Elastic variable cross-section device

A variable cross-section and elastic technology, which is applied in the direction of volume/mass flow generated by mechanical effects, fluid flow detection by measuring pressure difference, etc., can solve problems such as complex control process, complex measurement pipeline, and reduced installation space to achieve extended range Ratio, increasing cross-sectional area, reducing the effect of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

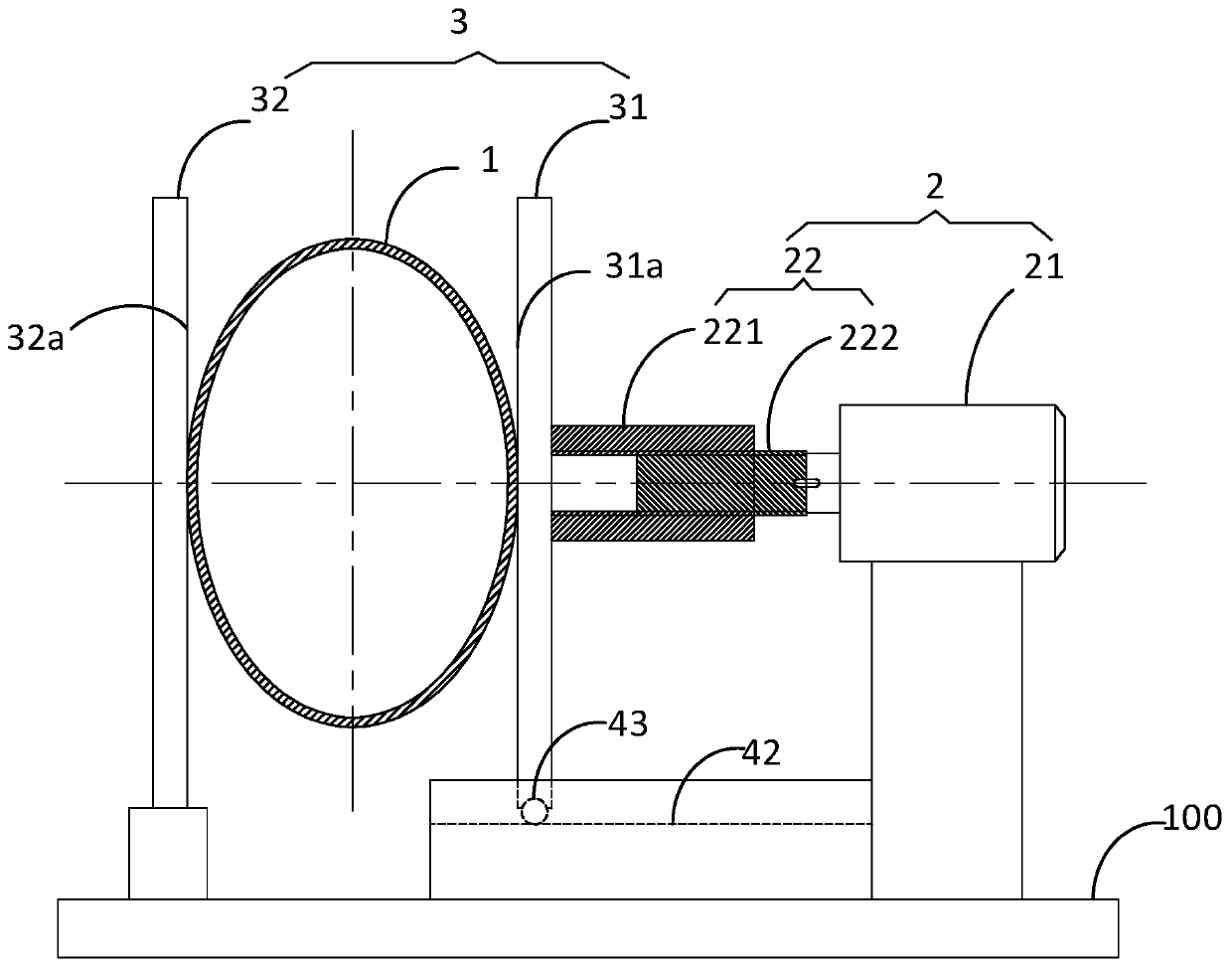

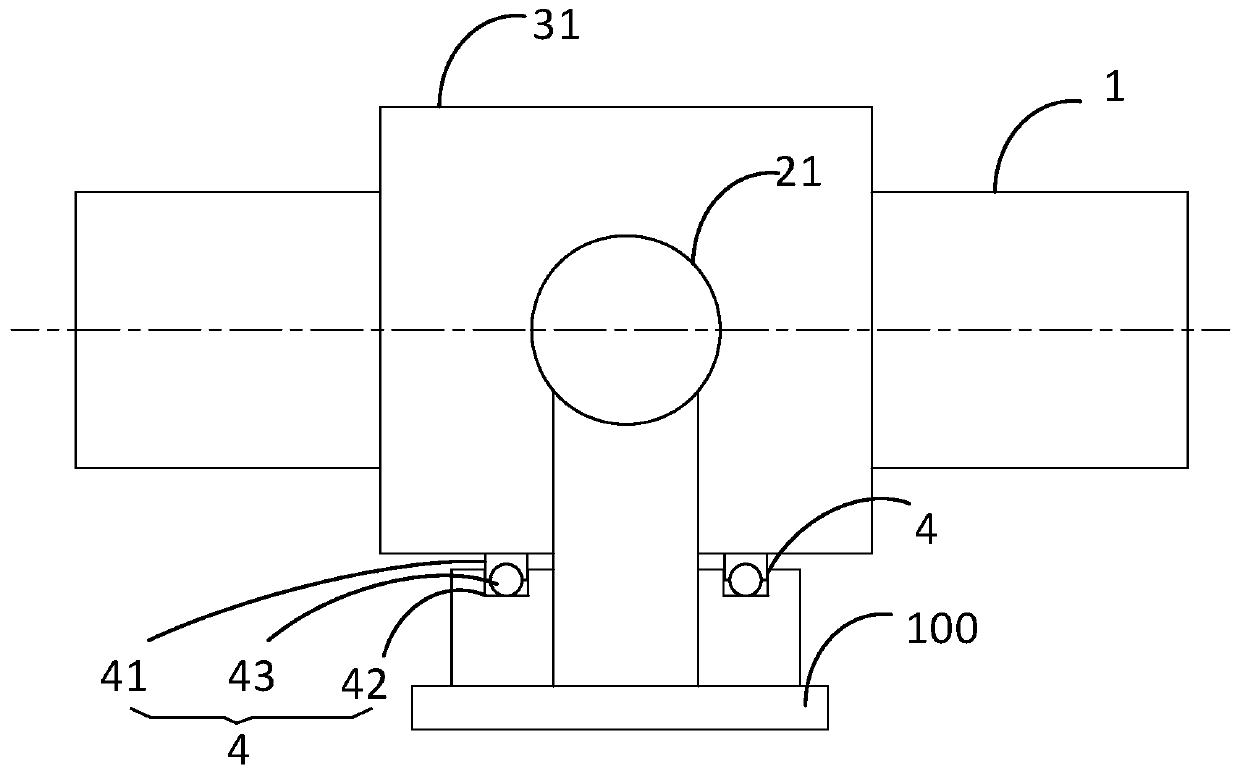

[0032] as attached figure 1 , figure 2 As shown, the embodiment of the present invention provides an elastic cross-section device, including: a detection pipeline 1, a driving part 2, an execution part 3, an axial deformation compensation pipe (such as a bellows, a casing structure, etc.) and a fixing bracket 100; Pipeline 1 is used to pass the fluid to be tested, and is made of elastic material; driving part 2 is used to provide driving force for actuator part 3; actuator part 3 is connected to the power output end of driving part 2, and is squeezed under the action of driving force Or release the detection pipeline 1 to change the cross-sectional area inside the detection pipeline. The bellows are connected between the two ends of the detection pipeline and the flow pipeline to be measured, and are used for compensating the change of the axial length of the detection pipeline caused by extrusion and deformation.

[0033] The detection pipeline 1 here is made of elastic ma...

Embodiment 2

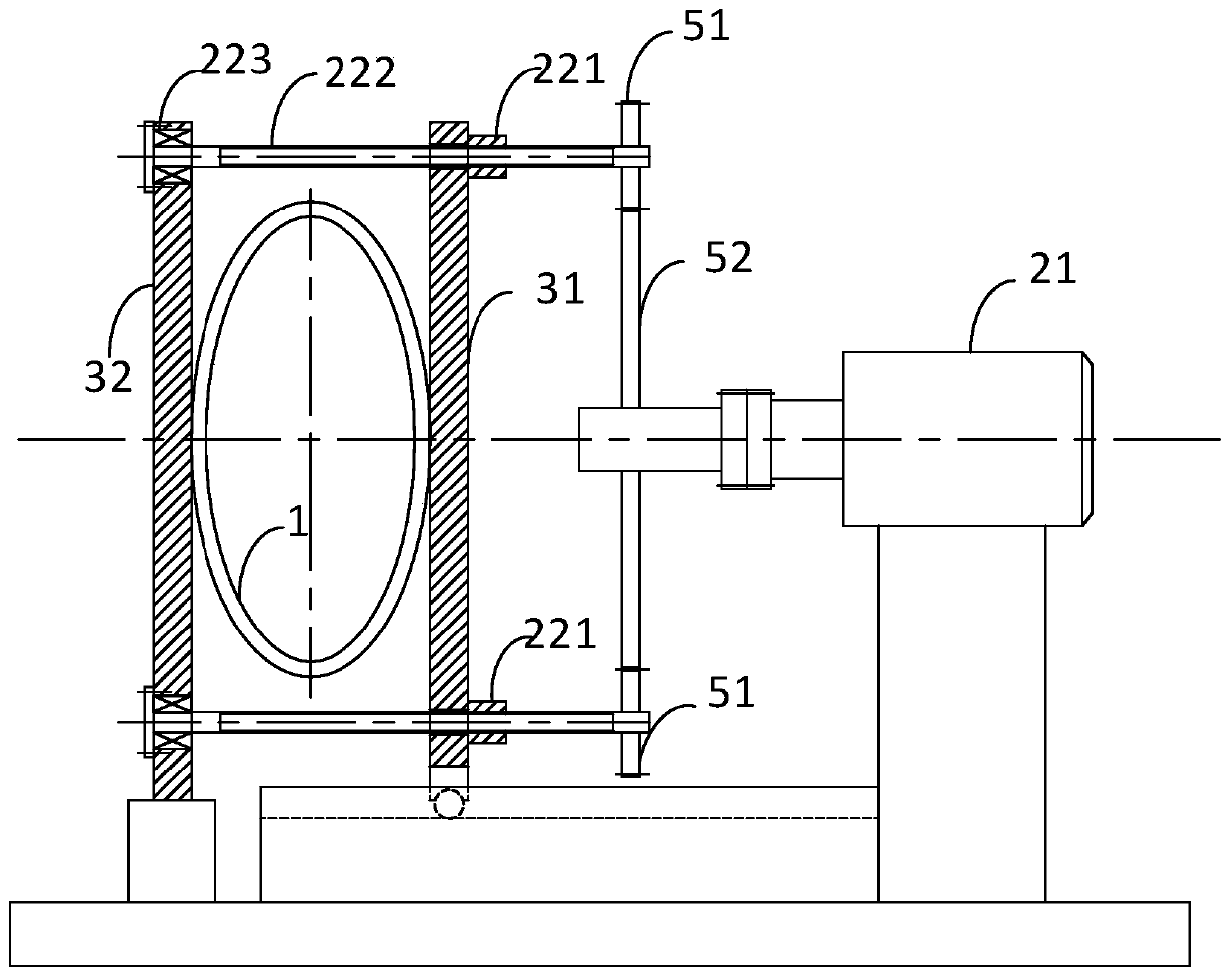

[0044] see image 3 , Figure 4 , the moving panel 31 and the static panel 32 are rectangular, and the position is facing; the transmission mechanism 22 also includes three first linear motion output units and a gear transmission unit 5; the gear transmission unit includes four From the gear 51 and a main gear 52; the screw sleeves 221 of the four first linear motion output units are respectively fixed at the positions of the four corners of the moving panel 32; the screw rods 222 of the four first linear motion output units pass through the moving The screw sleeve 221 of the panel 32 is rotatably connected to the static panel 31 at one end (in this embodiment, the bearing 223 is connected to the static panel 32, and the bearing cover is installed on the side of the static panel 31 away from the clamping surface to encapsulate the bearing 223), The other end is respectively connected to a driven gear 51 ; the four driven gears 51 are all externally meshed with a main gear 52 ...

Embodiment 3

[0047] In another embodiment of the present invention, not shown in the figure, the execution part 3 can use the clamping mechanism to simultaneously clamp or release both sides of the detection pipeline 1 to change the cross-sectional area of the detection pipeline. The clamping mechanism includes two The support arm and the hinge shaft that hinges the middle parts of the two arms together. After the two arms are hinged, they are X-shaped. One end is the actuating end and the other end is the execution end. A torsion spring is worn on the hinge shaft. In the natural state , the two arms at the actuator end are closed naturally, the two arms at the actuator end are naturally opened, and the two arms at the actuator end are opened under the action of the driving part until the two arms at the actuator end are opened to the maximum when the two arms at the actuator end are closed. Angle; when in use, the hinge axis is parallel to the central axis of the detection pipeline 1. Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com