Cable machine steel strand bending device

A technology for steel strands and cable machines, which is used in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of easy damage to the surface of the cable, uneven curvature of the bending circle, unstable torque output, etc., which is not easy to achieve. Damaged, simple structure, stable torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

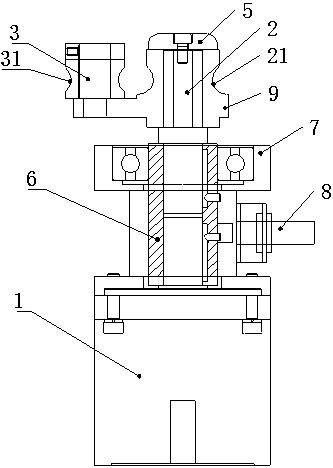

[0021] This embodiment provides a cable machine steel strand rounder, as attached figure 1 As shown, a motor 1 and a circle bending mechanism connected to the motor 1 are included, and a mounting plate 7 is arranged between the motor 1 and the circle bending mechanism.

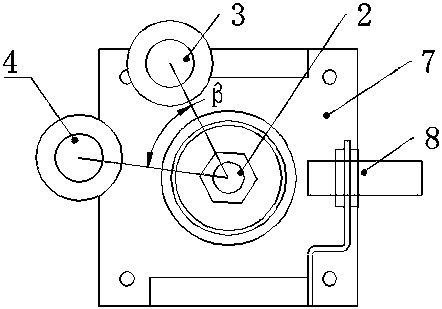

[0022] The bending mechanism includes a connecting shaft 2, a rotating shaft 3 and a fixed shaft 4. The motor 1 is connected to the connecting shaft 2 and drives the connecting shaft 2 to rotate synchronously. The connecting shaft 2 is provided with a gland 5; the axial surface of the connecting shaft 2 is provided with a groove 21 , the bottom of the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com