Large-diameter standard throttle device-type heat meter and calibration method thereof

A throttling device and large-diameter technology, which are applied in the field of large-diameter heat metering devices and their verification, and can solve the problems of difficult real-flow detection and difficult detection conditions for large-diameter heat meters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

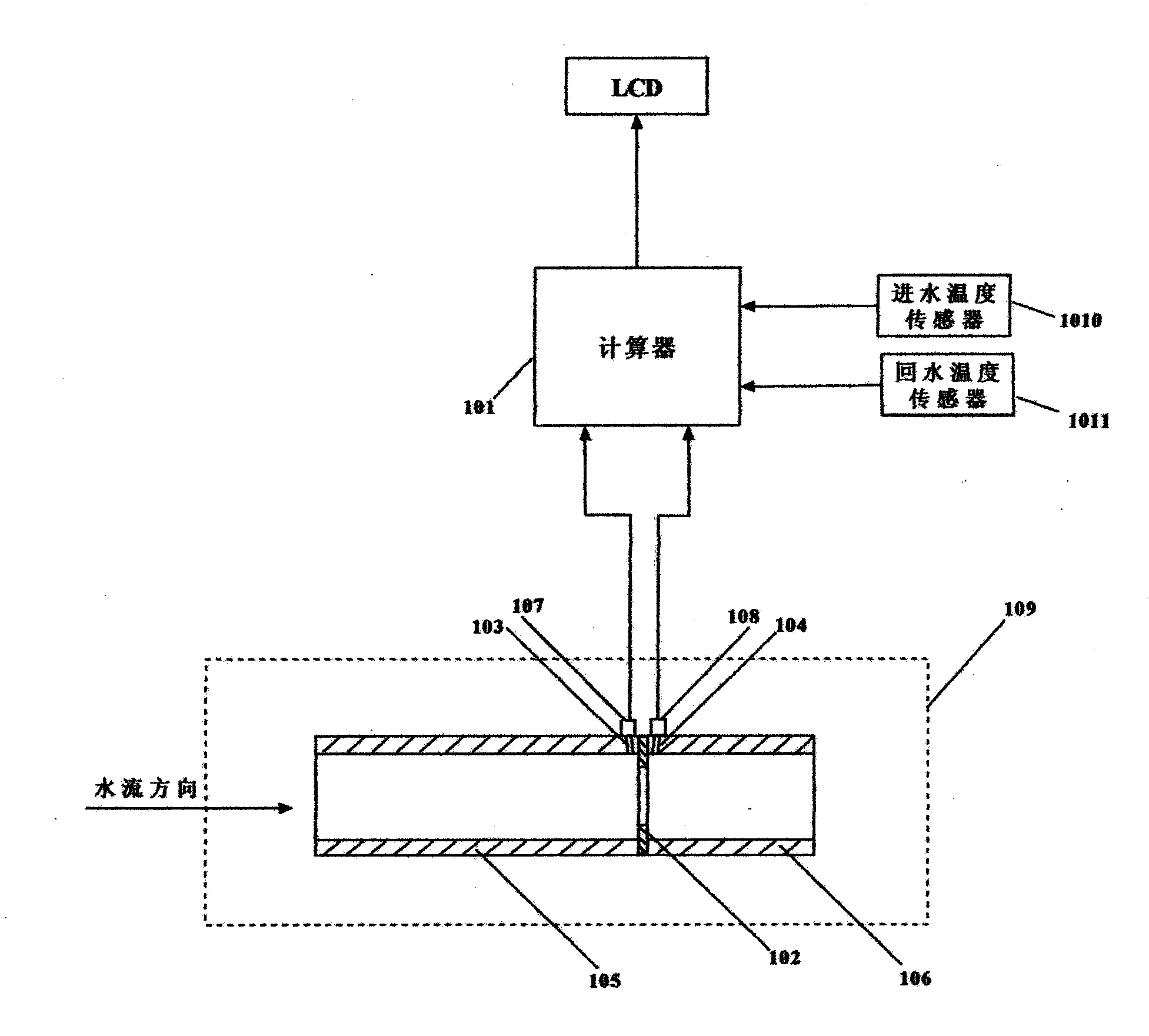

[0135] see figure 1 , figure 1 It is a structural schematic diagram of a large-diameter standard throttling device type heat meter of the present invention.

[0136] This embodiment is a large-diameter standard throttling device type heat meter, and the single-chip computer in its calculator 101 selects the MSP430 chip of low power consumption of U.S. TI Company; Inlet water temperature sensor 1010 and return water temperature sensor 1011 adopt platinum thermal resistance PT1000; the large-diameter flow sensor 109 is a large-caliber standard orifice plate throttling device flow sensor; the upstream pressure sensor 107 and the downstream pressure sensor 108 are microcomputer pressure sensors with an accuracy level of 0.2 and a range of 0 to 700kPa.

[0137] The standard orifice throttling device of the present invention is designed, manufactured, installed and used according to the provisions of the national standard GB / T2624-2006 of the People's Republic of China.

[0138] 1...

Embodiment 2

[0211] The specific embodiment of the verification method of the large-diameter standard throttling device type heat meter.

[0212] In this embodiment, the standard orifice throttling device type heat meter with a diameter of DN200mm in embodiment 1 is verified, and the component verification method is adopted.

[0213] 1. Verification of flow sensor

[0214] I. Inspection of standard orifice throttling device

[0215] The inspection of the standard orifice throttling device includes: the inspection of the standard orifice throttling parts, the standard pressure taking device and the upstream and downstream pipelines.

[0216] The standard orifice throttling device is inspected by the geometric inspection method.

[0217] (1) Technical requirements

[0218] It meets the technical requirements of items 6.1.1 to 6.1.6 of the national metrology verification regulations JJG640 and item 5.1 of the national standard GB / T2524.2.

[0219] (2) Test conditions

[0220] 1. Indoor e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com