V-taper flow meter based on MEMS sensor

A flow measurement device and sensor technology, which is applied to the volume/mass flow generated by mechanical effects, and the detection of fluid flow by measuring pressure difference, etc., can solve the problems of large error, poor dynamic characteristics, high loss, etc., and achieve wide and high range ratio Effect of low signal level, permanent pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

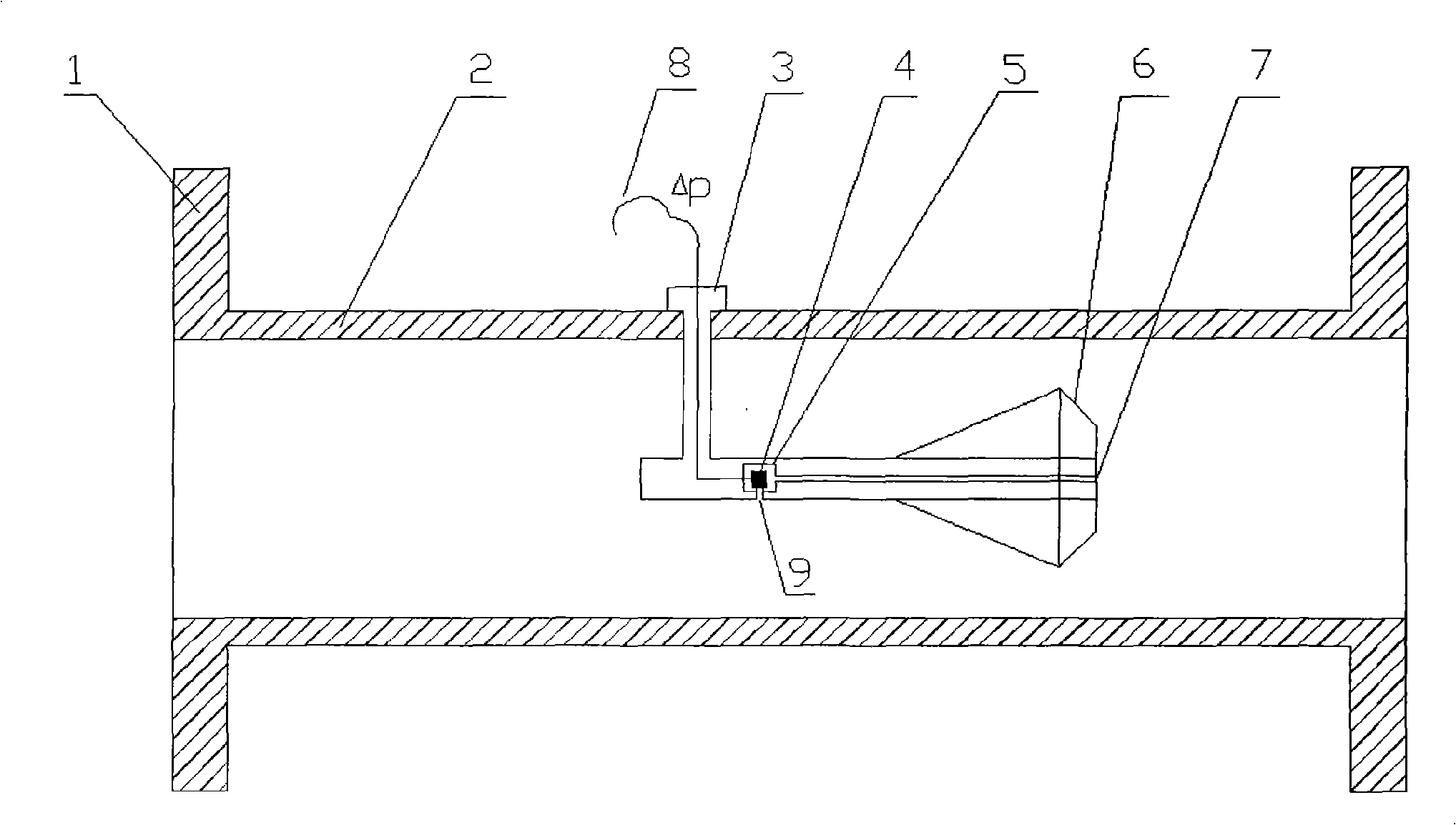

[0024] Such as figure 1 As shown, the front end of the V-shaped cone assembly 6 is fixedly connected to one end of the support frame 3, and the other end of the support frame 3 is fixed on the inner wall of the measuring tube 2; the MEMS sensitive core 4 is packaged in the packaging structure 5 and placed in the V-shaped cone Inside the assembly 6; when the fluid in the measuring tube 2 flows through the V-shaped cone of the V-shaped cone assembly 6, the fluid gradually throttles and shrinks to the inner wall of the pipeline. According to Bernoulli's principle, the V-shaped cone A pressure difference corresponding to the flow rate is generated before and after, and the pressure difference is measured by the MEMS sensitive core 4 and is led out of the measuring tube 2 through the signal line 8 . According to the flow-differential pressure mathematical relationship model and on-site actual calibration, the dynamic and steady-state measurement of flow can be realized.

Embodiment 2

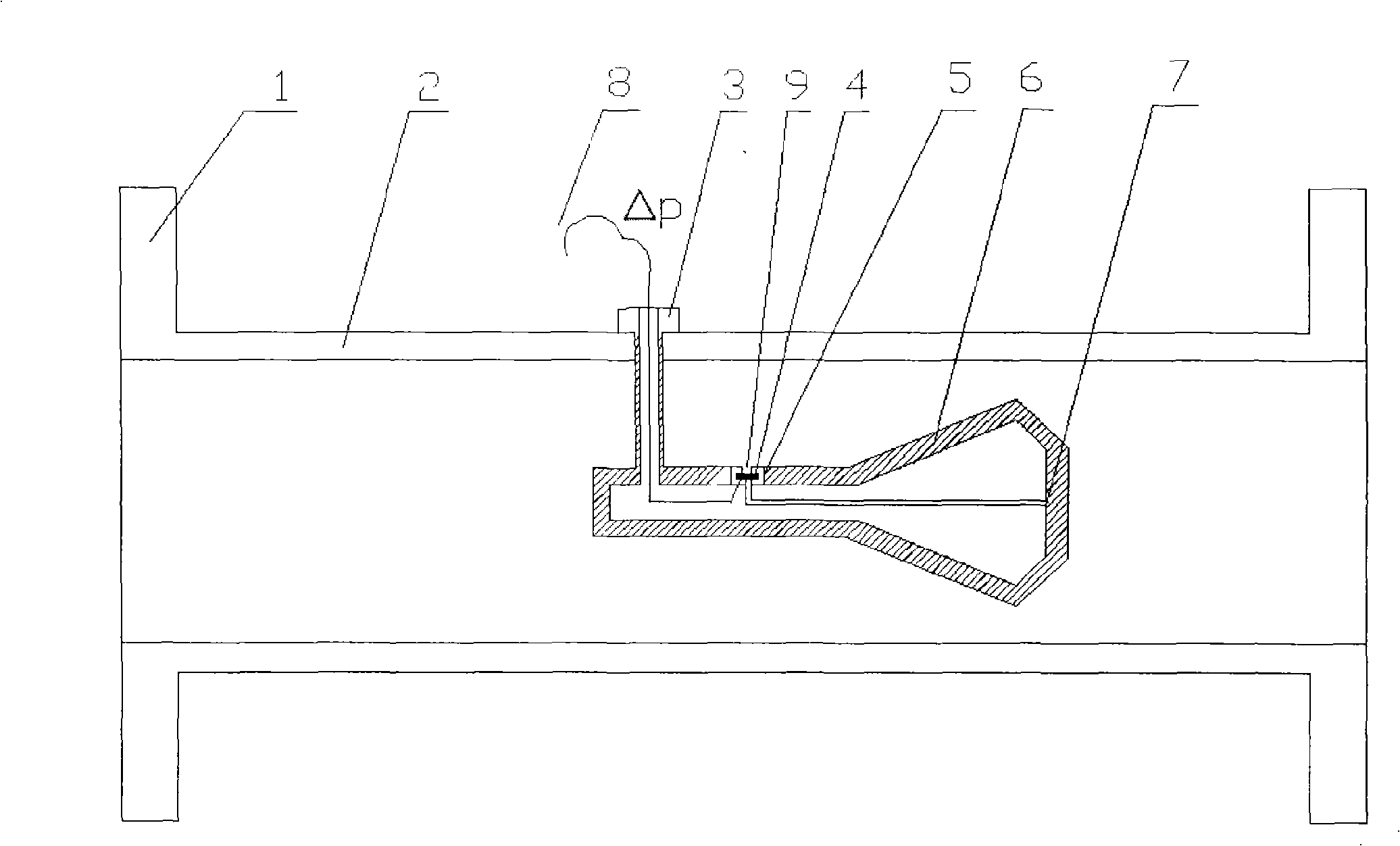

[0026] Such as figure 2 As shown, the front end of the V-shaped cone assembly 6 is fixedly connected to one end of the support frame 3, and the other end of the support frame 3 is fixed on the inner wall of the measuring tube 2; the MEMS sensitive core 4 is packaged in the packaging structure 5 and embedded in the V-shaped cone When the fluid in the measuring tube 2 flows through the V-shaped cone of the V-shaped cone assembly 6, the fluid gradually shrinks to the inner wall of the pipe According to Bernoulli's principle, the V-shaped inner cone produces a pressure difference corresponding to the flow rate, which is measured by the MEMS sensitive core 4 and leads out to the measuring tube 2 through the signal line 8 . According to the flow-differential pressure mathematical relationship model and on-site actual calibration, the dynamic and steady-state measurement of flow can be realized.

Embodiment 3

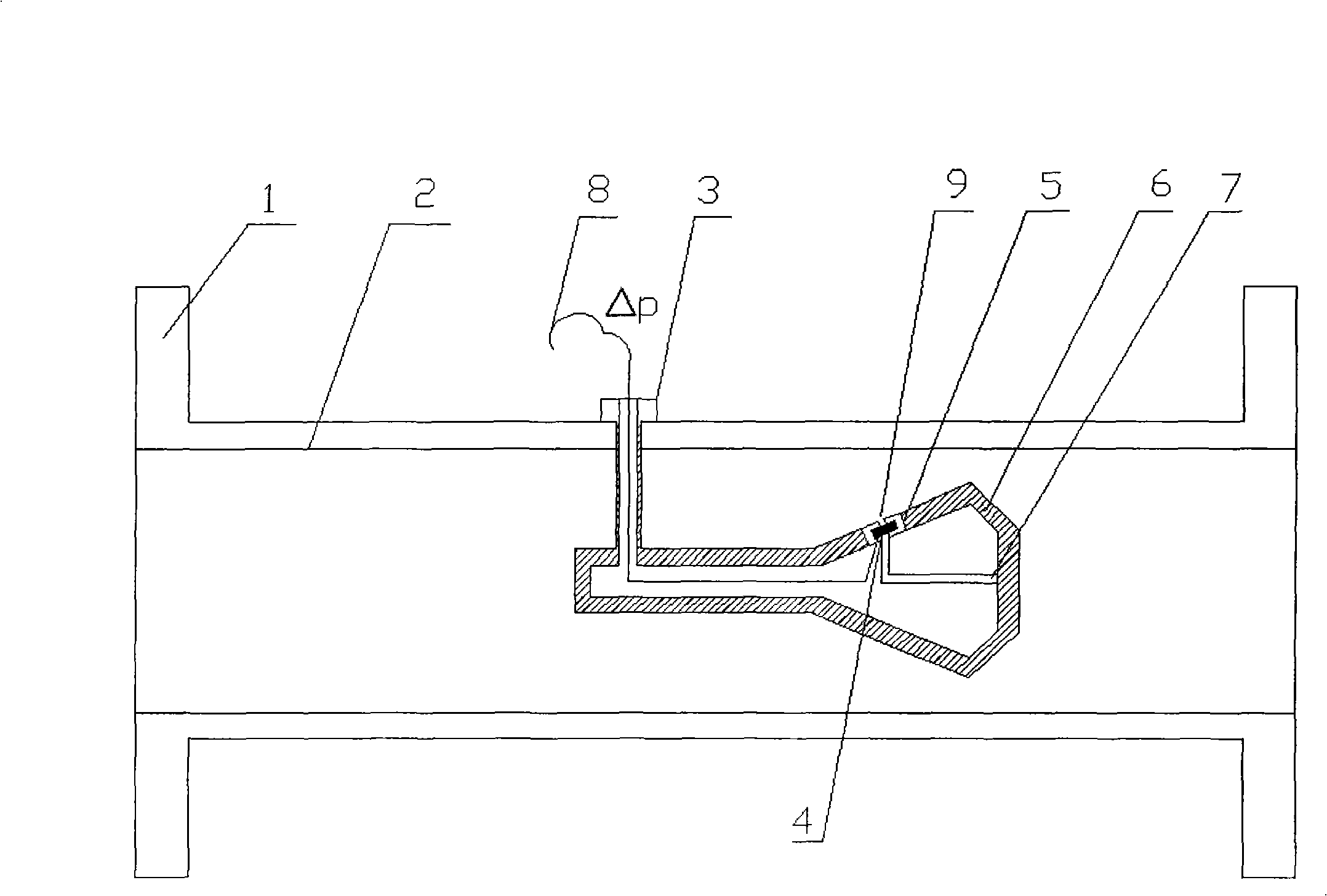

[0028] Such as image 3 As shown, the front end of the V-shaped cone assembly 6 is fixedly connected to one end of the support frame 3, and the other end of the support frame 3 is fixed on the inner wall of the measuring tube 2; the MEMS sensitive core 4 is packaged in the packaging structure 5 and embedded in the V-shaped cone The V-shaped conical tube wall of the assembly 6, and keep sealed with the tube wall; when the fluid in the measuring tube 2 flows through the V-shaped pointed cone of the V-shaped cone assembly 6, the fluid gradually throttles and shrinks into the inside of the pipe As for the side wall, according to Bernoulli's principle, the V-shaped inner cone produces a pressure difference corresponding to the flow rate. The pressure difference is measured by the MEMS sensitive core 4 and leads out to the measuring tube 2 through the signal line 8 . According to the flow-differential pressure mathematical relationship model and on-site actual calibration, the dynam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com