Stainless-steel ultrasonic water meter

An ultrasonic and stainless steel technology, applied in the field of stainless steel ultrasonic water meters, to achieve the effect of beautiful appearance, accurate measurement and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

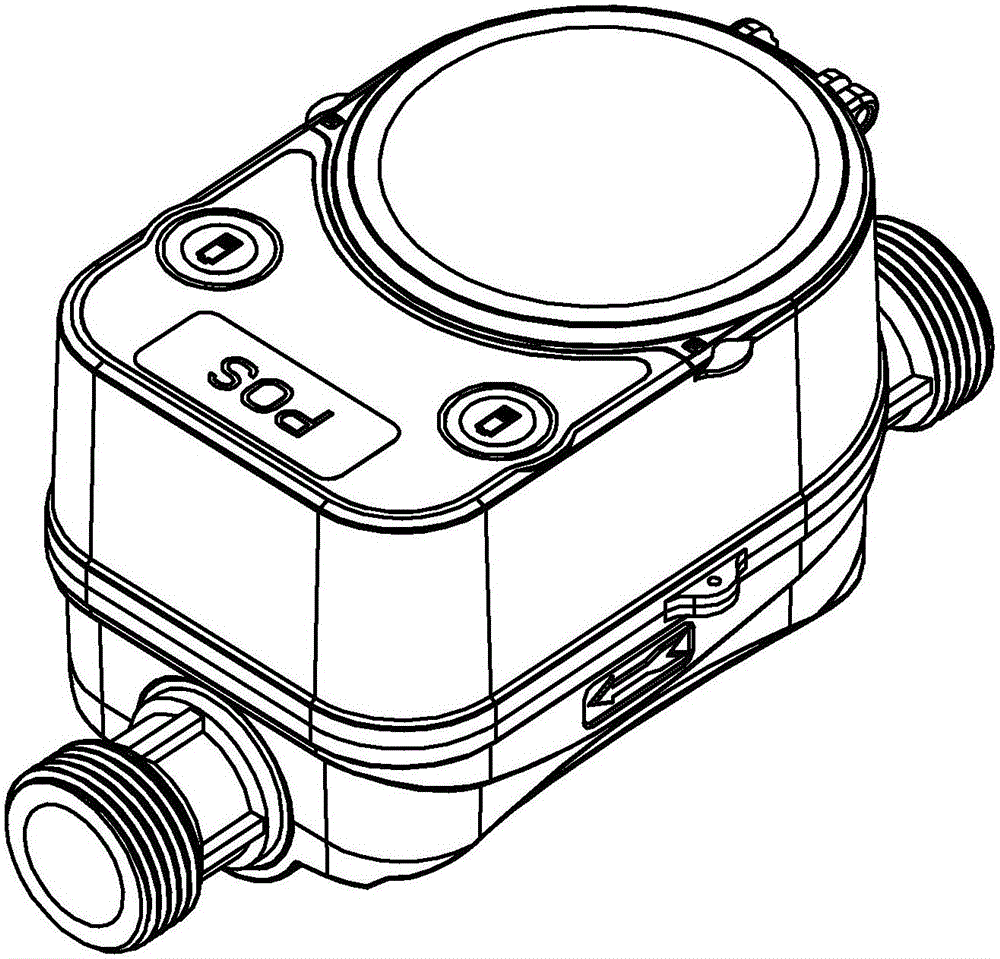

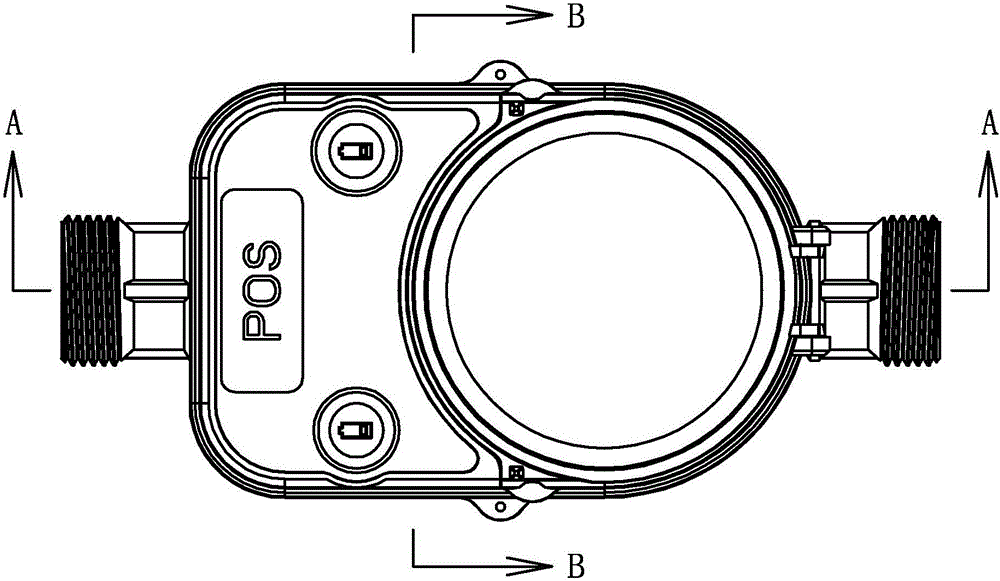

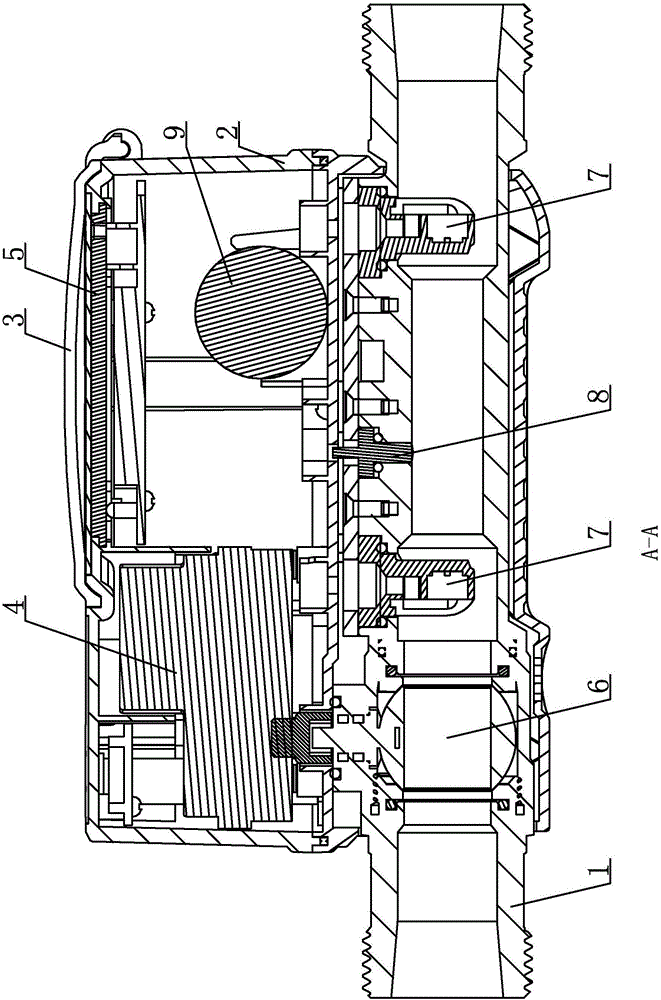

[0018] Specific implementation mode one: refer to Figure 1 to Figure 6 Specifically explain this embodiment, the stainless steel ultrasonic water meter described in this embodiment, it includes: stainless steel ultrasonic base meter 1, stainless steel shell 2, wireless transmission circuit one, wireless transmission circuit two, motor 4, main circuit 5, ultrasonic transducer 7. Temperature sensor 8, battery one 9 and battery two 10;

[0019] There are three openings on the side wall of the stainless steel ultrasonic base meter 1, and the two ultrasonic facing ends of the ultrasonic transducer 7 and the temperature measuring end of the temperature sensor 8 respectively pass through the three openings and are located inside the stainless steel ultrasonic base meter 1, and the The opening where it is located is sealed, and the two ultrasonic opposing ends of the ultrasonic transducer 7 face each other, and the temperature measuring end of the temperature sensor 8 is used to coll...

specific Embodiment approach 2

[0028] Specific implementation mode two: refer to Figure 5 Describe this embodiment in detail. This embodiment is to further describe the stainless steel ultrasonic water meter described in Embodiment 1. In this embodiment, the two ultrasonic waves of the ultrasonic transducer 7 and the temperature measuring end of the temperature sensor 8 The openings are sealed by sealing rings 11 respectively.

[0029] The sealing ring 11 is to prevent water from leaking from the stainless steel ultrasonic base meter 1 and is installed in the gap between the ball valve 6, the ultrasonic transducer 7 and the temperature sensor 8 and the stainless steel ultrasonic base meter 1, as attached Figure 5 shown.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment is to further explain the stainless steel ultrasonic water meter described in Embodiment 1. In this embodiment, battery one 9 is an ER26500H lithium battery, and battery two 10 is an ER18505M lithium battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com