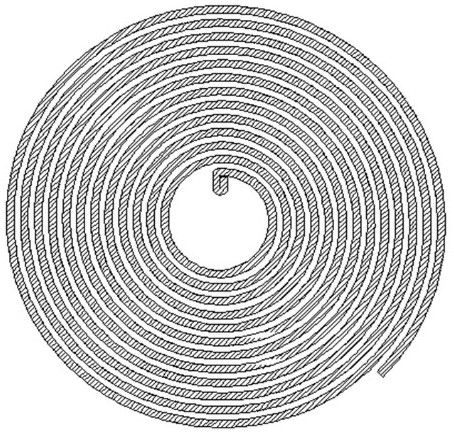

A kind of preparation method of planar scroll spring

A flat scroll spring and coil spring technology, which can be used in the direction of manufacturing springs, manufacturing tools, heat treatment equipment from wires, etc., can solve the problems of complex coil structure, deformation and damage, and difficult preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

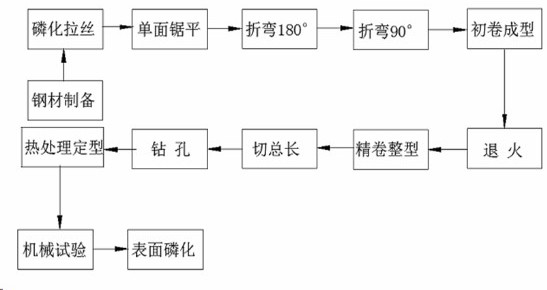

[0040] A kind of preparation method of planar scroll spring comprises the steps:

[0041] Step1: 60Si2CrVA steel material preparation, 60Si2CrVA steel material preparation includes: batching, electric furnace steelmaking, electroslag remelting, billet opening, peeling flaw detection, hot rolling, pickling, finishing forming, annealing, polishing 10 steps;

[0042] Then rolled into a thickness of 7mm, a width of 30mm steel strip A;

[0043] Step2: Phosphate and draw the steel strip A. There are no cracks, folds, pits, scratches, or burrs on the surface of the steel strip A. After the wire drawing, the raw material should be vertical and uniform without obvious concave-convex waves, and the steel strip B is made;

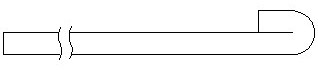

[0044] Step3: Saw the end face of the single end of the steel strip B flat with a sawing machine, chamfer around the end face, no pits or burrs are allowed on the surface, and make steel strip C;

[0045] Step4: Bend the flat end of the steel strip C to 180°, fix the...

Embodiment 2

[0057] A kind of preparation method of planar scroll spring comprises the steps:

[0058] Step1: 60Si2CrVA steel material preparation, 60Si2CrVA steel material preparation includes: batching, electric furnace steelmaking, electroslag remelting, billet opening, peeling flaw detection, hot rolling, pickling, finishing forming, annealing, polishing 10 steps;

[0059] Then rolled into a thickness of 7mm, a width of 30mm steel strip A;

[0060] Step2: Phosphate and draw the steel strip A. There are no cracks, folds, pits, scratches, or burrs on the surface of the steel strip A. After the wire drawing, the raw material should be vertical and uniform without obvious concave-convex waves, and the steel strip B is made;

[0061] Step3: Saw the end face of the single end of the steel strip B flat with a sawing machine, chamfer around the end face, no pits or burrs are allowed on the surface, and make steel strip C;

[0062] Step4: Bend the flat end of the steel strip C to 180°, fix the...

Embodiment 3

[0074] A kind of preparation method of planar scroll spring comprises the steps:

[0075] Step1: 60Si2CrVA steel material preparation, 60Si2CrVA steel material preparation includes: batching, electric furnace steelmaking, electroslag remelting, billet opening, peeling flaw detection, hot rolling, pickling, finishing forming, annealing, polishing 10 steps;

[0076] Then rolled into a thickness of 7mm, a width of 30mm steel strip A;

[0077] Step2: Phosphate and draw the steel strip A. There are no cracks, folds, pits, scratches, or burrs on the surface of the steel strip A. After the wire drawing, the raw material should be vertical and uniform without obvious concave-convex waves, and the steel strip B is made;

[0078] Step3: Saw the end face of the single end of the steel strip B flat with a sawing machine, chamfer around the end face, no pits or burrs are allowed on the surface, and make steel strip C;

[0079] Step4: Bend the flat end of the steel strip C to 180°, fix the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com