Micro-step drive control method of permanent magnet synchronous motor

A permanent magnet synchronous motor, micro-step technology, applied in motor generator control, electronic commutation motor control, control system and other directions, can solve problems such as control instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

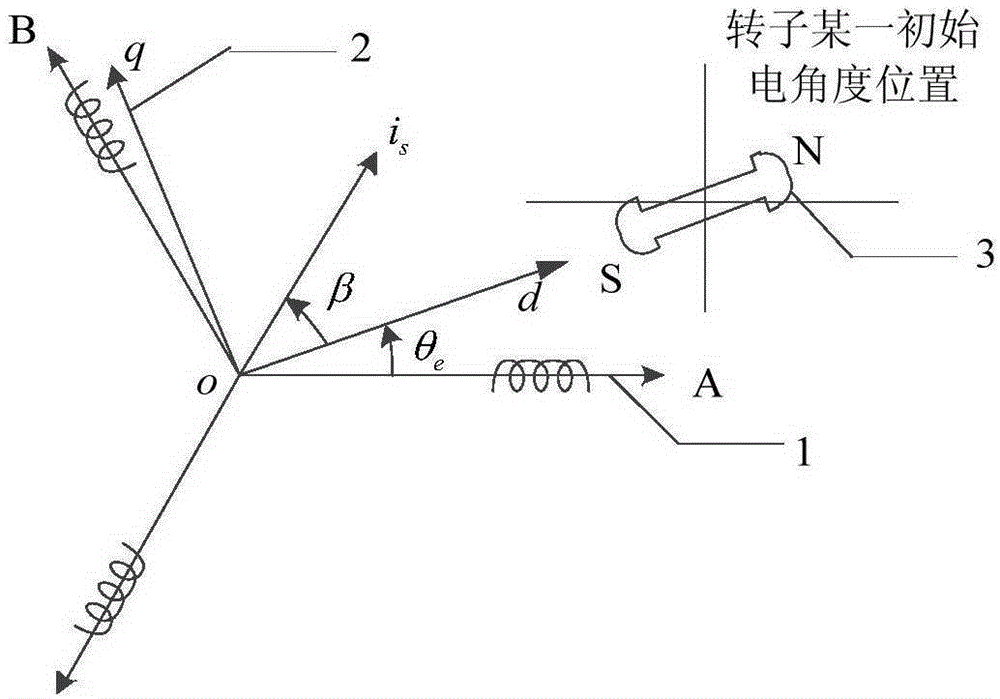

[0036] A permanent magnet synchronous motor micro-step drive control method, based on the permanent magnet synchronous motor field-oriented vector control, the goal is to control the permanent magnet synchronous motor rotor to rotate at a constant speed with the given position of the stator current vector. The realization principle is based on The principle of permanent magnet synchronous motor rotor field orientation, when a current vector is given at a fixed position, the positive direction of the permanent magnet of the permanent magnet synchronous motor rotor (direction of the N pole) is fixed at the given position.

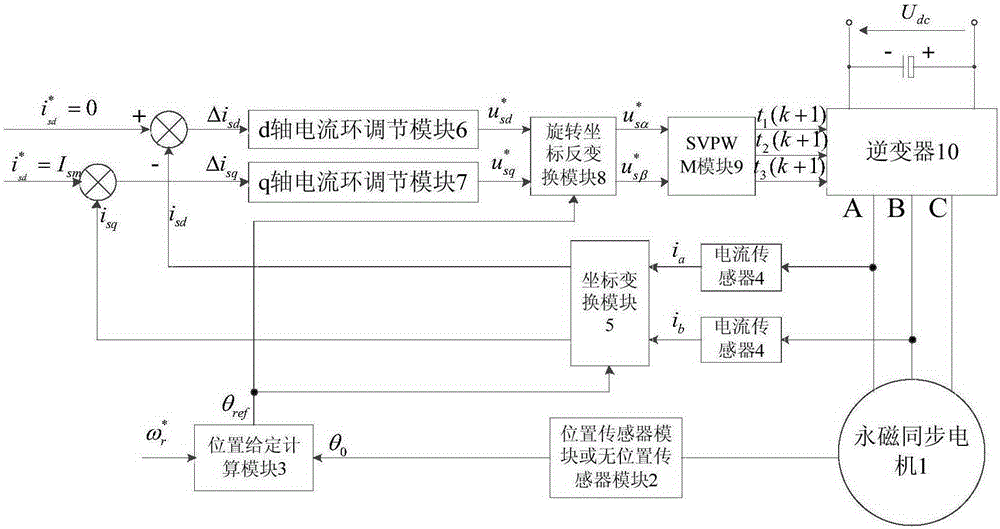

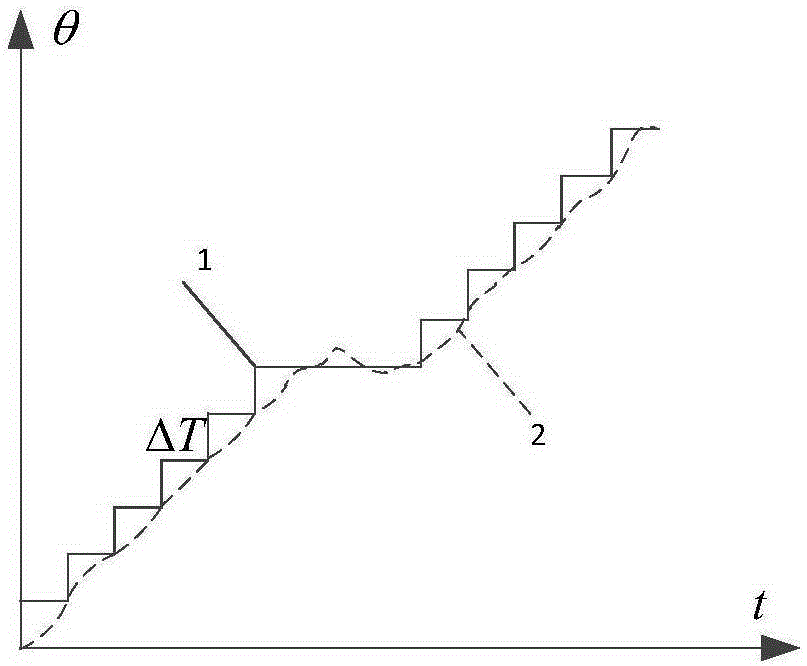

[0037] The method of the present invention adopts the following technical solutions: figure 1 The control system required for a micro-step drive control method of a permanent magnet synchronous motor according to the present invention includes a permanent magnet synchronous motor 1, a position sensor or a position sensorless rotor position detection module 2, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com