Plug-in type semi-parabola multi-point pressure tapping flow sensor

A flow sensor, parabolic technology, applied in volume/mass flow, liquid/fluid solid measurement, and fluid flow detection by measuring differential pressure caused by mechanical effects. The effect of improving measurement accuracy and wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

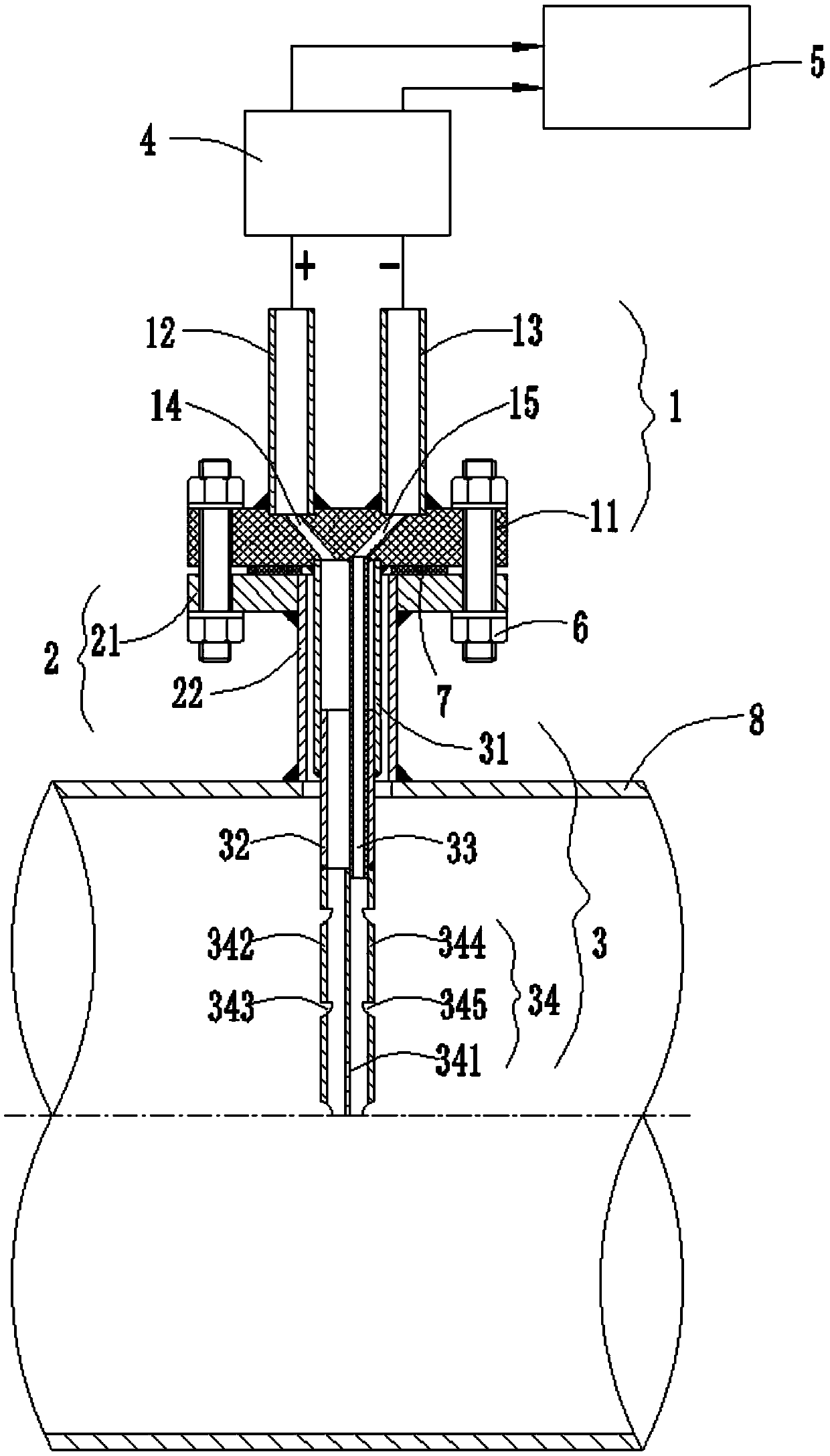

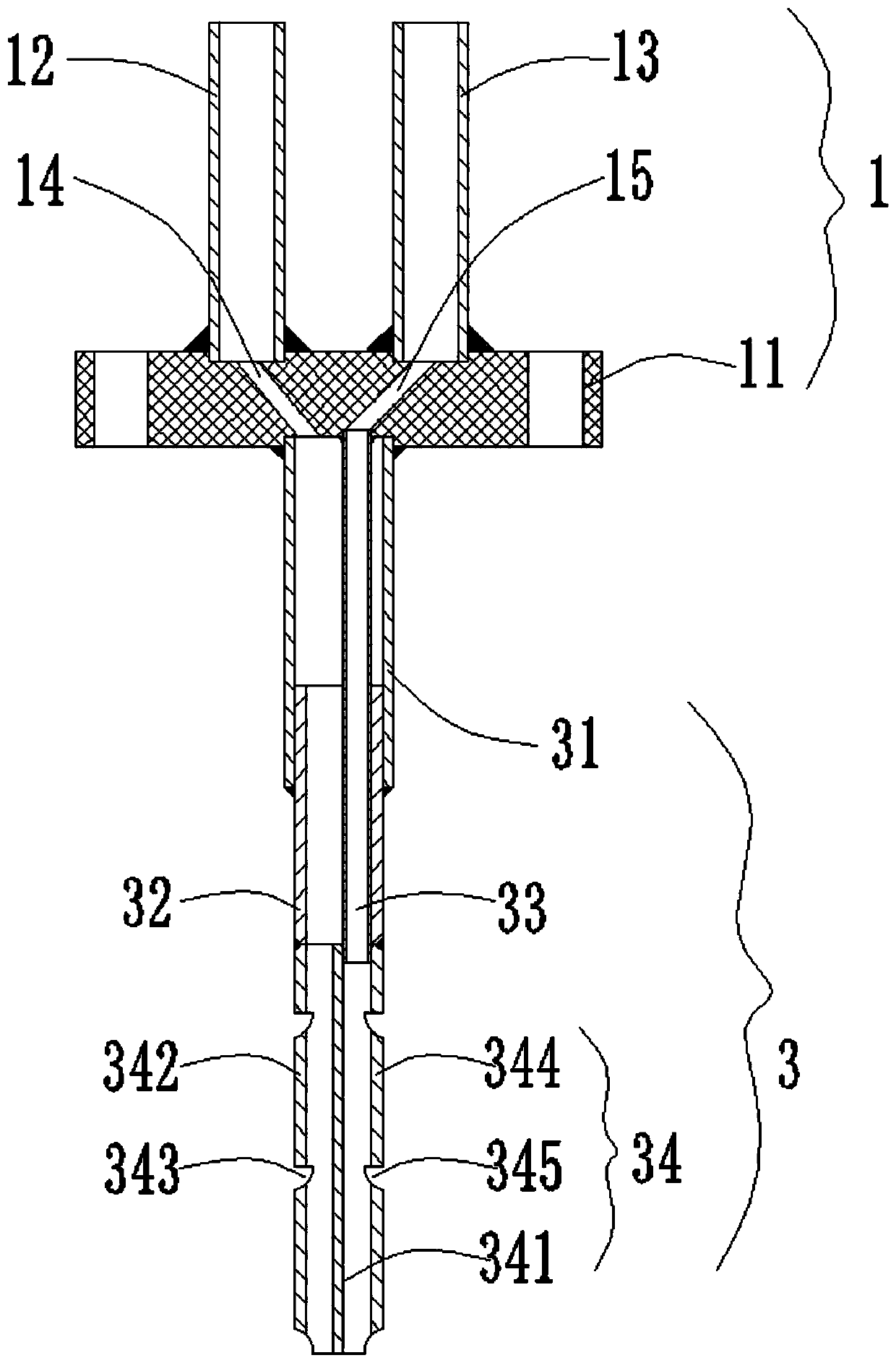

[0029] see Figure 1-2 , in an embodiment of the present invention, a plug-in semi-parabolic multi-point pressure-taking flow sensor includes a pressure-taking structure 1, a T-shaped installation socket 2 and a pressure detection element 3,

[0030] The pressure taking structure 1 includes a pressure taking flange 11, the upper side of the pressure taking flange 11 is vertically provided with a positive pressure taking pipe 12 and a negative pressure taking pipe 13, and the inside of the pressure taking flange 11 is provided with a positive pressure The pressure taking through hole 14 and the negative pressure taking through hole 15, the upper end of the positive pressure taking through hole 14 communicates with the positive pressure taking pipe 12, and the upper end of the negative pressure taking through hole 15 communicates with the negative pressure taking pipe 13;

[0031] The T-shaped mounting socket 2 includes a horizontal mounting base 21 for connecting with a pressur...

Embodiment 2

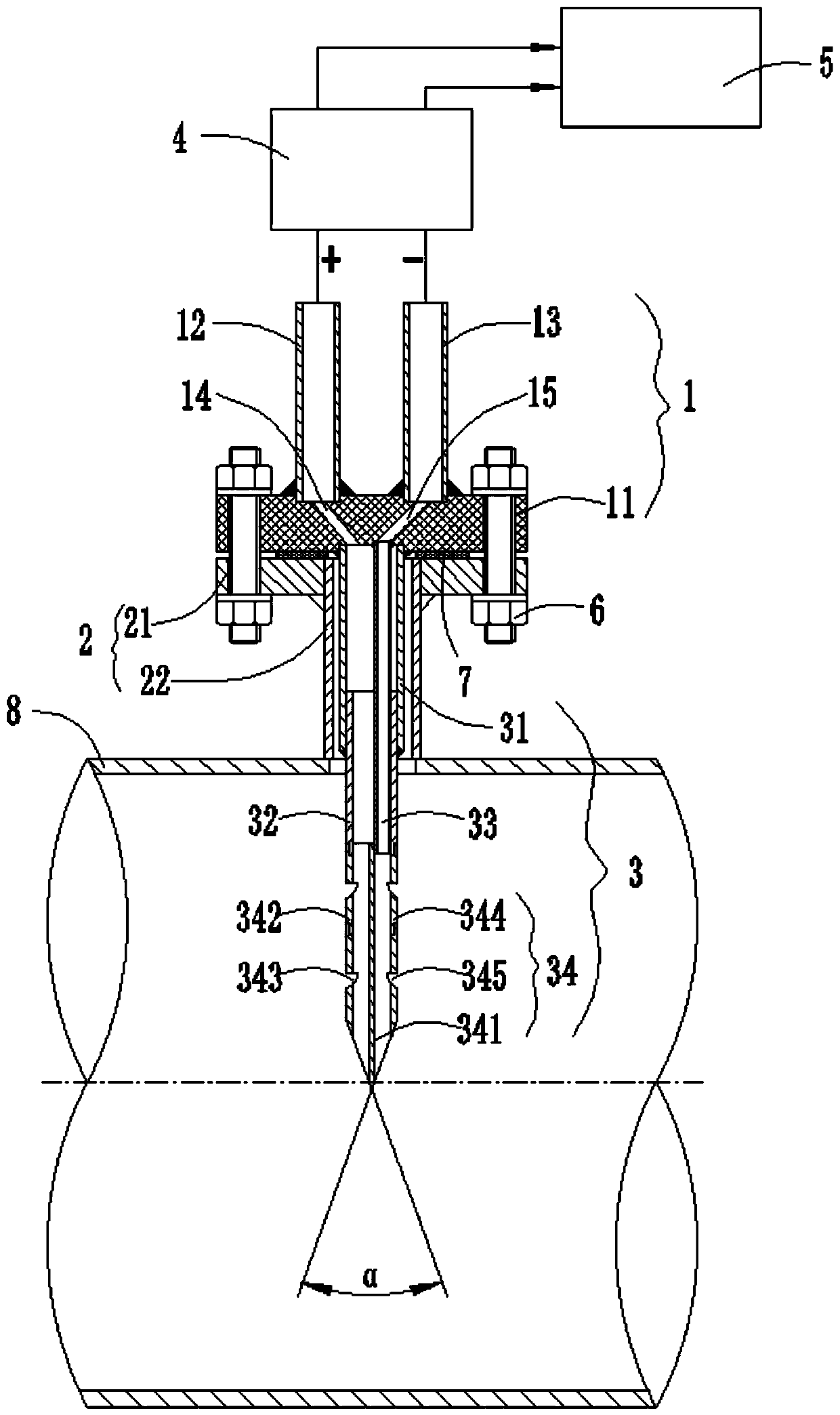

[0040] see Figure 3-5 , in an embodiment of the present invention, a plug-in semi-parabolic multi-point pressure-taking flow sensor includes a pressure-taking structure 1, a T-shaped installation socket 2 and a pressure detection element 3,

[0041]The pressure taking structure 1 includes a pressure taking flange 11, the upper side of the pressure taking flange 11 is vertically provided with a positive pressure taking pipe 12 and a negative pressure taking pipe 13, and the inside of the pressure taking flange 11 is provided with a positive pressure The pressure taking through hole 14 and the negative pressure taking through hole 15, the upper end of the positive pressure taking through hole 14 communicates with the positive pressure taking pipe 12, and the upper end of the negative pressure taking through hole 15 communicates with the negative pressure taking pipe 13;

[0042] The T-shaped mounting socket 2 includes a horizontal mounting base 21 for connecting with a pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com