Denitration and ammonia spraying pipeline flow monitoring device taking reducing agent as urea and application thereof

A technology of flow monitoring and reducing agent, which is applied in the direction of measuring device, volume/mass flow generated by mechanical effects, liquid/fluid solid measurement, etc. It can solve the problem of blockage of pressure pipes, difficult to reach above 200°C, and differential pressure flowmeters In order to avoid problems such as blockage of the pressure induction pipe, the effects of small throttling loss, wide range ratio, and blockage prevention are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

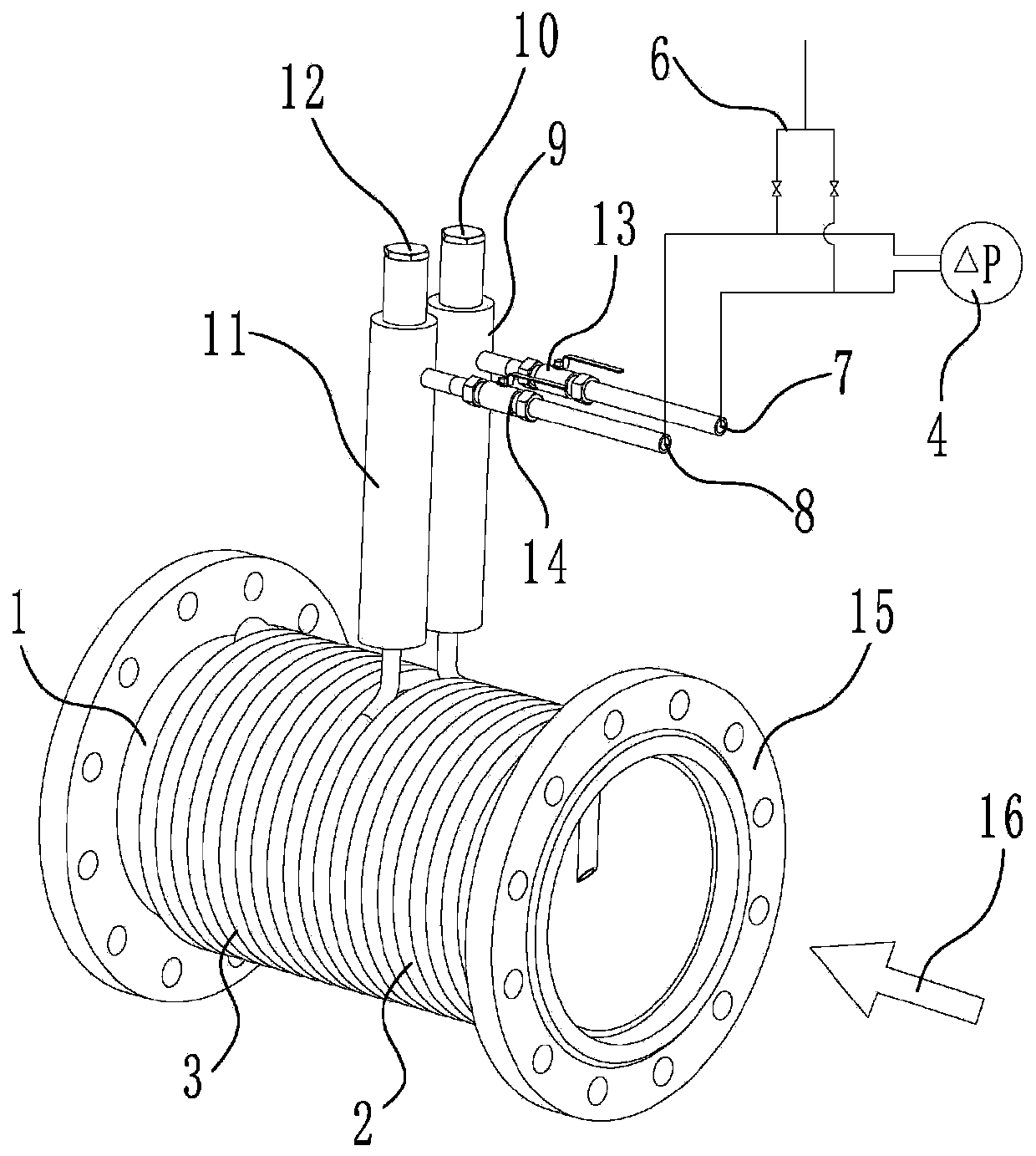

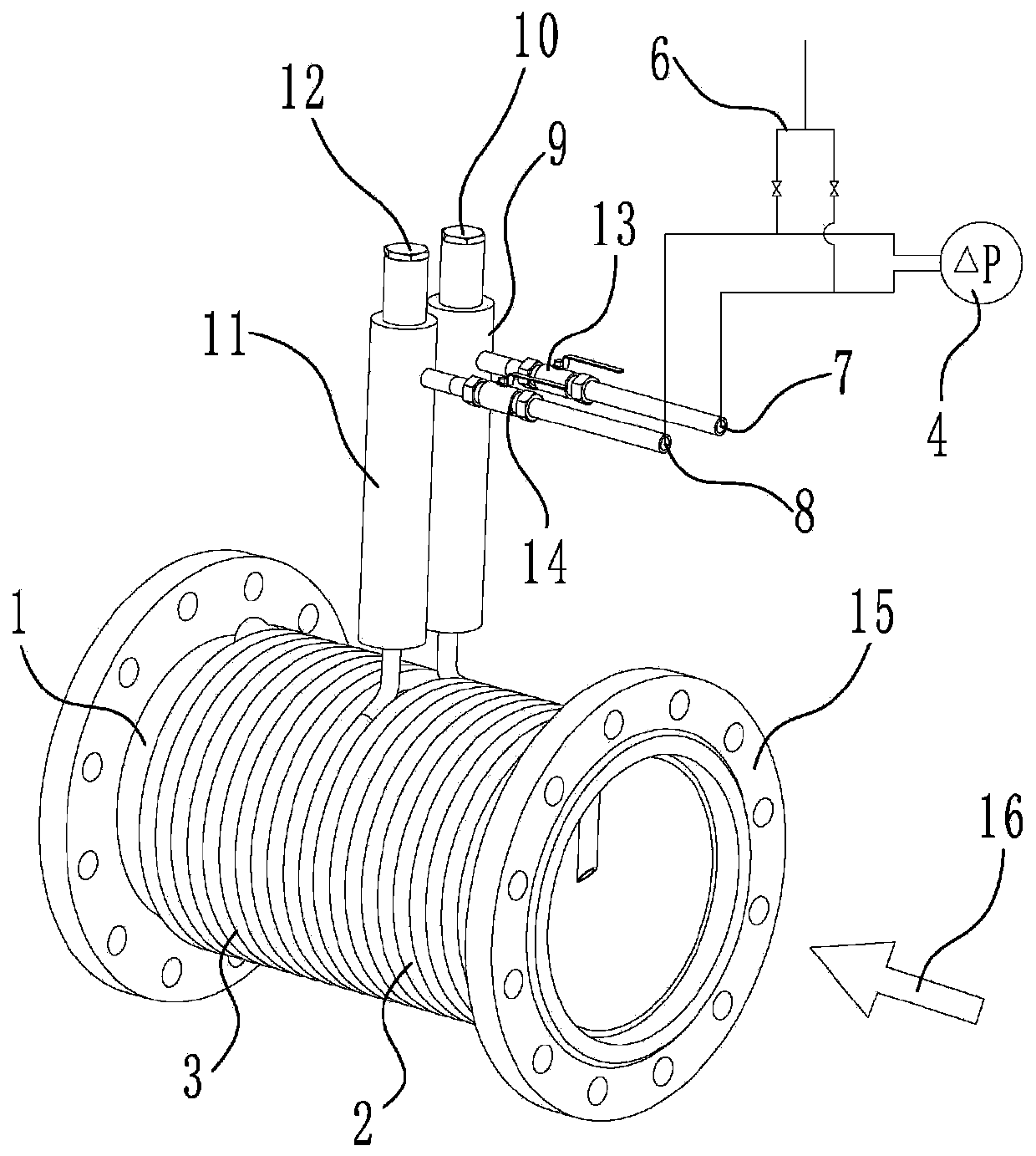

[0030] A denitration ammonia injection pipeline flow monitoring device with urea as the reducing agent, comprising a high-temperature measurement pipeline, an upstream pressure-inducing coil, an upstream connecting pipe, a downstream pressure-inducing coil, a downstream connecting pipe and a differential pressure gauge; the upstream pressure-inducing coil and the downstream The pressure-inducing coils are respectively coiled on the outer wall of the high-temperature measurement pipe, and the number of coils of the upstream pressure-inducing coils and the downstream pressure-inducing coils are both ≥2 turns (for example, 9 turns, 11 turns, or 15 turns, etc.); upstream One end of the pressure-inducing coil is connected to the upstream in the high-temperature measurement pipeline, and the other end is connected to the high-pressure interface of the differential pressure gauge through the upstream nozzle. The nozzle is connected to the low pressure interface of the differential pre...

Embodiment 2

[0034] On the basis of Embodiment 1, the following improvements are further made: in order to improve the sensitivity and accuracy of the measurement, and to improve the adaptability to the uneven flow field, the above-mentioned flow monitoring device also includes a throttle orifice plate, which is installed on the throttle orifice plate. In the high-temperature measurement pipeline, the upstream end of the upstream pressure-inducing coil and the high-temperature measurement pipeline is located upstream of the orifice plate, and the end of the downstream pressure-inducing coil that communicates with the downstream in the high-temperature measurement pipeline is located downstream of the orifice plate. That is, one end of the upstream pressure-inducing coil is connected to the space upstream of the orifice plate in the high-temperature measurement pipeline, the other end is connected to the high-pressure interface of the differential pressure gauge through the upstream nozzle, a...

Embodiment 3

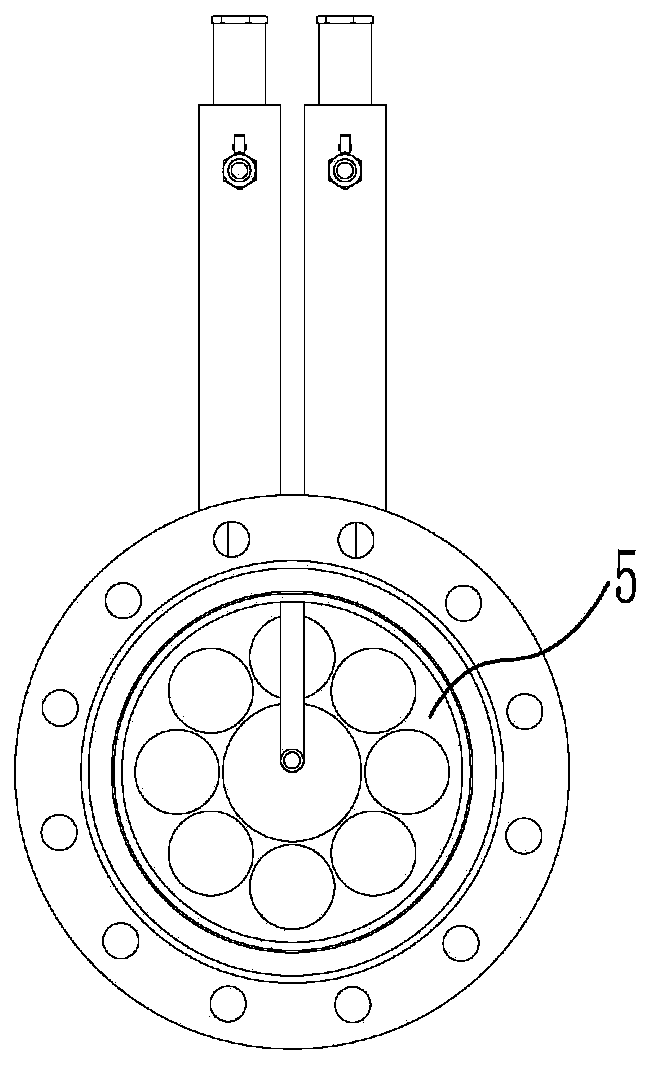

[0036] On the basis of Example 2, the following improvements are further made: In order to improve the adaptability of the flow monitoring device to the uneven flow field, the throttling orifice plate is selected as a porous throttling orifice plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com