Natural gas engine cylinder self-checking control system and natural gas engine cylinder self-checking control method

A technology of engine cylinder and control system, which is applied in engine control, electrical control, machine/engine, etc., and can solve problems such as unstable engine operation and unbalanced cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

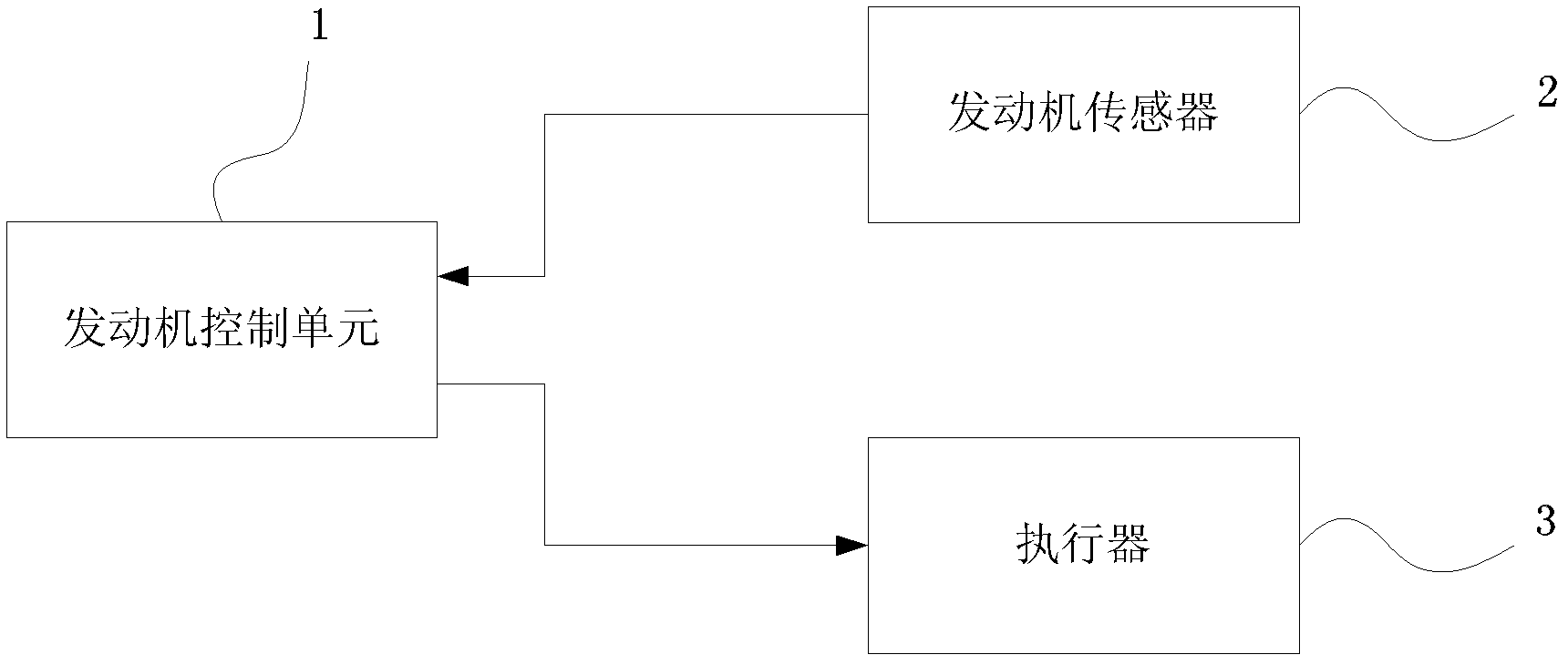

[0021] This embodiment provides a natural gas engine cylinder self-verification control system, such as figure 1 As shown, the self-checking control system includes an engine control unit (ECU) 1, an engine sensor 2 and an actuator 3; the engine sensor and the actuator are all connected to the engine control unit in communication; wherein the engine control unit 1 is used for The logic algorithm control of the entire self-checking control system includes the processing of input signals and output control; the engine sensor 2 is used to measure the engine speed signal; the actuator 3 is used to control the output drive injection pulse width signal.

[0022] The engine sensor 2 is a speed sensor. The engine speed sensor 2 includes commonly used magnetoelectric and Hall sensors. The actuator 3 includes a natural gas engine nozzle commonly used in various engines.

Embodiment 2

[0024] This embodiment provides a natural gas engine cylinder self-verification control method, the method comprising the following steps:

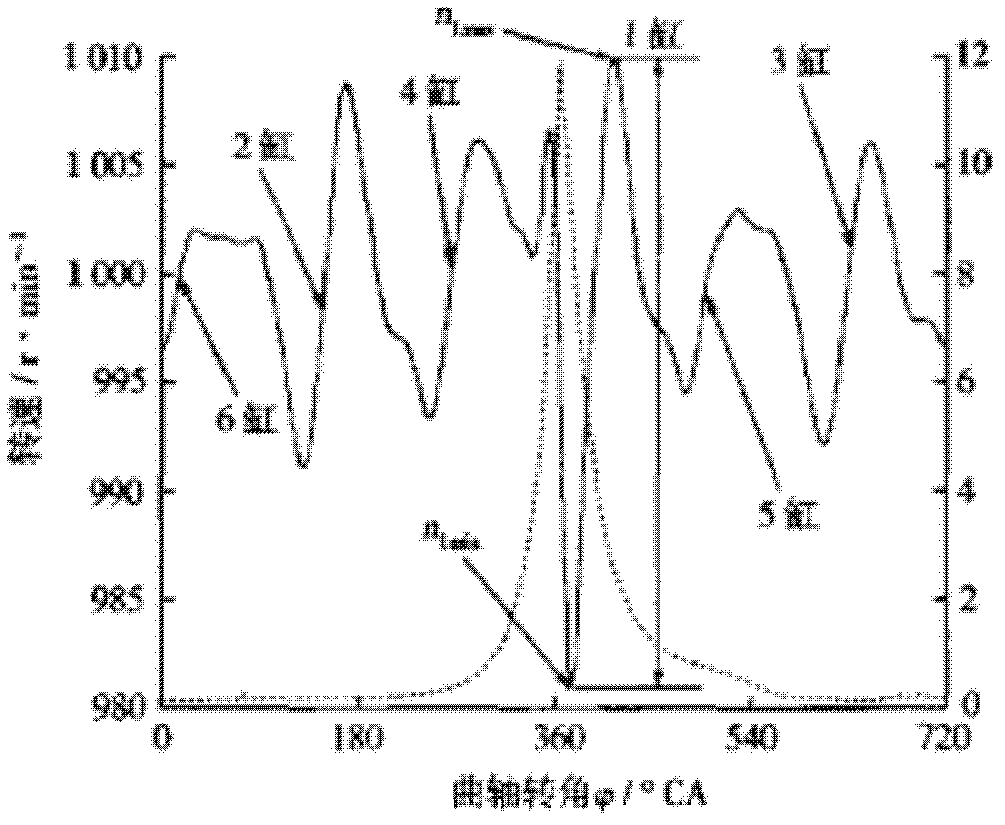

[0025] S10, the engine sensor measures the engine speed signal, and outputs the detected speed signal; the detailed process is: the engine sensor detects the fluctuation of the speed of each cylinder (that is, at each corresponding crankshaft angle), and then transmits the detected speed signal to the engine control unit.

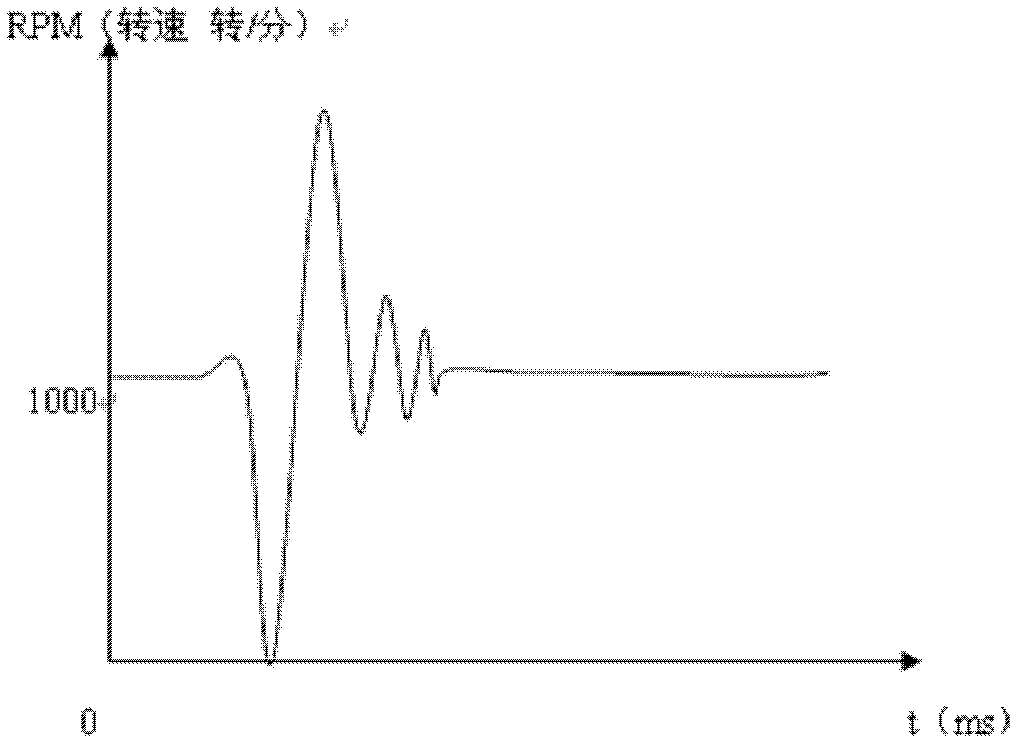

[0026] S11, the engine control unit calculates the angular acceleration after the rotation speed signal is averaged through a cycle, and further confirms the operation status of each cylinder according to the angular acceleration;

[0027] S12, judging whether the angular acceleration deviates from a preset index value;

[0028] S13, when the angular acceleration deviates from the preset index value, start the software adaptive program, adjust the driving injection pulse width of the natural gas nozzle of each cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com