System and method for controlling uniformity of gas injection amount of natural gas engines for vehicles

A control system and injection system technology, applied in engine components, machines/engines, fuel injection devices, etc., can solve problems such as poor flow consistency, sensitivity to variable apertures, and no related work on small flow, to maintain stable torque output, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

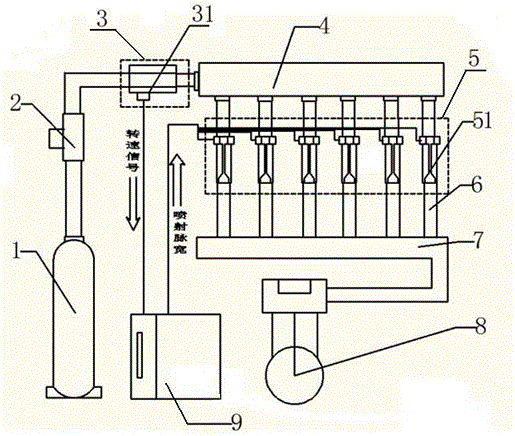

[0044] like figure 1 As shown, each injection system includes an air rail 4 , a metering unit 3 and an injection unit 5 connected to an ECU 9 .

[0045] The air inlet of the gas rail 4 is connected with the natural gas supply bottle 1 through the high-pressure solenoid valve 2 with a pressure reducer. The high-pressure electromagnetic valve 2 is also preferably fixed on the vehicle frame, and the gas rail 4 is preferably fixed on the engine 8 .

[0046] The metering unit 3 is arranged between the air inlet of the gas rail 4 and the high-pressure solenoid valve 2. The metering unit 3 includes a millisecond-level rotameter 31 connected to the ECU 9. The millisecond-level rotameter 31 can measure millisecond-level natural gas Transient flow is metered.

[0047] The injection unit 5 is connected with the air outlet of the gas rail 4, and the injection unit 5 includes several nozzles 51, such as figure 1As shown, the injection unit 5 preferably includes 6 nozzles 51, the inlets ...

Embodiment 2

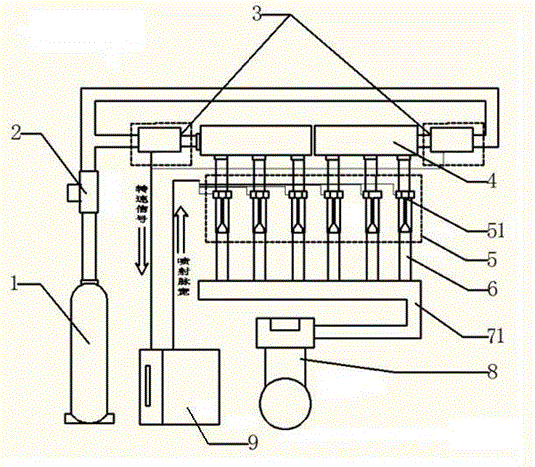

[0053] like figure 2 As shown, each injection system includes two air rails 4 , two metering units 3 and one injection unit 5 connected to the ECU 9 .

[0054] The air inlets of the two gas rails 4 are all connected with the natural gas supply cylinder 1 through the high-pressure solenoid valve 2 with a pressure reducer. The high-pressure solenoid valve 2 is also preferably fixed on the vehicle frame, and the two gas rails 4 are preferably fixed on the engine 8, and the two gas rails 4 are preferably arranged in parallel.

[0055] A metering unit 3 is respectively arranged between the air inlet of each air rail 4 and the corresponding high-pressure solenoid valve 2, and each metering unit 3 includes a millisecond-level rotameter 31 connected to the ECU 9, the millisecond-level The rotameter 31 can measure the transient flow of natural gas at millisecond level.

[0056] The injection unit 5 is connected with the air outlets of the two air rails 4, and the injection unit 5 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com