Fixing method of stator core fixing structure of water-cooled motor

A stator core and fixed structure technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problem of increased manufacturing cost, uneven deformation, uneven air gap, etc. problems, to achieve uniform air gap, stable motor torque output, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

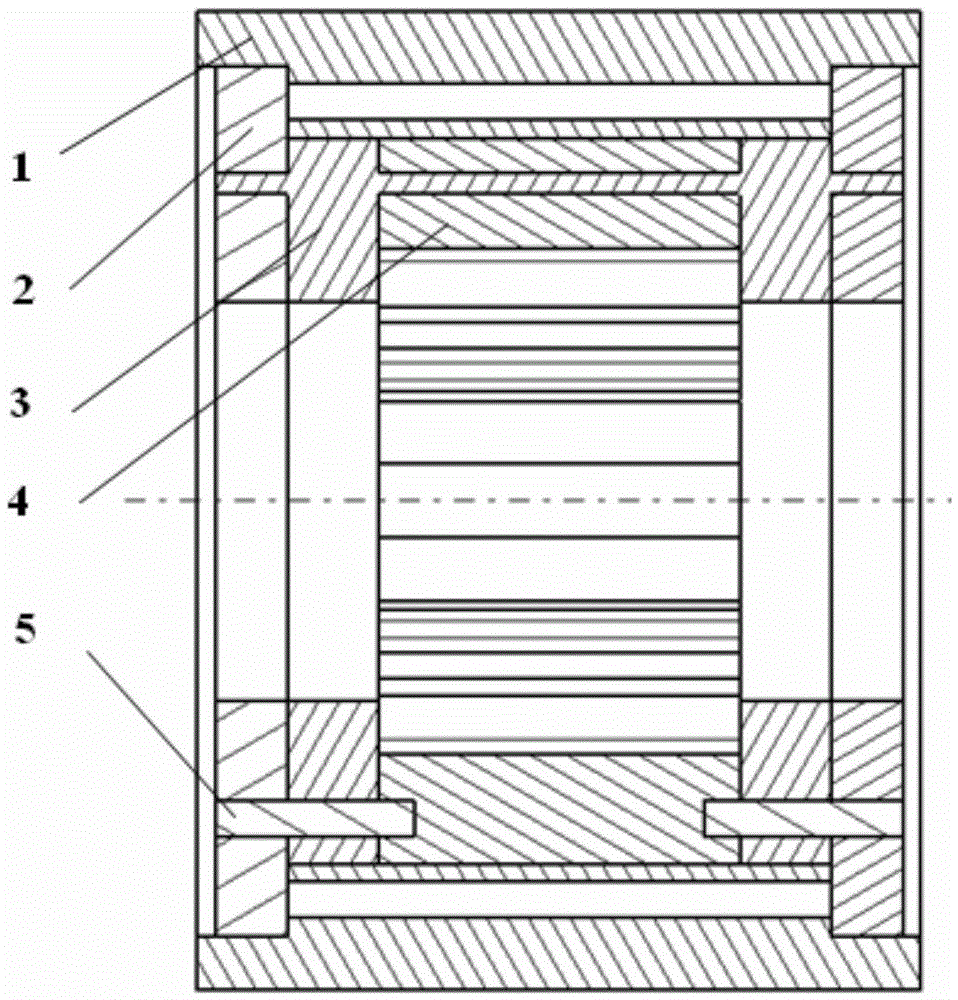

[0021] Such as figure 1 As shown, a stator core fixing structure of a water-cooled motor includes a housing 1, an annular waterway pressure plate 2 and a stator core 4. The inner wall of the housing 1 is respectively provided with annular waterways near the openings on both sides, and the stator core 4 Press-fitted in the housing 1, the water channel pressure plate 2 is press-fitted on the water channel of the housing 1 and rigidly connected with the housing 1, the stator core 4 is located between the water channel pressure plates 2 and rigidly connected with the water channel pressure plate 2, the housing 1 1. Colloid 3 is filled between the waterway pressure plate 2 and the stator core 4 . The liquid colloid 3 becomes hard solid colloid 3 after being cooled by heat preservation. The solid colloid 3 forms a colloid pin after passing through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com