Gas-liquid measurement method with super-small flow

A measurement method and small flow technology, applied in the direction of volume measurement, measurement capacity, liquid/fluid solid measurement, etc., can solve the problems affecting measurement work, measurement difficulty, blockage, etc. The effect of turndown ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

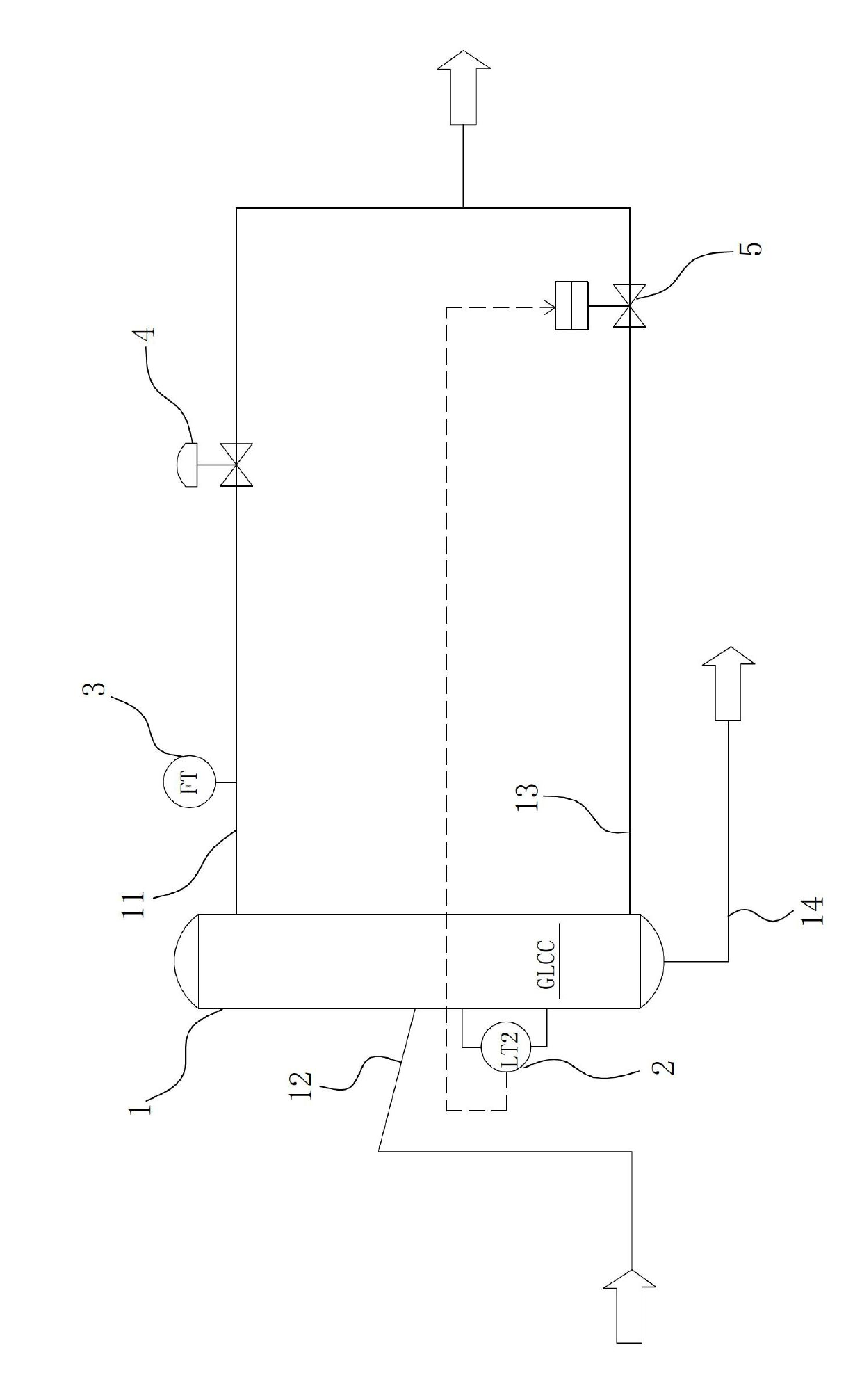

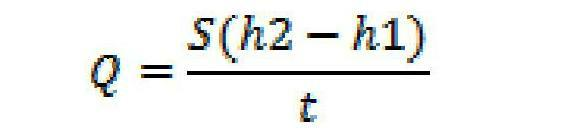

[0033] Such as figure 1 Shown is the gas-liquid metering system used in the ultra-small flow gas-liquid metering method of the present invention, which includes a gas-liquid separator 1, wherein the upper, middle, and lower side walls of the gas-liquid separator 1 are respectively provided with The gas-liquid separator 1 internally communicated with the gas outlet pipe 11, the raw liquid input pipe 12, and the liquid outlet pipe 13. The gas-liquid separator 1 is also provided with a liquid level transmitter 2 whose gas-liquid flow direction is as follows figure 1 As shown by the arrow in;

[0034] The steps of the ultra-small flow gas-liquid metering method of the present invention are as follows:

[0035] (1) The mixture to be metered enters the metering system from the raw liquid input pipe 12, and the mixture to be metered is separated into gas and liquid through the gas-liquid separator 1;

[0036] (2) The separated gas phase is measured by the gas phase flow meter 3 connected ...

Embodiment 2

[0049] The difference between the second embodiment and the first embodiment lies in the steps of liquid phase metering. The specific steps are as follows:

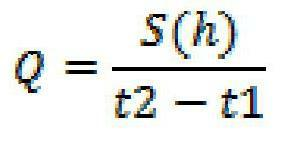

[0050] (i) Set a specific height and determine the time when the liquid injection in the gas-liquid separator 1 reaches the set height. Specifically, the liquid injection height inside the gas-liquid separator 1 is controlled by the liquid level switch valve 5. The liquid level switch Valve 5 is an on-off valve that opens and closes intermittently. When it is closed, record the time t1 at this time. When the liquid injection in the gas-liquid separator 1 reaches the set height, record the time t2 at this time, and the measurement ends. , The flow calculation formula is:

[0051] Q = s ( h ) t 2 - t 1

[0052] Q: Volume flow;

[0053] S: the cross-sectional area of the inner surface of the separator;

[0054] h: The specific height set.

[0055] (ii) The liquid phase switch valve 5 is opened to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com