Engine for motorcycle

A technology for three-wheeled motorcycles and engines, which is used in engine ignition, engine components, machines/engines, etc., can solve the problems of short push rod length, increased noise, large inner diameter of cylinder block and cylinder liner, etc., so as to improve the torque at low speed , Strengthen the mixing degree and improve the effect of aeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

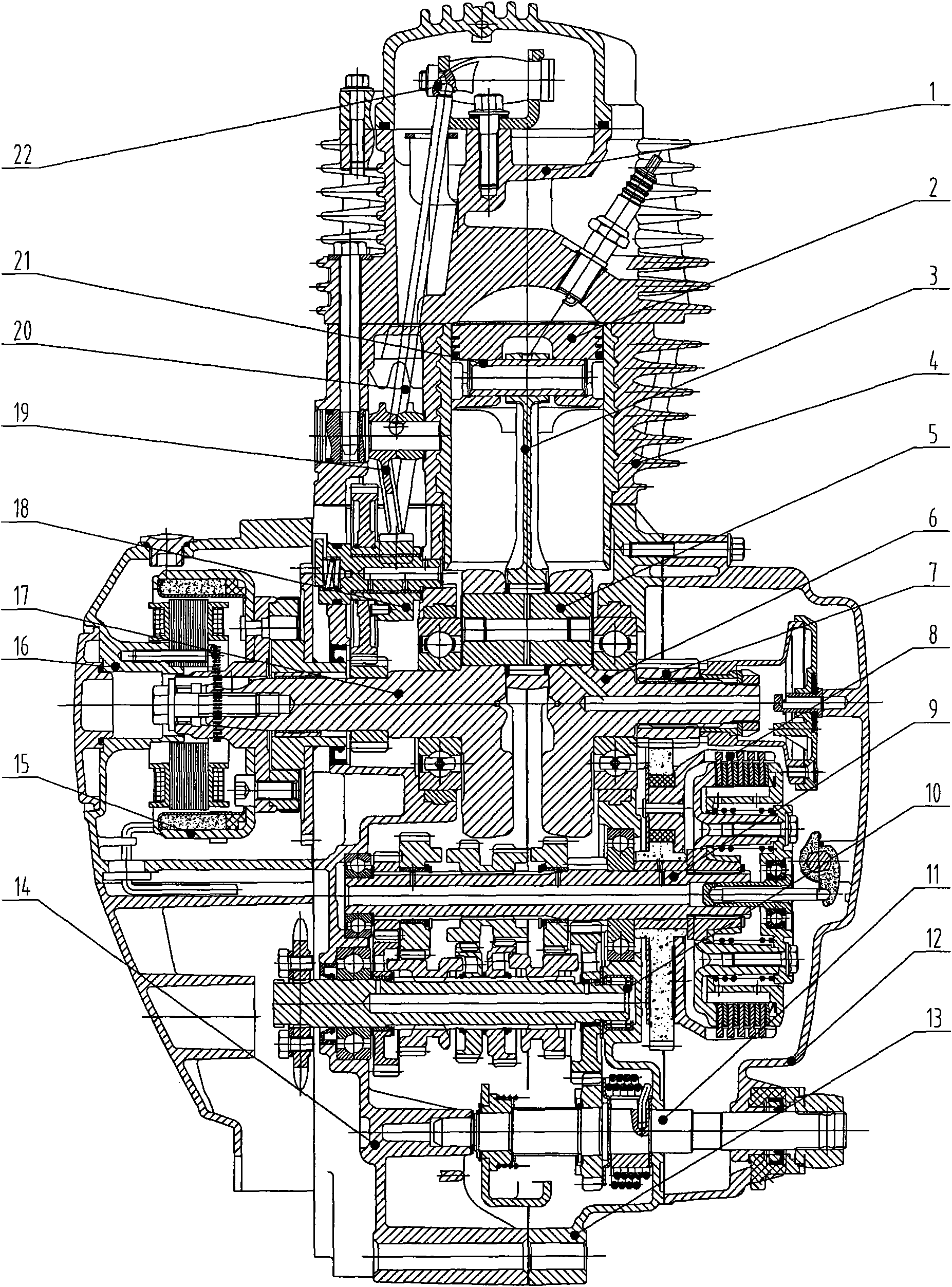

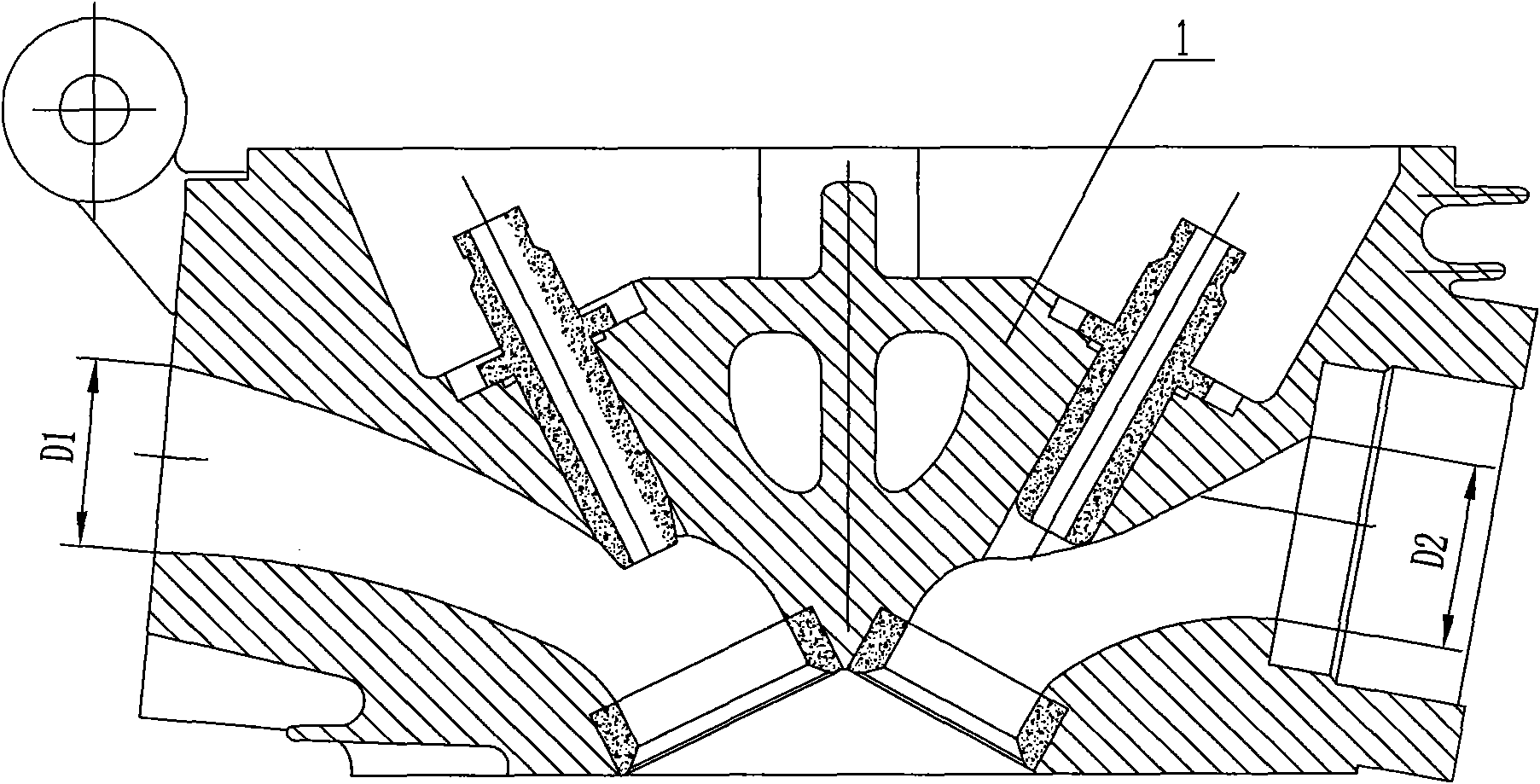

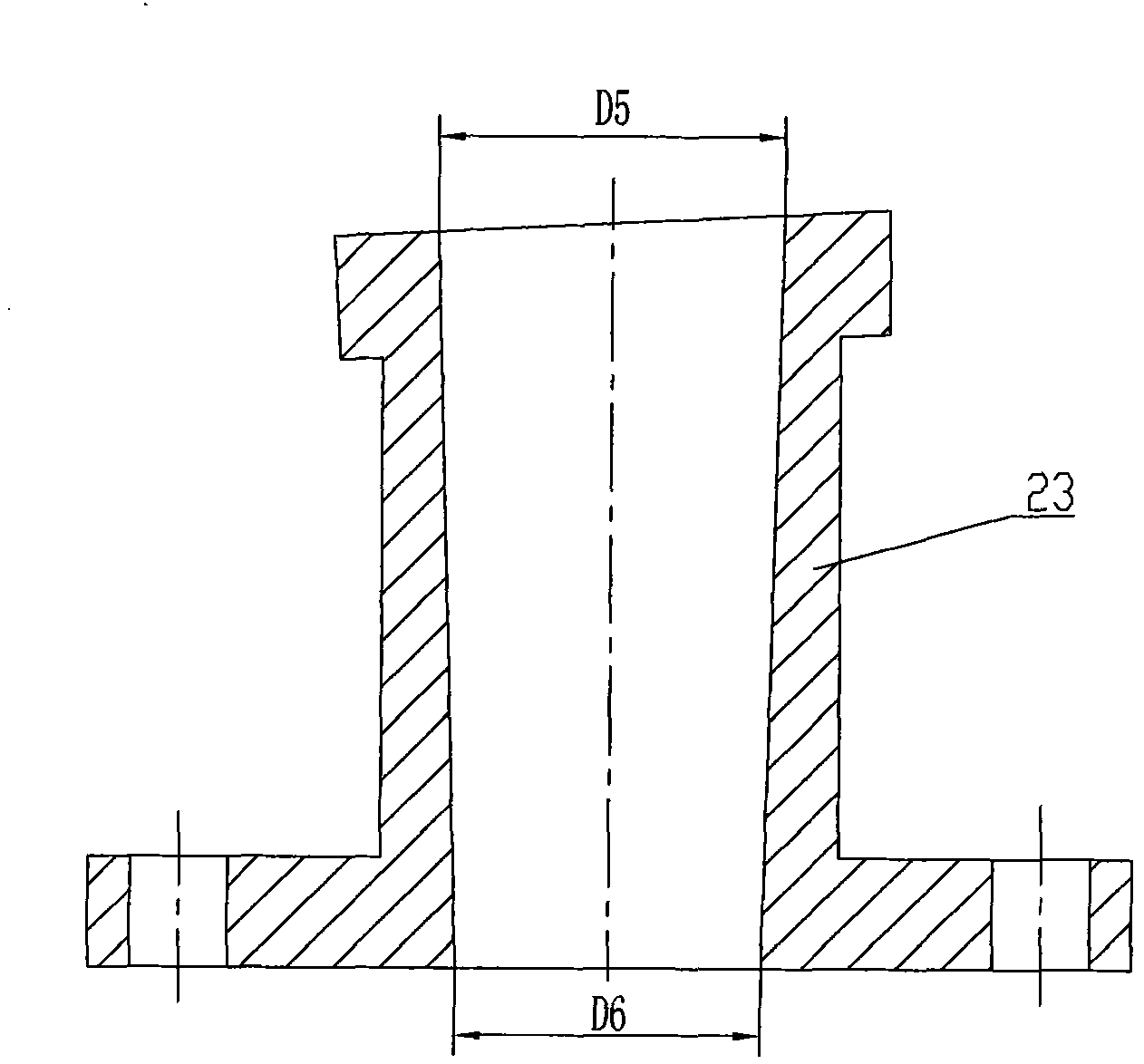

[0049] Such as Figure 1 to Figure 10 As shown, the present invention consists of cylinder head 1, piston 2, connecting rod 3, cylinder block 4, crank pin 5, right crank 6, primary driving gear 7, clutch combination 8, main shaft combination 9, secondary shaft combination 10, starting shaft 11 , right crankcase cover 12, right crankcase body 13, left crankcase body 14, magneto rotor 15, left crankcase cover 16, left crank 17, gas distribution cam 18, lower rocker arm combination 19, push rod 20, piston Pin 21, rocker arm bracket combination 22, intake pipe 23, exhaust valve 24, valve outer spring 25, valve inner spring 26 and intake valve 27 and other parts constitute. Wherein the left crankcase body 14 is fastened and fixed with the right crankcase body 13 to form the engine crankcase, the left crankcase cover 16 is installed at the left end of the left cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com