Thermal type perforated plate gas flowmeter applied to non-uniform flow field

A technology of gas flowmeter and porous plate, which is applied in the direction of volume/mass flow generated by mechanical effects, liquid/fluid solid measurement, fluid flow detection by measuring pressure difference, etc., and can solve problems such as low flow rate, condensation, crystallization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The 600MW coal-fired unit adopts the SCR denitrification process, uses liquid ammonia as the reducing agent, and uses normal temperature air to dilute the mixed gas to less than 5%. In order to overcome the flow resistance, the transmission pipeline system is equipped with a dilution fan. The denitrification system needs to be reconstructed by partitioned ammonia injection, and it is necessary to measure the distribution of the mixed gas flow in each partition. However, due to the limited increase in the pressure head of the dilution fan and the limited renovation space, the flow velocity on the flow measurement section of the main pipe (diameter DN250) in each partition is low and the distribution is uneven. Uniform, difficult to measure.

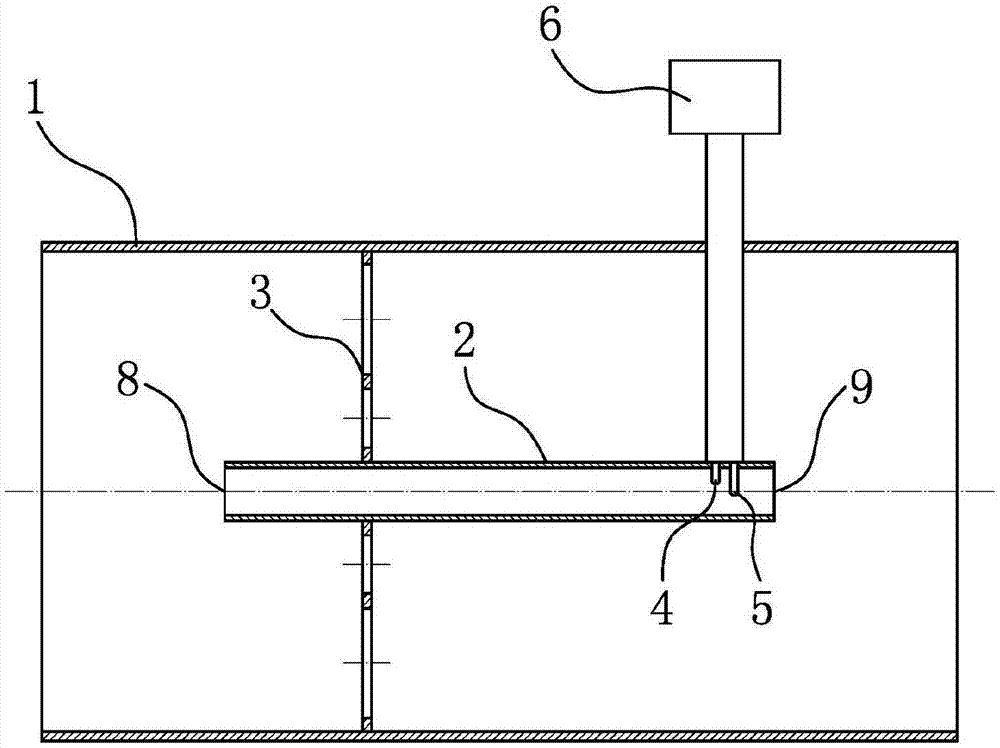

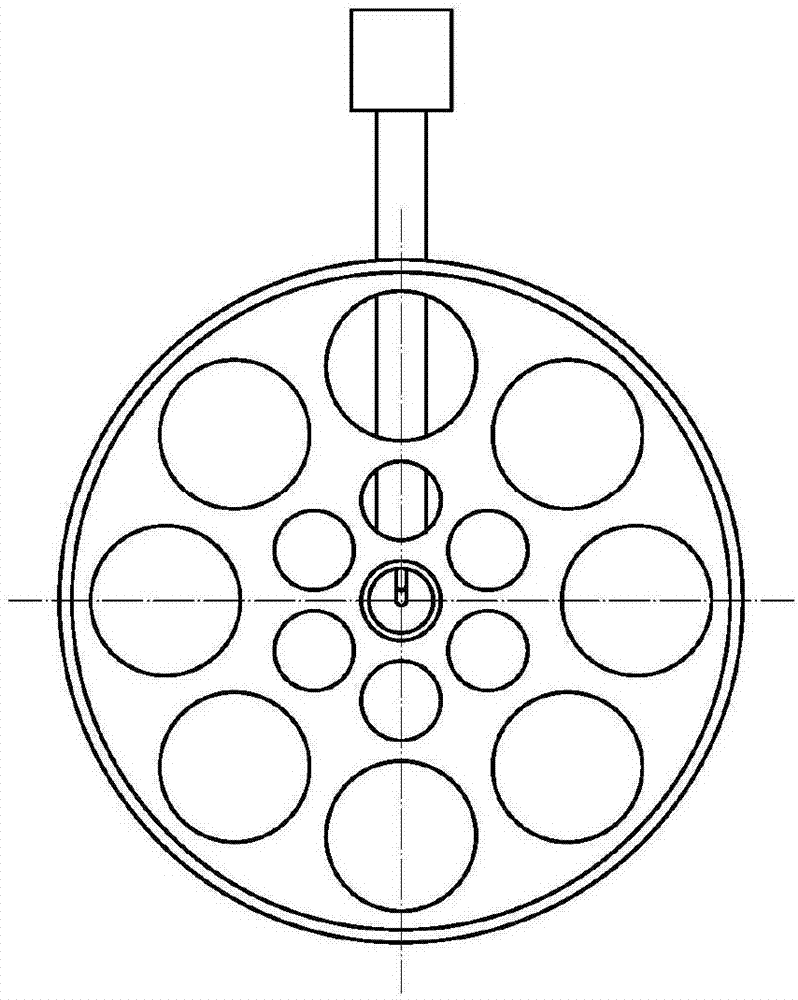

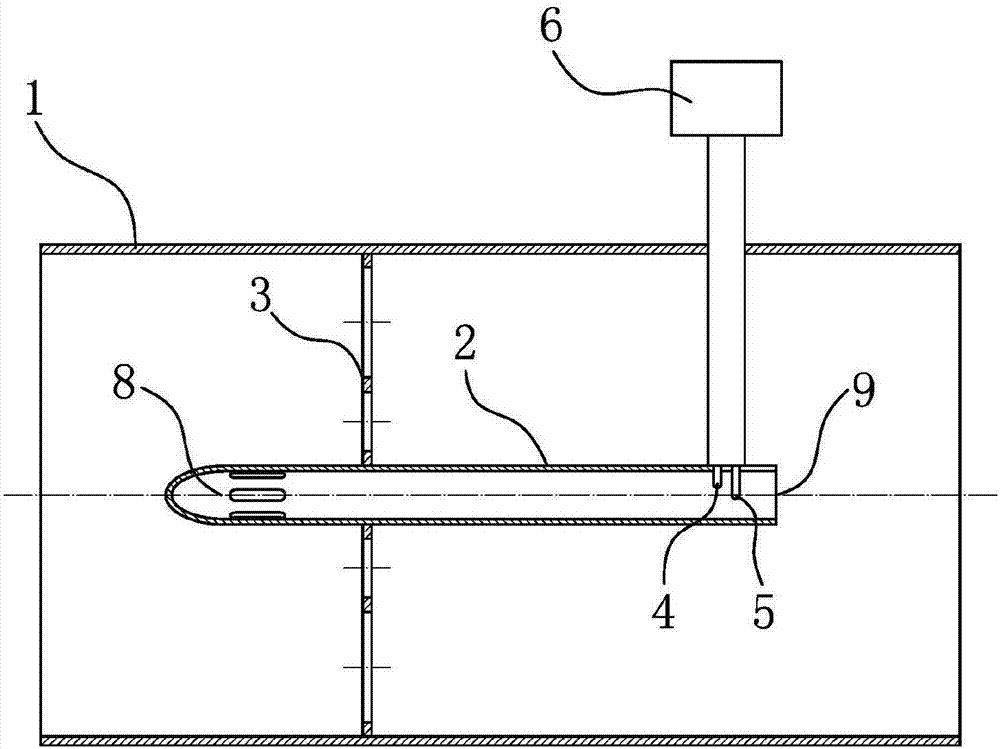

[0040] use as Figure 1-2The shown thermal porous plate gas flowmeter applied to the uneven flow field includes an outer casing, an inner casing, a first porous plate, a temperature sensor, a speed sensor and a signal transmitter; t...

Embodiment 2

[0043] The 1000MW coal-fired unit adopts the SCR denitrification process, uses urea as the reducing agent, adopts the pyrolysis method to produce ammonia, and uses the hot primary air at about 300°C as the dilution air to dilute the ammonia concentration to below 5%. The denitrification system needs to be reconstructed by partitioned ammonia injection, and it is necessary to measure the distribution of the mixed gas flow in each partition, but the renovation space is limited, and the flow velocity distribution on the flow measurement section of the main pipe (diameter DN250) of each partition is not uniform, and there are condensation and crystallization of urea when it is cold. The problem. According to the characteristics of urea, urea is unstable above 160°C and decomposes, but the decomposed NH 3 with CO 2 Below 200°C, urea will be synthesized and deposited in the pipeline, so all differential pressure flowmeters are not suitable.

[0044] The process of ammonia producti...

Embodiment 3

[0047] The 300MW coal-fired unit adopts the SCR denitrification process, uses urea as the reducing agent, adopts the hydrolysis method to produce ammonia, and uses the hot primary air at about 300°C as the dilution air to dilute the ammonia concentration to below 5%. The denitrification system needs to measure the distribution of the mixed gas flow in each zone when the denitrification system is upgraded. However, the renovation space is limited, and the flow velocity distribution on the flow measurement section of the main pipe of each zone is uneven. At the same time, there are also problems of condensation and crystallization of cold urea. According to the characteristics of urea, urea is unstable above 160°C and decomposes, but the decomposed NH 3 with CO 2 Below 200°C, urea will be synthesized and deposited in the pipeline, so all differential pressure flowmeters are not suitable.

[0048] The process flow of ammonia production by urea hydrolysis method is as follows: se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com