Electronic gas meter for mass and flow

A mass flow and gas metering technology, applied in indirect mass flowmeters, mass flow measuring devices, volume metering, etc., can solve problems such as differences in measurement accuracy, failure to prevent, and damage to measurement components, and achieve improved safety, simple structure, and Facilitate manufacturing and assembly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

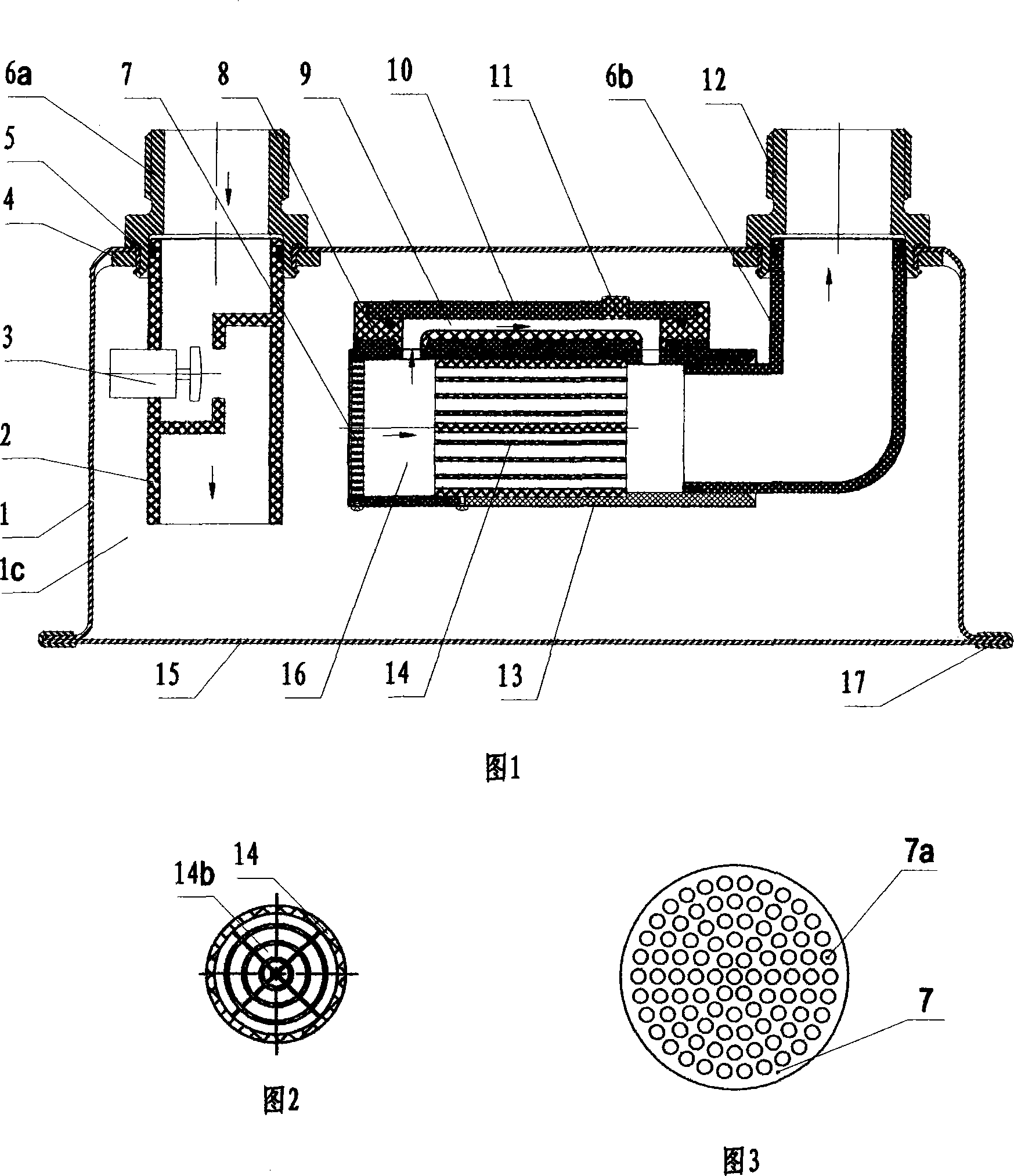

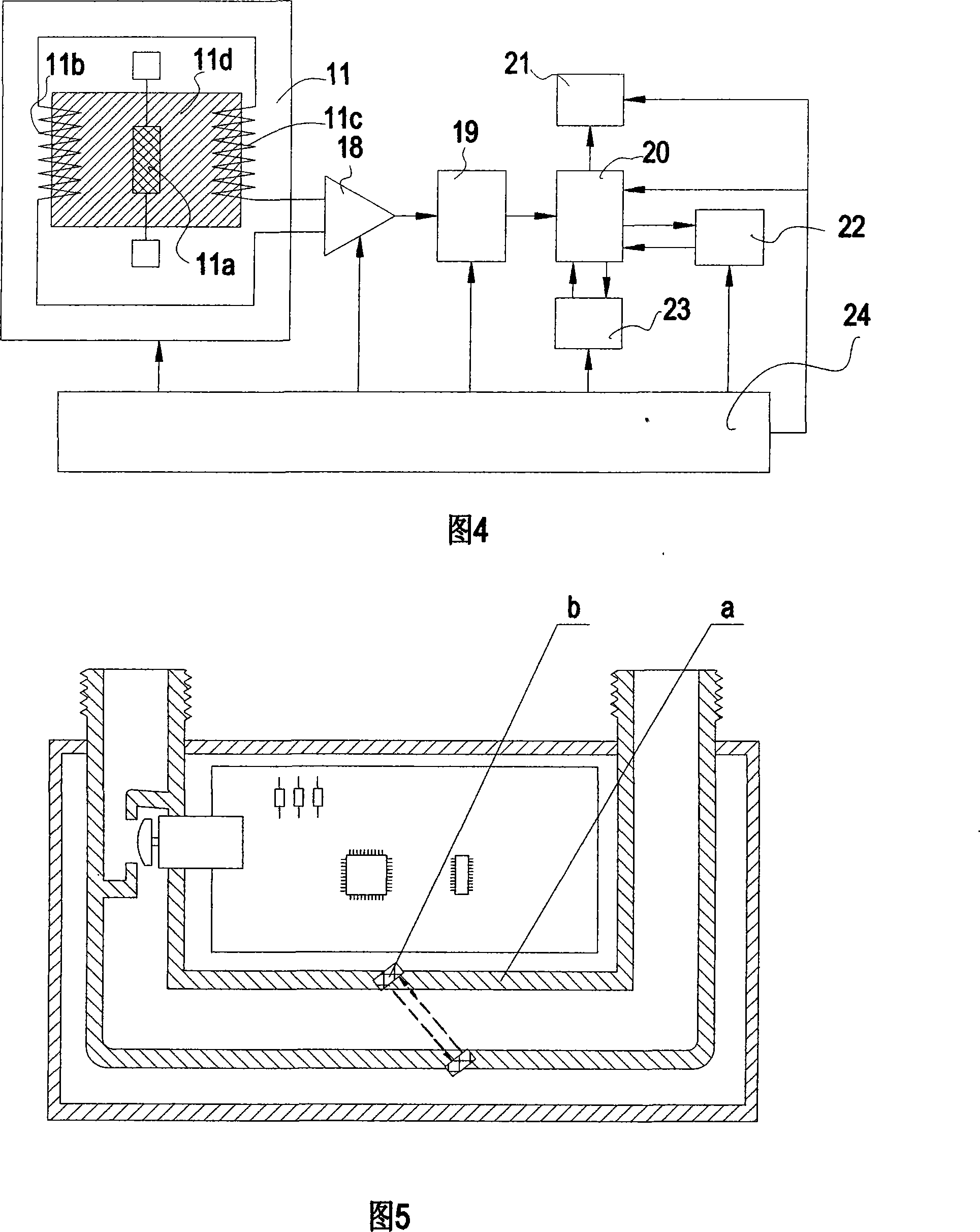

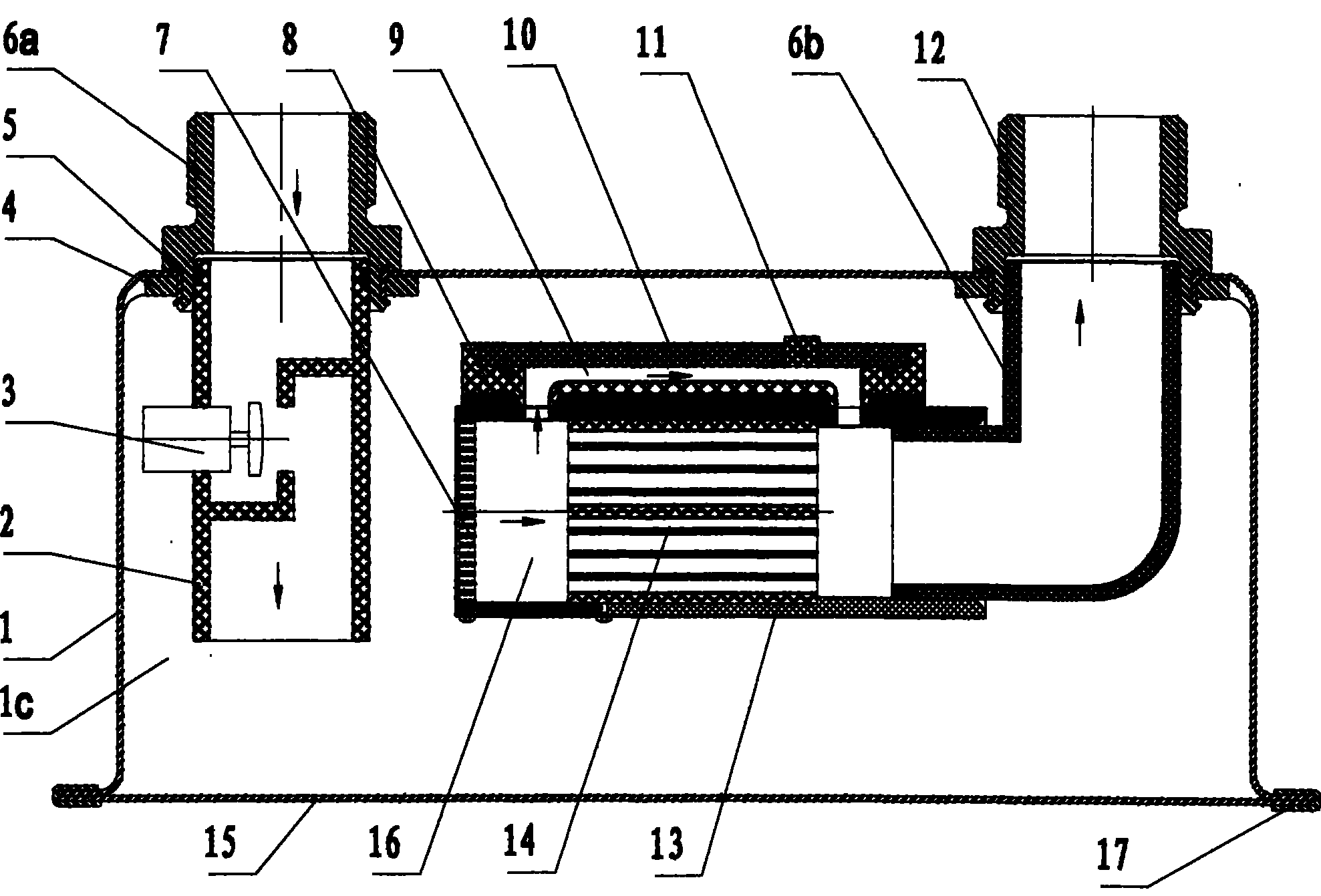

[0016] Referring to Figures 1 to 4, the housing 1 of the electronic mass flow gas meter is a housing with an airtight cavity 1c, and the inlet and outlet ports of the housing 1 are respectively fixedly connected with pipe joints 6a and 6b The pipe joints 6a and 6b of the air inlet and outlet ports are respectively riveted and fixed on the casing 1 through the gasket 4 matched with them, and a sealing ring 5 is provided between the pipe joint and the casing to seal the riveted joint. When riveting, the riveted ends of the pipe joints 6a and 6b pass through the hole on the shell 1 and put on the gasket 4, and the rubber seal ring 5 is set on the contact between the pipe joint and the shell. The pipe joint, the gasket, the seal ring and the shell Tightly connect and fix them together to form a sealed connection. The bottom of the shell is covered by the bottom plate 15. The flange of the bottom plate 15 and the shell 1 is pressed together by the sealing ring 17 to form a seal. Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com