Pipeline leak and pipe burst detection method of ultrasonic water meter

A detection method and ultrasonic technology, which are used in measurement devices, water saving, fluid tightness testing, etc., can solve the problems of ultrasonic water meter pipeline leakage, inability to reasonably detect pipeline leakage and pipe bursting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

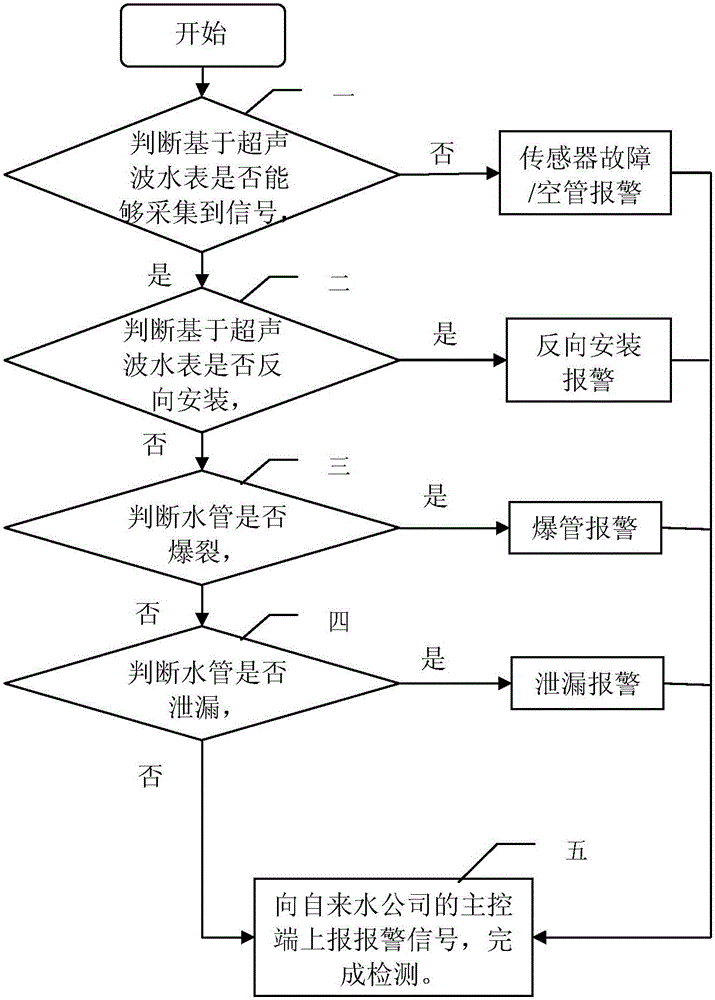

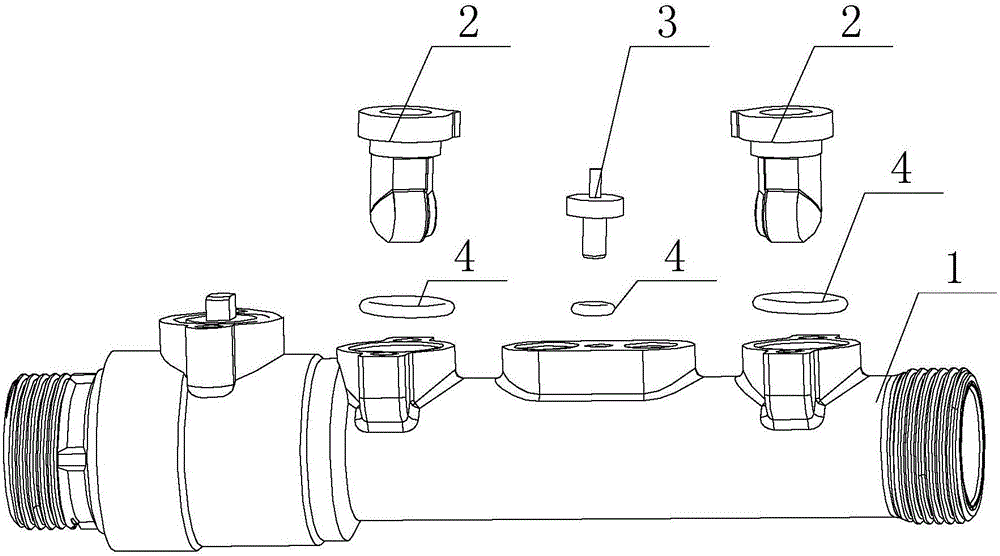

[0026] Specific implementation mode one: refer to figure 1 and figure 2 Specifically explain this embodiment, the ultrasonic water meter pipeline leakage and pipe burst detection method described in this embodiment, the method is realized by an ultrasonic water meter, and the ultrasonic water meter includes: an ultrasonic base meter 1 and an ultrasonic transducer 2;

[0027] There are two openings on the side wall of the ultrasonic base meter 1, and the two ultrasonic facing ends of the ultrasonic transducer 2 respectively pass through the two openings and are located inside the ultrasonic base meter 1, and the openings are sealed, and the ultrasonic transducer 2 The two ultrasonic opposing ends face each other,

[0028] The ultrasonic water meter pipeline leakage and pipe burst detection method comprises the following steps:

[0029] Step 1: Determine whether the ultrasonic water meter can collect signals, if so, perform step 2, otherwise, perform sensor failure / empty pipe...

specific Embodiment approach 2

[0036] Specific embodiment two: this embodiment is to further explain the ultrasonic water meter pipeline leakage and pipe burst detection method described in specific embodiment one. In this embodiment, the following steps are performed after step five:

[0037] Step 6: Determine whether there is user operation, if yes, accumulate the metering data obtained by the water meter, otherwise perform step 7;

[0038] Step 7: Record the time for the ultrasonic water meter to collect water flow, and make a difference between the time and the normal working time of the water meter. If the difference is greater than 2 hours, return to step 5, otherwise return to step 6.

[0039] In this embodiment, the ultrasonic water meter communicates wirelessly with the main control terminal of the water company. In order to save the internal power of the water meter, when the water meter is working normally, a continuous working time of 2 hours is set for the water meter to go online. Once there i...

specific Embodiment approach 3

[0040] Specific embodiment three: This embodiment is to further explain the ultrasonic water meter pipeline leakage and pipe burst detection method described in specific embodiment one or two. In this embodiment, the specific method for judging whether the ultrasonic water meter is installed in reverse in step two yes:

[0041] Make a difference between the reverse flow time and the downstream time collected by the ultrasonic transducer 2. If the difference is positive, the ultrasonic water meter is installed in the forward direction. If the difference is negative and the absolute value of the difference is greater than 3 seconds, the ultrasonic water meter is For reverse installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com