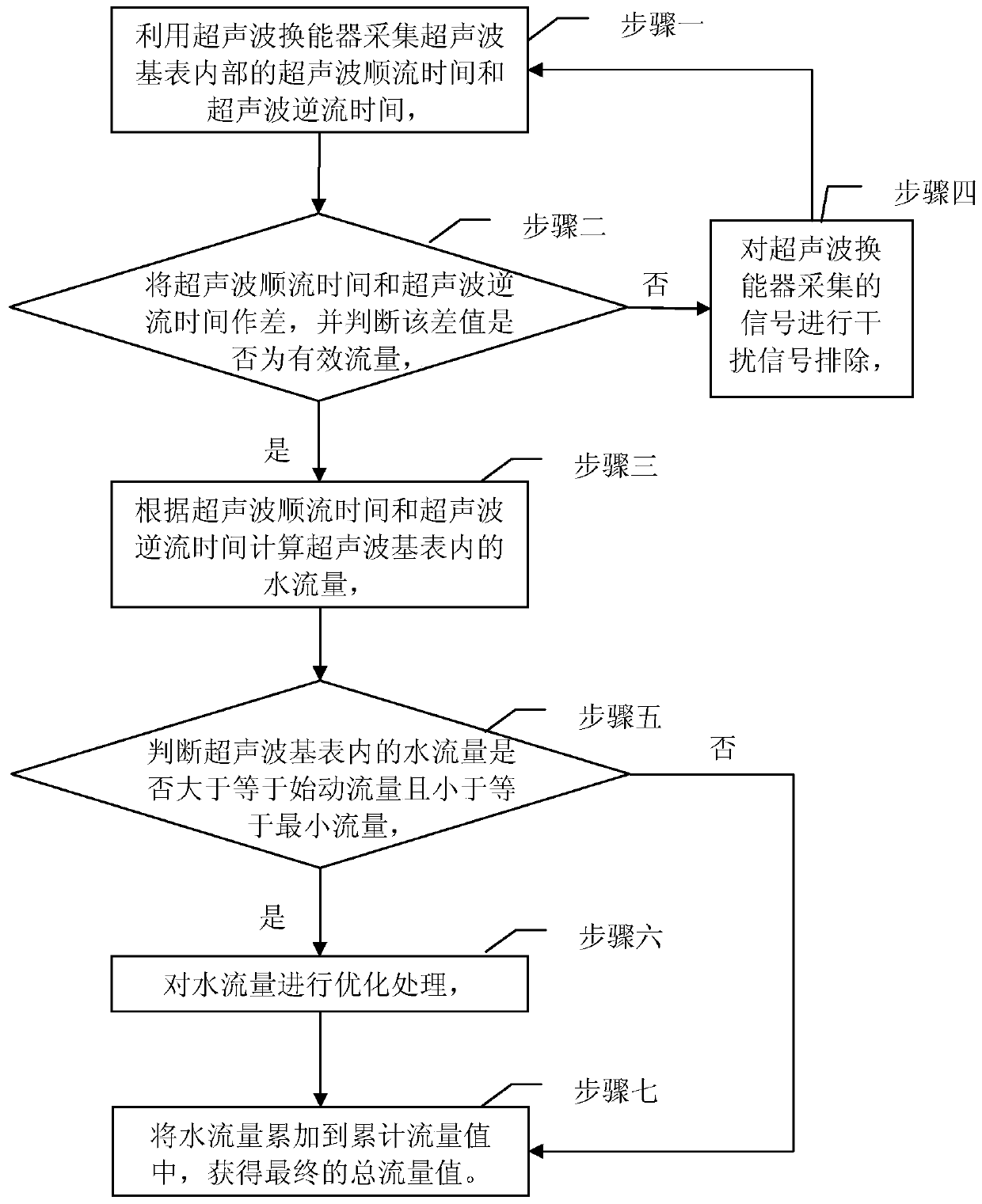

Ultrasonic water meter drip measurement method

ActiveCN105784032BHigh precisionImprove reliabilityVolume/mass flow measurementVolume meteringWater flowHydrology

The invention provides a drip metering method of an ultrasonic water meter and relates to the field of application of water meter. The drip metering method is used for solving the problem that a running-water company`s loss is generated when a user utilizes a drip method to steal water due to the structural defects of an existing common mechanical water meter. The drip metering method of the ultrasonic water meter comprises the following steps: collecting the water flow by use of an ultrasonic time difference theory; and comparing the collected water flow with starting flow and minimum flow during measurement, thereby eliminating drip errors and further improving the metering accuracy of the water meter. The drip metering method is applicable to any environment requiring the water meter to meter the water flow.

Owner:HARBIN SHENGCHANG TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com